Explore the Benefits of Online Kubota Parts Diagrams

In the world of machinery, having a clear understanding of how various elements interact is crucial for effective maintenance and repair. When tackling any equipment, visual representations play a significant role in facilitating comprehension. These illustrations help users identify specific components, their functions, and their relationships within the broader assembly.

Accessing these visual guides is now more convenient than ever, allowing enthusiasts and professionals alike to enhance their repair skills. With a wealth of resources available at your fingertips, locating detailed schematics has transformed the way individuals approach maintenance tasks. This accessibility empowers users to make informed decisions and streamline their work processes.

Whether you are a seasoned technician or a novice user, the ability to reference comprehensive visuals aids in diagnosing issues and planning effective solutions. By leveraging these resources, one can ensure that their machinery operates efficiently, reducing downtime and improving overall productivity.

Kubota Parts Diagram Online

This section aims to provide insights into the digital resources available for identifying and locating essential components for agricultural machinery. Understanding the layout and specifications of each element is crucial for maintenance and repairs, ensuring optimal performance.

Benefits of Digital Resources

- Accessibility: Users can easily access information from various devices.

- Efficiency: Quick search options allow for faster identification of required components.

- Comprehensive Information: Detailed illustrations and descriptions enhance understanding.

How to Navigate the Resources

- Start by selecting the machinery type.

- Utilize search features to find specific elements.

- Review the visual guides to confirm compatibility.

- Take note of part numbers for ordering.

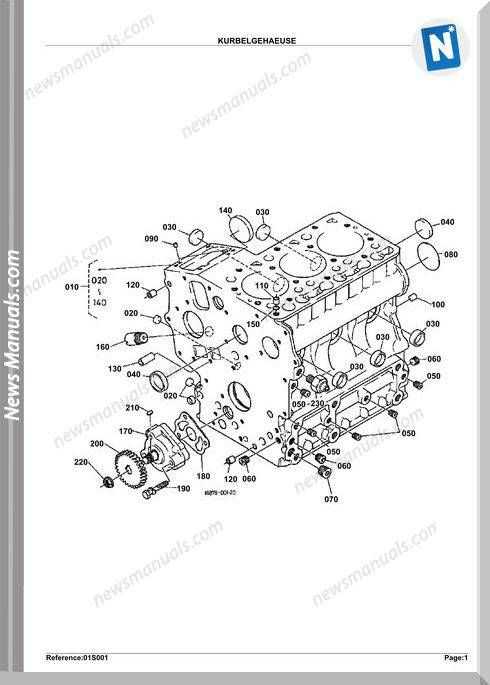

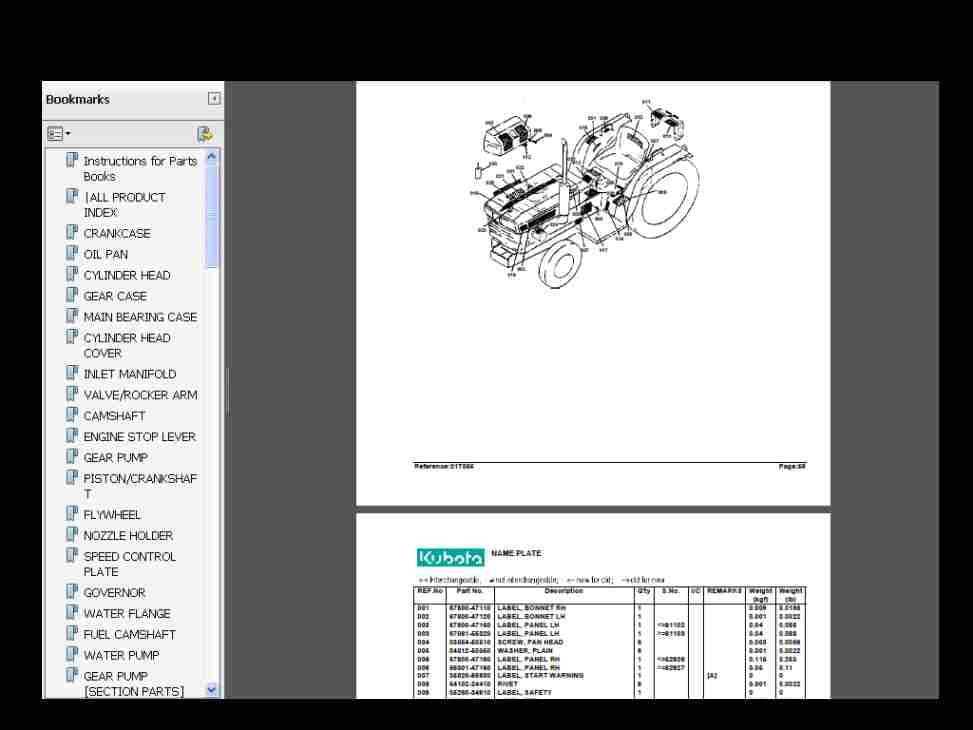

Understanding Kubota Parts Diagrams

Comprehending the visual representations of components is essential for anyone involved in machinery maintenance and repair. These illustrations serve as a crucial tool for identifying individual elements and understanding their relationships within the larger system. By becoming familiar with these resources, users can enhance their troubleshooting skills and improve efficiency in repair processes.

Familiarity with these visual aids allows operators to locate specific items quickly and gain insight into how different pieces work together. This knowledge can significantly reduce downtime, as it enables users to pinpoint issues and procure necessary components without unnecessary delays.

Moreover, understanding these representations empowers users to perform maintenance more effectively. Knowing the arrangement and function of each part can lead to better decision-making when it comes to repairs or upgrades. In summary, mastering these illustrations is a vital step toward achieving optimal performance and longevity of the equipment.

Benefits of Online Access

Accessing resources through digital platforms offers numerous advantages that enhance convenience and efficiency. With a few clicks, users can find essential information, fostering a more productive experience.

- Instant Availability: Information can be retrieved immediately, eliminating the need for physical searches or waiting for assistance.

- Comprehensive Resources: Digital platforms often provide a wider range of materials, including manuals, specifications, and illustrations.

- Cost-Effectiveness: Many online resources are free or available at a lower cost than printed alternatives, making them accessible to a broader audience.

Furthermore, the ability to update content frequently ensures that users always have access to the latest information, enhancing the overall experience.

- Enhanced User Experience: Interactive features allow for a more engaging exploration of materials, making it easier to locate specific details.

- Global Reach: Individuals from various locations can access the same information, fostering collaboration and knowledge sharing.

- Environmentally Friendly: Reducing reliance on paper resources contributes to sustainability efforts, supporting eco-friendly practices.

Overall, leveraging digital access streamlines processes and enriches the knowledge base for users across the board.

How to Navigate the Diagrams

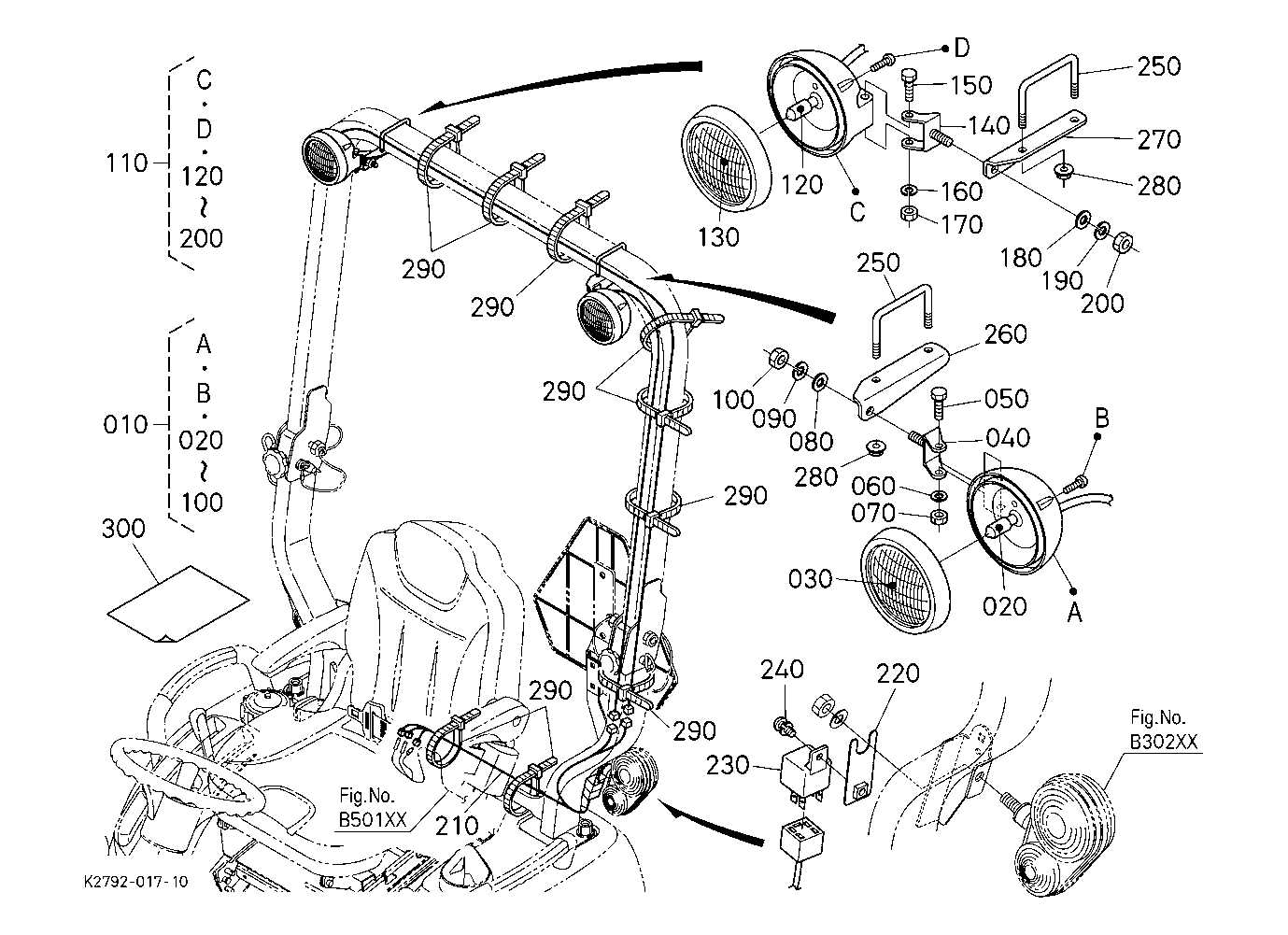

Understanding technical illustrations can significantly enhance your ability to manage machinery effectively. These visual representations are designed to guide users through complex components and their relationships. Mastering how to interpret these visuals will empower you to identify parts and troubleshoot issues with ease.

Key Features to Look For

- Labels: Familiarize yourself with the various labels used to identify components. This will help you quickly locate what you need.

- Color Coding: Pay attention to color codes that might indicate different categories or types of elements.

- Section Views: Look for cutaway views that provide additional perspective on how parts fit together.

Steps to Efficient Navigation

- Start by identifying the main sections of the illustration to gain an overview of the assembly.

- Use the labels and legends to pinpoint specific components.

- Follow lines and arrows that indicate connections or flows between parts.

- Refer to supplementary materials or manuals for additional context when needed.

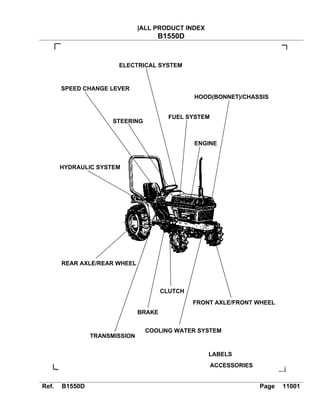

Common Kubota Models Explained

This section provides an overview of popular agricultural and construction machinery models, highlighting their features and functionalities. Understanding these machines is essential for selecting the right equipment for various tasks, from farming to landscaping.

Tractors

Tractors are versatile machines designed for various agricultural applications. They come in different sizes and horsepower ratings, making them suitable for tasks ranging from plowing to hauling. Models typically include both compact and utility versions, each tailored to meet specific operational needs.

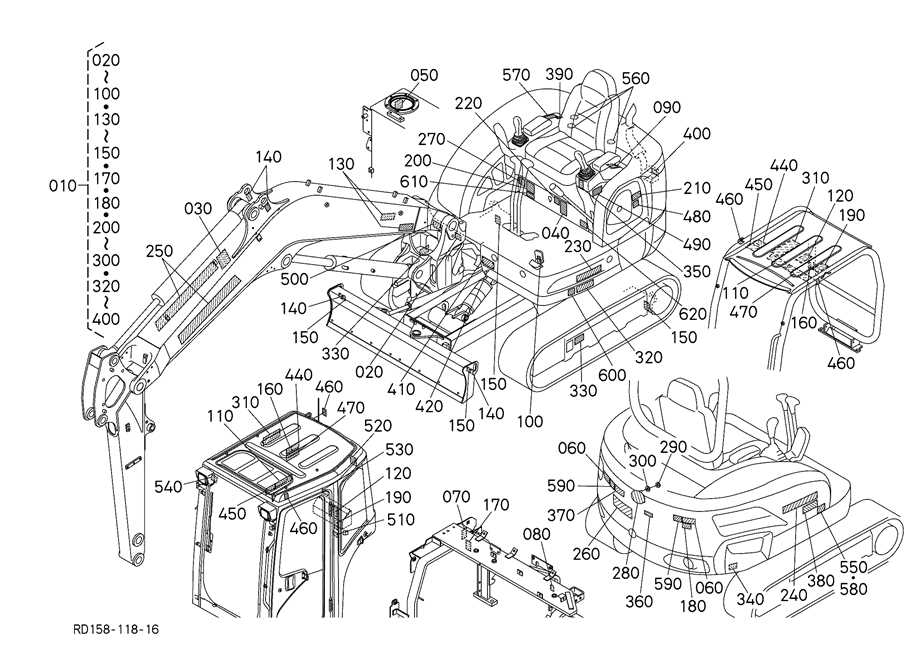

Excavators

Excavators are vital for construction and earth-moving projects. Known for their powerful digging capabilities, these machines often feature a rotating cab and extendable arms, allowing for precision work in tight spaces. Various models are equipped with different attachments, enhancing their versatility for tasks such as trenching and demolition.

Finding Replacement Parts Easily

Locating the necessary components for your machinery can often feel overwhelming. However, with the right strategies, the process can become straightforward and efficient. Accessing visual resources can significantly enhance your ability to identify the exact pieces you need for maintenance or repair tasks.

Here are some effective methods to simplify your search:

- Utilize Manufacturer Resources: Many companies provide detailed visual guides that outline each component and its placement.

- Explore Community Forums: Engaging with fellow users can yield valuable insights and recommendations on sourcing components.

- Check Retailer Websites: Authorized dealers often have searchable catalogs that allow you to find parts based on model numbers.

- Leverage Online Marketplaces: Platforms dedicated to machinery can offer a wide variety of components from different suppliers.

By adopting these approaches, you can enhance your chances of quickly finding the correct elements, ensuring your equipment remains in optimal condition.

Importance of Genuine Kubota Parts

Utilizing authentic components for machinery is crucial for ensuring optimal performance and longevity. These original items are specifically engineered to fit seamlessly and function effectively, safeguarding the investment made in heavy equipment.

Benefits of Using Authentic Components

- Enhanced Reliability: Genuine items are manufactured to meet the highest standards, reducing the risk of breakdowns.

- Improved Performance: Original components ensure that the machinery operates at its best, delivering consistent results.

- Longer Lifespan: Quality materials used in authentic parts lead to greater durability and longevity of the equipment.

- Warranty Protection: Using original components often maintains warranty coverage, protecting the owner from unexpected repair costs.

Potential Risks of Non-Genuine Alternatives

- Compatibility Issues: Non-original components may not fit properly, leading to operational inefficiencies.

- Increased Wear and Tear: Imitation parts may wear out faster, necessitating more frequent replacements.

- Higher Long-Term Costs: Although cheaper initially, the need for frequent repairs and replacements can accumulate expenses.

- Safety Hazards: Using inferior components can compromise the safety of the machinery and its operator.

Interpreting Part Numbers Effectively

Understanding the alphanumeric codes used for components is essential for efficient identification and selection. These codes often contain vital information that can streamline your search and ensure accuracy in procurement. By mastering the interpretation of these sequences, you can enhance your ability to find the correct items quickly.

Here are key aspects to consider when decoding these identifiers:

- Structure: Familiarize yourself with the general format of the codes, which typically includes a combination of letters and numbers that signify specific attributes.

- Categories: Identify the categories represented within the code. Often, different sections will indicate types, sizes, or models.

- Manufacturer Variations: Be aware that different manufacturers may have unique coding systems. Cross-reference when necessary to avoid confusion.

- Updates: Stay informed about any changes in coding conventions, as these may occur over time and impact how components are identified.

By honing your skills in interpreting these identifiers, you will improve your efficiency and accuracy in sourcing components, ultimately leading to more successful maintenance and repairs.

Frequently Asked Questions About Diagrams

This section aims to address common inquiries related to visual representations used in various industries. Understanding these visuals is crucial for effective maintenance and repair, as well as for ensuring seamless operations in technical fields.

What types of visuals are commonly used?

Different industries utilize various types of visuals. Here are some common categories:

| Type | Description |

|---|---|

| Schematics | Illustrations that show the components of a system and their relationships. |

| Exploded Views | Detailed drawings that show how parts fit together, often displayed in a layered format. |

| Flowcharts | Visual representations of processes, showing the sequence of steps or decisions. |

How can I use these visuals effectively?

To maximize the benefits of these illustrations, consider the following tips:

- Familiarize yourself with symbols and notations used in your specific area.

- Cross-reference with manuals and guides for better understanding.

- Practice interpreting different types of visuals to enhance your skills.

Tips for DIY Maintenance

Performing routine upkeep on your machinery can significantly enhance its longevity and efficiency. Understanding the basics of self-maintenance can save you time and money, while ensuring that your equipment remains in peak condition. Below are some practical tips to guide you through effective self-service practices.

Preparation is Key

- Gather all necessary tools before starting your work.

- Consult the user manual for specific guidelines and recommendations.

- Ensure you have the right materials for any replacements or repairs.

Regular Inspections

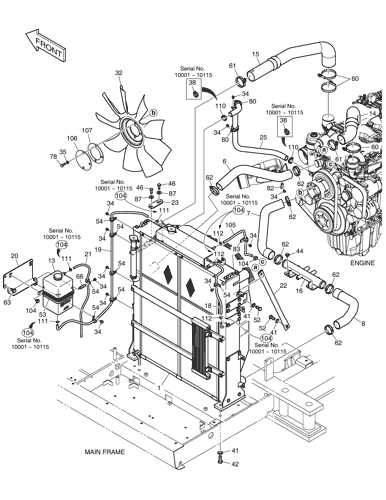

- Check fluid levels frequently to avoid any operational issues.

- Look for signs of wear and tear, such as leaks or cracks.

- Keep an eye on the condition of belts and hoses, replacing them as needed.

By following these simple strategies, you can maintain your machinery effectively and enjoy smoother operations over time.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in diagnosing mechanical issues, offering clarity and insight that can streamline the troubleshooting process. By utilizing schematics, users can identify components, understand their relationships, and pinpoint potential failures more effectively than through verbal descriptions alone.

Benefits of Visual Aids

Employing illustrations for troubleshooting brings several advantages:

- Enhanced understanding of complex systems.

- Quicker identification of faulty components.

- Improved accuracy in repairs and maintenance.

Common Issues and Their Solutions

| Issue | Description | Recommended Action |

|---|---|---|

| Electrical Failures | Inconsistent power supply leading to operational issues. | Check wiring connections and components against visual guides. |

| Mechanical Wear | Components showing signs of degradation or damage. | Refer to schematics to locate affected parts and replace as needed. |

| Fluid Leaks | Presence of fluids indicating potential seal or hose failures. | Utilize visual aids to trace the source and address the leak. |

By integrating these visual tools into the maintenance routine, operators can achieve a higher level of efficiency and effectiveness, ultimately prolonging the lifespan of their machinery.

Connecting with Kubota Support

When seeking assistance for your machinery, establishing a reliable connection with the support team can significantly enhance your experience. This section outlines various methods to reach out for help and the benefits of utilizing these resources.

Here are some effective ways to get in touch with the support team:

- Phone Support: Direct calls can provide immediate assistance and allow for detailed discussions about specific issues.

- Email Communication: Sending an email allows you to describe your problem in detail and receive a written response, which can be useful for future reference.

- Live Chat: Many companies offer real-time chat options on their websites, providing quick answers to your queries.

- Social Media: Engaging through platforms like Facebook or Twitter can also yield prompt responses and updates on new products or services.

Additionally, consider these helpful resources:

- FAQs: Frequently asked questions can quickly address common concerns without the need for direct contact.

- Community Forums: Participating in forums allows you to connect with other users and share experiences, which can lead to valuable insights.

- User Manuals: Comprehensive guides often contain troubleshooting sections that can resolve minor issues independently.

By utilizing these channels, you can ensure that your inquiries are handled efficiently, leading to a smoother operational experience with your equipment.

Resources for Further Learning

Enhancing your understanding of machinery components can significantly improve your maintenance and repair skills. Accessing a variety of educational resources allows enthusiasts and professionals alike to deepen their knowledge and become more proficient in their work.

Online Tutorials: Numerous platforms offer step-by-step guides and video demonstrations. These resources can help you visualize complex processes and gain practical insights.

Technical Manuals: Official documentation often provides comprehensive details on specific models, including assembly instructions and troubleshooting tips. Consulting these manuals is invaluable for accurate repairs.

Forums and Community Groups: Engaging with fellow users in dedicated discussion boards can foster a sense of community. Sharing experiences and solutions can lead to enhanced learning and problem-solving skills.

Workshops and Seminars: Attending hands-on training sessions can provide practical experience. These events are often led by experts, offering a unique opportunity to ask questions and gain firsthand knowledge.

Books and Publications: Investing in literature focused on machinery and maintenance can provide in-depth knowledge and reference material for future use. Many authors delve into best practices and innovative techniques.

Utilizing these resources can equip you with the necessary tools to effectively manage machinery, ensuring optimal performance and longevity.