Kubota SSV75 Parts Diagram Overview

The intricate design of heavy machinery often necessitates a comprehensive understanding of its various elements. Knowing how these components interconnect is crucial for maintenance and repair. This section aims to explore the layout of essential mechanisms, offering insight into their functionality and organization.

By examining the arrangement of each part, operators can gain valuable knowledge that enhances both efficiency and performance. Whether you are troubleshooting or performing routine checks, a clear grasp of the component configuration is imperative. Delve into the details to discover how each segment contributes to the ultimate operation of the machine.

In this exploration, we will break down the various assemblies, providing a roadmap to navigate through the complexities of the system. Understanding these layouts not only aids in effective management but also empowers users to optimize their equipment’s potential.

Kubota SSV75 Overview

This machine is a compact powerhouse designed for a variety of tasks, making it an essential tool in construction and landscaping industries. Its robust build and versatility allow operators to tackle challenging jobs with ease and efficiency.

Equipped with a reliable engine, this unit delivers impressive performance while maintaining fuel efficiency. The intuitive controls ensure that users can navigate various terrains effortlessly, enhancing productivity in every project.

In addition, its compact size allows for easy maneuverability in tight spaces, making it ideal for urban settings where larger machinery may struggle. The combination of strength and agility makes this equipment a favorite among professionals seeking reliable solutions.

With an array of compatible attachments, the machine can be adapted to meet diverse operational needs, from digging and lifting to grading and transporting materials. This flexibility is a key factor in its widespread popularity and effectiveness across different applications.

Overall, this model stands out for its durability, efficiency, and adaptability, making it a valuable asset for any contractor or operator looking to enhance their equipment lineup.

Importance of Parts Diagrams

Understanding the intricacies of machinery components is crucial for efficient maintenance and repairs. Visual representations serve as essential tools, providing clarity on the relationship between different elements, thereby simplifying troubleshooting and assembly processes.

Enhanced Clarity

Visual aids significantly enhance comprehension, allowing technicians to identify specific components quickly. This clarity reduces the likelihood of errors during repairs and ensures that each part is correctly handled.

Streamlined Maintenance

Utilizing detailed visuals fosters a more organized approach to upkeep. Technicians can easily locate parts, facilitating timely replacements and minimizing downtime.

| Benefit | Description |

|---|---|

| Improved Efficiency | Faster identification and resolution of issues. |

| Reduced Errors | Clear visuals minimize mistakes during repairs. |

| Cost Savings | Efficient maintenance leads to lower operational costs. |

Key Components of SSV75

The efficiency and functionality of a compact loader are largely determined by its essential elements. Understanding these critical components not only enhances operational effectiveness but also aids in maintenance and repair efforts. Each part plays a vital role in ensuring optimal performance and longevity of the equipment.

Engine: The heart of the machine, the engine is responsible for generating power. A robust engine ensures reliable performance under various conditions, enabling the operator to tackle diverse tasks with ease.

Hydraulic System: This system is crucial for the movement and operation of attachments. It converts mechanical energy into hydraulic power, facilitating lifting, tilting, and other essential functions, making it indispensable for various applications.

Transmission: The transmission system is responsible for controlling the speed and torque of the loader. Its design allows for smooth transitions between different operational speeds, enhancing maneuverability and control.

Chassis: The frame serves as the backbone of the machine, providing stability and support for all components. A well-designed chassis contributes to improved balance and weight distribution, ensuring safety during operation.

Attachment Interface: This feature allows for quick and easy connection of various tools and implements. A versatile attachment interface expands the functionality of the loader, enabling it to perform a wide range of tasks.

In summary, familiarity with these key components can significantly impact the performance and service life of the loader. Proper maintenance and understanding of each part are essential for maximizing productivity and efficiency.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in various machinery, utilizing fluid power to generate movement and force. These systems are designed to transmit energy through incompressible fluids, allowing for efficient and powerful operation.

Key components of hydraulic systems include:

- Fluid Reservoir: Stores the hydraulic fluid.

- Pump: Converts mechanical energy into hydraulic energy.

- Actuators: Translate hydraulic energy into linear or rotary motion.

- Valves: Control the flow and direction of the fluid.

- Filters: Ensure fluid cleanliness for optimal performance.

The ultimate effectiveness of a hydraulic system depends on the precise interaction of these components, enabling smooth operation in various applications.

Common Repairs for SSV75

Routine maintenance and repairs are essential for ensuring optimal performance and longevity of heavy machinery. Understanding common issues can help operators address problems promptly, minimizing downtime and costs.

Hydraulic System Maintenance: Regular checks on hoses and fittings are crucial, as leaks can lead to performance loss. Ensuring fluid levels are adequate is equally important for efficient operation.

Electrical Troubleshooting: Faulty wiring or blown fuses can disrupt functionality. Diagnosing these issues early can prevent more significant electrical failures down the line.

Track and Wheel Alignment: Misalignment can cause uneven wear and decreased efficiency. Regular adjustments help maintain optimal traction and stability.

Filter Replacements: Changing air and fuel filters regularly can significantly enhance engine performance. Clogged filters can lead to reduced power and increased emissions.

By staying proactive with these common repairs, operators can ensure their machinery operates at peak efficiency and reliability.

Finding Replacement Parts

Locating suitable components for machinery maintenance is crucial for ensuring optimal performance and longevity. Whether dealing with repairs or routine upkeep, having access to the right pieces can make a significant difference in efficiency and productivity.

Here are some effective strategies to help you in your search:

- Consult the Owner’s Manual: This document often includes a list of recommended components and specifications needed for replacements.

- Visit Authorized Dealers: These suppliers typically carry original items that meet quality standards, ensuring compatibility with your equipment.

- Online Retailers: Many websites specialize in machinery components, providing a vast selection. Be sure to check reviews and ratings for reliability.

- Local Parts Stores: Some brick-and-mortar shops may stock common items or can order them for you.

- Forums and Communities: Engaging with fellow users online can provide valuable recommendations on sourcing components effectively.

When searching, keep track of model numbers and specifications to avoid discrepancies. Ensuring you have accurate information will help in finding the best match for your needs.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of machinery. Regular attention not only enhances performance but also prolongs the life of vital components, ultimately saving time and resources.

Regular Inspections

Frequent assessments can identify wear and tear early. Focus on key areas such as the hydraulic system and engine components. Keeping an eye on these elements helps prevent unexpected breakdowns.

Fluid Management

Consistent checks and timely changes of fluids are crucial. Quality oil and coolant maintain optimal performance and reduce the risk of overheating. Always adhere to the manufacturer’s recommendations for fluid types and change intervals.

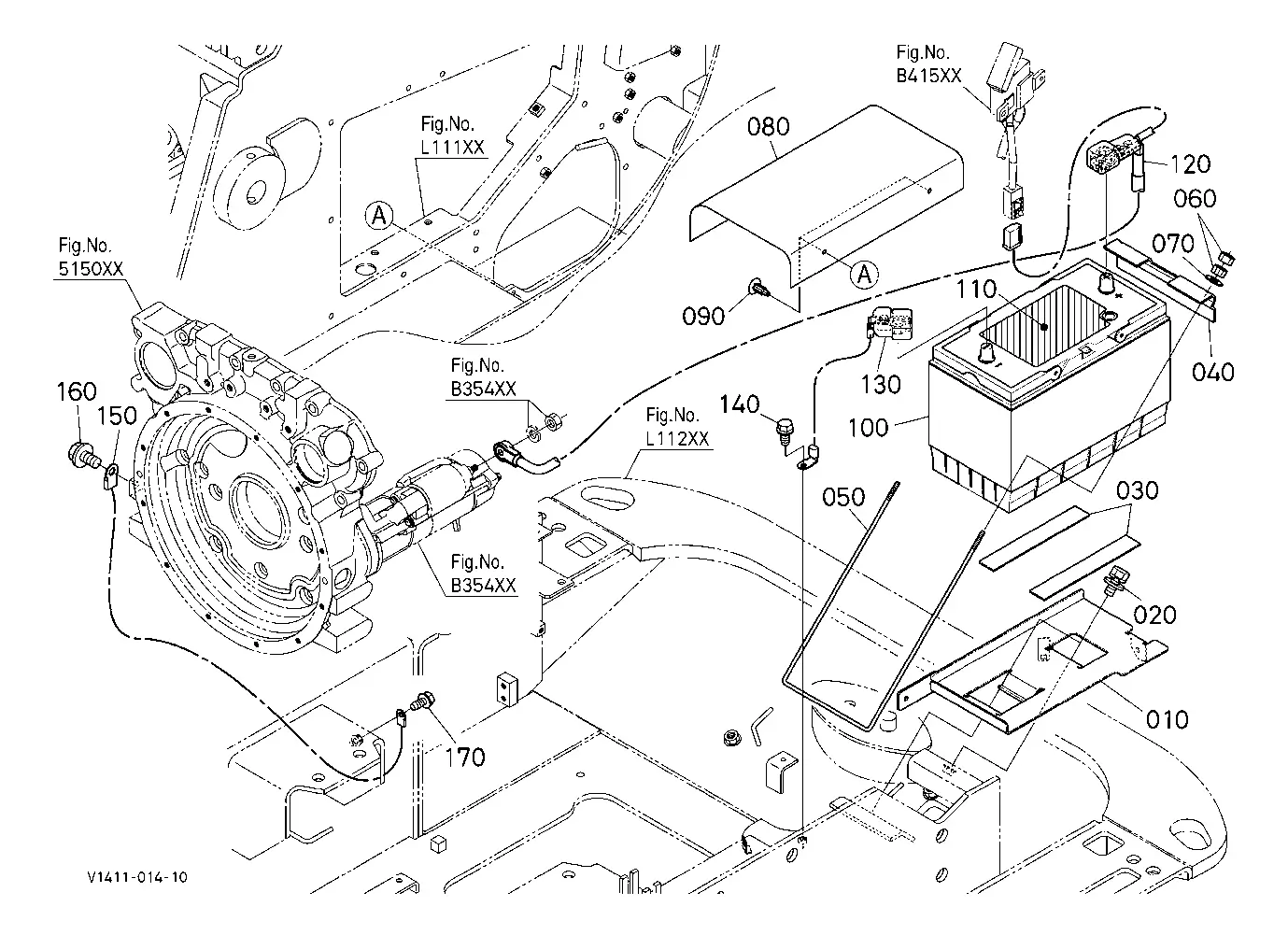

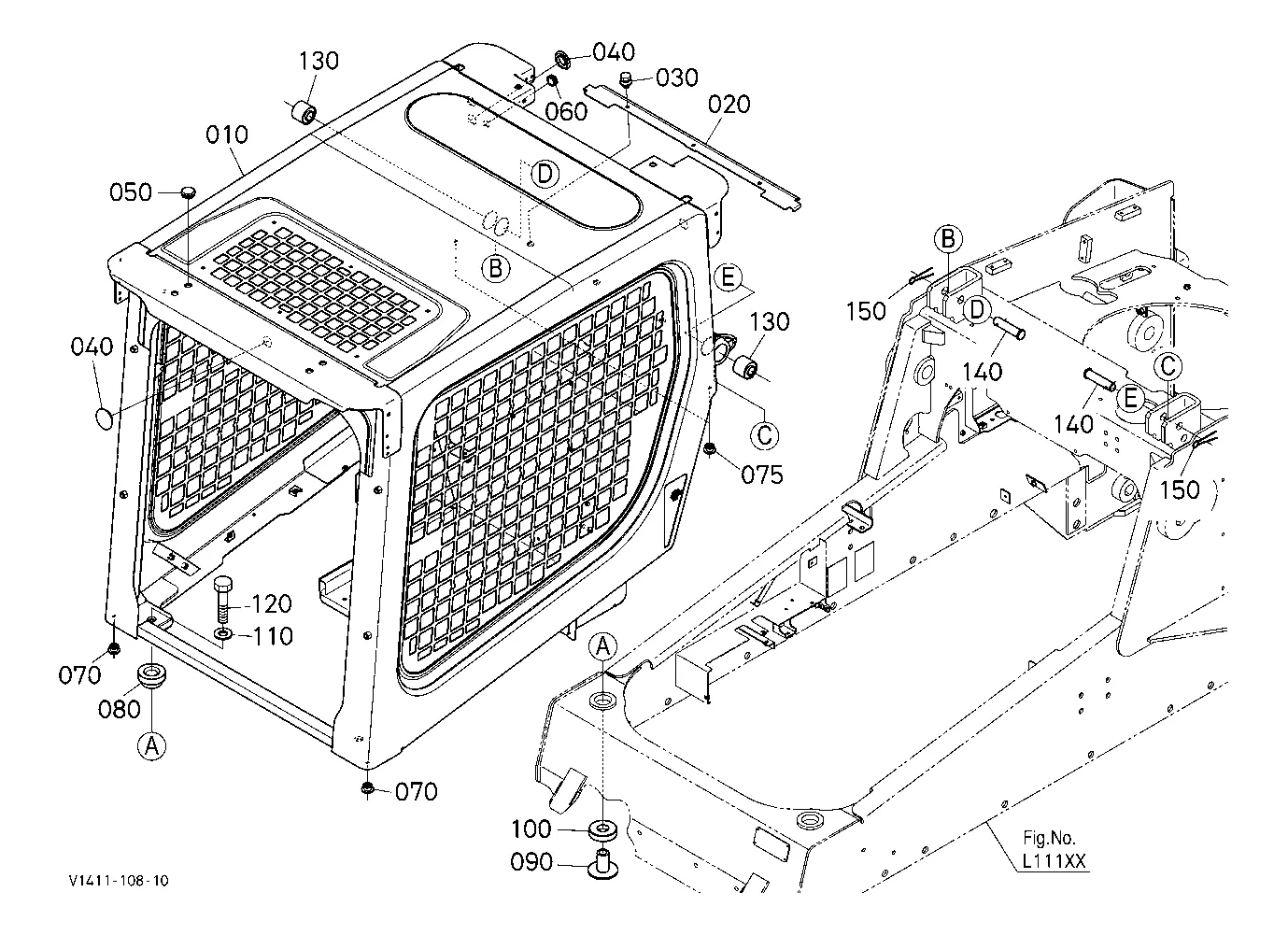

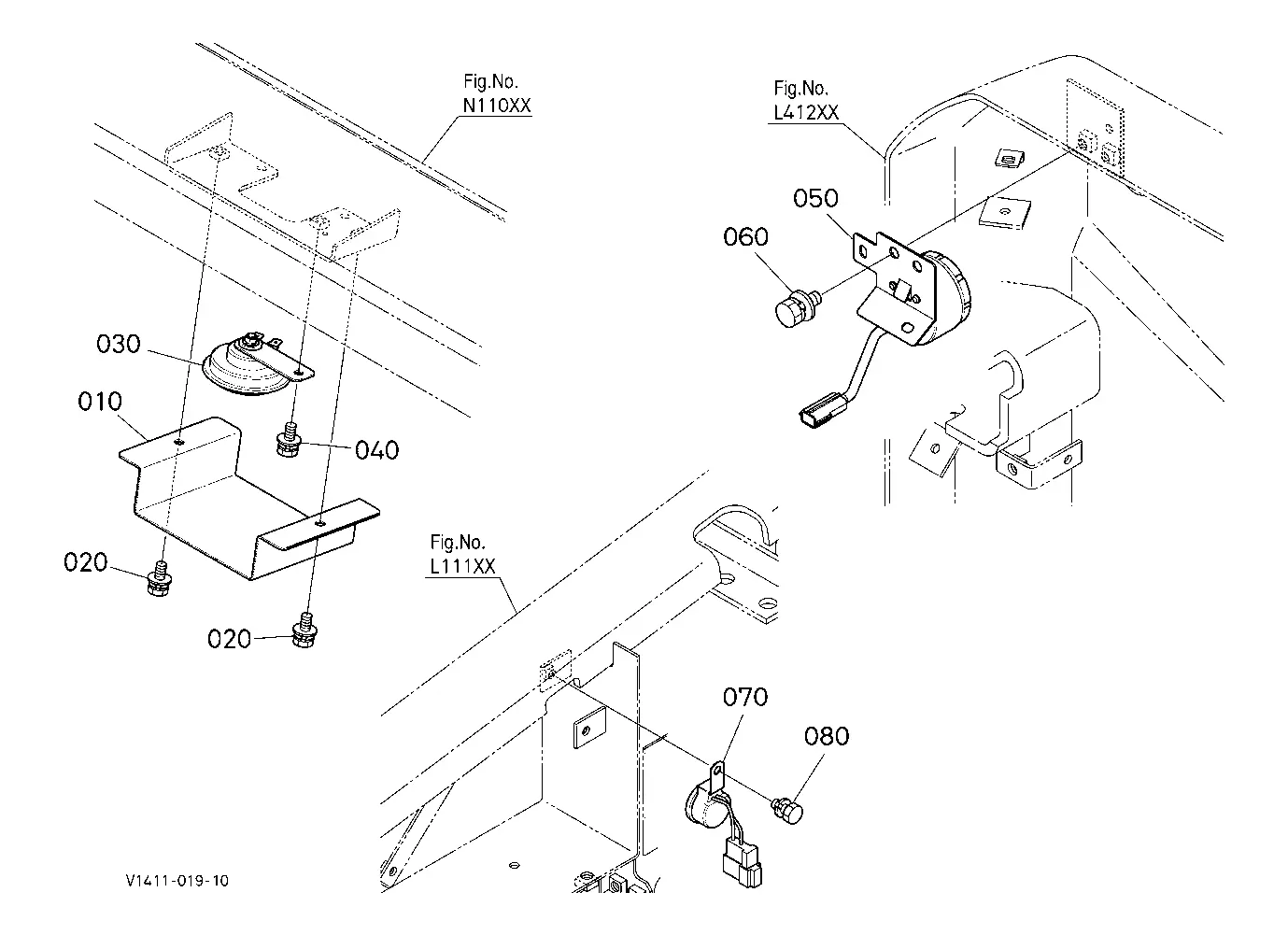

Identifying Parts by Diagram

Understanding how various components connect and function within a system is crucial for effective maintenance and repair. Diagrams offer a visual representation of these elements, helping users quickly locate and recognize individual sections of machinery. By examining the layout, users can better grasp the relationships between different elements and identify what needs attention.

How to Analyze Visual Layouts

To begin, focus on the structural organization displayed. Visual representations are often divided into logical sections, making it easier to determine the flow of components. Following the order from top to bottom or left to right can provide clarity when inspecting the setup.

- Look for labeled elements that correspond to the key or index provided.

- Check the arrangement for potential connections between components.

- Note any symbols indicating fasteners, wires, or tubing.

Locating Specific Components

Once familiar with the overall view, start narrowing down specific elements by their positioning or distinct features. Utilize the visual guides to pinpoint areas that match the description of the issue or task at hand.

- Use reference numbers to cross-check with detailed listings.

- Identify any sections that appear misaligned or show signs of wear.

- Follow the path of connections to trace sources of issues.

Aftermarket vs. OEM Parts

When it comes to maintaining or repairing machinery, a common decision involves choosing between original equipment from the manufacturer or alternatives offered by third-party providers. This choice often raises questions about quality, compatibility, and cost, all of which are crucial for the long-term performance and reliability of your equipment.

Quality and Durability

Original components are designed to meet the exact specifications of the equipment, ensuring a perfect fit and consistent performance. On the other hand, third-party alternatives may vary in terms of material and craftsmanship, sometimes offering a more affordable solution but potentially sacrificing durability.

Cost Efficiency and Availability

One major advantage of choosing aftermarket alternatives is the potential for cost savings. These components are typically priced lower than their original counterparts. However, while the lower price is attractive, the availability and compatibility with your specific model should be carefully considered to avoid performance issues.

Tools Needed for Repairs

When performing maintenance or addressing mechanical issues, having the right set of equipment is essential to ensure a smooth and efficient process. Without the appropriate instruments, even simple tasks can become challenging and time-consuming.

Basic Hand Tools: A solid collection of wrenches, screwdrivers, and pliers is critical for most mechanical tasks. These versatile items allow you to handle fasteners, nuts, and bolts of various sizes with precision and ease.

Measuring Devices: Proper alignment and fitting require accurate measurements. Tools like calipers, tape measures, and torque wrenches ensure that components are adjusted and tightened correctly to avoid future issues.

Power Tools: For more intensive repairs, power drills and impact drivers are invaluable, providing speed and strength that manual tools can’t match. These tools are particularly useful when working on larger or more stubborn fasteners.

Safety Equipment: No repair work should begin without protective gear. Gloves, safety glasses, and ear protection help shield you from potential hazards while ensuring that you can work comfortably and confidently.

Specialized Instruments: In some cases, specific tasks may require more advanced or specialized tools, such as diagnostic devices or pullers. These are crucial for identifying underlying problems or safely removing parts that are difficult to access.

Resources for Technical Support

When it comes to maintaining equipment, access to reliable assistance is key for ensuring optimal performance. Whether you’re troubleshooting a system issue or looking for specific components, knowing where to find help is essential. There are various ways to access technical expertise, from detailed manuals to professional assistance that can guide you through complex repairs or upgrades.

Online Manuals and Guides

One of the most efficient ways to get help is through digital guides, which often provide step-by-step instructions. These resources can be a great starting point for resolving issues or identifying the right components for your equipment. Make sure to check the official site or trusted third-party platforms for the latest updates.

Professional Assistance

For more complex problems or when immediate solutions are needed, professional support services can be invaluable. Whether through authorized service centers or direct contact with technicians, this approach ensures you get the expert help required to address issues swiftly and effectively.