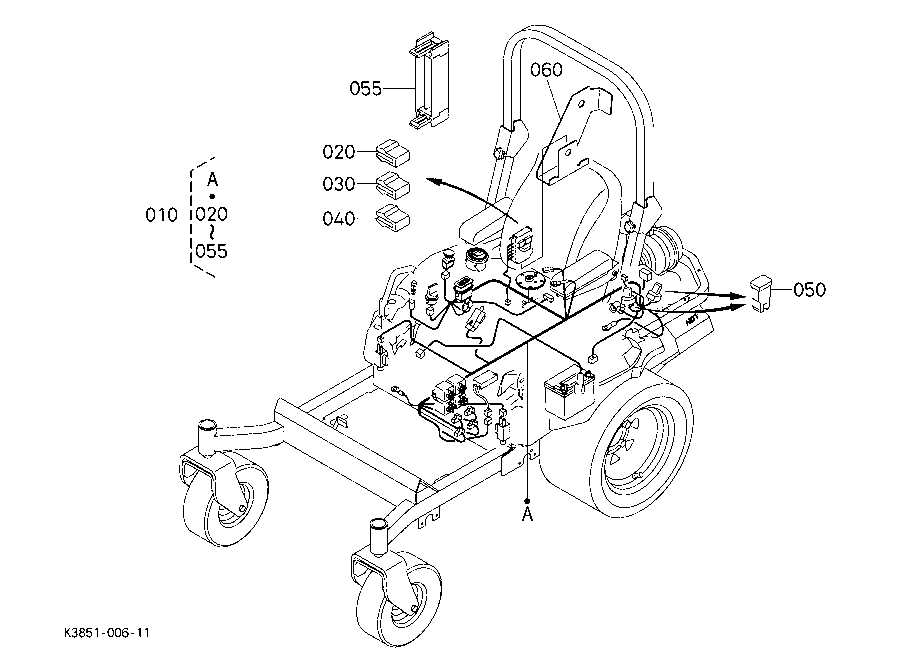

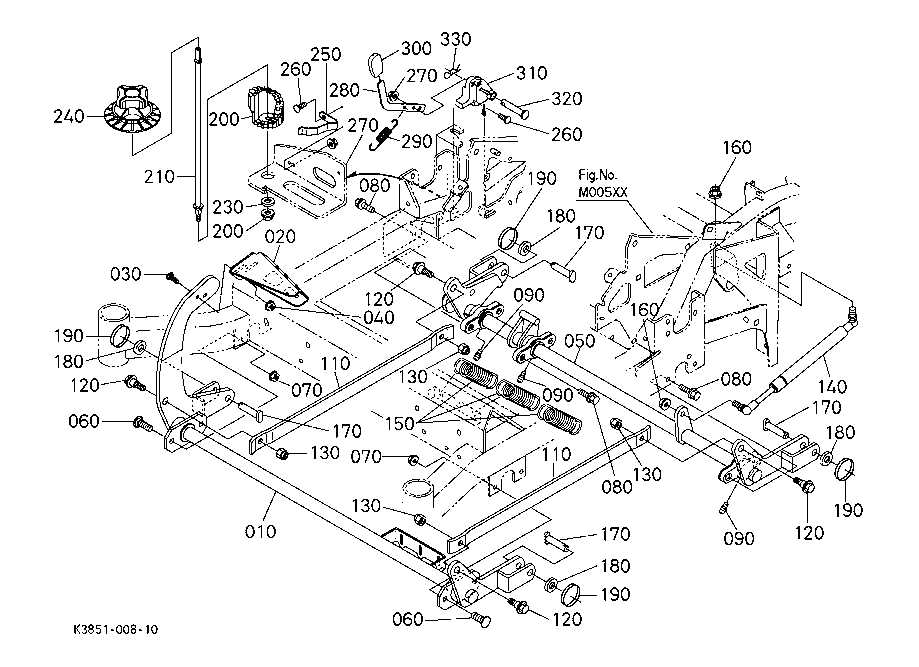

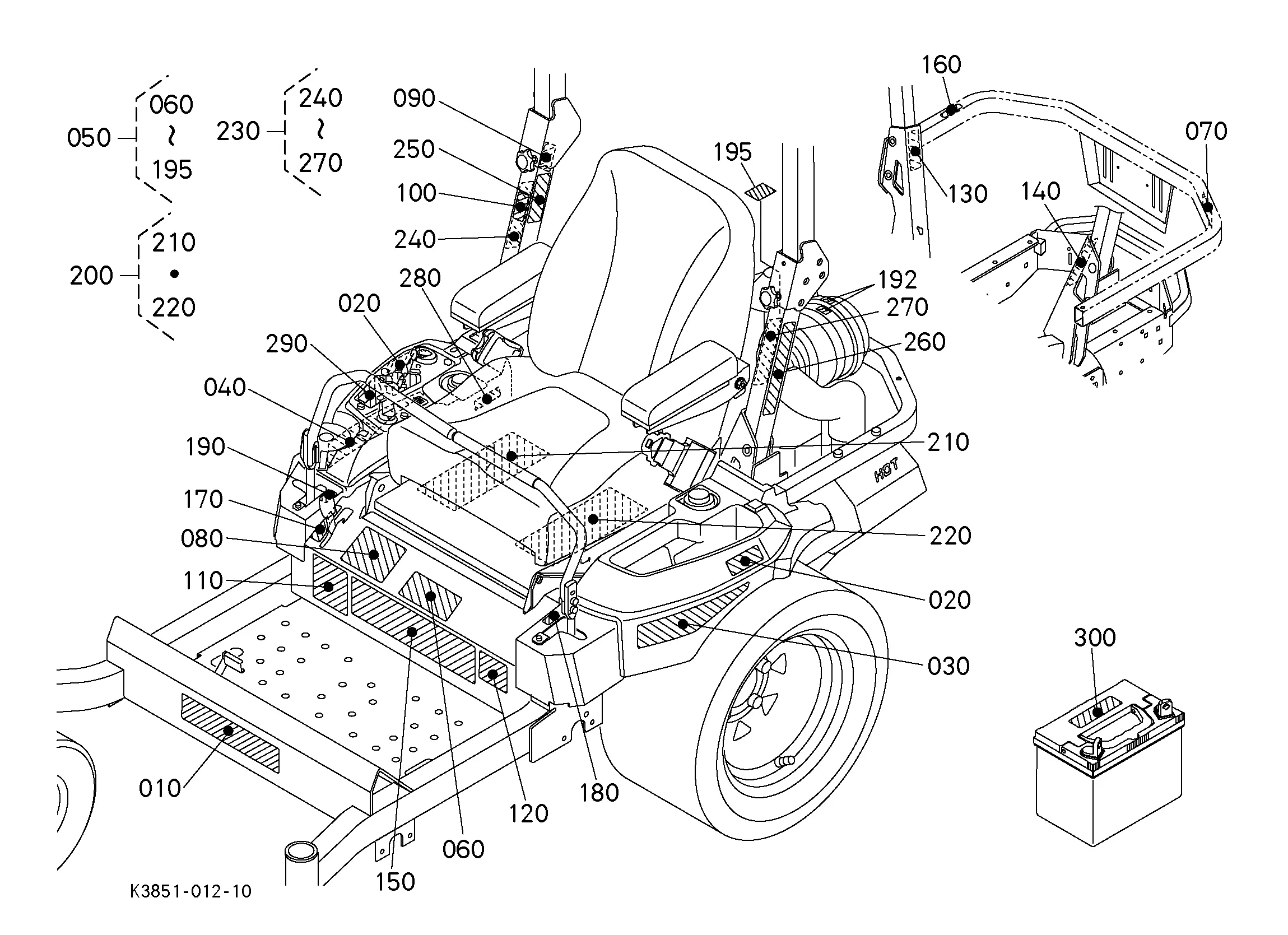

Kubota Z726XKW Parts Diagram Overview

In the realm of landscaping equipment, comprehending the intricate layout of various elements is crucial for effective maintenance and repair. A detailed overview of these components not only enhances the operational efficiency but also extends the lifespan of the machinery. By familiarizing oneself with the arrangement of parts, users can better diagnose issues and execute necessary interventions.

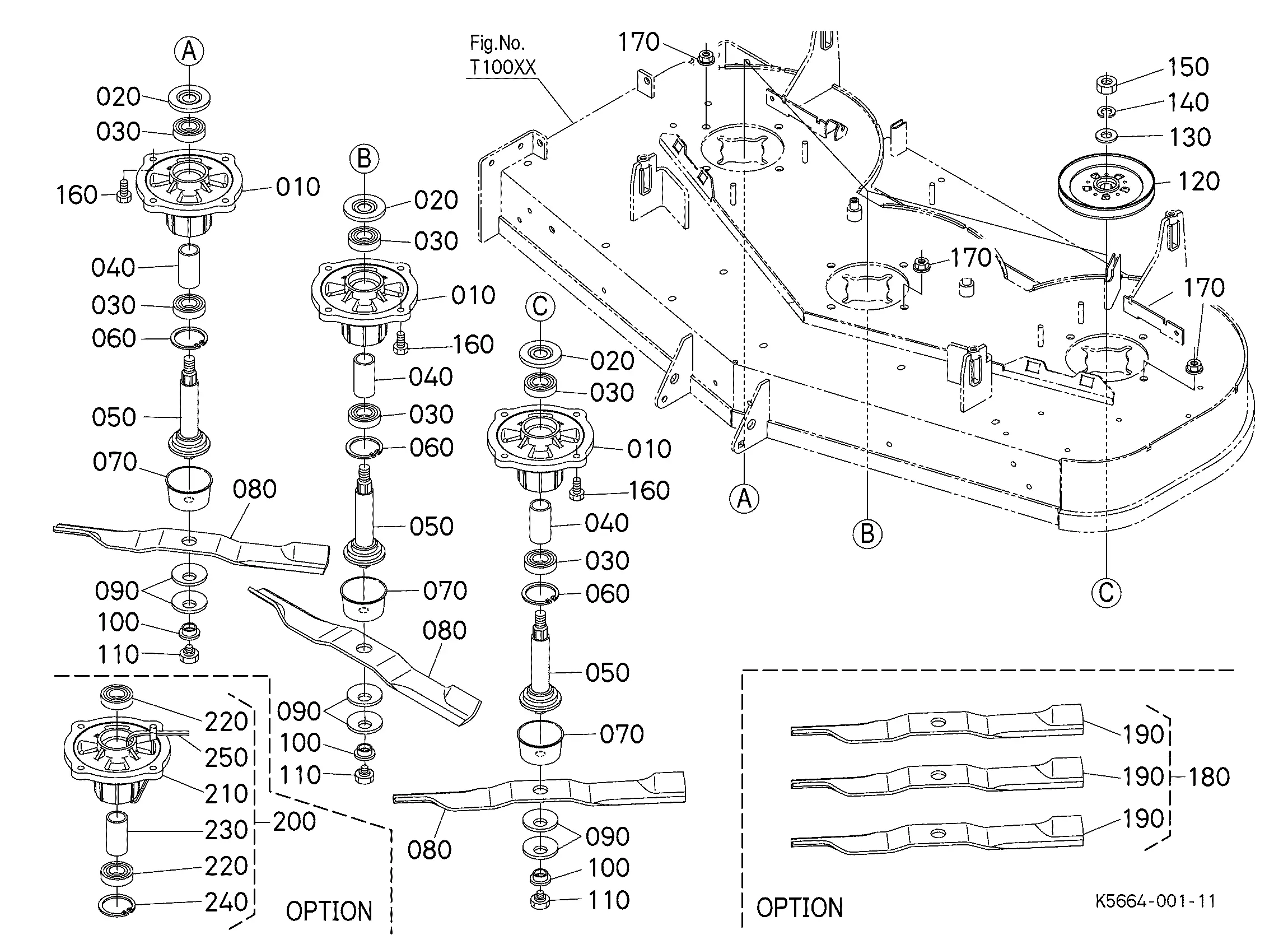

Exploring the schematic representation of a specific model unveils the interconnectedness of its features. Each element plays a vital role in the overall functionality, contributing to the seamless operation of the device. This knowledge empowers users to make informed decisions regarding upgrades, replacements, and routine servicing.

Moreover, understanding the structure allows for easier identification of compatible accessories and upgrades. With a comprehensive view, operators can optimize performance and tailor their equipment to meet specific landscaping needs. This insight into the machine’s configuration ultimately leads to a more productive and satisfying user experience.

Kubota Z726XKW Overview

This section provides a comprehensive look at a high-performance machine designed for professional landscaping and grounds maintenance. Its robust engineering and advanced features cater to the demands of both commercial and residential users, making it a reliable choice for tackling various outdoor tasks efficiently.

Key Features

The equipment boasts a powerful engine that ensures smooth operation and excellent fuel efficiency. Its user-friendly controls and ergonomic design enhance operator comfort, allowing for extended use without fatigue. Additionally, the cutting system is engineered for precision, offering adjustable heights to accommodate different grass types and conditions.

Applications

This versatile model is ideal for various applications, from mowing large lawns to maintaining parks and sports fields. Its agility and maneuverability allow it to navigate tight spaces, while its durability ensures long-lasting performance in demanding environments. Overall, it stands out as a top choice for professionals seeking reliability and efficiency in their daily operations.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as valuable resources, allowing operators and technicians to identify and locate individual elements quickly. These illustrations facilitate a clearer comprehension of assembly and disassembly processes, ultimately enhancing overall efficiency.

Moreover, having access to such visuals aids in troubleshooting. When a malfunction occurs, pinpointing the exact area requiring attention becomes simpler, reducing downtime and associated costs. Users can also better communicate issues with service professionals, streamlining the repair process.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Visual aids clarify complex structures, making it easier to grasp their functions. |

| Efficient Repairs | Quick identification of components leads to faster troubleshooting and solutions. |

| Improved Communication | Clear visuals help convey issues accurately to technicians or support staff. |

| Reduced Downtime | Effective identification of parts minimizes the time machinery is out of operation. |

Understanding the Z726XKW Components

Familiarity with the various elements of a complex machine is essential for effective maintenance and repair. Each component plays a crucial role in ensuring optimal performance and longevity. A comprehensive grasp of these individual parts enables users to identify issues swiftly and implement solutions efficiently.

Within this particular model, a variety of systems work in harmony. From the engine that powers the unit to the intricate hydraulic systems that provide maneuverability, each section contributes to the overall functionality. Knowledge of the specific roles and interconnections of these elements can significantly enhance operational efficiency.

Additionally, recognizing wear and tear on different components is vital for preemptive care. Regular inspections and an understanding of the signs of degradation can lead to timely interventions, ultimately saving time and resources. By mastering the intricacies of these machine elements, users can ensure their equipment remains in peak condition for years to come.

Common Issues with Z726XKW Parts

When dealing with machinery components, several common challenges may arise that can impact performance and longevity. Understanding these issues is essential for effective maintenance and operation.

Wear and Tear: Over time, certain elements are prone to deterioration due to constant use. This can lead to decreased efficiency and potential malfunctions if not addressed promptly.

Improper Installation: Incorrect assembly can cause significant problems, resulting in misalignment and operational failures. It’s crucial to ensure that each component is installed according to the manufacturer’s specifications.

Material Fatigue: Exposure to harsh conditions can lead to material breakdown. Regular inspections can help identify signs of fatigue before they escalate into more serious issues.

Compatibility Issues: Using components that are not designed for specific systems can create operational inconsistencies. Always verify that the components are compatible with your machinery to avoid complications.

Lack of Maintenance: Neglecting routine upkeep can lead to the accumulation of dirt and debris, which affects performance. Implementing a regular maintenance schedule is essential for optimal operation.

By being aware of these common issues, operators can take proactive steps to ensure the reliability and efficiency of their equipment.

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to maintain and repair machinery. These illustrations provide a detailed view of various elements and their relationships, enabling users to identify specific items needed for replacement or repair. Mastering the skill of interpreting these visuals can save time and effort when working on equipment.

Familiarize Yourself with Symbols

Each illustration often includes a set of standardized symbols and labels. Recognizing these can simplify the process of locating individual pieces. Pay attention to legends or keys, as they provide essential information about what each symbol represents. This foundational knowledge is crucial for efficient navigation through the visual guide.

Follow the Numbering System

Typically, components are numbered sequentially in these visuals. By following the order, you can trace the assembly and disassembly processes more easily. This numbering often corresponds to a list of items, making it straightforward to find exact replacements or accessories when needed. A clear understanding of this system can streamline your maintenance tasks.

Where to Find Authentic Parts

Ensuring the longevity and efficiency of your machinery relies heavily on sourcing genuine components. Authentic items not only enhance performance but also maintain the integrity of your equipment. Understanding where to locate these original parts can make a significant difference in both functionality and reliability.

One of the most reliable sources is the manufacturer’s official dealership. They typically offer a comprehensive selection of original components and can provide expert guidance on compatibility. Additionally, authorized retailers often have access to exclusive items and are more likely to stock the latest releases.

Another excellent option is online platforms dedicated to equipment maintenance. Reputable websites often feature a wide array of genuine components, accompanied by detailed descriptions and specifications. Always check for customer reviews and ratings to ensure the credibility of the seller.

Local repair shops specializing in machinery can also be valuable resources. Many of these businesses have established relationships with suppliers, allowing them to obtain original items at competitive prices. Consulting with knowledgeable technicians can help you make informed decisions about your purchases.

Lastly, attending industry expos or trade shows can provide opportunities to connect directly with manufacturers and suppliers. These events often showcase new products and technologies, making them ideal for discovering authentic items and networking with industry professionals.

Maintenance Tips for Z726XKW

Ensuring the longevity and optimal performance of your machine requires regular attention and care. By following a few essential maintenance practices, you can keep your equipment running smoothly and efficiently. This not only enhances productivity but also prevents costly repairs in the long run.

Regular Inspections

Conducting frequent inspections is crucial for identifying wear and tear before it becomes a major issue. Check for loose bolts, worn belts, and leaks in the hydraulic system. Pay close attention to the filters and fluids, ensuring they are clean and at the appropriate levels. Regularly scheduled checks can save time and resources.

Cleaning and Lubrication

Keeping the machine clean is vital for its performance. Remove debris and dirt from all components to prevent clogs and overheating. Additionally, lubricate moving parts as recommended in the manufacturer’s guidelines. Proper lubrication reduces friction and extends the lifespan of essential components, contributing to the overall health of the equipment.

Comparing Parts with Other Models

When evaluating components from one model against another, it’s essential to understand the nuances that differentiate them. Each machine is engineered with specific functions in mind, which can lead to variations in design and performance characteristics. By examining these distinctions, users can make informed decisions about compatibility and upgrades.

Key Differences to Consider

- Compatibility: Not all components are interchangeable, even among models from the same manufacturer. It’s crucial to verify dimensions and fittings.

- Material Quality: Variations in material can impact durability and performance, affecting the overall longevity of the equipment.

- Performance Metrics: Different models may have specific performance standards, influencing efficiency and output levels.

Benefits of Cross-Model Comparisons

- Improved understanding of the technology behind different models.

- Informed choices when selecting upgrades or replacements.

- Potential cost savings by identifying compatible parts from other series.

By systematically comparing components from various models, users can optimize their machinery’s performance and ensure they are using the best available options for their specific needs.

Tools Needed for Repairs

When tackling maintenance and repair tasks, having the right instruments is essential for efficiency and effectiveness. The correct tools not only streamline the process but also ensure that work is performed safely and to a high standard. Below is a comprehensive list of necessary equipment that will aid in your repair efforts.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Hammer

Power Tools

- Drill (cordless or corded)

- Angle grinder

- Impact wrench

- Reciprocating saw

Having these tools on hand will greatly facilitate repair tasks, allowing for a smoother workflow and better results.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components ensures superior performance and longevity for machinery. These components are specifically designed to fit and function seamlessly, enhancing the overall efficiency of your equipment.

Quality Assurance

One of the primary advantages of utilizing original components is the assurance of quality. These items undergo rigorous testing and adhere to strict manufacturing standards, providing numerous benefits:

- Consistency in performance.

- Reliability over time.

- Reduced risk of failures and breakdowns.

Perfect Fit and Compatibility

Original components are engineered to match the exact specifications of your machinery. This compatibility results in:

- Enhanced efficiency and productivity.

- Minimized wear and tear on other components.

- Easier installation and maintenance.

Investing in original equipment manufacturer items ultimately leads to a more dependable and effective operational experience.

DIY Repair vs. Professional Service

When it comes to maintenance and fixing machinery, enthusiasts often face a dilemma: should they tackle repairs themselves or enlist the help of professionals? Each option comes with its own set of advantages and drawbacks that can significantly influence the decision-making process.

Advantages of DIY Repairs

Choosing to repair equipment independently can lead to substantial cost savings and a deeper understanding of how the machinery functions. Hands-on experience can enhance skills and build confidence. Moreover, the flexibility of working at one’s own pace and convenience allows for a personalized approach to maintenance.

Benefits of Professional Assistance

On the other hand, relying on experts can ensure that repairs are conducted efficiently and effectively. Professionals possess specialized knowledge and access to the latest tools, which can result in a quicker turnaround time. Additionally, their expertise can prevent potential mistakes that may arise from inexperience, ultimately safeguarding the integrity of the machinery.

Ultimately, the choice between self-repair and professional service hinges on individual capabilities, the complexity of the task, and the specific needs of the equipment. Each route offers unique benefits that can lead to successful outcomes when approached thoughtfully.

Resources for Kubota Owners

For enthusiasts and operators of specific machinery, having access to reliable information and resources is essential for effective maintenance and operation. Whether you’re a seasoned user or new to this type of equipment, the right tools and knowledge can enhance your experience and prolong the life of your machinery.

Where to Find Manuals and Guides

- Official Manufacturer Website: Most companies offer downloadable manuals and guides that provide in-depth information on operation and maintenance.

- Online Forums: Communities dedicated to machinery users often share tips, troubleshooting advice, and even custom modifications.

- Local Dealers: Authorized dealers can provide printed materials and expert advice tailored to your specific model.

Maintenance Tips and Best Practices

- Regular Inspections: Check fluid levels and perform visual inspections to catch issues early.

- Seasonal Maintenance: Follow seasonal checklists to prepare your equipment for different conditions.

- Proper Storage: Keep your machinery in a sheltered area to protect it from the elements and prolong its lifespan.