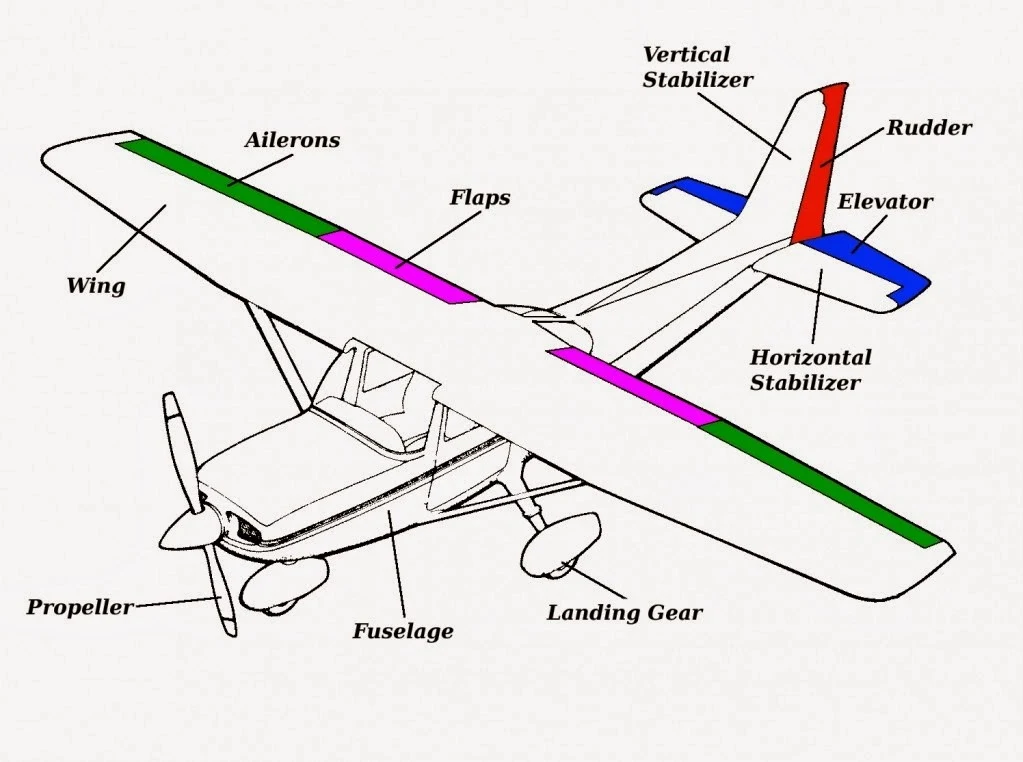

Labeled Diagram of Airplane Parts for Easy Understanding

The intricate design of flying machines encompasses a variety of elements, each serving a specific function to ensure safe and efficient operation. By exploring these essential components, one can gain a deeper appreciation for the engineering marvels that allow for air travel.

Visual representations play a crucial role in demystifying the structure of these vehicles. Utilizing annotated illustrations helps enthusiasts and professionals alike to grasp the relationships and functions of various sections within the craft.

In this exploration, we will delve into the ultimate guide to identifying key features and mechanisms, enhancing both knowledge and practical understanding. Familiarity with these components is invaluable for anyone engaged in aviation, whether for hobby or profession.

Labeled Airplane Parts Diagram

This section explores the essential components of an aircraft, providing a comprehensive overview of their functions and significance. Understanding these elements is crucial for both enthusiasts and professionals in the aviation industry.

Key Components Overview

The structure of an aircraft consists of various integral elements, each serving a specific purpose. From the fuselage to the wings, each section plays a vital role in ensuring safe and efficient flight.

Functionality and Importance

Every component contributes to the overall performance and safety of the craft. For instance, the propulsion system is critical for generating thrust, while control surfaces ensure maneuverability. Familiarity with these features enhances appreciation and knowledge of aviation technology.

Importance of Aircraft Diagrams

Visual representations play a crucial role in understanding the complex structure of flying vehicles. They provide clarity and enhance communication among professionals, ensuring safety and efficiency in operations.

Facilitating Communication

- Clear reference points for technicians and engineers

- Improved collaboration between different teams

- Streamlined training for new personnel

Enhancing Safety and Maintenance

- Identifying critical components quickly

- Assisting in troubleshooting and repairs

- Ensuring compliance with safety regulations

Overview of Airplane Components

The intricate design of an aircraft encompasses a multitude of elements that work harmoniously to ensure safe and efficient flight. Understanding these essential components is crucial for grasping how they contribute to the overall functionality and performance of the vehicle. Each element serves a specific purpose, ultimately supporting the complex operations of aviation technology.

Key Structural Elements

The primary framework of an aircraft is composed of various structural components, each playing a vital role in maintaining integrity and stability. The following are some of the most significant:

- Fuselage: The central body that houses the cockpit, passenger area, and cargo.

- Wings: These appendages provide lift and support during flight.

- Empennage: The tail section, which includes stabilizers and control surfaces.

Critical Systems

Beyond the structure, several systems are integral to the operation and safety of the vehicle:

- Propulsion System: Comprises engines that generate thrust.

- Navigation System: Enables accurate route tracking and positioning.

- Control System: Allows pilots to manage flight maneuvers effectively.

Each of these components and systems plays an indispensable role in ensuring that the aircraft operates smoothly, emphasizing the importance of understanding their functions for anyone involved in aviation.

Main Structures of an Aircraft

The intricate framework of an aircraft serves as the backbone of its design, providing essential support and functionality. Each component plays a critical role in ensuring stability, efficiency, and safety during flight. Understanding these fundamental structures is key to appreciating how they contribute to overall performance.

Fuselage is the central body of the vehicle, housing the crew, passengers, and cargo. It must be robust enough to withstand various forces while maintaining a streamlined shape.

Wings, crucial for lift generation, are designed to optimize airflow and enhance aerodynamic performance. Their shape and size significantly influence the aircraft’s capabilities.

Empennage, or tail assembly, provides stability and control. It consists of the horizontal and vertical stabilizers, which work together to ensure balanced flight.

Landing Gear is vital for takeoff and landing, designed to absorb shock and provide support on the ground. Its configuration varies depending on the aircraft’s type and intended use.

Each of these structures plays an ultimate role in the successful operation of the vehicle, ensuring that it meets the rigorous demands of aviation.

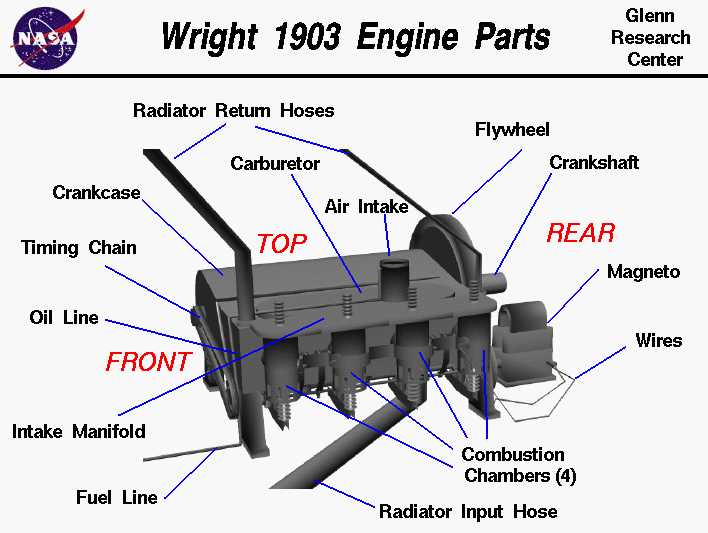

Engine Types and Their Functions

Understanding the various types of propulsion systems is crucial for comprehending how aircraft operate efficiently in the skies. Each system is designed to convert fuel into energy, providing the necessary thrust to lift and maneuver an aircraft. This section explores the main categories of engines, highlighting their unique features and operational roles.

Turbojet engines are among the earliest types developed for flight, known for their simplicity and high-speed capabilities. They operate by drawing in air, compressing it, mixing it with fuel, and igniting the mixture to produce a high-velocity exhaust. This design makes them ideal for supersonic aircraft.

In contrast, turbofan engines have gained popularity due to their efficiency and quieter operation. They utilize a large fan at the front to bypass a significant amount of air around the core engine, resulting in increased thrust and reduced noise levels. This makes them suitable for commercial and long-haul flights.

Another variant, the turboprop engine, combines jet and propeller technologies. It utilizes a gas turbine to drive a propeller, offering excellent performance at lower speeds and altitudes. This type is often found in regional and cargo aircraft, where short takeoff and landing capabilities are essential.

Lastly, piston engines, commonly used in smaller general aviation aircraft, operate on the principle of internal combustion. They convert fuel into mechanical energy through a series of pistons and cylinders, providing reliable performance for light aircraft. Each engine type plays a vital role in aviation, tailored to specific operational needs and performance requirements.

Flight Control Surfaces Explained

In the world of aviation, specific elements play a crucial role in managing an aircraft’s movement and stability. These components enable pilots to steer and maintain the desired flight path, ensuring safety and efficiency during operations. Understanding these surfaces is essential for comprehending how an aircraft responds to pilot inputs and external forces.

Ailerons are located on the trailing edges of the wings and are primarily responsible for rolling the craft. When one aileron is deflected upward while the other is pushed downward, the plane tilts around its longitudinal axis, facilitating smooth turns.

Elevators, positioned on the tail section, control pitch. By adjusting these surfaces, pilots can raise or lower the nose, allowing for ascents and descents. Proper management of this motion is vital for maintaining a steady altitude.

Rudders are found on the vertical stabilizer and help manage yaw. By altering the angle of the rudder, pilots can direct the nose left or right, countering any unwanted lateral movement caused by crosswinds or other factors.

Additional components, such as flaps and slats, enhance lift during takeoff and landing phases. These adjustable surfaces increase the wing’s surface area and alter airflow, allowing for better performance at lower speeds.

In summary, understanding these various elements is vital for grasping the mechanics behind flight dynamics, contributing to both the pilot’s control and the aircraft’s overall performance.

Understanding Landing Gear Systems

The landing gear is a crucial component of any aircraft, serving as the interface between the vehicle and the ground. This system ensures a safe and efficient transition during takeoff and landing, playing a vital role in the overall performance and safety of flight operations.

Components of Landing Gear

Each landing gear system is made up of various elements that work together to provide stability and support. These include struts, wheels, brakes, and actuators, all designed to withstand the forces encountered during landing and taxiing.

Types of Landing Gear Configurations

There are several configurations of landing gear, each suited to different aircraft designs and operational needs. Understanding these configurations is essential for recognizing how they contribute to an aircraft’s performance.

| Configuration | Description |

|---|---|

| Tricycle | Features a nose wheel and two main wheels, offering stability during ground operations. |

| Tailwheel | Includes two main wheels and a small tail wheel, common in vintage aircraft. |

| Skid | Utilized primarily in helicopters, providing a simple landing solution on uneven surfaces. |

Role of Avionics in Aviation

The integration of sophisticated electronic systems has transformed the realm of flight operations. These technologies enhance safety, navigation, and communication, playing a pivotal role in modern aviation.

Key Functions

- Navigation: Provides accurate positioning and route management.

- Communication: Ensures reliable transmission between aircraft and ground control.

- Monitoring: Tracks various flight parameters for operational safety.

Impact on Safety

The advancements in avionics have significantly improved the safety standards in aviation. Enhanced data processing and real-time analytics contribute to informed decision-making during flights.

Cabin Interior Features and Layout

The design and arrangement of the interior space play a crucial role in enhancing passenger comfort and overall travel experience. Every element, from seating to storage, is meticulously planned to optimize functionality and aesthetics. A well-organized interior not only caters to the practical needs of travelers but also contributes to a pleasant atmosphere during the journey.

Seating Arrangement

The layout of seating options is essential for maximizing available space while ensuring comfort. Various configurations, such as traditional rows or innovative staggered placements, aim to provide more legroom and accessibility. Additionally, the choice of materials and design influences not only comfort but also the overall ambiance of the cabin.

Amenities and Features

Modern interiors are equipped with a range of amenities that enhance the passenger experience. From advanced entertainment systems to adjustable lighting, each feature is designed to meet the diverse preferences of travelers. Storage solutions, such as overhead bins and seat-back pockets, further improve convenience, allowing passengers to keep essential items within easy reach.

Fuel Systems and Their Components

Effective fuel management is crucial for the optimal performance and safety of any aircraft. This intricate network ensures that the energy required for propulsion is stored, managed, and delivered to the engine efficiently. Understanding the various elements that contribute to this system is essential for both maintenance and operational success.

Key Elements of Fuel Systems

The architecture of fuel management involves several critical components, each playing a unique role in the overall functionality. These parts work in unison to maintain a steady flow of fuel, manage pressure, and ensure proper filtration to avoid contamination.

Overview of Components

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel required for flight operations. |

| Fuel Pump | Delivers fuel from the tank to the engine. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Fuel Lines | Transports fuel between components safely. |

| Fuel Control Unit | Regulates the flow and pressure of fuel entering the engine. |

Wings: Design and Performance

The design and efficiency of these critical components play a vital role in the overall functionality of an aircraft. Their shape and structure directly influence aerodynamic characteristics, impacting lift and drag, which are essential for flight stability and maneuverability.

Innovative designs often incorporate various shapes and materials to optimize performance. Factors such as aspect ratio and wing loading significantly affect how well the vehicle can ascend, cruise, and descend. Engineers continuously explore advancements to enhance fuel efficiency and overall flight experience.

Understanding the balance between structural integrity and aerodynamic efficiency is crucial. Modern technology allows for simulations and testing that delve into the effects of different configurations, ensuring that the final design meets the ultimate goals of safety and performance.

Common Aircraft Materials and Their Uses

In the aviation industry, the selection of materials plays a crucial role in ensuring safety, performance, and efficiency. Various substances are utilized in the construction of different components, each chosen for its specific properties and advantages. Understanding these materials helps in appreciating the intricacies of aircraft design and functionality.

Metals

Metals are foundational in the creation of air vehicles due to their strength and durability. Here are some commonly used metals:

- Aluminum: Lightweight and resistant to corrosion, making it ideal for fuselage and wing structures.

- Steel: Known for its toughness, often used in high-stress areas such as landing gear.

- Titanium: Offers exceptional strength-to-weight ratio and resistance to extreme temperatures, suitable for engine components.

Composites

Composite materials have gained popularity due to their ability to combine multiple properties for enhanced performance:

- Carbon Fiber Reinforced Polymer (CFRP): Lightweight and strong, widely used in modern airframe construction.

- Glass Fiber Reinforced Polymer (GFRP): Provides good strength and is often used in non-structural components.

- Kevlar: Excellent for impact resistance, often used in areas requiring additional protection.

The careful selection of these materials not only impacts the weight and efficiency of the aircraft but also influences maintenance and operational costs. As technology advances, new materials continue to emerge, pushing the boundaries of what is possible in aviation design.

Maintenance and Safety Checks of Parts

Regular inspection and upkeep are crucial for ensuring optimal functionality and longevity of aircraft components. These practices help in identifying potential issues before they escalate into significant problems, thereby enhancing overall safety and reliability.

Routine inspections involve systematic evaluation of each component, focusing on wear and tear, corrosion, and other forms of deterioration. Technicians utilize checklists to ensure that no aspect is overlooked, which is vital for maintaining the integrity of the entire system.

Preventive maintenance plays a key role in mitigating risks. By adhering to scheduled servicing protocols, operators can address minor concerns proactively. This approach not only improves performance but also reduces unexpected downtimes.

Additionally, compliance with regulations is essential. Aviation authorities mandate specific checks and balances that must be followed rigorously. This adherence not only safeguards the aircraft but also protects the lives of passengers and crew.

In conclusion, a comprehensive approach to maintenance and safety evaluations ensures that all elements function harmoniously, thus fostering a secure flying environment. Regular attention to these practices is indispensable for the aviation industry.