Greenworks Lawn Mower Parts Overview

When it comes to maintaining outdoor machinery, having a clear understanding of its various elements is essential. This knowledge not only helps in troubleshooting but also assists in identifying replacement options when needed. A comprehensive overview of these components can significantly enhance the efficiency and longevity of your device.

By familiarizing yourself with the individual sections and functionalities, you empower yourself to perform routine maintenance tasks with confidence. This insight is particularly valuable for those who enjoy DIY projects, allowing them to tackle repairs and upgrades independently.

Whether you’re a seasoned expert or a novice enthusiast, exploring the intricate relationships between these components can lead to a more seamless experience in managing your outdoor tasks. Engaging with this knowledge opens up a world of possibilities for improving the performance of your machinery.

When it comes to maintaining a well-groomed outdoor space, having a solid understanding of the essential elements of a grass-cutting machine is crucial. This section aims to provide insight into the various components that make up these machines, allowing users to identify and comprehend their functions effectively.

Key Elements of a Cutting Machine

Each unit comprises multiple sections, each playing a vital role in its overall operation. Familiarizing oneself with these components enhances both performance and maintenance efforts.

- Motor: The powerhouse responsible for driving the entire mechanism.

- Blade: The critical component that performs the cutting action.

- Chassis: The framework that holds all parts together.

- Handle: The user interface that allows for maneuverability.

Understanding Component Functions

Recognizing the specific roles of each segment can lead to more informed decisions regarding repairs and upgrades. Below are essential functions of the main elements:

- The motor provides the energy needed for operation.

- The blade is engineered to achieve a clean cut.

- The chassis ensures stability and durability during use.

- The handle allows the user to steer and control the machine effectively.

Key Parts of Greenworks Mowers

Understanding the essential components of a cutting device is crucial for efficient operation and maintenance. Each element plays a vital role in ensuring optimal performance and durability. Familiarity with these components allows users to troubleshoot issues and enhance the lifespan of their equipment.

Motor and Power Source

The engine serves as the heart of the system, providing the necessary energy for operation. Whether it’s powered by electricity or a battery, the energy source directly impacts the efficiency and convenience of use. Choosing the right power type can significantly influence performance and ease of maintenance.

Cutting Mechanism

The cutting system is designed to deliver precision and consistency. Various blade styles and configurations contribute to the effectiveness of the device. Regular inspection and maintenance of this component ensure a clean cut and enhance the overall health of the lawn.

Identifying Common Replacement Items

When maintaining outdoor equipment, recognizing frequently needed components is crucial for ensuring optimal performance. Regular wear and tear can lead to a decrease in efficiency, making it essential to identify and replace these elements promptly.

Blades are among the most vital components, as they directly influence cutting effectiveness. Dull or damaged blades can result in uneven cuts, necessitating their replacement for a clean and healthy appearance of your green spaces.

Another important item to consider is the battery. Over time, batteries can lose their ability to hold a charge, leading to performance issues. Ensuring you have a reliable battery is essential for uninterrupted operation.

Additionally, filters play a significant role in maintaining the engine’s efficiency. Clogged or dirty filters can restrict airflow, causing the machinery to work harder and potentially leading to overheating or other problems.

Lastly, keep an eye on belts, as they are responsible for transferring power between components. Worn or frayed belts can affect functionality, making timely replacements necessary to prevent further damage.

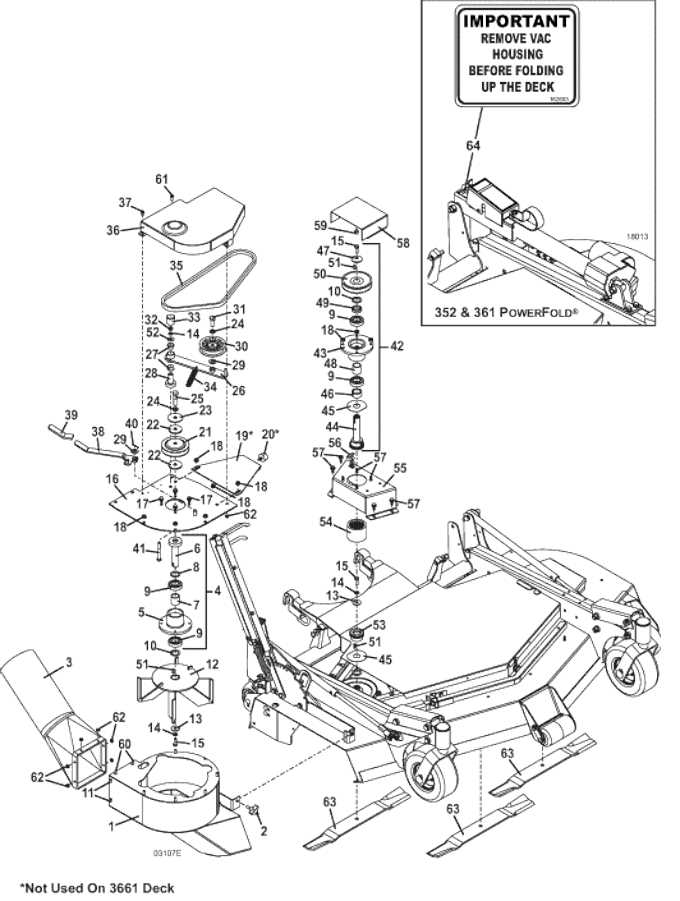

How to Read Parts Diagrams

Understanding mechanical schematics is essential for anyone looking to maintain or repair equipment. These illustrations provide a clear breakdown of individual components and their relationships, helping to simplify the process of assembly or troubleshooting. By learning how to interpret these visuals correctly, you can ensure efficient repairs and avoid costly mistakes.

Identifying Key Elements

Each element in a technical drawing is labeled with a unique identifier, such as numbers or symbols, which correspond to a specific component. Familiarizing yourself with these symbols and labels is the first step to mastering the diagram. It’s crucial to pay attention to the way components are positioned, as this often reflects how they fit together in the actual machine.

Following the Flow

Diagrams often display the order of assembly or function by grouping elements logically. To make sense of the drawing, follow the layout carefully, observing the connections between parts. This approach helps you visualize how everything works together, making the process of repair or assembly more intuitive.

Maintenance Tips for Lawn Mowers

Proper upkeep of garden equipment is crucial to ensure long-term efficiency and prevent unnecessary breakdowns. Regular care helps optimize performance, extend the lifespan of the machinery, and reduce the need for frequent repairs.

Inspect and Clean the Blades

Periodically checking and sharpening the cutting edges ensures a smooth, precise cut. If the blades become dull or damaged, they can tear the grass, leading to uneven results. Cleaning the edges after each use prevents the buildup of debris that can cause rust.

Check Fluid Levels Regularly

Ensuring that oil and other essential fluids are at appropriate levels is vital for the smooth operation of the machine. Low or dirty oil can cause friction and damage the motor, leading to costly repairs.

Replace Filters as Needed

Air filters can become clogged over time, reducing airflow and affecting the engine’s performance. Replacing them regularly ensures that the equipment runs efficiently and reduces the risk of overheating.

Store in a Dry, Covered Area

To avoid moisture damage, always store the machinery in a dry, sheltered location. Exposure to the elements can cause corrosion and reduce the longevity of the equipment.

Tools Needed for Part Replacement

Replacing components in various mechanical or electrical equipment requires the right set of tools to ensure a smooth and efficient process. Having the correct tools on hand not only simplifies the task but also helps to avoid potential damage to the machine or its parts. Below is a list of essential tools that are commonly required for replacing key components in such devices.

- Screwdrivers: A variety of screwdrivers, including both flathead and Phillips, are necessary for removing screws of different sizes and types.

- Wrenches: Adjustable wrenches or socket sets are useful for loosening or tightening nuts and bolts of various dimensions.

- Pliers: These come in handy for gripping, twisting, or pulling wires or small components during the repair process.

- Allen Keys: Also known as hex keys, these are often needed for screws with hexagonal sockets.

- Replacement Hardware: Keeping spare nuts, bolts, and washers on hand can be useful in case any components need to be swapped during the repair.

By preparing the appropriate tools beforehand, you can ensure a more efficient and effective replacement process, saving time and preventing unnecessary frustration.

Common Issues and Solutions

When using outdoor equipment, occasional problems are bound to arise. Understanding typical malfunctions and knowing how to address them can help ensure efficient and long-lasting performance. Identifying the root cause of an issue early can prevent more serious damage and reduce the need for costly repairs.

Issue: Equipment not starting

If the machine fails to start, check the power source first. A loose connection or a depleted battery is a frequent cause. Ensuring that all connections are secure and the power supply is fully charged can often resolve the issue.

Issue: Inconsistent performance

Uneven cutting or reduced efficiency may occur due to dull or damaged components. Inspect the cutting mechanism for any signs of wear, and consider sharpening or replacing parts as needed. Regular maintenance is key to maintaining optimal performance.

Issue: Overheating

Continuous use in challenging conditions may lead to overheating. If this happens, allow the equipment to cool down and check for any obstructions that could block ventilation. Operating in cooler periods or giving the machine regular breaks can prevent overheating.

Safety Precautions When Repairing

When performing maintenance or repairs, it’s essential to prioritize safety to prevent accidents or injuries. Adopting safe practices before starting any work will not only protect you but also ensure the task is completed efficiently. Follow these precautions to maintain a safe working environment.

- Always disconnect the equipment from any power source before beginning any repair to avoid electric shocks or accidental activation.

- Wear appropriate protective gear such as gloves, safety goggles, and sturdy footwear to protect against sharp tools and flying debris.

- Ensure that the workspace is well-lit and free of clutter, providing you with enough room to maneuver and work safely.

- Use tools that are in good condition, and ensure they are suitable for the specific task to avoid accidents caused by faulty equipment.

- Read the user manual or guidelines for the device you’re repairing to understand specific safety instructions and technical requirements.

- Never attempt repairs beyond your expertise. If in doubt, seek professional assistance to avoid potential risks.

By following these precautions, you can minimize risks and ensure that the repair process goes smoothly without compromising safety.

Where to Find Genuine Parts

When it comes to maintaining the efficiency and longevity of your equipment, sourcing authentic components is essential. Opting for original replacements ensures compatibility and reduces the risk of malfunction, helping you avoid potential issues in the long run. These genuine pieces are specifically designed to fit perfectly and meet the required standards, providing reliable performance over time.

| Source | Advantages | Considerations |

|---|---|---|

| Official Retailers | Direct access to authentic components, warranty support | Higher price, limited availability |

| Authorized Dealers | Guaranteed authenticity, knowledgeable support | Potentially longer delivery times |

| Online Marketplaces | Convenient, wide selection | Risk of counterfeit items, check seller reviews |

Upgrades for Enhanced Performance

When looking to improve the efficiency and functionality of outdoor equipment, various upgrades can be implemented. These enhancements are designed to boost the overall performance and ensure a more reliable operation, especially in demanding conditions. By selecting the right components, you can significantly extend the lifespan of your device and make maintenance easier.

Power and Efficiency

Upgrading key elements related to power delivery and energy efficiency can lead to noticeable improvements in performance. Whether it’s optimizing the motor system or enhancing the battery, these changes ensure smoother and more consistent functionality during operation.

- High-capacity batteries for extended runtime

- Advanced motor systems for better energy conversion

- Smart controllers to manage power output effectively

Durability and Maintenance

Another focus for upgrades is on the durability of the equipment. Replacing standard components with more robust options can reduce wear and tear over time, cutting down on the need for frequent repairs and extending the overall lifespan of the system.

- Reinforced blades or cutting systems

Warranty and Support Information

Understanding the warranty coverage and available support options is crucial for maintaining and repairing any equipment effectively. This section outlines the key aspects of the protection plan and how users can access assistance when necessary.

Coverage Details

Most products come with a manufacturer’s guarantee that covers defects in materials and workmanship for a specified period. It’s important to review the terms to know what is included and what may be excluded from the agreement. Typical coverage may range from several months to a few years, depending on the type of equipment.

- Defects in materials

- Issues with workmanship

- Limitations on specific components

How to Access Support

For any concerns or troubleshooting needs, reaching out to the service team can provide solutions quickly. Most companies offer multiple ways to get assistance, including:

- Phone support for immediate help

- Email inquiries for detailed questions

- Online resources like user manuals and FAQs

Ensure to have the purchase details and warranty information ready when contacting customer service to expedite the process.

Benefits of Regular Maintenance

Consistent upkeep of equipment ensures its longevity, peak performance, and helps avoid unexpected breakdowns. By dedicating time to care for your tools, you can maximize their efficiency and save on costly repairs.

Enhanced Performance

Routine inspections and adjustments allow machines to operate at their full potential. This prevents gradual wear and tear from affecting the overall functionality, ensuring every part works seamlessly together.

Cost Efficiency

Preventative care reduces the risk of expensive failures. Regular servicing can catch minor issues early, preventing them from developing into more serious, costly repairs.

- Prolongs the lifespan of equipment

- Improves operational efficiency

- Minimizes repair costs