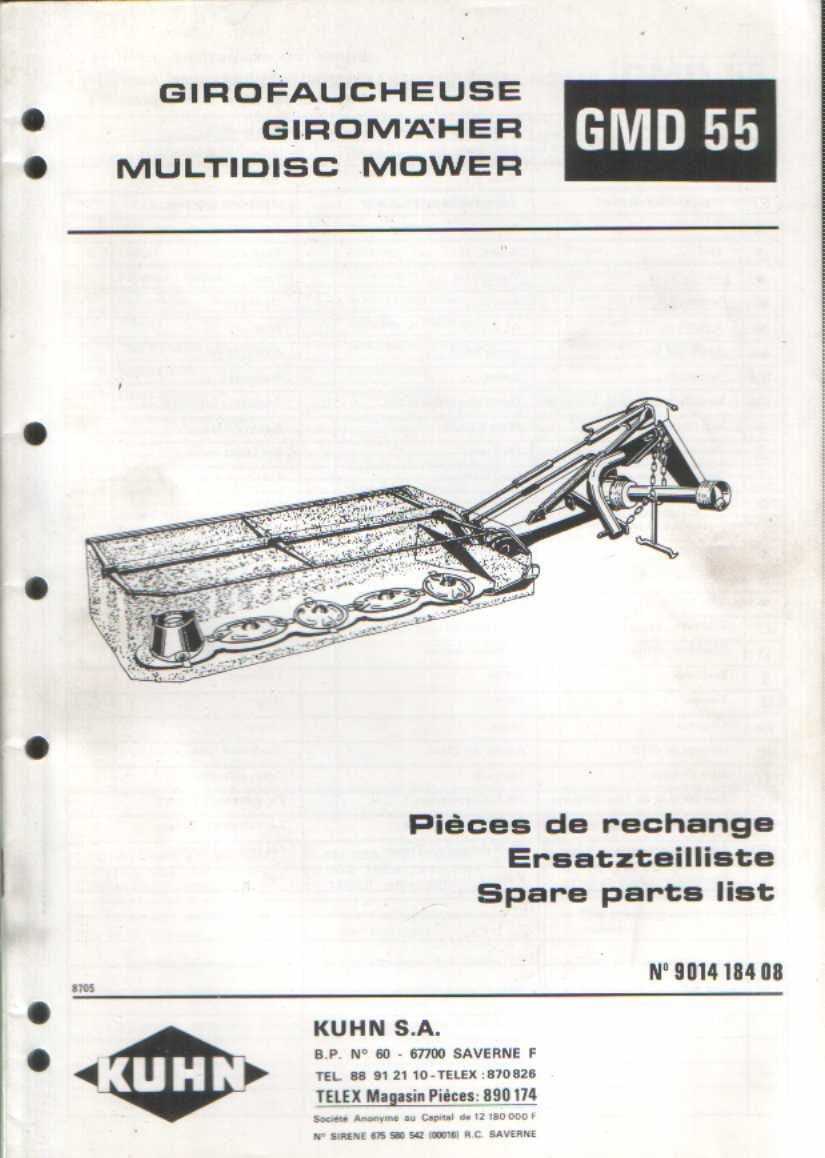

Kuhn Disc Mower Parts Diagram for Easy Reference

The efficiency and functionality of agricultural cutting equipment rely heavily on a comprehensive understanding of its components. Familiarity with the various elements that constitute this machinery is essential for maintenance and troubleshooting. Each piece plays a pivotal role in the overall operation, ensuring that the equipment performs optimally in the field.

In this section, we will explore the intricate network of parts that contribute to the seamless operation of these machines. By breaking down each component, users can gain insights into how they interact with one another and the importance of their maintenance. This knowledge not only enhances operational effectiveness but also extends the lifespan of the equipment.

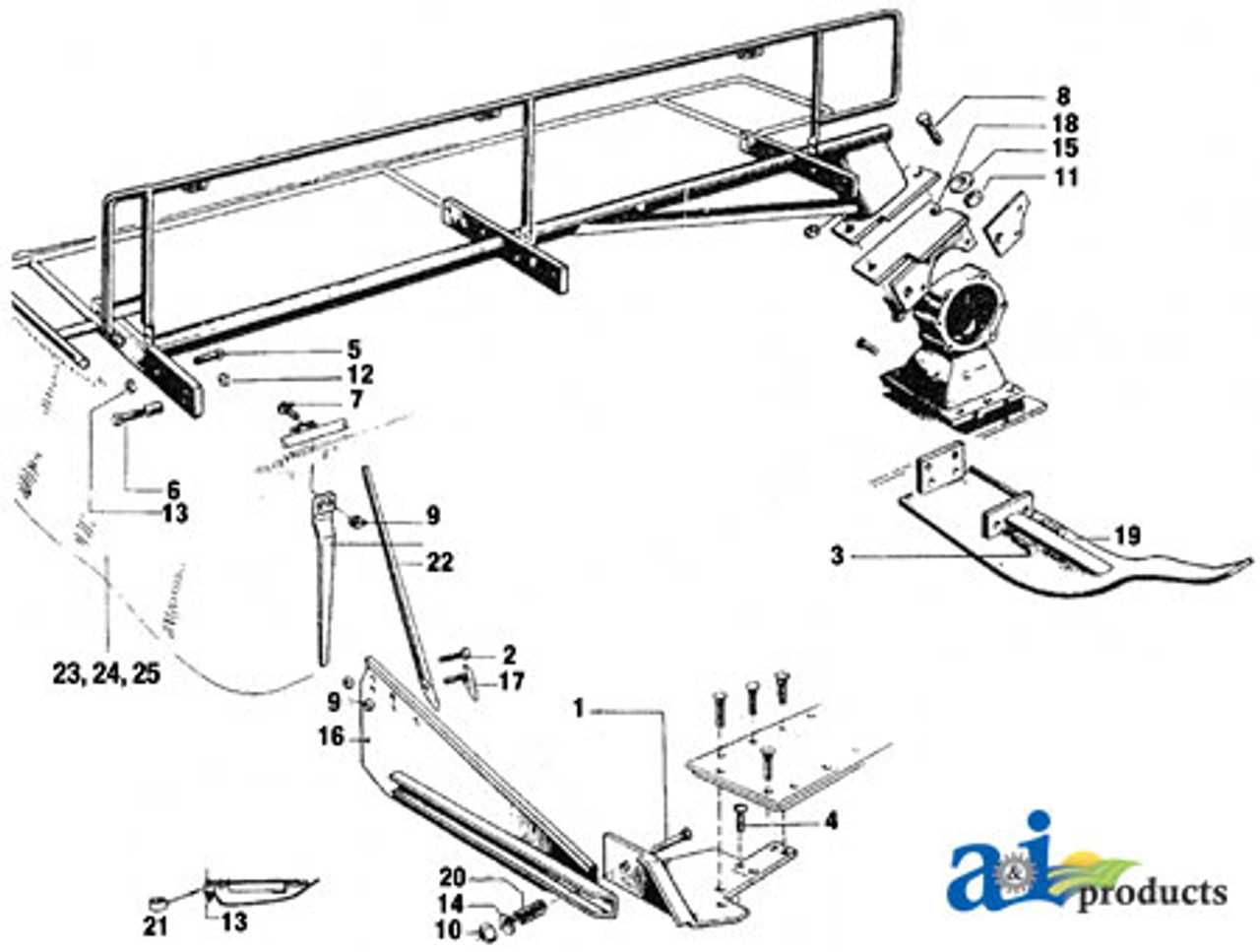

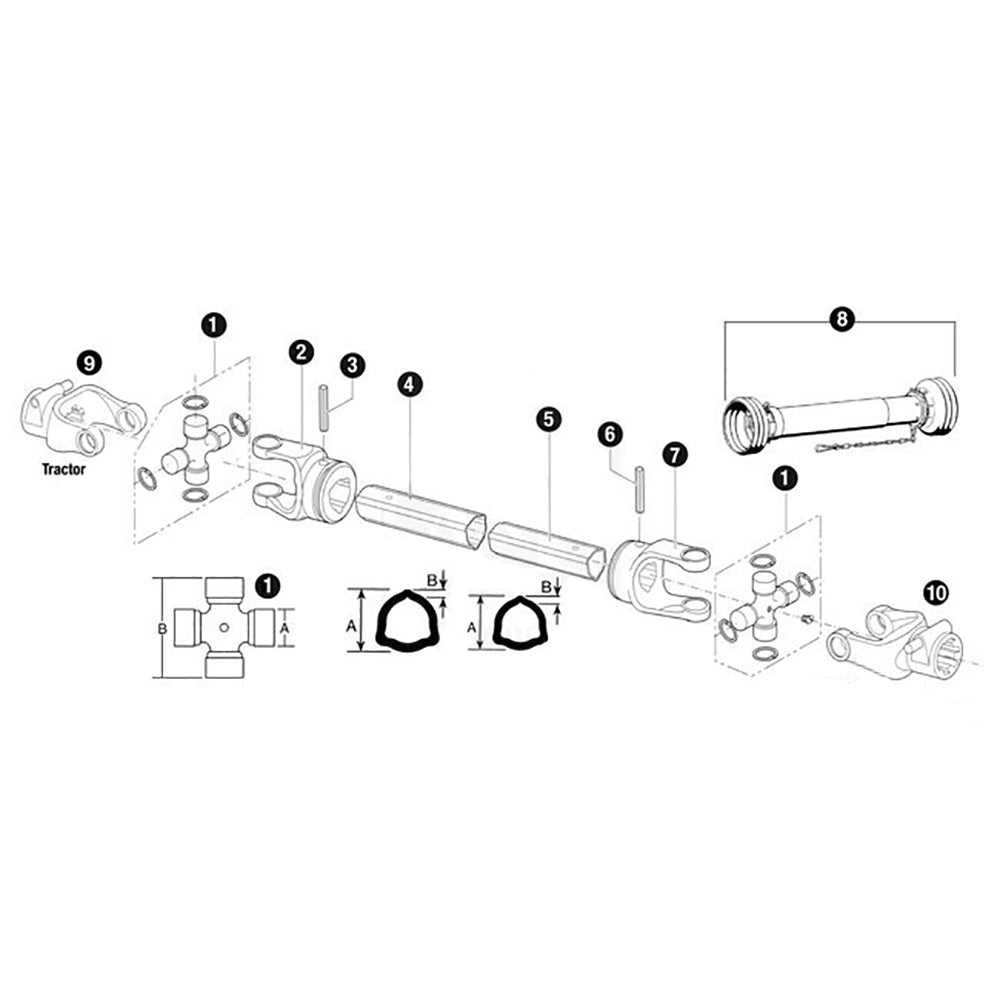

Visual representations of these components can serve as invaluable tools for both novices and experienced operators alike. They provide clarity in understanding the arrangement and function of each part, enabling users to make informed decisions regarding repairs and upgrades. Mastering this information equips operators with the skills necessary to maximize the productivity of their agricultural endeavors.

Understanding Kuhn Disc Mower Components

The efficiency of any cutting machine relies on its individual elements, which work in harmony to achieve optimal performance. Recognizing the roles of each component can greatly enhance maintenance and operation. This understanding enables users to troubleshoot effectively and ensures longevity.

Each element plays a pivotal role in the overall functionality. The cutting units are designed to ensure precision and reliability, while the drive systems provide the necessary power to operate effectively. Understanding these interactions can significantly impact operational efficiency.

Moreover, maintenance practices tailored to specific components can prevent breakdowns and costly repairs. Regular inspections and timely replacements are crucial for keeping the machinery in peak condition. Ultimately, a thorough knowledge of the components allows for informed decisions regarding upkeep and operation.

Key Features of Disc Mowers

Understanding the essential characteristics of modern cutting equipment is vital for optimizing performance and efficiency in agricultural practices. These tools are designed to enhance productivity and improve the overall quality of crop management.

- Efficient Cutting Mechanism: The primary feature includes a rotating blade system that delivers a clean cut, promoting better regrowth and crop health.

- Durability: Built with robust materials, these machines are engineered to withstand harsh working conditions, ensuring long-lasting performance.

- Adjustable Cutting Height: Operators can easily modify the cutting height, allowing for versatility depending on the type of crop and terrain.

- Quick Maintenance: Designed for easy access to critical components, facilitating faster servicing and minimizing downtime.

- Compact Design: Many models feature a streamlined profile for enhanced maneuverability in tight spaces.

- Enhanced Safety Features: Safety mechanisms are integrated to protect users, reducing the risk of accidents during operation.

These features collectively contribute to the effectiveness of agricultural operations, making them indispensable tools in modern farming.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the durability and efficient performance of machinery. By adhering to a systematic maintenance schedule, operators can prevent unexpected failures and extend the lifespan of their equipment significantly. Proper care not only enhances functionality but also ensures safety during operation.

Neglecting maintenance can lead to various issues that may compromise performance and increase repair costs. Below are some key benefits of routine care:

| Benefit | Description |

|---|---|

| Increased Efficiency | Regular checks can help optimize performance, leading to better productivity. |

| Cost Savings | Preventative measures reduce the likelihood of expensive repairs or replacements. |

| Enhanced Safety | Well-maintained equipment minimizes risks associated with malfunctions. |

| Extended Equipment Life | Consistent care ensures longevity, allowing for more years of reliable service. |

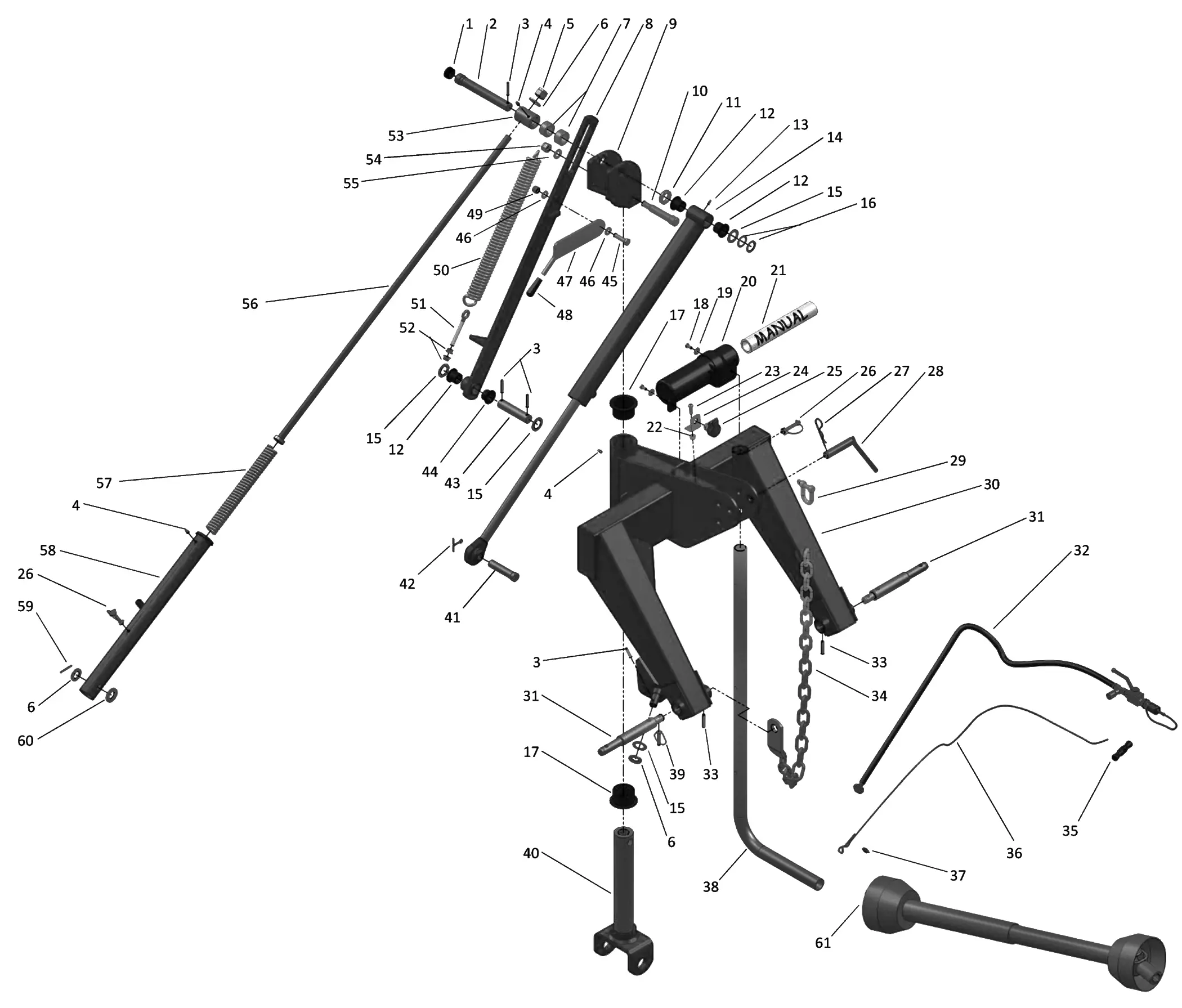

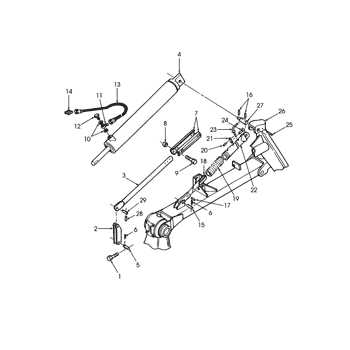

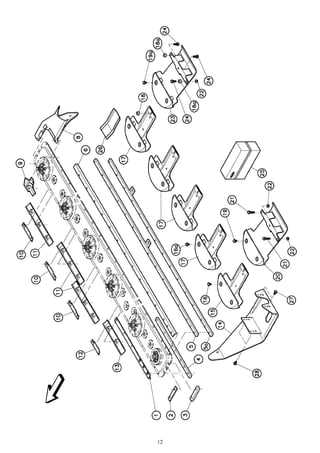

How to Read Parts Diagrams

Understanding the visual representation of components is essential for efficient maintenance and repair tasks. These illustrations provide a clear overview of how different elements interact within a system, allowing users to identify necessary replacements and assembly processes.

Begin by familiarizing yourself with the legend or key that accompanies the visual guide. This will clarify symbols and markings, ensuring that you can easily recognize each element’s function. Pay attention to the layout, as it often follows the logical flow of assembly or operation.

Additionally, look for part numbers which are typically indicated next to each component. This information is crucial when ordering replacements or consulting service manuals. Lastly, take note of any highlighted sections that may indicate special instructions or common points of failure, enhancing your understanding of the entire assembly.

Common Issues with Kuhn Mowers

When operating agricultural cutting equipment, users may encounter a variety of challenges that can affect performance and efficiency. Understanding these issues can aid in timely maintenance and enhance the longevity of the machinery.

1. Uneven Cutting: One prevalent problem is inconsistent cutting height, which can lead to uneven results in the field. This often results from worn or damaged blades, requiring regular inspection and replacement to ensure optimal performance.

2. Overheating: Excessive heat generation during operation can be detrimental. This may be caused by insufficient lubrication or debris accumulation, which hinders the machinery’s functionality. Regular cleaning and lubrication can help mitigate this issue.

3. Hydraulic Leaks: Leaks in hydraulic systems can significantly impair the efficiency of the equipment. These leaks often stem from worn seals or damaged hoses. Prompt identification and repair are crucial to maintaining hydraulic pressure and overall performance.

4. Drive System Failures: Issues with the drive mechanism can lead to a complete halt in operation. This might be due to misalignment or wear in the drive components. Regular checks can prevent these failures and ensure smooth operation.

5. Noise and Vibration: Excessive noise and vibration during operation may indicate underlying mechanical issues. Loose components or imbalanced blades can contribute to these problems, necessitating a thorough inspection and adjustments as needed.

By being aware of these common concerns, operators can take proactive steps to address them, ensuring reliable and efficient performance from their cutting machinery.

Replacement Parts: What You Need

When maintaining agricultural equipment, understanding the essentials for upkeep is crucial. Having the right components on hand ensures optimal performance and longevity of your machinery. This section will guide you through the necessary elements to keep your equipment running smoothly.

Identification: Recognizing the specific components that may need replacement is the first step. Regular inspection can reveal wear and tear, allowing for timely action.

Quality: Opt for high-quality substitutes to guarantee durability. Investing in reliable replacements can save time and costs in the long run.

Compatibility: Ensure that any selected components are compatible with your machinery. Cross-referencing model numbers and specifications is essential for a seamless fit.

Availability: Check local suppliers and online resources for easy access to the needed components. A well-stocked inventory can minimize downtime during repairs.

Ultimately, staying informed about the components crucial to your equipment will lead to better performance and increased efficiency.

Visual Guide to Mower Parts

This section aims to provide a comprehensive overview of the various components involved in the cutting mechanism of grass management equipment. By breaking down each element, users can better understand their function and importance in ensuring optimal performance.

Understanding Components: Familiarizing oneself with the essential elements is crucial for maintenance and troubleshooting. Each section plays a vital role in the overall efficiency and effectiveness of the machinery.

Key Elements: Highlighting significant features like blades, gear systems, and protective casings can enhance operational knowledge. Recognizing these parts will empower users to make informed decisions regarding repairs and replacements.

By delving into this visual guide, operators can gain insight into the intricate workings of their equipment, ultimately leading to improved handling and longevity.

Tools Required for Repairs

Proper maintenance of agricultural machinery is essential for optimal performance and longevity. To ensure effective repairs, a range of specialized tools is necessary. Understanding the right instruments can significantly streamline the repair process and enhance overall efficiency.

Essential Instruments

Start with a set of wrenches and screwdrivers, as these are fundamental for disassembling components. Additionally, a torque wrench is crucial for ensuring that fasteners are tightened to manufacturer specifications, preventing future malfunctions.

Advanced Tools

For more intricate repairs, consider using hydraulic jacks and pulleys to manage heavy parts safely. A multimeter is also invaluable for diagnosing electrical issues, making it easier to pinpoint faults and rectify them efficiently.

Assembly and Disassembly Instructions

This section provides clear guidelines for both putting together and taking apart the equipment efficiently and safely. Following these instructions will help ensure that all components are properly aligned and secured, which is crucial for optimal performance.

Disassembly Steps

Begin by ensuring the unit is powered down and secured. Carefully remove any attached elements, starting from the outer sections and moving inward. Use appropriate tools to detach fasteners, and store all components in a labeled container to prevent loss.

Assembly Steps

To reassemble, start with the central components and gradually add outer sections. Make sure to align parts precisely and tighten all connections securely. Double-check that everything is in its designated place before performing a final inspection to ensure functionality.

Finding Authentic Kuhn Parts

Ensuring the quality and performance of your agricultural machinery starts with sourcing genuine components. Authentic items not only enhance functionality but also extend the lifespan of your equipment. This section provides essential tips for locating original replacements to keep your machines running smoothly.

Why Authentic Components Matter

Using original items can significantly impact your equipment’s efficiency and reliability. Here are some reasons to prioritize authenticity:

- Quality assurance and durability

- Optimal compatibility with existing machinery

- Manufacturer warranties and support

Where to Find Genuine Replacements

When searching for reliable components, consider the following sources:

- Authorized dealers and distributors

- Manufacturer’s official website

- Reputable online marketplaces with verified sellers

- Local agricultural supply stores

By focusing on these resources, you can ensure the longevity and performance of your equipment through authentic components.

Tips for Efficient Mowing Practices

Effective grass cutting requires careful planning and execution to achieve optimal results. Implementing strategic methods can enhance productivity and ensure a healthier landscape.

- Schedule mowing during dry conditions to prevent clumping and ensure an even cut.

- Maintain sharp blades for a clean and precise cut, which promotes healthier growth.

- Adjust cutting height according to grass type to encourage robust root development.

- Use the right technique, such as alternating directions, to prevent soil compaction.

By adopting these strategies, you can significantly improve efficiency and maintain a thriving outdoor space.