Understanding the Mustang 940 Parts Diagram for Better Maintenance

Understanding the intricate assembly of machinery is crucial for both enthusiasts and professionals alike. This section delves into the various elements that constitute a specific model, highlighting their functions and interconnections. By gaining insight into these components, users can enhance their operational knowledge and maintenance skills.

Each unit is designed with precision, ensuring optimal performance and longevity. Recognizing how each piece interacts with others enables a more comprehensive approach to troubleshooting and repair. Whether you’re a seasoned expert or a novice, familiarity with these crucial elements will empower you to tackle any challenge that may arise.

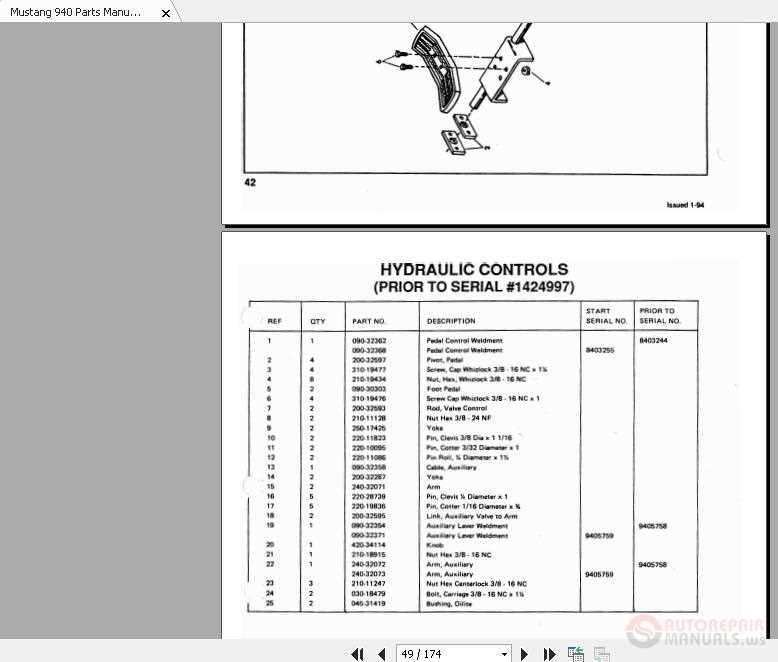

Additionally, visual aids play a vital role in grasping complex structures. They serve as a valuable reference, illustrating the placement and relationship of each component within the assembly. This visual representation enhances understanding and promotes efficient problem-solving strategies.

Understanding the Mustang 940 Parts Diagram

Gaining insight into the components of a specific vehicle model is crucial for effective maintenance and repairs. A visual representation of these elements not only aids in identifying individual parts but also enhances overall comprehension of how they interconnect and function together.

Familiarizing oneself with this schematic can significantly improve the efficiency of troubleshooting and repairs. Here are some key advantages of studying such a representation:

- Enhanced Clarity: A well-structured visual guide simplifies the identification of each element, making it easier to locate and address issues.

- Streamlined Maintenance: Understanding how various components interact can lead to more effective routine checks and servicing.

- Improved Troubleshooting: Quick access to a detailed layout allows for faster diagnostics when problems arise.

- Informed Upgrades: Knowledge of existing parts aids in making informed decisions regarding enhancements or replacements.

When exploring this representation, consider focusing on:

- The relationship between different components.

- The location of critical systems.

- Common wear areas and potential points of failure.

By leveraging this information, users can achieve a greater level of proficiency in handling their vehicle, ultimately leading to a more reliable and enjoyable driving experience.

Importance of Accurate Parts Diagrams

In the realm of machinery and equipment maintenance, precise illustrations of components play a crucial role. They serve as essential guides, enabling technicians and operators to identify individual elements effectively and ensure proper functionality. The significance of these visual representations cannot be overstated, as they contribute to efficient repairs and enhance the overall reliability of the system.

Having a detailed visual reference aids in minimizing errors during assembly or disassembly, allowing for a smoother workflow. Moreover, accurate illustrations facilitate effective communication among team members, ensuring everyone is on the same page regarding the necessary elements. This clarity ultimately leads to improved maintenance processes and extended equipment longevity.

| Benefits of Accurate Illustrations | Description |

|---|---|

| Enhanced Clarity | Clear visuals reduce confusion and misinterpretation. |

| Improved Efficiency | Streamlined processes save time during repairs. |

| Increased Safety | Accurate references help avoid mistakes that could lead to accidents. |

| Effective Training | New team members can learn faster with visual aids. |

In conclusion, the importance of having reliable visual guides in any technical field cannot be underestimated. They not only enhance operational efficiency but also contribute to a safer and more knowledgeable working environment.

Key Components of Mustang 940

This section provides an overview of the essential elements that contribute to the efficient functioning of a specific model in the agricultural machinery sector. Understanding these components is crucial for maintenance, repairs, and optimal performance.

Core Elements

The primary aspects that play a significant role in the operation of the machinery include various systems designed for functionality and durability. Each component is engineered to work seamlessly with others, ensuring smooth performance during demanding tasks.

| Component | Function |

|---|---|

| Engine | Powers the entire unit and drives various functionalities. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulic System | Controls movement and operations of attachments and implements. |

| Chassis | Provides structural support and stability during operation. |

| Electrical System | Supplies power for ignition, lighting, and other electrical components. |

Importance of Maintenance

How to Read the Diagram Effectively

Understanding a schematic representation can significantly enhance your ability to work with complex machinery. By familiarizing yourself with its layout and symbols, you can streamline your repair or assembly tasks. This guide will help you navigate these illustrations with confidence and precision.

Start by identifying the key components indicated in the representation. Each element is typically labeled with unique identifiers that provide insight into its function. Pay attention to the legend or key, as it explains the symbols used and their corresponding meanings. This will serve as your roadmap for the entire layout.

Next, trace the connections between the various parts. Understanding how these components interact with one another is crucial for diagnosing issues or planning maintenance. Look for lines or arrows that indicate movement or flow, as these will guide you through the operational process.

It’s also important to recognize the scale of the illustration. Some representations may not be to scale, which can affect your understanding of the dimensions and placements of each component. Always consider the context in which these visuals are used.

Lastly, take your time to review the entire schematic thoroughly. Repetition can aid retention, so don’t hesitate to revisit challenging sections until you’re comfortable. With practice, interpreting these visuals will become second nature, enhancing your overall proficiency with the equipment.

Common Issues with Mustang 940 Parts

When working with heavy machinery, certain components often exhibit recurring problems that can impact performance and reliability. Understanding these common challenges is essential for effective maintenance and repair. From wear and tear to compatibility issues, various factors contribute to the deterioration of these vital elements.

Wear and Tear: Over time, regular use can lead to significant degradation. Components may experience fatigue, resulting in decreased efficiency. Regular inspections and timely replacements can help mitigate this issue.

Compatibility Concerns: Not all elements are interchangeable, and using incorrect replacements can cause further complications. It’s crucial to verify that new components match the specifications of the original ones.

Installation Errors: Improper installation can lead to a host of problems, including misalignment and functionality issues. Ensuring that all components are installed correctly is vital for optimal operation.

Environmental Factors: Exposure to harsh conditions can accelerate wear. Dust, moisture, and extreme temperatures can affect durability, making it important to choose high-quality materials that can withstand these elements.

Addressing these common challenges proactively can enhance the longevity and performance of your equipment, ensuring that it remains reliable for years to come.

Where to Find Quality Diagrams

Finding accurate and detailed illustrations for machinery components is crucial for effective maintenance and repair. Accessing reliable resources can significantly enhance your understanding and ability to work with complex systems. Below are some of the best options to locate high-quality visual references.

Online Resources

- Manufacturer Websites: Many original equipment manufacturers provide official resources that include comprehensive schematics.

- Forums and Community Groups: Online communities often share valuable insights and images that can assist in troubleshooting and repairs.

- Specialized Websites: Websites dedicated to machinery and equipment frequently offer downloadable guides and diagrams for various models.

Printed Materials

- Service Manuals: Printed manuals from manufacturers usually include detailed illustrations and assembly instructions.

- Trade Publications: Industry magazines often feature articles and resources that include visual aids for different equipment types.

- Books: Comprehensive guides on machinery repair often provide valuable diagrams and explanations.

Maintenance Tips for Mustang 940 Parts

Proper upkeep is essential for the longevity and efficiency of any machinery. Regular attention to components ensures smooth operation and can prevent costly repairs. Here are some valuable recommendations to enhance the durability of your equipment.

- Conduct routine inspections to identify wear and tear early.

- Keep all connections clean and well-lubricated to prevent rust and friction.

- Follow a strict schedule for replacing consumables such as filters and fluids.

- Utilize high-quality replacement components to maintain performance standards.

- Document maintenance activities to track service history and identify recurring issues.

By adhering to these guidelines, you can ensure that your machinery operates at peak performance, minimizing downtime and maximizing productivity.

Comparing OEM and Aftermarket Parts

When it comes to vehicle components, the choice between original equipment manufacturer (OEM) and alternative suppliers can significantly impact performance, longevity, and cost. Understanding the differences between these two options is essential for making informed decisions, ensuring optimal functionality and reliability of your vehicle.

Quality and Reliability

One of the primary considerations in this comparison is the quality and reliability of the components. Here are some factors to consider:

- OEM Components: Typically produced by the vehicle manufacturer, ensuring a precise fit and adherence to original specifications.

- Aftermarket Components: Manufactured by third parties, often varying in quality. Some may meet or exceed OEM standards, while others might fall short.

Cost Considerations

Pricing is another critical aspect when evaluating your options:

- OEM Prices: Generally higher due to brand value, research, and development costs associated with manufacturing.

- Aftermarket Prices: Often more affordable, providing various options that can fit different budgets, though potential savings may come with trade-offs in quality.

Ultimately, the choice between these two categories hinges on individual priorities such as budget, performance expectations, and willingness to compromise on certain features. Making an informed decision will contribute to the overall maintenance and efficiency of your vehicle.

Tools Needed for Mustang Repairs

Having the right tools is essential for successful maintenance and repair of any vehicle. A well-equipped workshop not only streamlines the repair process but also ensures safety and efficiency. Understanding the necessary equipment can greatly enhance the experience and outcome of your automotive projects.

Essential Hand Tools

- Wrenches (standard and metric)

- Sockets and Ratchets

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Torque Wrench

- Jack and Jack Stands

Power Tools and Diagnostic Equipment

- Impact Wrench

- Electric Drill

- Multimeter

- OBD-II Scanner

- Battery Charger

Equipping your space with these tools not only prepares you for common repairs but also empowers you to tackle more complex projects with confidence. Regular maintenance will extend the life of your vehicle and improve its performance.

Safety Precautions During Maintenance

Ensuring a secure environment while conducting upkeep tasks is essential for both the operator and the equipment. Adhering to safety protocols can significantly reduce the risk of accidents and injuries. Below are crucial guidelines to follow during maintenance procedures.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Ensure the work area is well-lit and free of clutter to minimize tripping hazards.

- Before starting any maintenance task, disconnect the power source to prevent accidental activation.

Moreover, consider the following steps:

- Read the operator’s manual thoroughly to understand specific safety recommendations.

- Use tools that are in good condition and appropriate for the task to prevent equipment failure.

- Engage lockout/tagout procedures when servicing machinery to prevent unexpected energization.

- Keep a fire extinguisher nearby, especially when working with flammable materials.

- Ensure that you have easy access to first aid kits and emergency contact numbers.

By implementing these safety measures, maintenance tasks can be performed more effectively and safely, safeguarding both the individual and the equipment involved.

Cost Analysis of Replacement Parts

Understanding the financial implications of substituting components is crucial for maintaining efficiency and reliability in any vehicle. A thorough examination of costs associated with these components allows owners to make informed decisions, ultimately enhancing the longevity and performance of their machinery.

Factors Influencing Costs

Several variables play a significant role in determining the expenses related to component replacements. Quality of the parts, manufacturer, and market demand can all affect pricing. Additionally, choosing between original equipment and aftermarket options can lead to substantial differences in overall expenditure.

Long-Term Investment

While initial costs may seem daunting, investing in high-quality components often results in reduced maintenance and repair expenses over time. Evaluating the lifetime value of these items is essential for achieving the ultimate balance between cost and performance, ensuring that choices made today positively impact future operational costs.

Case Studies: Successful Repairs and Upgrades

This section highlights various examples of effective restoration and enhancement projects that demonstrate the potential for improvement in performance and durability. By examining specific instances, we can glean insights into best practices and innovative solutions that have been successfully implemented by enthusiasts and professionals alike.

Example 1: Engine Overhaul for Enhanced Performance

In one notable case, a vintage vehicle underwent a comprehensive engine overhaul that transformed its efficiency and power output. The owner identified worn components and opted for high-quality replacements, including upgraded pistons and a performance camshaft. This meticulous attention to detail not only revitalized the engine but also resulted in a significant boost in horsepower, allowing for a more thrilling driving experience.

Example 2: Suspension Upgrades for Improved Handling

Another successful project involved upgrading the suspension system to enhance handling and ride quality. The owner replaced the original shock absorbers with adjustable coilovers, allowing for personalized tuning based on driving preferences. Additionally, reinforced sway bars were installed to reduce body roll during cornering. The outcome was a much more responsive and enjoyable driving experience, highlighting the importance of proper suspension in overall vehicle performance.