Baker Forklift Parts Diagram Explained

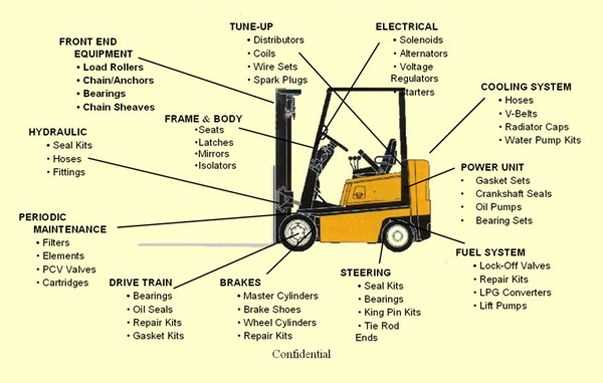

In the realm of industrial equipment, the functionality and efficiency of vehicles play a pivotal role in various operations. A thorough comprehension of the intricate mechanisms involved is essential for maintenance and performance optimization. This section delves into the crucial elements that contribute to the overall operation of these powerful machines.

When examining the structure of such vehicles, it’s vital to recognize the diverse components that work in harmony to ensure smooth operation. Each segment, from the lifting apparatus to the propulsion system, serves a distinct purpose, impacting the machine’s performance and longevity. By exploring these elements, one gains valuable insights into troubleshooting and enhancing operational efficiency.

Furthermore, visual representations can significantly aid in understanding the layout and interconnectivity of these essential features. A detailed illustration serves as a roadmap, guiding technicians and operators through the complexities of machinery. Grasping the relationships between different elements fosters better maintenance practices and promotes a safer working environment.

Understanding Baker Forklift Components

Gaining insight into the various elements that contribute to the functionality of heavy machinery is essential for effective operation and maintenance. Each component plays a vital role in ensuring that the vehicle performs efficiently and safely. This section delves into the essential elements that make up these machines, highlighting their significance and interconnectivity.

Main Elements

The primary components can be categorized into several groups, each serving distinct purposes yet working harmoniously together. Understanding these groups aids in troubleshooting and enhances overall performance.

| Component Group | Description |

|---|---|

| Power Systems | Responsible for generating the energy necessary for movement and operation. |

| Maneuvering Mechanisms | Includes steering and control systems that allow for precise navigation. |

| Load Handling Equipment | Facilitates lifting and transporting materials, crucial for operational tasks. |

| Safety Features | Incorporates systems designed to protect operators and prevent accidents. |

Importance of Regular Maintenance

Routine inspections and maintenance of these essential elements are crucial for longevity and safety. Identifying wear and tear early can prevent significant issues, ensuring optimal performance and minimizing downtime. Familiarity with these components allows operators to take proactive measures, contributing to a more efficient working environment.

Importance of Accurate Parts Diagrams

Having precise visual representations of machinery components is crucial for maintenance and repair tasks. Such illustrations facilitate understanding, ensuring that technicians can easily identify each element and its function within the overall system.

Accurate visual guides enhance several aspects of mechanical servicing:

- Efficiency: Technicians can quickly locate necessary components, reducing downtime and improving workflow.

- Safety: Clear visuals help prevent incorrect assembly, minimizing the risk of accidents and equipment failures.

- Training: New staff can grasp complex systems faster with well-detailed visuals, streamlining the onboarding process.

- Cost-Effectiveness: Fewer errors in maintenance lead to lower repair costs and extended equipment lifespan.

In summary, detailed visual references are vital for effective management of mechanical systems, ensuring both operational success and safety in various applications.

Common Issues with Forklift Parts

Understanding the common challenges associated with machinery components is essential for effective maintenance and operation. Many factors can lead to malfunctions, which ultimately affect overall performance and safety. Recognizing these issues early can help in mitigating potential downtime and repair costs.

Here are some frequent problems that operators may encounter:

| Issue | Description | Symptoms |

|---|---|---|

| Wear and Tear | Components may degrade over time due to regular usage, leading to decreased efficiency. | Increased noise, vibrations, or reduced functionality. |

| Hydraulic Leaks | Leaks can occur in the hydraulic system, affecting lifting capabilities. | Fluid puddles, decreased lifting power, or sluggish response. |

| Electrical Failures | Wiring issues or faulty connections can lead to power loss or erratic behavior. | Unresponsive controls, flickering lights, or unexpected shutdowns. |

| Tire Damage | Damaged tires can impact stability and maneuverability. | Poor traction, uneven wear, or visible punctures. |

| Brake Issues | Worn-out or malfunctioning brakes can compromise safety. | Longer stopping distances, unusual noises, or failure to engage. |

Regular inspection and timely maintenance are crucial in addressing these concerns, ensuring that machinery operates efficiently and safely.

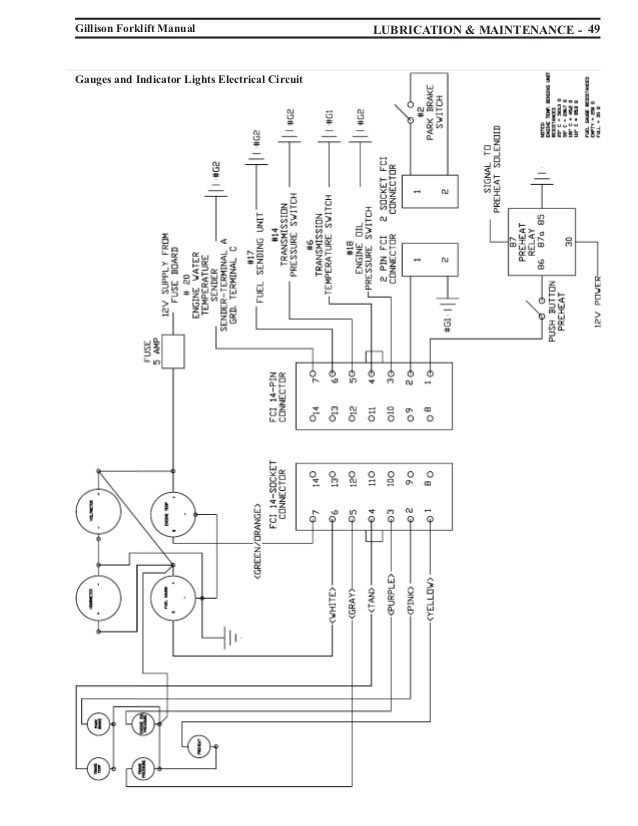

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in maintenance and repairs. These visual aids provide a clear representation of components, making it easier to identify parts and their relationships within a system. By familiarizing yourself with the structure and symbols used in these illustrations, you can enhance your efficiency in troubleshooting and assembly tasks.

Familiarize Yourself with Symbols

Technical illustrations often use a range of symbols to represent different elements. It is crucial to learn these representations, as they convey important information about the components. Look for a legend or key included with the illustration that defines each symbol. This reference will guide you in understanding the specific meanings associated with each part.

Follow the Flow of Information

Each illustration typically follows a logical flow, showing how components interact within the system. Pay close attention to the connections and sequences presented, as this will help you grasp how each element functions in relation to others. Recognizing the layout will assist in pinpointing potential issues or during the assembly process.

Essential Tools for Forklift Repairs

When it comes to maintaining heavy machinery, having the right instruments is crucial for effective service and longevity. A well-equipped toolkit can significantly enhance the efficiency and safety of repair tasks, ensuring that equipment remains in optimal condition. The following tools are fundamental for any technician working on lifting equipment.

First, a comprehensive set of wrenches is essential for loosening and tightening various components. These tools come in different sizes, allowing for versatility in tackling numerous fasteners. Socket sets are also invaluable, providing ease in accessing hard-to-reach bolts and nuts.

In addition to hand tools, power tools play a vital role in modern maintenance. Electric drills and impact wrenches can dramatically reduce the time needed for disassembly and reassembly, making repairs more efficient. Moreover, having a quality torque wrench ensures that all connections are secured to the manufacturer’s specifications, preventing potential failures.

Safety gear cannot be overlooked either. Personal protective equipment such as gloves, goggles, and steel-toed boots is necessary to protect technicians from potential hazards while performing their duties. Lastly, a reliable diagnostic tool can help identify issues quickly, streamlining the repair process and minimizing downtime.

Finding Genuine Baker Replacement Parts

Ensuring the longevity and optimal performance of your equipment relies heavily on sourcing authentic components. Utilizing high-quality replacements not only enhances functionality but also safeguards the integrity of the machinery. When seeking out these essentials, it is crucial to prioritize authenticity to avoid complications down the line.

Benefits of Authentic Components

Investing in original elements offers numerous advantages. Reliability is paramount; genuine components are designed to meet strict standards, ensuring seamless compatibility with your machinery. Furthermore, using such items can significantly extend the lifespan of your equipment, minimizing the risk of unexpected breakdowns.

Where to Find Genuine Replacements

To locate authentic replacements, consider engaging with authorized dealers and manufacturers. These sources not only guarantee the legitimacy of the items but also provide expert guidance on installation and maintenance. Additionally, reputable online platforms can offer a wide selection, making it easier to find what you need while ensuring that quality is never compromised.

Maintenance Tips for Forklift Longevity

Ensuring the durability and efficiency of heavy machinery requires a proactive approach to upkeep. Regular care not only enhances performance but also extends the lifespan of the equipment, reducing downtime and repair costs. Implementing a systematic maintenance routine can lead to significant benefits in operational reliability and safety.

Here are some essential practices to consider:

| Maintenance Activity | Frequency | Description |

|---|---|---|

| Fluid Checks | Weekly | Monitor hydraulic, engine oil, and coolant levels to ensure optimal operation. |

| Tire Inspection | Monthly | Examine tires for wear and proper inflation to maintain traction and stability. |

| Battery Care | Monthly | Inspect and clean battery terminals; ensure proper charging and fluid levels. |

| Brake System Check | Every 500 hours | Assess brake functionality and replace worn components to ensure safety. |

| Filter Replacement | Every 1000 hours | Change air and oil filters to promote engine health and performance. |

Following these recommendations can significantly enhance the reliability and efficiency of your machinery, ultimately leading to smoother operations and lower overall costs.

Identifying Parts by Model Numbers

Understanding the specifics of various machinery components is essential for effective maintenance and repairs. Each unit is designated with a unique model number that serves as a key reference for identifying the appropriate elements needed for servicing or replacement. This system not only streamlines the procurement process but also ensures compatibility and optimal performance.

Benefits of Model Number Identification

- Ensures accurate replacement, reducing the risk of errors.

- Facilitates easy tracking of components across different models.

- Enhances efficiency by minimizing downtime during repairs.

- Supports effective inventory management.

How to Locate Model Numbers

- Check the manufacturer’s label typically found on the unit.

- Refer to the owner’s manual for detailed specifications.

- Look for model numbers in online databases or parts catalogs.

- Contact customer support for assistance in identifying specific components.

By following these guidelines, operators can easily pinpoint the exact components required for their equipment, ensuring longevity and reliability in operations.

Safety Considerations in Forklift Repairs

Ensuring safety during maintenance and repair activities is crucial for preventing accidents and injuries. Proper precautions and practices can significantly reduce risks associated with mechanical work. Here are key safety considerations to keep in mind.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety glasses, and steel-toed boots, to protect against potential hazards.

- Work Environment: Maintain a clean and organized workspace to minimize tripping hazards and ensure easy access to tools and equipment.

- Equipment Inspection: Conduct a thorough inspection of tools and machinery before starting repairs to identify any defects or issues that may pose safety risks.

In addition to general safety measures, specific practices should be followed during mechanical interventions:

- Lockout/Tagout Procedures: Implement lockout/tagout protocols to prevent accidental startup of equipment while maintenance is underway.

- Proper Training: Ensure that all personnel involved in repairs are adequately trained and knowledgeable about safety standards and procedures.

- Emergency Preparedness: Familiarize yourself with emergency protocols and ensure easy access to first aid kits and fire extinguishers.

By adhering to these safety considerations, the likelihood of accidents can be minimized, creating a safer environment for all involved in maintenance activities.

Where to Buy Forklift Parts Online

Finding quality components for heavy machinery online can be straightforward if you know where to look. Numerous retailers specialize in offering a wide range of items that can meet various operational needs. Here are some key places to consider when searching for essential components for your equipment.

- Manufacturer Websites: Start with the official sites of well-known brands. They often have dedicated sections for accessories and components, ensuring you get genuine items.

- Specialty Online Retailers: Numerous e-commerce platforms focus specifically on industrial equipment. These websites frequently provide detailed descriptions and customer reviews, helping you make informed choices.

- Marketplace Platforms: Websites like eBay or Amazon can be valuable resources. Many sellers offer new and refurbished components at competitive prices.

- Local Dealers with Online Presence: Many local distributors maintain an online catalog. This option often allows for quick delivery and local support.

- Wholesale Suppliers: For bulk purchases, consider wholesalers who specialize in industrial machinery. They can offer significant discounts and a wide selection.

Always check the return policy and warranty information before making a purchase. Ensuring compatibility with your specific model is crucial for optimal performance.