Understanding Bobtach Parts Diagram

In any machinery, grasping the arrangement and functionality of individual elements is crucial for effective operation and maintenance. A clear illustration of these components can greatly enhance the understanding of how each part interacts within the system. This section aims to provide insights into the various elements that contribute to the overall performance of the equipment.

By analyzing the configuration of each segment, users can identify potential issues and streamline the repair process. Familiarity with the layout not only aids in troubleshooting but also promotes efficient upkeep, ensuring longevity and optimal performance. The representation serves as a valuable resource for both novices and seasoned professionals alike.

Through this exploration, we emphasize the significance of recognizing the interconnections and functions of every piece, ultimately leading to a more informed approach to handling the machinery. The information presented here is designed to facilitate a deeper understanding and appreciation for the intricate workings of the system.

This section will explore the intricacies of a particular system used in various machinery, focusing on its components and functionality. By breaking down the elements that constitute this setup, readers will gain a deeper understanding of how each part works together to ensure optimal performance.

Key topics to discuss include:

- Overview of the system’s function and importance in equipment operation

- Detailed explanation of the individual components and their roles

- Common issues encountered with the system and troubleshooting tips

- Maintenance practices to enhance longevity and efficiency

In summary, this article will serve as a comprehensive guide, aiming to equip readers with essential knowledge about the system’s design and operational mechanics.

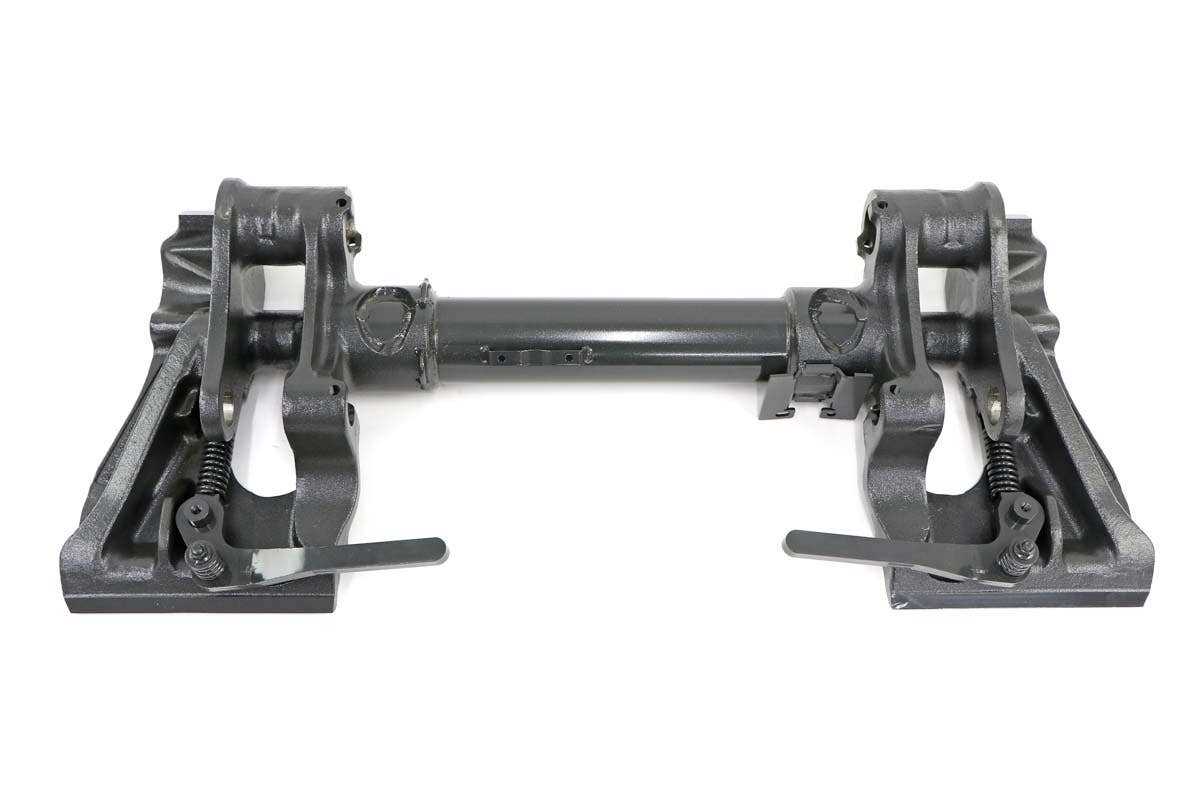

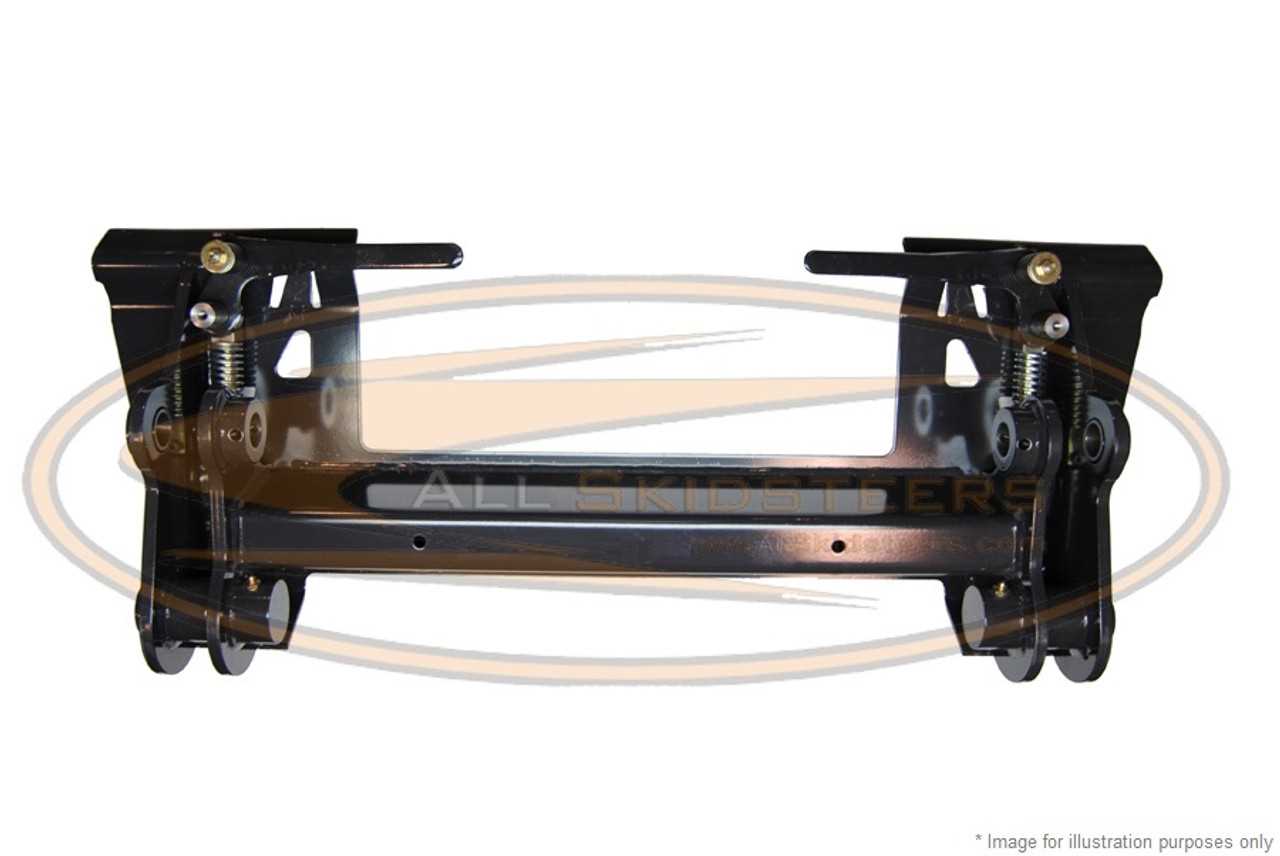

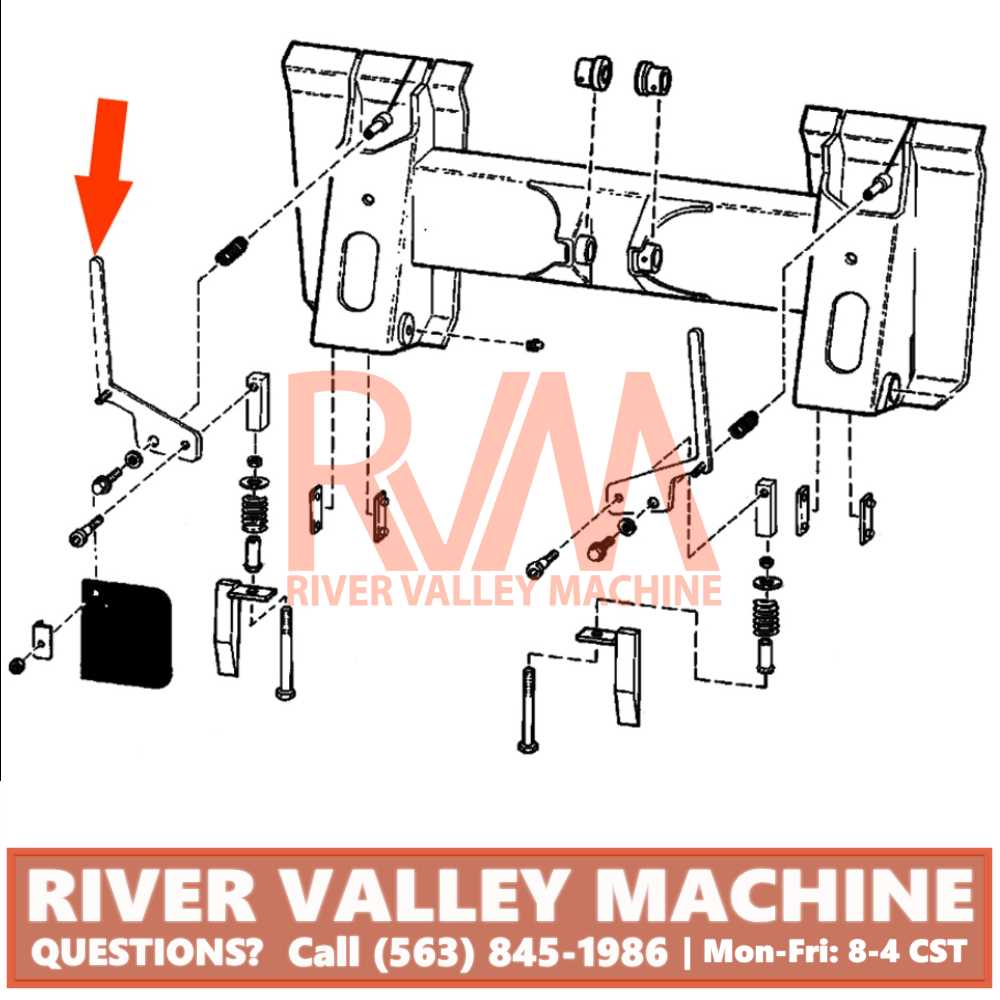

Essential Components of Bobtach

Understanding the crucial elements of any system is vital for effective operation and maintenance. Each component plays a specific role, contributing to the overall functionality and performance. In this section, we will explore the fundamental pieces that make up this particular assembly, shedding light on their significance and interrelations.

Key Functional Elements

The primary functional elements are designed to ensure optimal performance. These components include mechanisms for attachment and detachment, which facilitate the ease of use. Additionally, structural elements provide stability and support, ensuring that the system operates smoothly under various conditions.

Importance of Maintenance

Regular upkeep of these essential elements is crucial to prolonging the lifespan and efficiency of the system. Identifying potential wear and tear allows for timely interventions, reducing the risk of malfunction. Thus, understanding each component’s role aids in maintaining the integrity and reliability of the entire assembly.

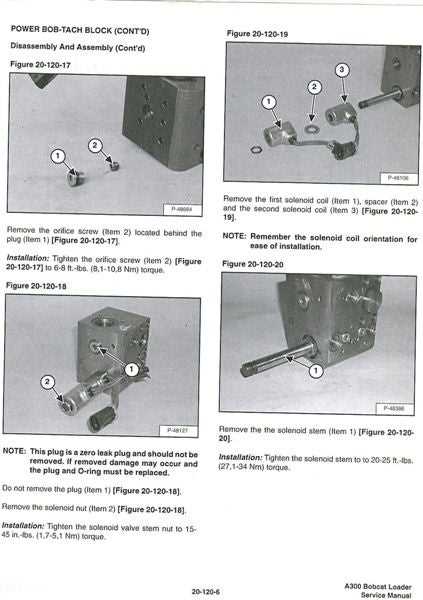

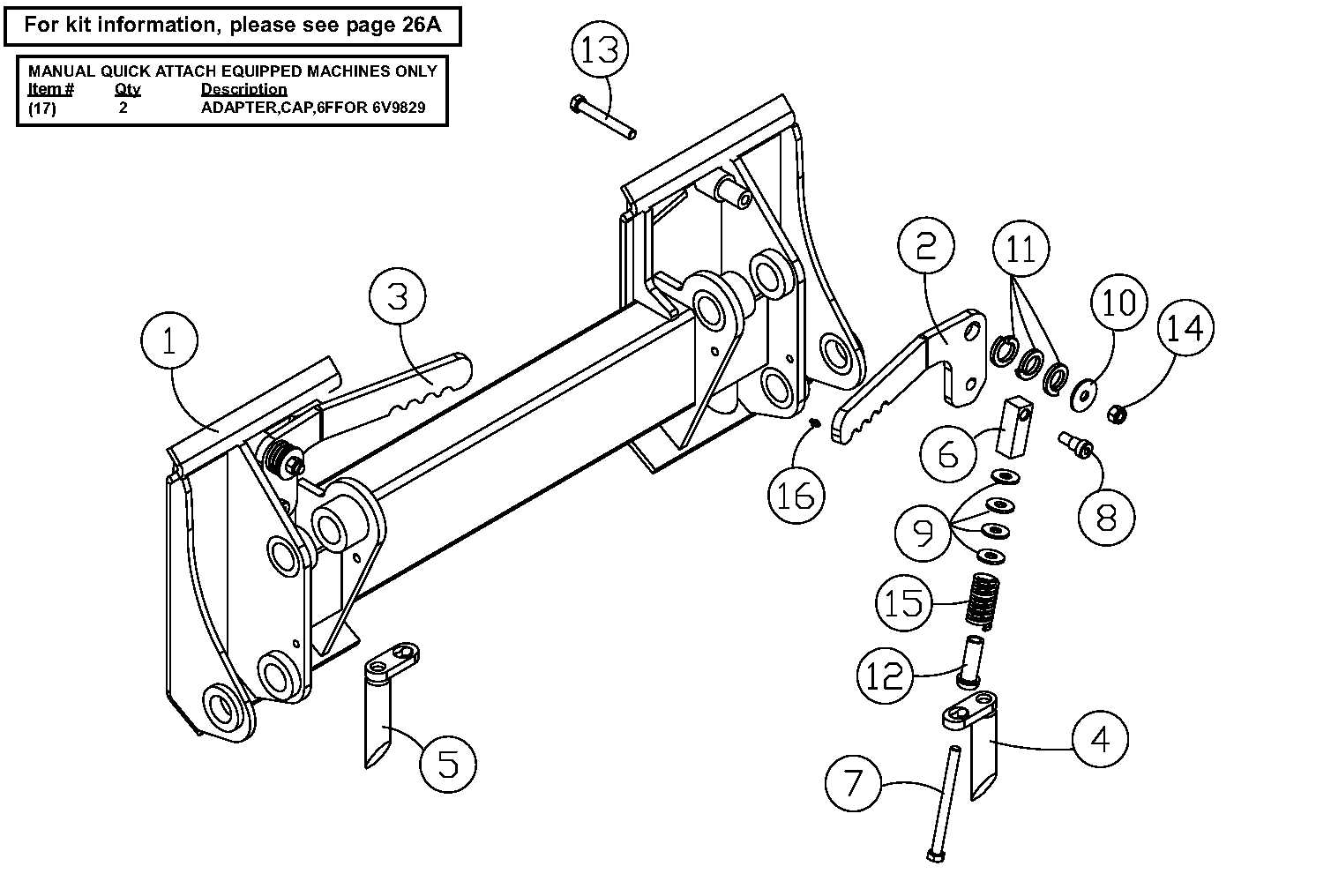

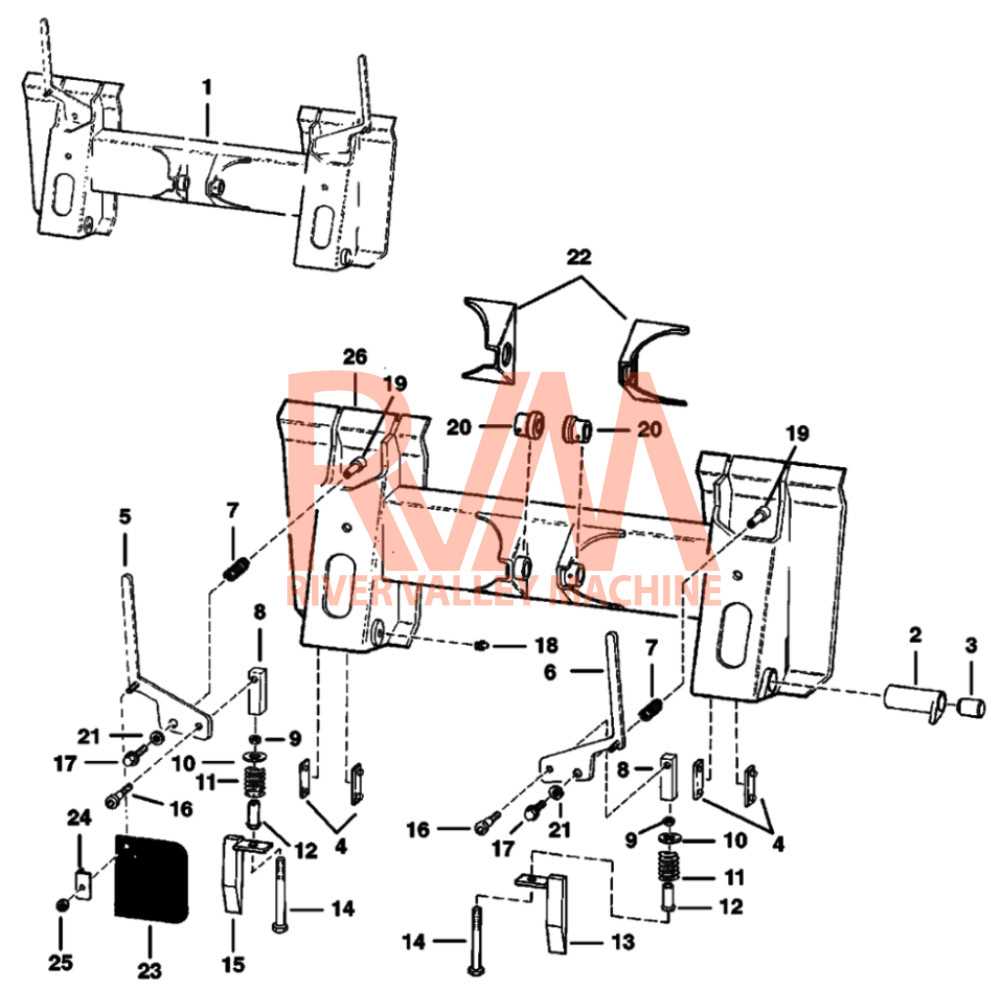

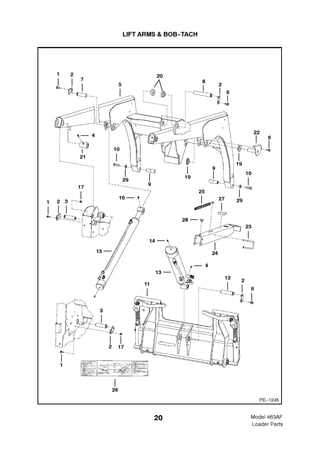

How to Interpret the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and troubleshooting. These illustrations provide valuable insights into the arrangement and functionality of various elements within a system, allowing users to identify parts and their relationships accurately.

Key Components to Consider

When examining these visual guides, focus on the following critical aspects:

| Element | Description |

|---|---|

| Labels | Indicate the names or identifiers of specific elements, ensuring clarity. |

| Connections | Show how different components interact or are linked, which aids in understanding their function. |

| Numbers | Provide references for parts, helping in the ordering or replacement process. |

Steps for Effective Use

To utilize these illustrations effectively, follow these steps:

- Familiarize yourself with the layout and orientation of the visual.

- Identify and match labels to physical components.

- Take note of connections to understand how elements work together.

- Refer to any accompanying documentation for additional context.

Common Issues with Bobtach Parts

In any machinery, various components can experience wear and tear, leading to a range of operational challenges. Identifying these frequent problems is crucial for maintaining efficiency and ensuring longevity. Understanding the common faults can help users address issues promptly, reducing downtime and repair costs.

Wear and Tear: Over time, certain elements may become less effective due to constant use. Regular inspection and timely replacement of these elements can prevent more significant malfunctions.

Improper Installation: Incorrectly installed components can lead to misalignment and operational inefficiencies. It is essential to follow manufacturer guidelines during installation to ensure optimal performance.

Damage from Environmental Factors: Exposure to harsh conditions, such as extreme temperatures or corrosive substances, can compromise the integrity of different parts. Utilizing protective measures can extend the lifespan of these components.

Compatibility Issues: Using components that are not compatible with the machinery can lead to performance problems. Always verify compatibility to avoid unnecessary complications.

Maintenance Neglect: Failing to perform regular maintenance can result in accumulation of dirt and debris, affecting the functionality of various components. Establishing a routine maintenance schedule is vital to ensure smooth operation.

Maintenance Tips for Bobtach Systems

Ensuring the longevity and efficiency of your attachment systems requires regular upkeep and attention. By implementing simple maintenance practices, users can enhance performance, reduce the risk of malfunctions, and extend the lifespan of their equipment. This section outlines essential tips to maintain your machinery effectively.

Regular Inspections

Conducting frequent assessments of your equipment is crucial. Look for any signs of wear, loose connections, or damage that could affect functionality. Addressing minor issues early can prevent larger problems down the line.

Lubrication and Cleaning

Maintaining cleanliness and ensuring proper lubrication are vital for optimal operation. Regularly clean any debris or dirt that accumulates, as it can hinder performance. Use suitable lubricants on moving parts to minimize friction and prevent premature wear.

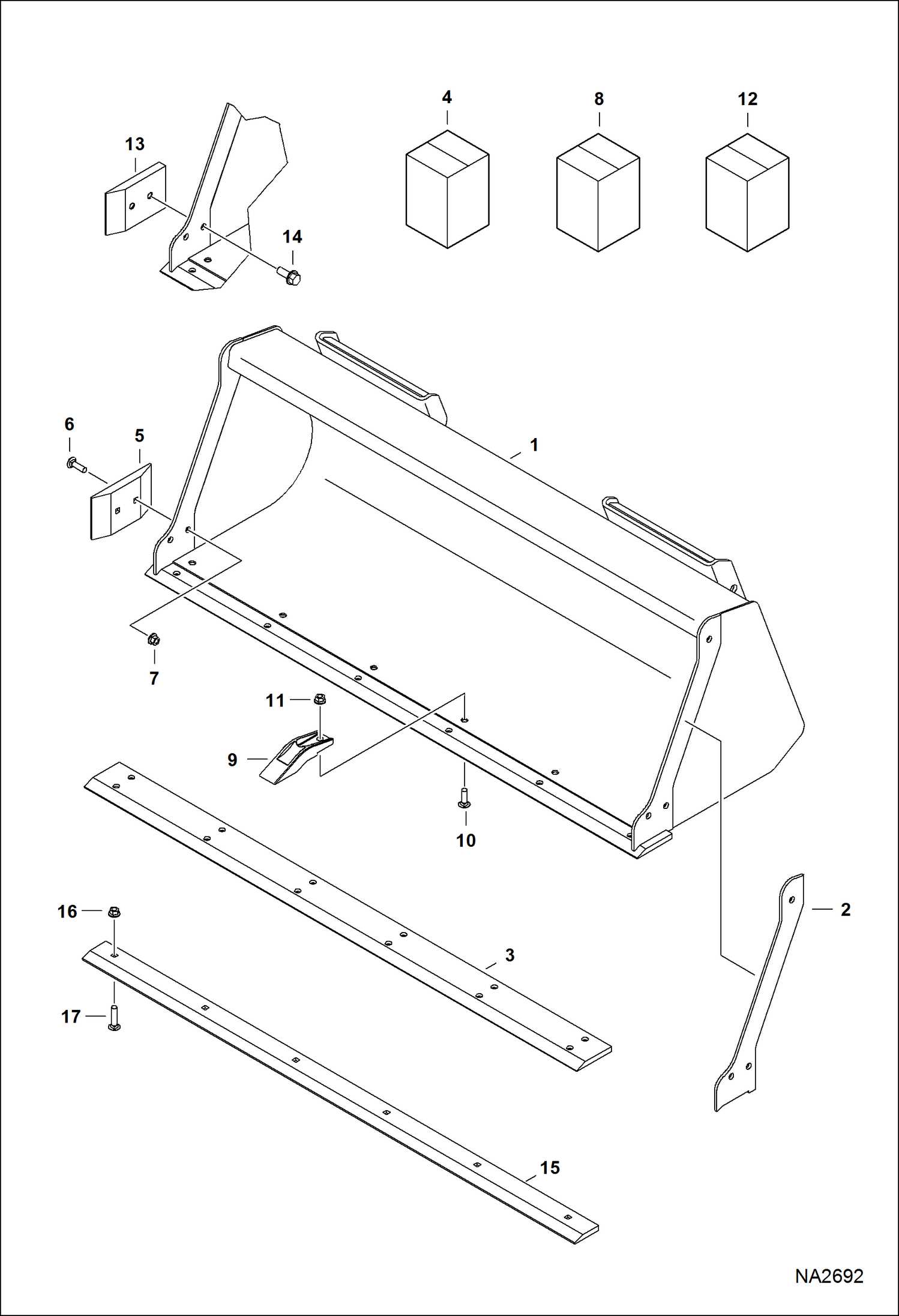

Replacement Parts for Bobtach

When it comes to maintaining machinery, having the right components on hand is essential for ensuring optimal performance and longevity. Various elements may require periodic replacement to keep your equipment running smoothly.

Below are some common components that may need to be replaced:

- Hydraulic hoses: Essential for transferring fluid and maintaining pressure.

- Filters: Necessary for keeping fluids clean and preventing contaminants from causing damage.

- Seals and gaskets: Important for preventing leaks and maintaining pressure in hydraulic systems.

- Bearings: Critical for reducing friction and wear in moving parts.

- Fasteners: Needed to securely hold components together and ensure structural integrity.

It is advisable to consult the equipment manual or a professional to identify the specific replacements required for your machinery. Regular maintenance and timely replacements can help avoid costly repairs and downtime.

Advantages of Using Bobtach Technology

Innovative technology solutions have revolutionized the way machinery operates, providing numerous benefits that enhance efficiency and productivity. The integration of advanced mechanisms in equipment has led to significant improvements in functionality, ease of use, and maintenance.

One of the primary benefits of this technology is its ability to streamline operations, allowing users to complete tasks more quickly and effectively. Here are some key advantages:

- Enhanced Efficiency: The innovative design reduces operational downtime, enabling faster project completion.

- Improved Versatility: Adaptable systems can accommodate various attachments, making the machinery suitable for a wide range of applications.

- Simplified Maintenance: User-friendly features facilitate easier upkeep, minimizing service interruptions and associated costs.

- Increased Safety: Advanced safety mechanisms help protect operators and enhance overall site safety during equipment use.

- Cost Savings: Long-term investment in such technology can lead to reduced operational expenses and higher return on investment.

In summary, the implementation of cutting-edge technology not only boosts productivity but also provides significant advantages that contribute to a more efficient and safe working environment.

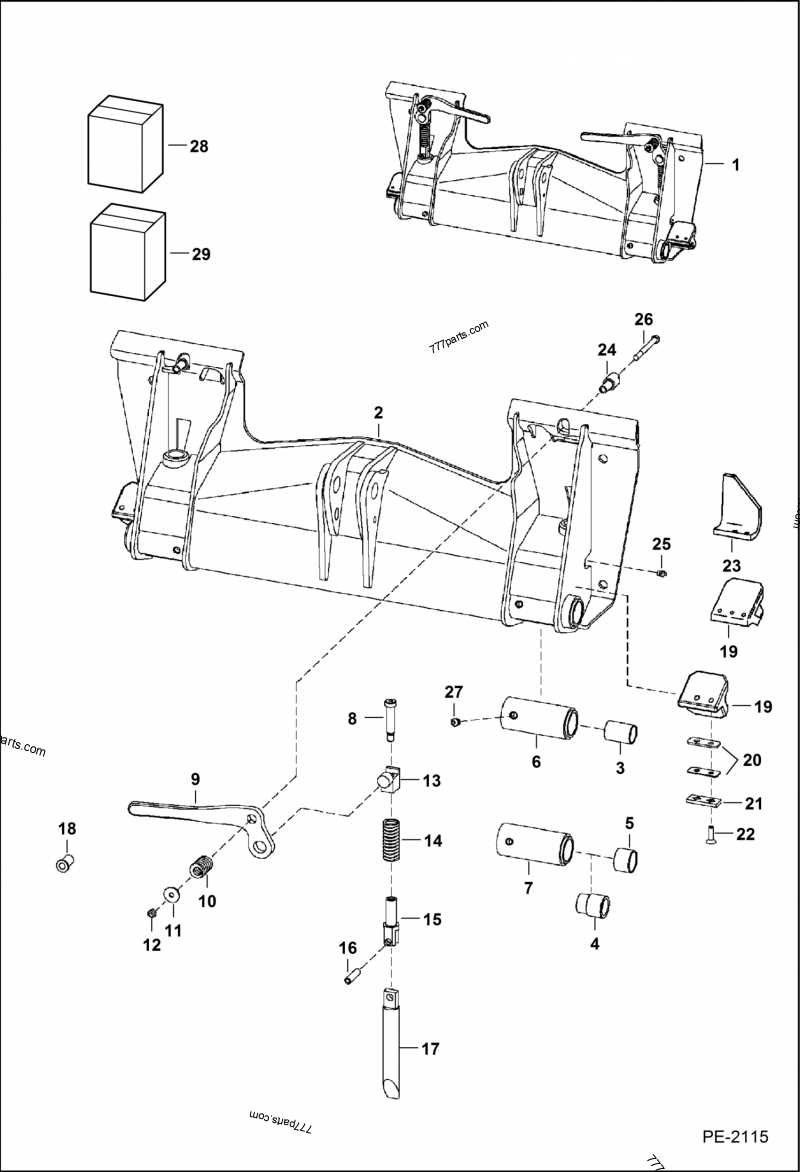

Installation Process for Bobtach Components

The process of setting up various components involves several key steps to ensure proper functionality and integration. Understanding these steps is crucial for achieving optimal performance and reliability of the machinery involved. This section outlines the necessary procedures and best practices for a successful assembly.

Preparation Steps

Before commencing the installation, it is essential to gather all necessary tools and components. Ensuring that everything is in place will help streamline the process and reduce the likelihood of errors. Key preparations include reviewing the installation manual and conducting an inventory check.

Installation Guidelines

Follow the systematic approach outlined below for effective installation:

| Step | Description |

|---|---|

| 1 | Position the main component in the designated area, ensuring a secure base. |

| 2 | Align secondary components as indicated, ensuring compatibility and fit. |

| 3 | Secure all connections using the appropriate fasteners and tools. |

| 4 | Test the setup for stability and functionality before proceeding. |

| 5 | Finalize the installation by conducting a thorough inspection of all connections. |

Adhering to these guidelines will facilitate a smooth and efficient installation process, ensuring that the components operate effectively and reliably.

Comparing Bobtach with Other Systems

Modern attachment systems offer varying levels of efficiency and convenience when it comes to connecting tools or equipment. Understanding the differences between these systems helps in choosing the best solution for specific tasks, ensuring quick transitions and reliable performance.

Efficiency of Quick Attachment Systems

Quick attachment systems are known for their ability to reduce downtime, allowing users to switch between tools swiftly. Compared to older models, these setups often feature more advanced mechanisms that minimize manual adjustments, ensuring a tighter and more secure fit between the machine and its attachments.

Adaptability Across Different Brands

While many attachment systems are designed for specific machines, some are more adaptable across different brands and models. This flexibility can significantly impact a user’s choice, especially when operating various types of equipment. Systems with broader compatibility tend to offer greater value in diverse work environments.

Frequently Asked Questions about Bobtach

In this section, we will address some of the most common inquiries regarding the attachment system used in various machines. Understanding how it operates, its maintenance requirements, and troubleshooting advice can help ensure smooth usage and prolong its lifespan.

How often should the system be inspected? Regular inspections are crucial to maintain efficiency and prevent unexpected failures. It’s recommended to check all components periodically to ensure everything is functioning properly.

What are the signs of wear and tear? Frequent use can cause visible signs such as rust, bending, or reduced performance. These symptoms indicate that parts may need replacement or servicing to avoid further damage.

How can I improve the longevity of the system? Proper lubrication and keeping the mechanism clean from debris will help extend its working life. Follow recommended maintenance routines to avoid common issues related to neglect.

Is it difficult to replace specific components? Replacing individual elements can be done with basic tools and instructions. However, it is important to follow guidelines to ensure safety and proper installation.

Where to Find Bobtach Diagrams

Locating detailed schematics for equipment can be essential when it comes to repairs or maintenance. Whether you’re troubleshooting an issue or performing routine upkeep, having access to the right visual resources makes the process smoother and more efficient.

Online Resources

There are numerous online platforms offering a wide range of technical drawings and assembly illustrations. From manufacturer websites to specialized databases, these sources provide accurate and up-to-date information that’s easy to access. Always ensure that you’re using trusted websites to avoid outdated or incorrect visuals.

Service Manuals

Service guides often contain comprehensive breakdowns, showcasing different components and their connections. These publications are an excellent resource for anyone needing precise visual aids for repairs. Manuals can typically be found through official retailers or by requesting them directly from the manufacturer.