Understanding the Parts Diagram of Hilti TE 700-AVR

When it comes to heavy-duty machinery, comprehending the intricate structure of its elements is crucial for optimal performance. Every unit consists of numerous components that work in harmony to achieve efficiency and reliability. Grasping the layout of these elements can significantly enhance maintenance practices and repair efforts, ultimately extending the lifespan of the equipment.

Within this discussion, we will explore the arrangement and functionality of the various segments of a specific high-performance tool. By examining how each piece interrelates, users can gain valuable insights into troubleshooting and upgrading their devices. This knowledge not only empowers operators but also fosters a deeper appreciation for engineering excellence.

Moreover, a clear visualization of these components serves as an indispensable resource for anyone involved in the upkeep or operation of such machinery. Understanding how to identify and access these parts will streamline repair processes and minimize downtime. Whether you are a seasoned technician or a newcomer, familiarity with these key elements can make a significant difference in your operational efficiency.

Understanding Hilti TE 700-AVR Parts

When exploring the intricate components of a heavy-duty tool designed for precision and efficiency, it is essential to grasp the roles of its various elements. Each component plays a critical part in the overall functionality, ensuring that the device operates smoothly and meets the demands of challenging tasks.

Key Elements: Central to the device’s operation are the motor, housing, and mechanism that facilitate its various functions. These components work in unison to deliver exceptional performance, whether in drilling or chiseling applications.

Maintenance Considerations: Regular inspection and upkeep of each element are crucial for longevity and efficiency. Understanding the wear patterns and common failure points can help users prevent unexpected breakdowns and enhance the tool’s lifespan.

Additionally, being aware of replacement options for essential components can significantly minimize downtime. Knowledge of the specific parts and their functions allows for more informed decisions during repairs and upgrades.

Overview of Hilti TE 700-AVR

This section provides a comprehensive look at a high-performance tool designed for heavy-duty applications in construction and renovation projects. Known for its efficiency and advanced features, this equipment is essential for professionals seeking reliable performance in challenging environments.

Key Features

The tool boasts several innovative characteristics that enhance its functionality and user experience. Its design focuses on minimizing vibration, thereby improving comfort during extended usage. Additionally, it offers exceptional power output, making it suitable for various tasks, including demolition and drilling.

Specifications

| Feature | Description |

|---|---|

| Power | High-performance motor for efficient operation |

| Weight | Optimized for balance and reduced fatigue |

| Vibration Control | Advanced technology to minimize user fatigue |

| Applications | Suitable for various materials including concrete and masonry |

Key Features of the Tool

This powerful instrument is designed for heavy-duty applications, offering a range of advanced functionalities to enhance performance and efficiency. Its robust construction ensures durability, making it suitable for various challenging environments.

- Vibration Reduction Technology: Minimizes user fatigue during prolonged use, promoting comfort and safety.

- High Impact Energy: Provides exceptional performance for tough tasks, ensuring effective penetration in various materials.

- Ergonomic Design: Tailored for ease of handling, reducing strain on the user while maintaining control.

- Versatile Applications: Capable of tackling a wide range of tasks, from drilling to chiseling, adapting to the user’s needs.

- Easy Maintenance: Designed for quick and straightforward upkeep, ensuring longevity and consistent performance.

These features collectively enhance the tool’s capability, making it an invaluable asset for professionals in construction and renovation projects.

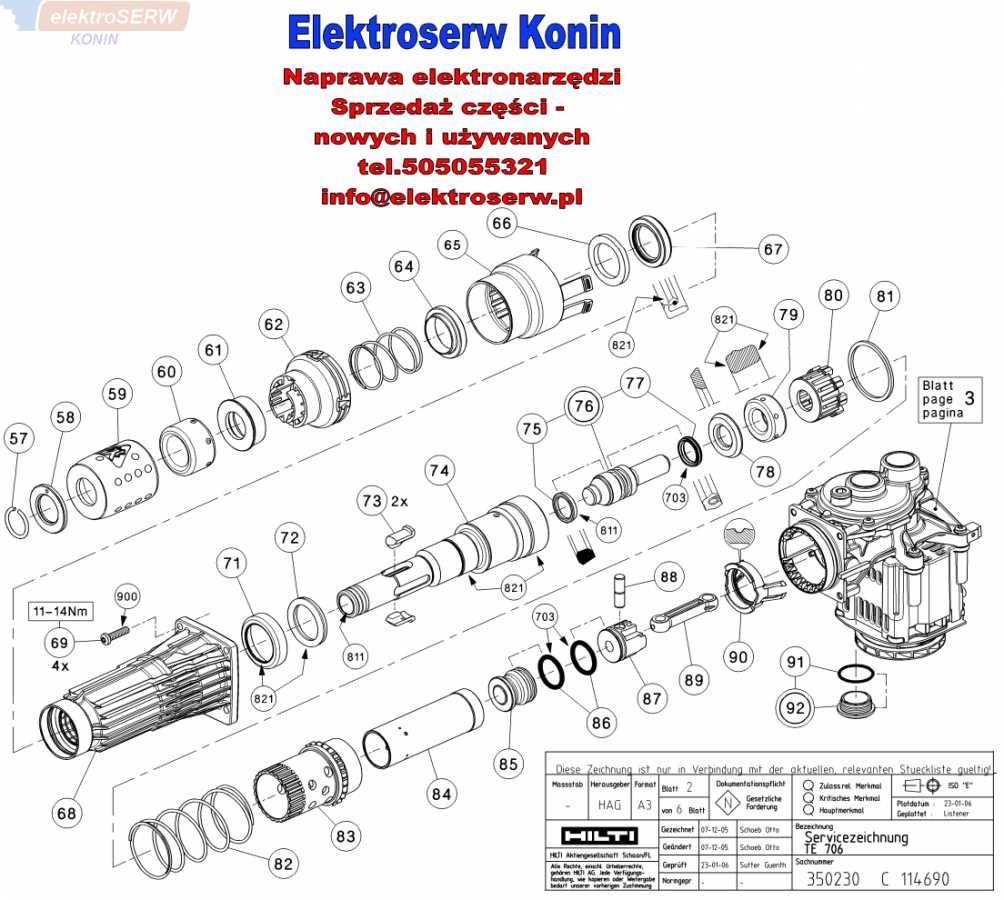

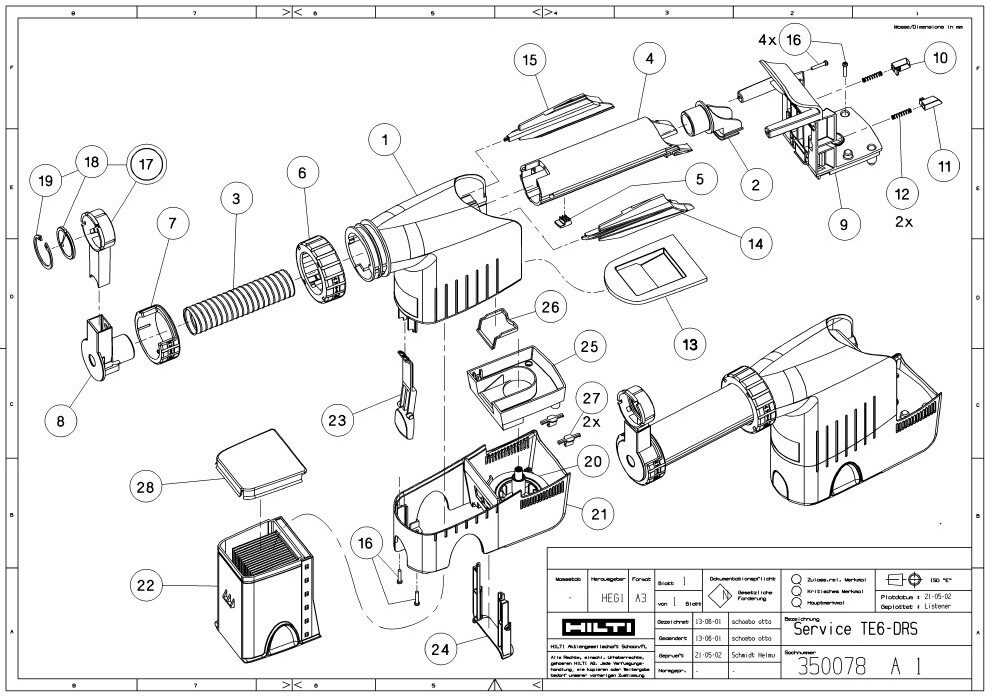

Importance of Parts Diagrams

Understanding the various components of machinery is essential for effective maintenance and repair. Visual representations that illustrate the relationship and function of each piece provide clarity and streamline the process. These guides serve as invaluable tools for technicians, enabling them to quickly identify issues and ensure efficient reassembly.

Enhancing Communication

Visual aids significantly improve communication among team members. When everyone can reference a clear illustration, misunderstandings are minimized. This fosters a collaborative environment where complex tasks become more manageable.

Facilitating Maintenance

Proper upkeep of equipment relies heavily on accurate identification of its elements. Detailed representations allow technicians to easily locate parts, understand their functions, and carry out repairs or replacements with confidence. This reduces downtime and enhances productivity.

| Benefit | Description |

|---|---|

| Clear Identification | Helps in recognizing components easily, reducing errors in repairs. |

| Time Efficiency | Saves time during troubleshooting and assembly processes. |

| Improved Training | Serves as a training tool for new technicians, accelerating their learning curve. |

Components of the TE 700-AVR

This section explores the essential elements that make up a high-performance tool designed for heavy-duty applications. Understanding these components is crucial for effective operation, maintenance, and repair. Each part plays a specific role in ensuring the device functions optimally and delivers reliable performance.

Power Unit: The core of the tool, the power unit provides the necessary energy to drive its functions. This component is engineered for durability and efficiency, ensuring consistent output even under demanding conditions.

Vibration Reduction System: A key feature that enhances user comfort, this system minimizes vibrations during operation. By absorbing shock, it allows for longer usage periods without fatigue, improving overall productivity.

Control Mechanism: This part allows the operator to manage the tool’s functions with precision. Intuitive controls ensure ease of use, enabling adjustments for various tasks and materials.

Drill Bit Holder: A vital component for attaching different drill bits, it ensures a secure fit and allows for quick changes. This versatility is essential for adapting to various job requirements.

Cooling System: Designed to prevent overheating, this system plays a crucial role in maintaining optimal performance during extended use. Effective cooling contributes to the longevity of the tool.

In summary, each of these integral components contributes to the overall functionality and efficiency of the device, making it a reliable choice for professionals in the field.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. Such illustrations serve as a guide to identify and locate various elements of a device, making it easier to manage repairs or replacements.

Here are key steps to effectively interpret these illustrations:

- Familiarize Yourself with Symbols:

- Each symbol represents a specific component.

- Refer to the legend for clarification on these symbols.

- Follow the Layout:

- Components are typically arranged logically, following the assembly sequence.

- Pay attention to how parts connect to one another.

- Note the Reference Numbers:

- Each component is usually assigned a unique identifier.

- Use these numbers to cross-reference with parts lists or manuals.

- Check for Annotations:

- Look for any notes or instructions included with the illustration.

- These can provide valuable insights on installation or maintenance procedures.

By following these guidelines, you can navigate through complex illustrations with ease, ensuring that repairs are conducted accurately and efficiently.

Common Replacement Parts Available

In any high-performance tool, certain components may require periodic substitution to maintain optimal functionality. Identifying and acquiring these essential items can greatly enhance the longevity and efficiency of your equipment. Below are some frequently needed replacements that users often seek.

- Drill Bits: Specialized bits for various materials ensure precise drilling and cutting.

- Carbide Cutters: Durable options for heavy-duty tasks, ideal for concrete and masonry work.

- Handles: Ergonomic replacements improve grip and control during operation.

- Motor Brushes: Essential for maintaining electrical efficiency and performance.

- Seals and Gaskets: Critical for preventing dust and moisture ingress, prolonging tool life.

- Filters: Air and dust filters help maintain cleanliness and efficiency in operation.

Ensuring that you have these components on hand can significantly reduce downtime and keep your tools performing at their best. Regular inspections and timely replacements are key to effective maintenance.

Tools Needed for Repairs

When it comes to conducting effective maintenance on equipment, having the right set of tools is essential. Properly equipped technicians can ensure efficient repairs, minimizing downtime and enhancing performance. This section outlines the necessary implements that can aid in troubleshooting and restoring functionality.

Essential Implements

To start, a reliable screwdriver set is crucial for loosening and tightening various fasteners. Make sure to include both flathead and Phillips options to accommodate different screw types. Additionally, a wrench set will provide versatility for handling nuts and bolts of various sizes, enabling secure connections during reassembly.

Additional Accessories

Moreover, a multimeter can be invaluable for diagnosing electrical issues. This tool measures voltage, current, and resistance, allowing technicians to pinpoint problems accurately. Don’t forget a set of pliers, which can assist with gripping, bending, and cutting wires or other materials. Lastly, a good quality workbench will provide a sturdy surface for all repair tasks, keeping everything organized and within reach.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your power tools requires regular upkeep and attention. By following a few essential practices, you can significantly extend the lifespan of your equipment, ensuring that it performs optimally for years to come.

- Regular Cleaning: Remove dust and debris after each use. Pay attention to ventilation slots to prevent overheating.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Inspect Cables: Regularly check power cords and connections for any signs of damage or wear. Replace damaged components immediately.

Additionally, performing routine checks can help identify potential issues before they escalate.

- Check Fastenings: Ensure all screws and fasteners are tight. Loose parts can lead to further damage.

- Monitor Performance: Pay attention to any changes in operation, such as unusual noises or reduced efficiency.

- Store Properly: Keep tools in a dry, secure place to avoid moisture damage and physical impacts.

By implementing these maintenance strategies, you can enhance the reliability and lifespan of your equipment, ultimately saving time and costs associated with repairs or replacements.

Identifying Faulty Components

Recognizing defective elements within machinery is crucial for maintaining optimal performance. Proper diagnostics can help in pinpointing issues that may disrupt functionality, ensuring efficient operation and prolonging the lifespan of the equipment.

When examining a tool, several indicators may suggest that components are malfunctioning:

- Unusual noises during operation

- Inconsistent power output

- Excessive vibration

- Overheating

- Visible damage or wear

To effectively identify problematic parts, follow these steps:

- Perform a visual inspection for any signs of damage or unusual wear.

- Listen for atypical sounds that could indicate mechanical issues.

- Monitor the tool’s performance for irregularities in power or speed.

- Check for overheating, especially after extended use.

- Test components systematically to isolate and identify the faulty unit.

Utilizing these methods can aid in quickly addressing issues, ensuring that the equipment remains reliable and efficient.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Many users seek reliable outlets that provide original replacements to avoid the pitfalls of counterfeit options, which can compromise both functionality and safety.

One of the best avenues for obtaining genuine components is through the manufacturer’s official website. Here, you can often find a comprehensive catalog of available items, ensuring that you are purchasing high-quality products tailored specifically for your tools.

Additionally, authorized dealers and local distributors often stock authentic replacements. These establishments typically have knowledgeable staff who can assist you in selecting the correct items for your specific model, enhancing your overall experience.

Another option is to attend trade shows or industry exhibitions, where reputable brands often showcase their products. Such events can provide direct access to authentic merchandise, along with opportunities for networking and learning about new innovations in the field.

Lastly, consider joining online forums or community groups focused on your industry. Members frequently share recommendations for trusted suppliers, helping you connect with resources that offer legitimate components.

Repair vs. Replacement Decisions

When faced with a malfunctioning tool or equipment, users often grapple with the choice between repairing it or opting for a new unit. This decision can significantly impact both finances and productivity, making it essential to weigh the pros and cons of each option carefully.

Factors to Consider

Several elements play a crucial role in determining whether to fix or replace. First, assess the cost involved in each option. If repair expenses are minimal compared to the price of a new model, fixing may be the more economical choice. However, if the equipment is frequently breaking down, investing in a new unit could save time and reduce frustration.

Long-Term Implications

Consider the durability and longevity of the existing tool. If it has a history of issues, it might be wise to invest in a replacement, as ongoing repairs can quickly accumulate. Additionally, advancements in technology could offer better efficiency and features in newer models, enhancing overall performance.

Customer Support and Resources

Accessing effective support and resources is crucial for maximizing the performance and longevity of your equipment. Understanding how to navigate these available services can enhance your experience and ensure you are well-equipped to tackle any challenges that may arise during use.

Comprehensive Assistance

For users seeking guidance, various channels are available to provide help. Dedicated support teams are ready to address inquiries, troubleshoot issues, and offer expert advice tailored to your specific needs. Whether through phone consultations, online chat, or email correspondence, assistance is just a few clicks away.

Educational Materials

In addition to direct support, a wealth of resources is offered to help users familiarize themselves with their equipment. Instructional videos, detailed manuals, and troubleshooting guides are accessible online. These materials not only enhance understanding but also empower users to perform maintenance and repairs independently. Investing time in these resources can lead to improved efficiency and safer operation.

Make the most of the available support systems to ensure a seamless and productive experience with your tools.