Miller 252 Parts Diagram Overview

In the realm of machinery and equipment, having a clear understanding of the individual elements that make up a system is essential. Each component plays a crucial role, contributing to the overall functionality and efficiency of the operation. A detailed overview of these elements not only aids in effective maintenance but also enhances the ability to troubleshoot potential issues.

Visual representations serve as invaluable tools for both technicians and operators. By illustrating the arrangement and relationship between various components, these graphics facilitate a deeper comprehension of how each part interacts within the larger assembly. This knowledge empowers users to address repairs and upgrades with confidence and precision.

Furthermore, being familiar with the configuration of these elements can streamline workflows and improve productivity. Whether for training new personnel or guiding experienced workers through complex tasks, a comprehensive layout serves as a foundational resource that can significantly impact operational success. Emphasizing clarity and accessibility in these illustrations can lead to better outcomes and reduced downtime.

Understanding Miller 252 Parts Diagram

This section delves into the intricacies of a specific assembly blueprint essential for ensuring optimal performance and maintenance of equipment. Familiarizing oneself with the visual representation of components can greatly enhance troubleshooting and repair processes.

Recognizing the structure of the schematic provides clarity on the function and interrelation of various elements. This understanding is crucial for both novice and experienced users. Key benefits include:

- Improved maintenance efficiency

- Faster identification of malfunctioning components

- Enhanced ability to communicate issues with technical support

To navigate the blueprint effectively, it is important to understand the following aspects:

- Labels and Symbols: Familiarize yourself with the icons used to represent different components.

- Connections: Pay attention to how elements are linked, which can indicate their operational relationships.

- Component Locations: Know where each part is situated to streamline repairs and replacements.

By mastering these aspects, users can ensure they are well-equipped to handle maintenance tasks and extend the lifespan of their equipment.

Overview of Miller 252 Components

This section delves into the various elements that comprise a particular welding machine, highlighting their functions and interrelationships. Understanding these components is crucial for both efficient operation and maintenance of the equipment.

The essential components include power supply units, control systems, and cooling mechanisms, each playing a significant role in the machine’s performance. A thorough comprehension of these parts enables users to optimize usage and troubleshoot effectively when issues arise.

| Component | Function |

|---|---|

| Power Source | Provides the necessary electrical energy for welding operations. |

| Control Panel | Allows the operator to adjust settings and monitor the machine’s performance. |

| Cooling System | Prevents overheating of internal components, ensuring longevity and reliability. |

| Electrode Holder | Secures the welding electrode and facilitates proper arc formation. |

| Gas Supply | Delivers shielding gas to protect the weld pool from contamination. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery and systems. These illustrations serve as essential tools for identifying individual elements, ensuring proper assembly, and facilitating maintenance tasks. By providing a clear overview, they enable users to navigate intricate designs with ease and confidence.

Enhancing Communication

Utilizing visual aids significantly improves communication among technicians, engineers, and manufacturers. When discussing specific components, these representations eliminate ambiguity and allow for a shared understanding. This clarity fosters collaboration, reducing the likelihood of errors and enhancing overall efficiency in both production and repair processes.

Streamlining Maintenance

Effective maintenance relies on precise identification of components and their relationships within a system. Visual guides simplify troubleshooting by helping users quickly locate parts that may need inspection or replacement. Furthermore, they can serve as educational tools for training new personnel, ensuring that all team members are well-versed in the system’s layout.

Key Features of the Miller 252

The advanced welder model showcases a range of innovative characteristics that enhance performance and usability. Designed for both amateur and professional use, it offers a robust solution for various welding tasks, ensuring efficiency and reliability in every project.

High Performance: This equipment is engineered to deliver exceptional output, allowing for seamless operation across multiple materials. Its powerful capabilities ensure a clean and precise weld, essential for high-quality results.

User-Friendly Interface: With an intuitive control panel, operators can easily adjust settings to suit specific applications. This feature simplifies the process for beginners while providing seasoned users with the precision they require.

Portability: Designed with mobility in mind, this model is lightweight and compact, making it easy to transport between job sites. This portability does not compromise its performance, allowing users to achieve professional results anywhere.

Durability: Built to withstand demanding environments, the welder is constructed from high-quality materials that ensure longevity. This robustness translates to lower maintenance costs and extended service life, making it a wise investment for any workshop.

Versatile Applications: Suitable for a variety of welding techniques, this device can handle everything from light fabrication to heavy-duty projects. Its adaptability makes it an essential tool for diverse industries and skilled trades.

How to Read the Diagram

Understanding a visual representation of components can significantly enhance your ability to work effectively with machinery. These illustrations provide crucial insights into the relationships between various elements, aiding in both assembly and troubleshooting processes. Familiarity with how to interpret these visuals is essential for achieving optimal performance and maintenance.

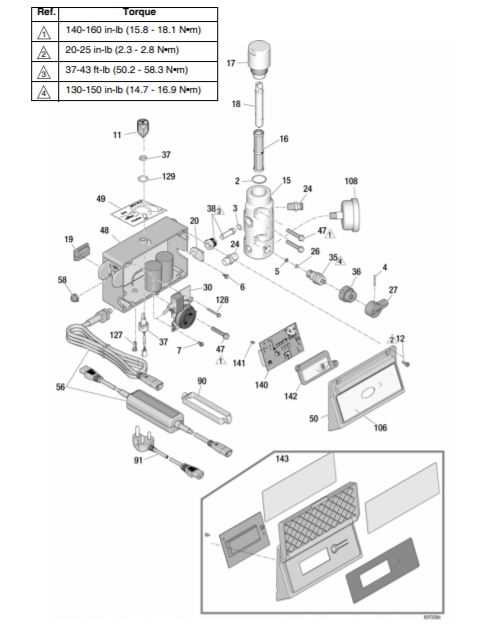

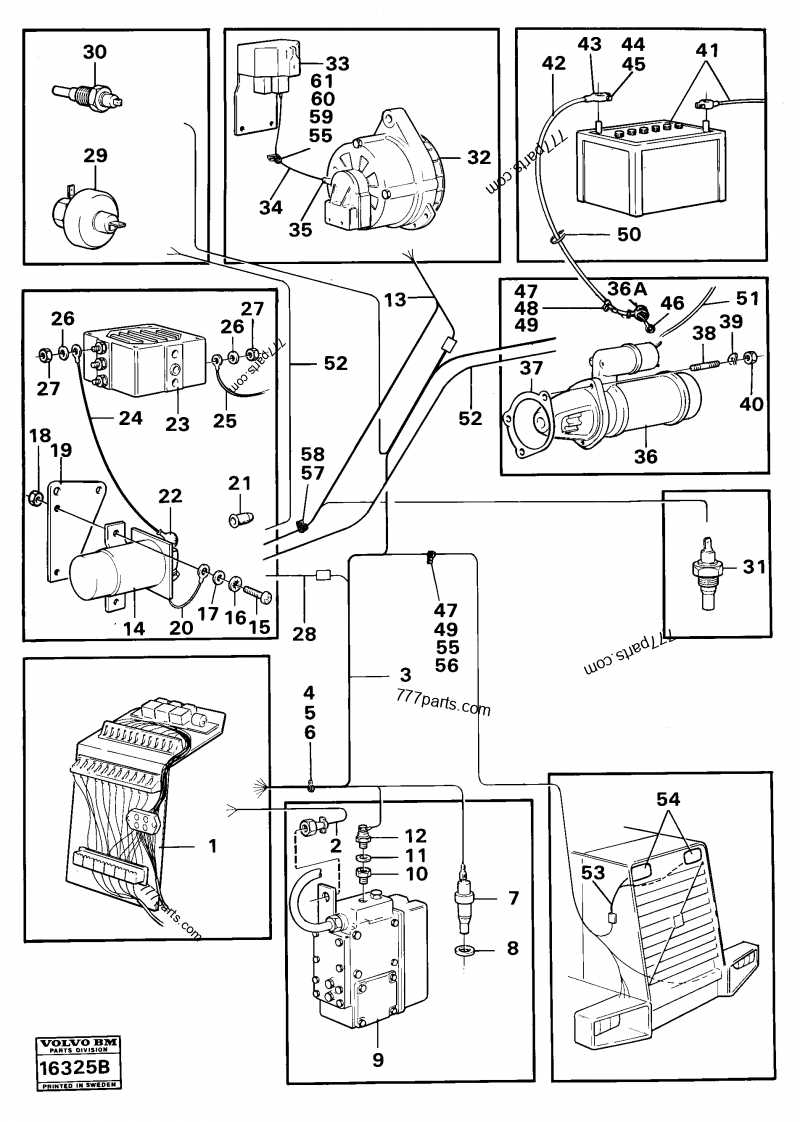

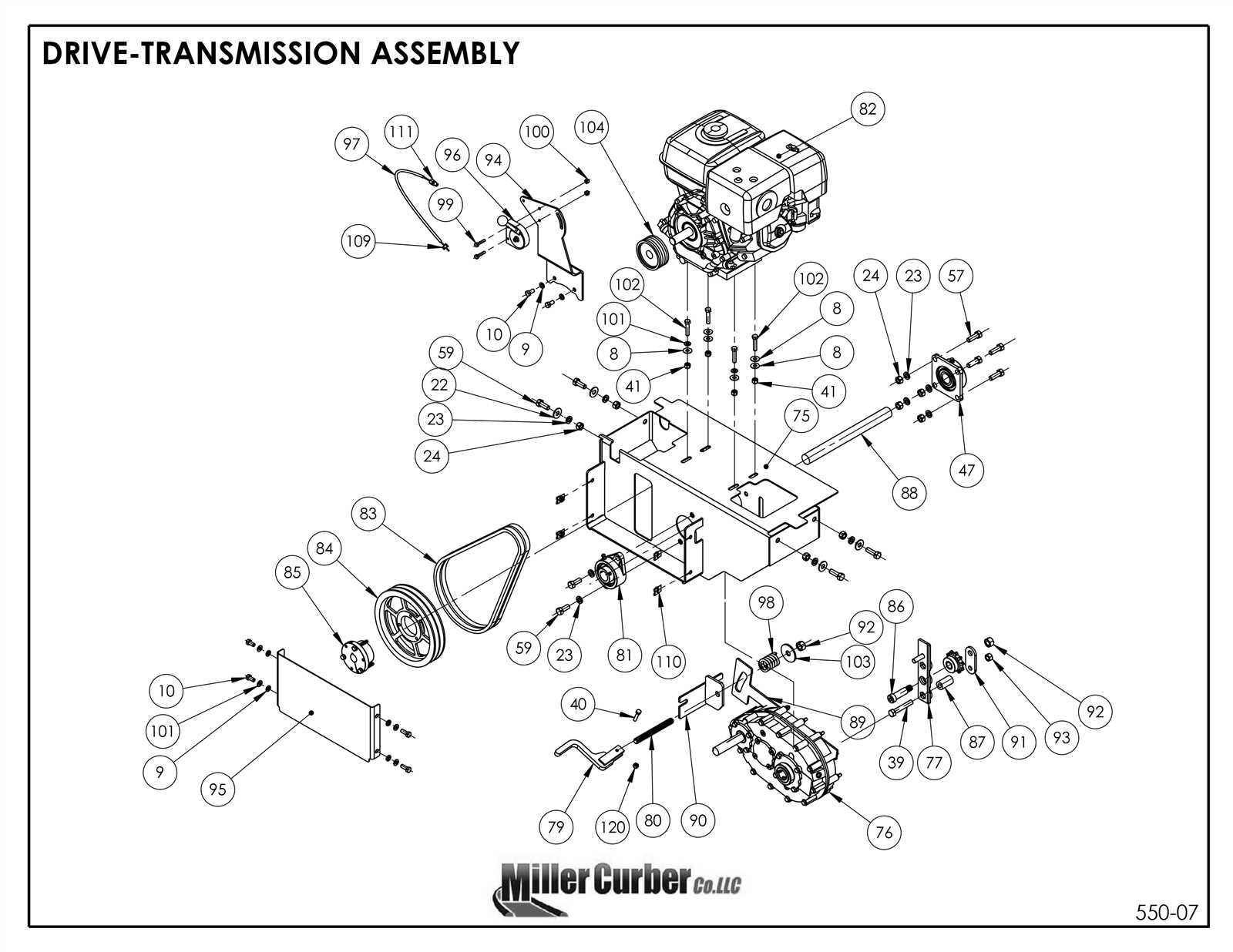

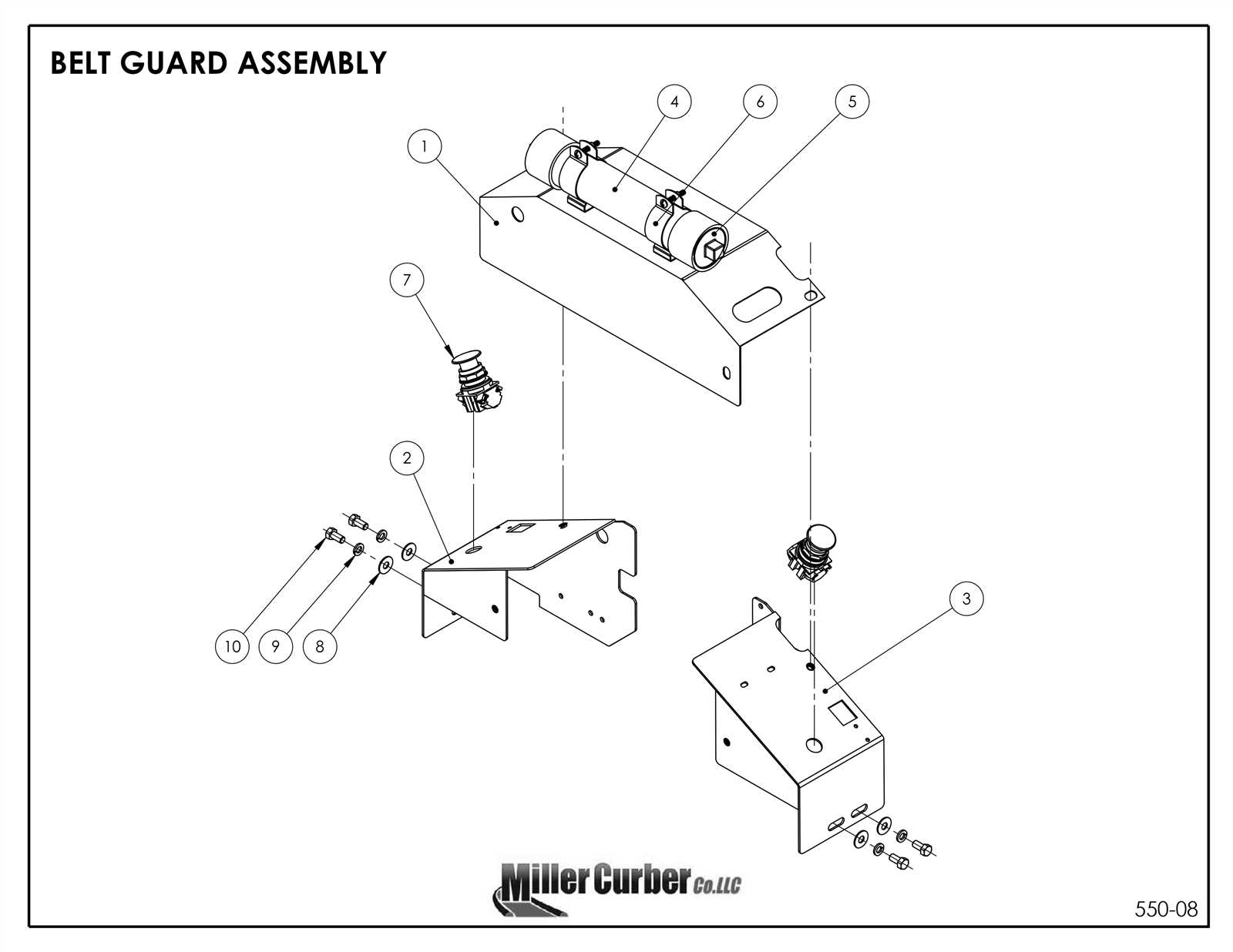

Identifying Key Features

Start by locating the main sections of the illustration. Typically, each part is labeled with a unique identifier, making it easier to reference specific items. Pay attention to the numbering system, as it often corresponds with a list that details the specifications and functions of each component. This correlation is vital for effective communication when ordering replacements or discussing repairs.

Understanding Connections and Layout

Next, observe how the components are interconnected. Arrows or lines usually indicate the flow of energy or movement between parts. Recognizing these pathways will help you troubleshoot issues or understand the assembly sequence. Additionally, the spatial arrangement of the elements often reflects their physical positioning within the machine, providing context that aids in practical application.

Common Issues with Miller 252 Parts

In the realm of welding equipment, certain challenges can arise that affect performance and reliability. Users often encounter various complications stemming from components, which can impact the overall functionality of their devices. Understanding these frequent problems can aid in effective troubleshooting and maintenance.

Electrical Faults

One of the most prevalent issues is related to electrical malfunctions. These can manifest as inconsistent power supply, leading to erratic behavior during operation. Worn connections and damaged cables often contribute to these faults, necessitating regular inspections to ensure everything remains in optimal condition.

Wear and Tear of Consumables

Another common concern involves the degradation of consumable items. Nozzles and electrodes can wear out over time, resulting in poor arc stability and decreased weld quality. Regular replacement of these components is essential to maintain high standards and achieve desirable results in welding projects.

Replacement Parts and Accessories

Ensuring the longevity and optimal performance of your equipment often hinges on having the right components and supplementary items. These essential elements not only facilitate seamless operation but also enhance overall efficiency. When it comes to maintenance and upgrades, a well-thought-out selection of replacements can make all the difference in achieving the desired results.

Identifying Compatible Components is crucial for anyone looking to maintain or enhance their machinery. Understanding specifications and compatibility ensures that the chosen items will fit seamlessly and function effectively. This knowledge can prevent unnecessary downtime and promote smooth operations.

Quality Accessories play a significant role in extending the lifespan of your equipment. Investing in reliable add-ons can improve functionality, provide additional features, and ultimately lead to a more satisfying user experience. Whether for safety enhancements or performance boosts, the right accessories can elevate your operations.

When seeking out replacements, consider trusted suppliers who offer a range of options to meet various needs. Researching and selecting high-quality products can prevent issues down the line and contribute to a more efficient working environment.

In summary, taking the time to explore available components and accessories is vital for maintaining equipment efficiency and performance. By prioritizing quality and compatibility, users can ensure their machinery remains in top condition for years to come.

Maintenance Tips for Longevity

Ensuring the extended lifespan of any equipment requires regular attention and care. By adopting a systematic approach to upkeep, you can significantly enhance performance and reduce the likelihood of costly repairs. This section outlines essential practices that contribute to durability and efficiency over time.

Firstly, always adhere to the manufacturer’s recommendations regarding service intervals and procedures. Regular inspections help identify potential issues before they escalate, allowing for timely interventions. Additionally, keeping the workspace clean and organized minimizes the risk of contamination and damage.

Utilizing quality lubricants and replacement components is crucial. Inferior materials can lead to premature wear and tear, affecting functionality. Furthermore, maintaining proper operating conditions, including temperature and humidity, can prevent unnecessary strain on the machinery.

Another vital aspect is training personnel in proper handling techniques. Ensuring that all operators are knowledgeable about correct usage can significantly decrease the chances of accidents and malfunctions. Encouraging a culture of care and responsibility will foster a more efficient environment.

Finally, documenting all maintenance activities creates a valuable history that can inform future decisions. By keeping detailed records, you can track performance trends and make data-driven adjustments to your maintenance strategy.

Where to Find Original Parts

Locating authentic components for your machinery can be a crucial task for ensuring optimal performance and longevity. The best approach involves a combination of official channels and reputable suppliers that specialize in such items. Quality assurance is vital, as using substandard alternatives can lead to complications and reduced efficiency.

Authorized distributors are often the most reliable source, as they provide genuine items directly from manufacturers. Additionally, exploring online marketplaces that focus on industrial supplies can yield favorable results, but it’s essential to verify the seller’s credibility. Networking with industry professionals can also uncover valuable recommendations for sourcing these essential elements.

Comparison with Other Models

In the realm of welding equipment, understanding the differences among various units is crucial for making informed choices. Each model offers unique features and capabilities that cater to specific needs. By examining these distinctions, users can better assess which device aligns with their requirements and preferences.

When juxtaposing the featured unit with its counterparts, several key factors emerge. Performance is often a primary consideration; some models excel in speed and efficiency, while others may prioritize precision and control. Durability also plays a significant role, as certain devices are designed to withstand harsher conditions, making them suitable for heavy-duty applications.

Additionally, user-friendliness can vary significantly between models. Some units incorporate advanced technology that simplifies operation, whereas others may rely on more traditional methods. This aspect can greatly influence a user’s overall experience and satisfaction.

Lastly, cost-effectiveness is an essential element in the comparison. While some machines may come with a higher price tag, their long-term value and maintenance requirements should be carefully evaluated against lower-priced alternatives. Understanding these variables helps users navigate their options more effectively.

Expert Recommendations for Users

When engaging with complex machinery, having a clear understanding of its components and functionality is essential for optimal performance and longevity. Users are encouraged to familiarize themselves with the various elements involved to ensure efficient operation and maintenance.

Understanding Your Equipment

Before diving into usage, it’s crucial to grasp the purpose of each element. Here are some tips:

- Review the manufacturer’s guidelines thoroughly.

- Identify critical components that require regular attention.

- Utilize reliable resources to clarify any uncertainties.

Maintenance Best Practices

Proper upkeep not only enhances performance but also extends the lifespan of your apparatus. Consider the following recommendations:

- Schedule routine inspections to catch potential issues early.

- Keep all moving parts lubricated as per the specifications.

- Replace worn or damaged elements promptly to prevent further complications.

By following these expert insights, users can maximize efficiency and ensure their equipment operates smoothly over time.

Resources for Further Information

For those seeking to enhance their understanding of equipment components, numerous resources are available that provide valuable insights and guidance. These materials can help users grasp the intricacies of their machinery and improve maintenance practices.

Online Forums: Engaging with communities on platforms dedicated to machinery can offer practical advice and troubleshooting tips from experienced users.

Manufacturer Manuals: Accessing official documentation from the creators of the equipment often reveals detailed explanations and illustrations that can clarify various elements.

Educational Websites: Numerous websites provide tutorials, articles, and videos that delve into specific aspects of machinery and its upkeep.

Workshops and Seminars: Participating in hands-on learning experiences can enhance knowledge and provide direct interaction with experts in the field.

Utilizing these resources can ultimately lead to a more comprehensive understanding and better performance of your equipment.