Ultimate Guide to Shindaiwa Parts Diagram

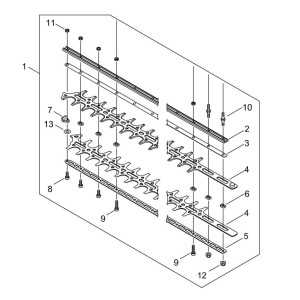

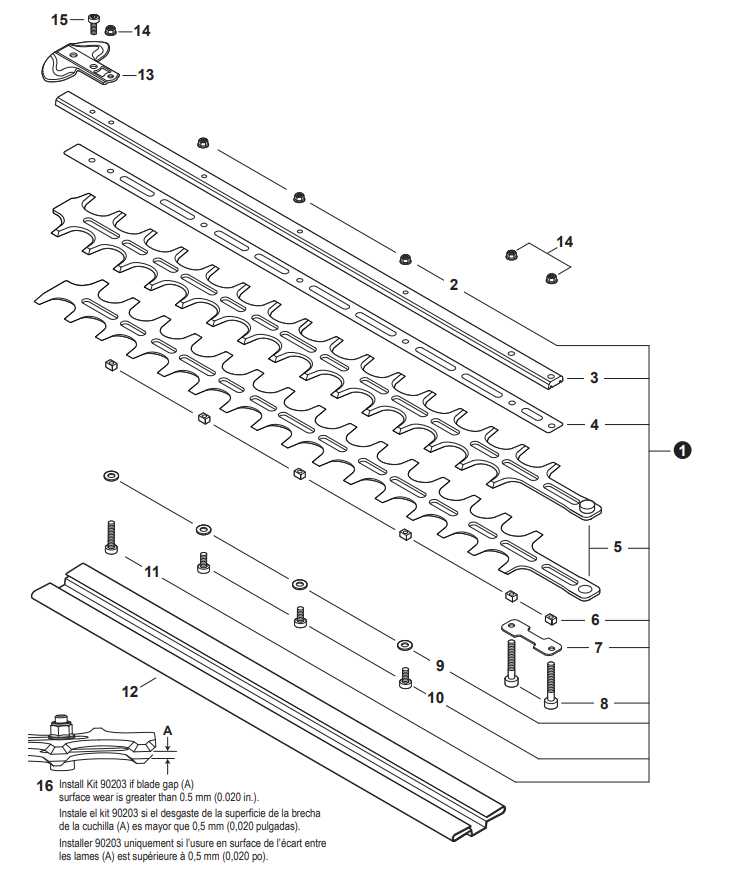

In the realm of outdoor power tools, the ability to navigate the intricacies of machinery can significantly enhance maintenance and repair processes. This section delves into the visual representations that illustrate the components and their interconnections within various models, serving as essential guides for both amateurs and professionals alike.

These visual aids not only clarify the arrangement of different elements but also facilitate troubleshooting and assembly tasks. With detailed illustrations, users can easily identify specific pieces and understand how they interact to ensure optimal performance.

Moreover, comprehending these layouts can lead to informed decisions when it comes to replacements or upgrades, ultimately extending the lifespan of the equipment. Whether you are a seasoned technician or a hobbyist, familiarity with these schematics is invaluable for efficient upkeep and operation.

Understanding Shindaiwa Equipment Components

Comprehending the various elements of outdoor machinery is crucial for effective operation and maintenance. Each component plays a vital role in the overall functionality and performance of the equipment, ensuring tasks are completed efficiently and reliably. By familiarizing oneself with these parts, users can optimize their equipment’s lifespan and performance.

| Component | Description |

|---|---|

| Engine | The heart of the machinery, responsible for providing the necessary power for operation. |

| Blade | The cutting element designed for various tasks, from trimming to heavy-duty cutting. |

| Fuel Tank | Holds the fuel required for the engine, impacting the duration of operation. |

| Handle | Provides grip and control, essential for maneuvering the equipment effectively. |

| Starter | Engages the engine, initiating the power needed to begin operation. |

Importance of Parts Diagrams

Understanding the intricacies of machinery relies heavily on visual aids that depict individual components and their relationships. These illustrations serve as essential tools for users and technicians alike, facilitating effective maintenance and repairs. By providing a clear overview, they help ensure that each element is properly identified and understood, ultimately enhancing operational efficiency.

Enhanced Clarity in Maintenance

Detailed visual representations allow users to quickly locate and assess specific items within a complex assembly. This clarity reduces the likelihood of errors during repair processes and contributes to faster turnaround times. Additionally, having a comprehensive guide helps in making informed decisions about necessary replacements or adjustments.

Facilitating Communication

Illustrative resources bridge the gap between various stakeholders, including technicians, manufacturers, and customers. When everyone is on the same page regarding component identification, it fosters a more efficient dialogue, enabling quicker problem-solving and minimizing misunderstandings. This shared knowledge ultimately leads to improved service quality and customer satisfaction.

How to Access Shindaiwa Diagrams

Accessing technical illustrations for your equipment is essential for effective maintenance and repair. These visual aids provide crucial information on components, assembly, and troubleshooting. Understanding how to locate and utilize these resources can greatly enhance your experience with machinery.

Online Resources

The internet offers a wealth of information at your fingertips. Here are some effective ways to find the illustrations you need:

- Official Manufacturer Website: Start by visiting the manufacturer’s official site. They often have dedicated sections for support and resources.

- Online Forums and Communities: Engage with user forums where enthusiasts share insights and documents. Members often upload manuals and guides.

- Third-Party Websites: Various websites specialize in equipment resources. Look for sites that provide downloadable content related to your machinery.

Printed Manuals and Guides

If you prefer physical copies, consider these options:

- Purchase from Retailers: Many retailers sell printed manuals that include detailed visuals and specifications.

- Check Local Libraries: Some libraries may have copies of manuals available for public use or borrowing.

- Request from the Manufacturer: If you own older models, contacting the manufacturer directly may yield copies of archived materials.

Utilizing these avenues will ensure you have the necessary information for optimal operation and maintenance of your equipment.

Common Components in Shindaiwa Models

Understanding the essential elements of various models can enhance maintenance and repair processes. Each device is constructed with specific components that work harmoniously to ensure optimal performance, durability, and efficiency.

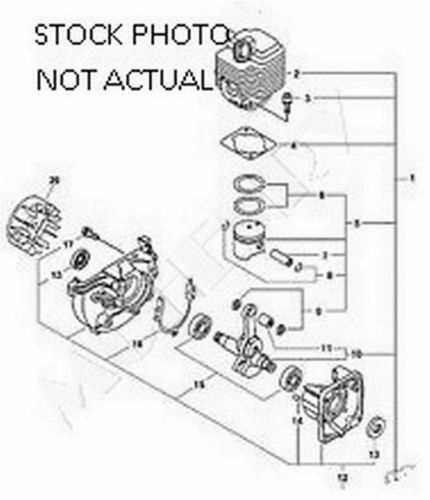

Engine Assembly

The heart of any machine, the engine assembly, includes critical parts such as the cylinder, piston, and crankshaft. These elements are vital for converting fuel into mechanical energy, making them indispensable for overall functionality.

Cutting Mechanisms

Devices often feature different cutting mechanisms, such as blades and trimmers. These tools are designed to provide precision and ease of use, allowing for effective operation in various environments. The design and material quality significantly impact their longevity and effectiveness.

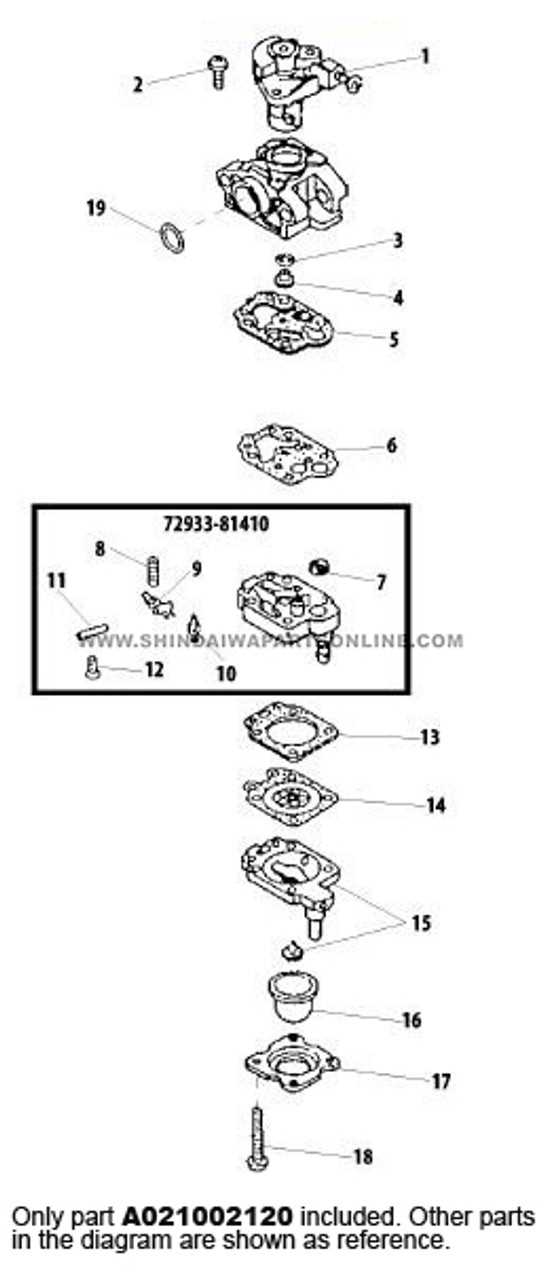

Identifying Parts Using Diagrams

Understanding the layout and configuration of various components is essential for efficient maintenance and repairs. Visual aids allow you to quickly locate the necessary elements and recognize how different pieces fit together. Whether you’re troubleshooting an issue or planning a replacement, this approach helps ensure accuracy and efficiency.

Why Visuals Are Essential

Illustrations provide a clear and concise way to grasp complex assemblies. They remove ambiguity by showing the exact placement and relationship between different components. This makes it easier to follow instructions, reducing the margin for error.

How to Use Visual Aids Effectively

To make the most of these tools, it’s important to focus on key areas of the illustration, such as labels and numbering. This allows for faster identification and understanding of the required components. Below is an example of how visual aids can be structured for clarity:

| Component | Description | Location Reference | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Housing | Main body that encases the motor | Top-left | |||||||||||||||||||||||||||||

| Fuel Line | Tube connecting the fuel tank to the engine | Center-right | |||||||||||||||||||||||||||||

| Ignition Switch | Control for starting and stopping the engine |

Benefits of Using Genuine PartsOpting for authentic components ensures that equipment performs at its best. These original items are designed specifically for the machinery, providing a perfect fit and optimal functionality. Relying on such elements can enhance the durability and reliability of the tool, reducing the chances of unexpected breakdowns. Below are the key advantages of choosing genuine replacements:

Maintenance Tips for Shindaiwa EquipmentRegular upkeep is essential to ensure the longevity and optimal performance of your outdoor tools. Following a few key practices can help you maintain efficient operation and reduce downtime caused by unexpected breakdowns. By staying proactive, you’ll keep your machinery running smoothly for years to come. Cleaning and InspectionConsistently cleaning your machinery after each use prevents the buildup of dirt, debris, and other harmful materials. Inspect the equipment thoroughly, paying close attention to any wear or damage on moving components. Regular checks allow you to catch issues early and prevent costly repairs. Lubrication and AdjustmentsKeeping all moving parts well-lubricated is crucial for smooth operation. Ensure that all joints, gears, and other mechanisms are properly greased. Additionally, make necessary adjustments to ensure that all components are working in harmony. Proper alignment and tension can significantly reduce strain and prolong the equipment’s life.

Repairing Common Equipment IssuesMaintaining outdoor power tools requires attention to detail, especially when dealing with frequent problems that can arise during operation. Addressing these concerns early on helps to avoid larger breakdowns and extends the lifespan of the machine. Below, we discuss solutions to some of the most frequent malfunctions experienced by users. Engine Starting ProblemsOne of the most common issues is difficulty starting the motor. This can be due to several factors, such as a clogged fuel line, dirty spark plug, or improper fuel mixture. To resolve this, always check the fuel system for blockages, clean or replace the spark plug, and ensure the fuel used is fresh and mixed correctly. Overheating During OperationOverheating is another frequent issue that can affect performance. This usually happens when air filters are clogged, or cooling systems are obstructed. Regularly inspect and clean the air filter to ensure proper airflow. Additionally, make sure the cooling fins are free from debris to prevent excessive heat buildup. Ordering Parts: A Step-by-Step GuideWhen it comes to maintaining your equipment, ensuring that every component is in working order is crucial. Whether you’re replacing a worn-out piece or upgrading to improve performance, understanding the process of acquiring new components can save time and effort. Follow this guide for a smooth and efficient experience. Step 1: Identify the Required ComponentStart by determining which specific element of your device needs replacement. Review your equipment’s manual or use a trusted source to match the correct item. Pay attention to model numbers or specifications to ensure compatibility. Step 2: Choose a Reliable SupplierOnce you’ve identified the necessary item, the next step is to find a dependable provider. Look for retailers that offer quality assurances, competitive pricing, and fast shipping options. It’s important to verify that the seller specializes in the type of components you need to avoid potential issues with fit or functionality. Pro Tip: Always compare multiple sources before making a purchase. Checking customer reviews and return policies can help ensure a positive buying experience. Understanding Model Numbers and SpecificationsWhen analyzing any equipment, understanding the model numbers and specifications is crucial for identifying the correct components and ensuring compatibility. Each model is assigned a unique identification number, which provides valuable information about the product’s series, version, and manufacturing details. By decoding these numbers, users can make informed decisions regarding maintenance, replacements, and upgrades. Specifications often include key features such as engine type, performance metrics, and dimensions. These details help in comparing different versions and choosing the right solution for specific tasks.

By familiarizing yourself with these elements, you can ensure that any replacements or enhancements are appropriate for the equipment, prolonging its operational life and optimizing performance. Resources for Shindaiwa UsersFor those who rely on equipment for various tasks, having access to valuable tools and support materials is essential. Finding the right information can help ensure that devices are maintained efficiently and operate at their best for extended periods. Proper care, alongside access to trusted resources, can make a significant difference in the longevity of your tools. Manuals are an excellent place to begin. They provide step-by-step instructions and cover the essential details needed for both routine care and more specific maintenance tasks. Additionally, there are online platforms that offer access to instructional guides, helping users become more familiar with their equipment’s functions. Video tutorials are also beneficial, offering a visual walkthrough of various tasks. These videos can simplify complex procedures and provide a clear understanding of what needs to be done. Lastly, user forums are invaluable for exchanging tips, troubleshooting issues, and sharing experiences. Engaging with a community of users provides a wealth of knowledge, allowing individuals to resolve common concerns and enhance their overall experience. Maximizing Equipment Lifespan Through Parts KnowledgeUnderstanding the various components that make up your machinery is essential for ensuring it operates efficiently for years to come. Proper care, regular inspection, and replacing worn elements can significantly extend the usability of any tool or machine. By familiarizing yourself with each element’s role, you not only prevent unnecessary wear but also ensure smooth performance in the long run. Regular Maintenance and InspectionRoutine maintenance plays a critical role in preserving the durability of equipment. A proactive approach can identify potential issues before they lead to significant breakdowns. Regular checks ensure all elements function as intended, reducing the chances of malfunction.

Optimal Usage of MachineryBeyond maintenance, proper usage habits contribute greatly to the longevity of equipment. Avoid overloading or using the tool in ways that exceed its intended purpose. Follow operational guidelines closely to ensure that each component is performing within its designed capacity.

|