Understanding the Components of Tank Car Parts Diagram

In the world of transportation, the efficient movement of liquids relies on a sophisticated system of elements working in harmony. Each individual component plays a vital role in ensuring the safety, reliability, and functionality of these essential conveyances. A comprehensive grasp of these elements is crucial for anyone involved in logistics, engineering, or maintenance within this industry.

Exploring the structure of these vessels reveals a complex interplay of mechanisms and materials, designed to withstand various environmental challenges. From the outer shell that provides protection to the intricate systems within, every segment is engineered with precision. Understanding these features enhances our appreciation of the technology behind liquid transport.

Moreover, delving into the various functionalities of each segment allows for improved operational practices and troubleshooting. Knowledge of how these components interact enables better management and optimization of performance, ensuring that the transportation of materials remains safe and efficient. By examining the intricacies of these systems, we can uncover best practices and innovations that drive the industry forward.

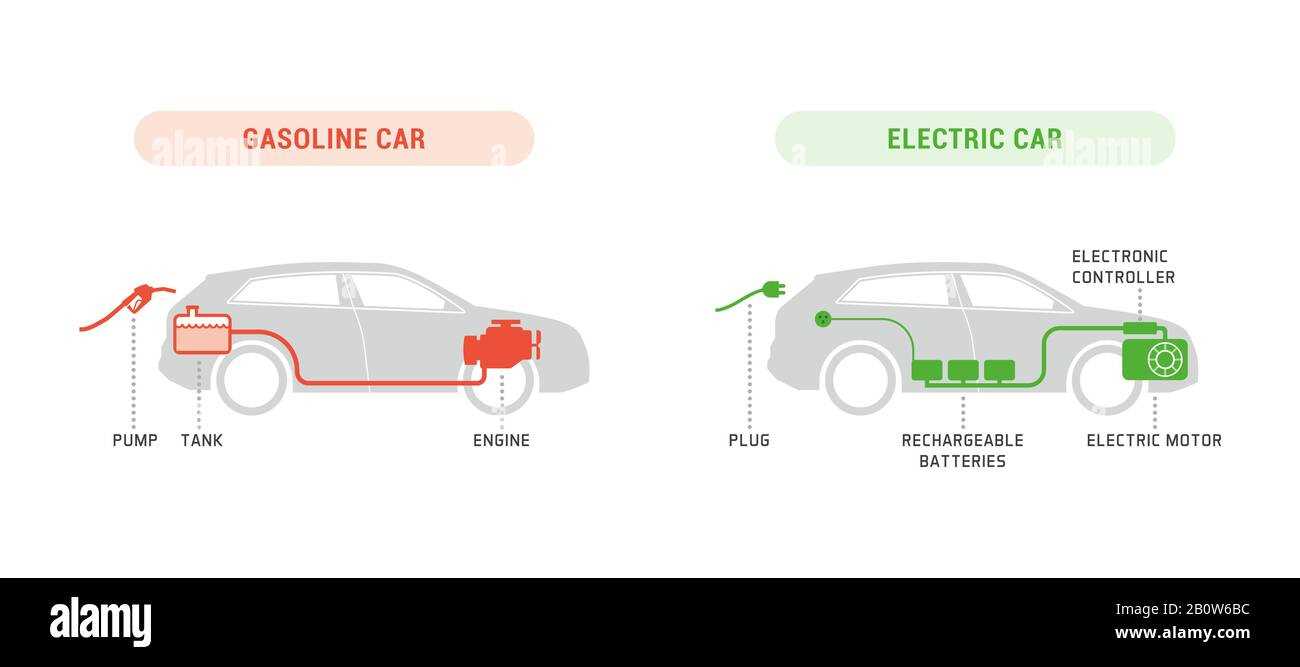

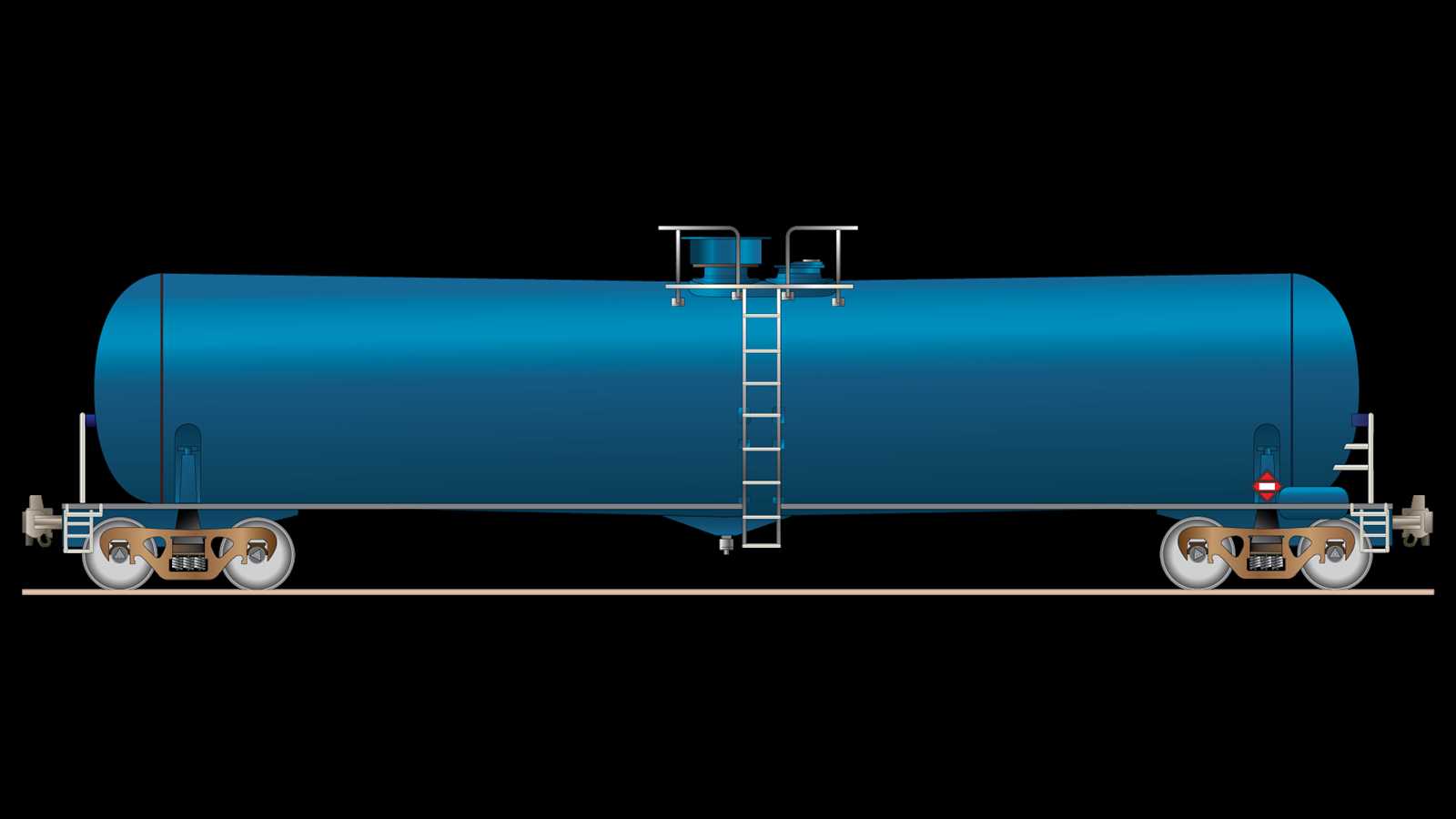

Tank Car Components Overview

This section explores the essential elements that contribute to the functionality and safety of specialized transport vehicles designed for liquid cargo. Understanding these components is crucial for ensuring optimal performance and compliance with industry standards.

Key Elements

Among the various features, the containment structure plays a vital role in holding the liquid securely. Additionally, the support framework and wheels are engineered to facilitate smooth movement across various terrains, enhancing operational efficiency.

Safety Mechanisms

Modern designs incorporate advanced safety mechanisms, such as pressure relief devices and leakage prevention systems. These innovations significantly reduce the risk of spills and ensure that hazardous materials are transported with the utmost care.

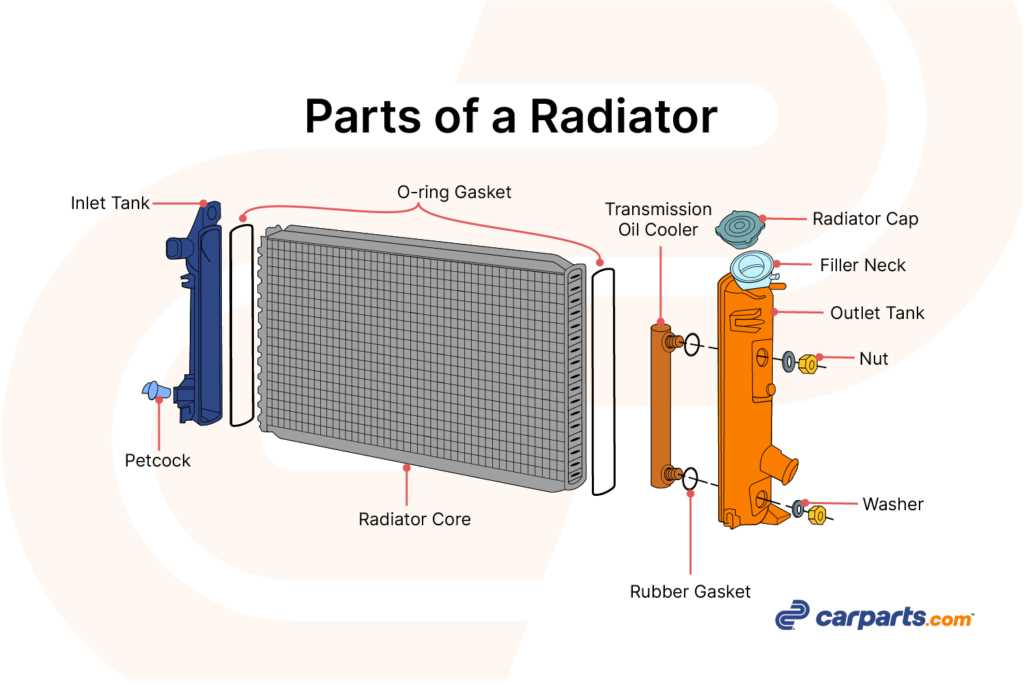

Understanding Tank Car Design

The design of specialized freight vehicles is essential for the safe and efficient transportation of liquids and gases. These vehicles are engineered with a variety of features that ensure stability, security, and compliance with safety regulations. A thorough understanding of their construction helps in appreciating the complexities involved in their operation and maintenance.

Structural Components

At the core of these vehicles is a robust structure that can withstand internal pressures and external forces. This includes a cylindrical body designed for optimal weight distribution, as well as reinforced frames that enhance durability. The integration of insulation and specialized coatings further protects the contents from environmental factors.

Safety Features

Modern designs prioritize safety through the inclusion of advanced features such as pressure relief valves, emergency shut-off systems, and reinforced couplings. These innovations are crucial in preventing leaks and ensuring that hazardous materials are transported without risk to the environment or public safety. Understanding these elements is vital for those involved in logistics and regulatory compliance.

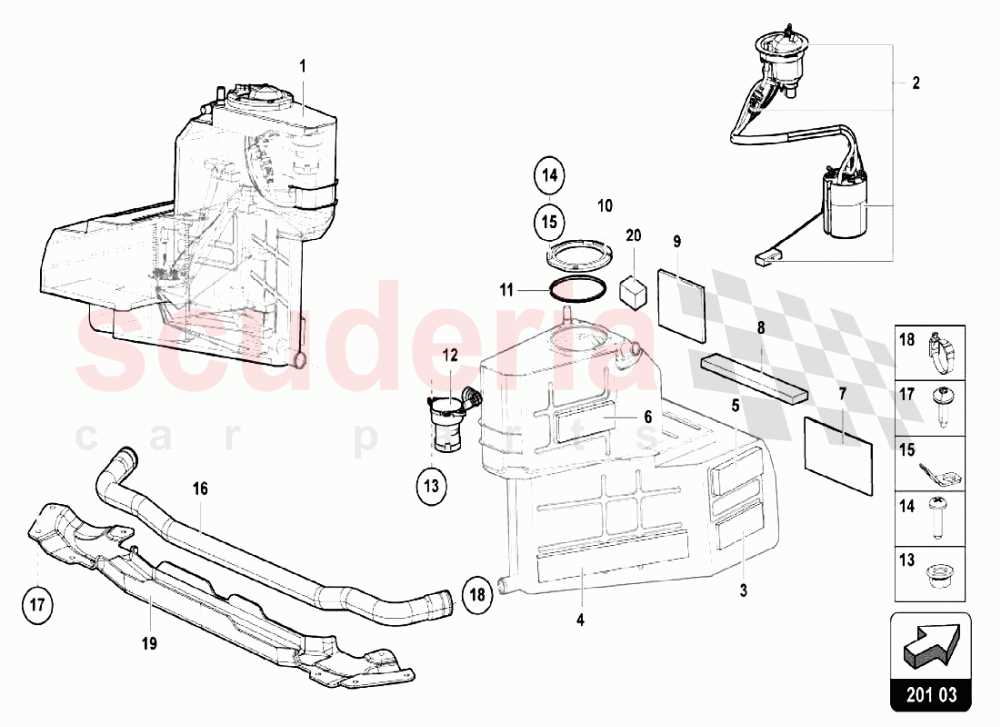

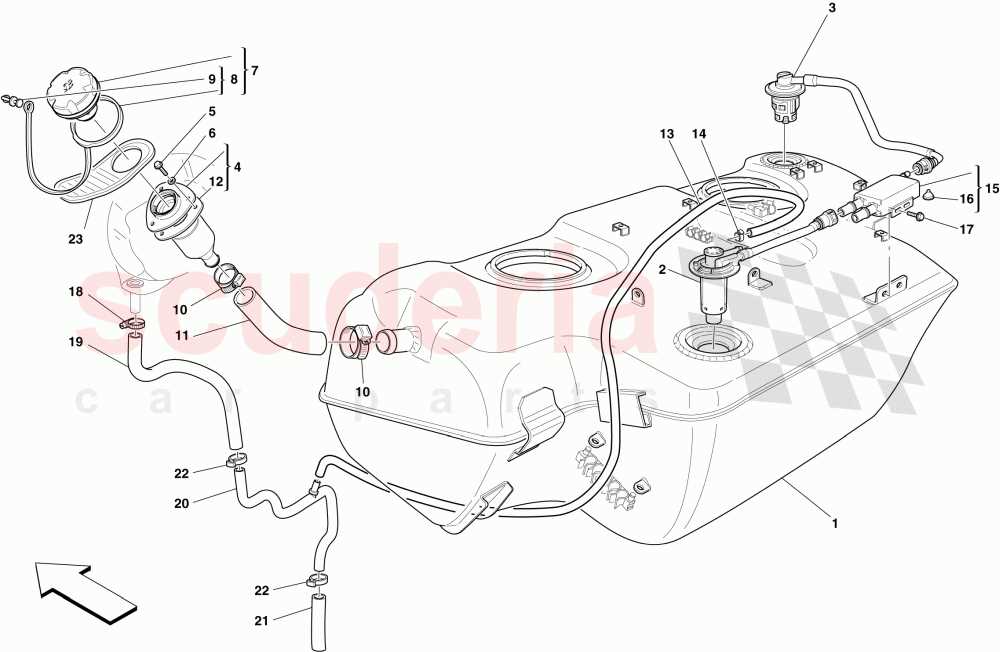

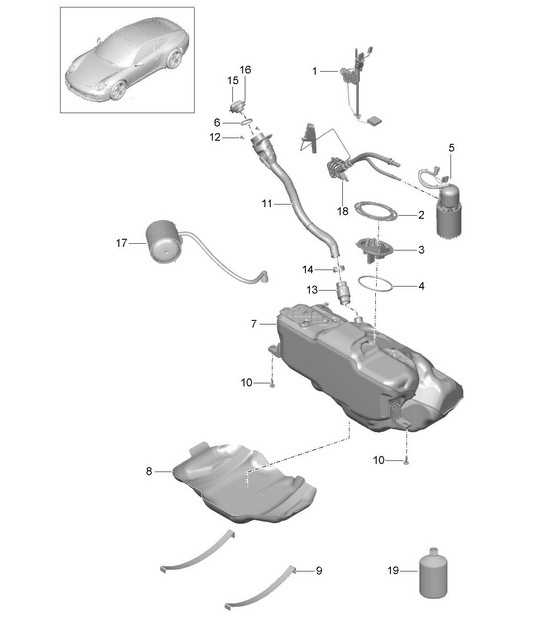

Key Parts of Tank Cars Explained

Understanding the essential components of specialized transport vehicles is crucial for ensuring safe and efficient operation. These elements work together to facilitate the movement of liquids, particularly hazardous materials, while adhering to strict safety standards. Below, we delve into the main features that define these vehicles, highlighting their functions and importance.

Essential Features

Among the various characteristics, several stand out due to their critical roles in maintaining structural integrity and operational efficiency. Each component serves a unique purpose, contributing to the overall effectiveness of liquid transportation.

| Component | Function |

|---|---|

| Cylinder | Holds the liquid cargo securely and is designed to withstand pressure. |

| Coupler | Connects to other vehicles for safe towing and stability during transit. |

| Manway | Provides access for loading, unloading, and maintenance procedures. |

| Insulation | Regulates temperature and protects the contents from extreme conditions. |

Safety Mechanisms

In addition to their primary functions, many of these elements incorporate safety features that mitigate risks associated with transporting volatile substances. These innovations ensure compliance with regulations and enhance overall security during transit.

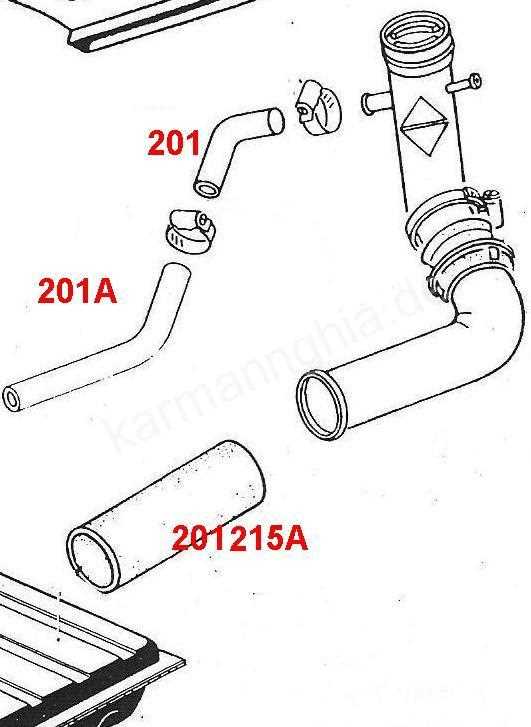

Functionality of Tank Car Systems

This section explores the essential mechanisms that contribute to the operation and efficiency of liquid transportation units. These systems are designed to ensure safe handling, storage, and movement of various substances, while maintaining integrity and compliance with industry standards.

Key Components and Their Roles

- Structural Framework: Provides the necessary support and shape to withstand pressure and environmental factors.

- Loading and Unloading Systems: Facilitate the transfer of liquids, ensuring minimal spillage and contamination.

- Safety Features: Include valves and pressure relief systems to prevent accidents and leaks during transit.

- Insulation Mechanisms: Help maintain the temperature of the transported materials, particularly for sensitive or volatile liquids.

Operational Efficiency

Efficient operation relies on the synergy of various systems. The following aspects contribute to overall effectiveness:

- Monitoring Systems: Continuous tracking of pressure, temperature, and liquid levels ensures optimal performance.

- Maintenance Protocols: Regular checks and servicing of components to prevent failures and enhance longevity.

- Compatibility Considerations: Ensuring that materials used in construction and operation are suitable for the substances being transported.

Common Materials Used in Tank Cars

The selection of materials for these specialized vessels is crucial for ensuring durability, safety, and efficiency in transporting various substances. Each material plays a significant role in the overall performance and reliability of the containers, especially when handling hazardous or sensitive contents.

Metals

Metals are often the primary choice for construction due to their strength and resistance to corrosion. Key types include:

- Carbon Steel: Widely used for its affordability and durability.

- Stainless Steel: Preferred for transporting corrosive materials due to its excellent resistance.

- Aluminum: Lightweight and resistant to rust, making it suitable for specific applications.

Composite Materials

Composite materials are increasingly popular for their lightweight properties and enhanced strength. Notable examples are:

- Reinforced Plastics: Used for non-corrosive cargo, providing flexibility and resilience.

- Fiber-Reinforced Composites: Offering superior strength-to-weight ratios, suitable for specialized transport needs.

The careful choice of these materials contributes to the efficiency and safety of transporting various goods across long distances.

Maintenance Tips for Tank Car Parts

Regular upkeep of essential components is crucial for ensuring the safe and efficient operation of transportation systems. Implementing a proactive maintenance routine can help prevent failures and extend the lifespan of various elements involved in the conveyance of liquids and gases.

Regular Inspections

Conducting frequent evaluations of all significant elements is vital. Look for signs of wear, corrosion, or leaks. Establish a schedule for inspections that aligns with operational demands, and ensure that qualified personnel carry out the assessments.

Proper Lubrication and Cleaning

Maintaining cleanliness is essential for optimal functioning. Regularly clean surfaces to remove any accumulated residues that could lead to inefficiencies. Additionally, apply appropriate lubricants to moving mechanisms to reduce friction and wear. Choose high-quality products that meet industry standards for best results.

Safety Features in Tank Car Design

Ensuring the secure transport of hazardous materials is paramount in the design of these specialized vehicles. Various mechanisms and structural elements are integrated to mitigate risks and enhance protection during transit. The focus is on minimizing potential leaks and maintaining integrity under various conditions.

Robust Construction: The outer shell is typically made from high-strength materials that can withstand significant impacts and pressures. This durability is crucial for preventing breaches that could lead to spills or leaks.

Leak Detection Systems: Advanced monitoring technologies are employed to detect any signs of leakage early. These systems provide real-time data, allowing for prompt intervention before a small issue escalates into a major incident.

Pressure Relief Devices: To manage internal pressure fluctuations caused by temperature changes, these vehicles are equipped with safety valves. These valves help prevent rupture by allowing excess pressure to escape safely.

Emergency Shutoff Valves: In the event of an accident, these valves can quickly halt the flow of contents, reducing the risk of hazardous material release. Their strategic placement ensures they are accessible and effective under emergency conditions.

Training and Protocols: Operators and personnel are provided with comprehensive training on safety protocols and emergency procedures. This human element is vital for ensuring that everyone involved understands their role in maintaining safety throughout the transport process.

Through these features, the design not only aims to protect the cargo but also prioritizes the safety of the environment and the communities through which these vehicles travel.

Loading and Unloading Mechanisms

This section explores the various systems designed for efficiently transferring liquids in bulk. Understanding these mechanisms is essential for optimizing operations in various industries, ensuring safety and effectiveness during the process.

| Mechanism Type | Description |

|---|---|

| Pneumatic Systems | Utilizes air pressure to facilitate the movement of substances, offering rapid loading and unloading capabilities. |

| Gravity Feed | Relies on gravitational pull to transfer liquids, ideal for consistent and controlled flow rates. |

| Positive Displacement Pumps | Employs pumps to move liquids by trapping a fixed volume and forcing it through the system, ensuring high efficiency. |

| Flow Meters | Incorporated for accurate measurement during the transfer process, enhancing control and compliance with regulations. |

Innovations in Tank Car Engineering

Recent advancements in the field of transport vehicles have significantly transformed the efficiency and safety of liquid transportation systems. Engineers are increasingly focused on enhancing durability, improving payload capacity, and integrating cutting-edge technology to ensure the highest standards of operation.

One major area of innovation is the development of lightweight materials. Utilizing composite materials reduces overall weight, enabling greater fuel efficiency and higher cargo loads. Additionally, advanced coatings are being applied to enhance corrosion resistance, thereby extending the lifespan of these vehicles.

Another crucial advancement involves the implementation of smart monitoring systems. These systems utilize sensors to track temperature, pressure, and structural integrity in real time, allowing for proactive maintenance and minimizing the risk of failures during transit.

| Innovation | Description | Benefits |

|---|---|---|

| Lightweight Materials | Use of composites to reduce weight | Improved fuel efficiency and increased capacity |

| Smart Monitoring | Real-time tracking of key parameters | Enhanced safety and reduced downtime |

| Enhanced Safety Features | Advanced braking and containment systems | Minimized risk of spills and accidents |

| Automated Loading/Unloading | Systems that streamline cargo handling | Increased efficiency and reduced labor costs |

Overall, these innovations are setting new standards in the industry, ensuring that the transportation of liquids is safer, more efficient, and environmentally friendly.

Regulatory Standards for Tank Cars

The safe transportation of hazardous materials requires adherence to a complex framework of regulations designed to ensure the integrity and reliability of transport vehicles. These standards encompass various aspects, from design and construction to maintenance and operation, aimed at minimizing risks associated with the movement of dangerous substances.

Government agencies play a crucial role in establishing these guidelines, ensuring compliance through rigorous inspections and certifications. Key regulations often dictate the materials used, structural integrity, and safety features that must be included to prevent leaks or ruptures during transit.

International standards also contribute to a unified approach, promoting consistency across borders. These agreements facilitate safer transport practices and encourage collaboration between nations in monitoring and enforcing compliance with safety protocols.

Ultimately, adherence to these regulations is vital not only for the protection of the environment and public safety but also for maintaining the overall efficiency and reliability of the transportation industry.

Future Trends in Tank Car Technology

The evolution of freight transportation is witnessing significant innovations aimed at enhancing safety, efficiency, and environmental sustainability. As industries seek to optimize their logistics, the advancements in vehicle design and technology play a crucial role in shaping the future of this sector.

Innovative Materials and Construction

One of the key trends involves the use of advanced materials that promise greater durability and lighter weight. This transition can lead to increased payload capacity and reduced fuel consumption.

- Composite materials that resist corrosion and damage.

- Lightweight alloys that enhance overall efficiency.

- Smart materials that respond to environmental changes.

Automation and Monitoring Systems

Integrating automation and smart monitoring systems is set to revolutionize operations. These technologies aim to provide real-time data, enhancing safety and reliability.

- Automated braking systems to reduce accidents.

- Real-time monitoring for detecting leaks or malfunctions.

- Predictive maintenance using AI to minimize downtime.

As the industry embraces these advancements, the future looks promising with enhanced performance and reduced environmental impact. The ongoing commitment to innovation will drive progress and ensure safer transportation solutions for various commodities.