Understanding Vermeer Trencher Parts Diagram for Better Maintenance

The intricate world of excavation equipment involves various mechanisms that work in harmony to achieve efficiency and precision. Knowing the layout and function of these elements is crucial for both operation and maintenance. Each component plays a vital role in the overall performance of the machine.

In this section, we will explore the essential structures that contribute to the functionality of these powerful tools. By breaking down the assembly into its core segments, we aim to provide a comprehensive overview that enhances user knowledge and promotes effective upkeep.

Whether you are a seasoned operator or a novice, understanding the relationship between these integral parts will ultimately empower you to troubleshoot issues more effectively. A clear grasp of how these elements interact can significantly enhance the longevity and performance of your equipment.

Understanding Vermeer Trenchers

This section delves into the intricacies of specialized digging machinery, designed for efficient underground operations. Such equipment plays a vital role in various construction and utility projects, enabling the seamless installation of pipelines, cables, and other essential infrastructure.

Mechanics and Functionality: These machines operate using advanced technology that ensures precision and effectiveness. With a variety of models available, they cater to different soil conditions and project requirements. Key features include powerful engines, durable cutting components, and intuitive controls, which collectively enhance productivity.

Applications and Versatility: The versatility of this machinery allows it to be utilized in numerous settings, from urban environments to rural landscapes. They are particularly advantageous in tight spaces where traditional excavation methods may be impractical. Understanding their capabilities aids operators in selecting the right model for specific tasks.

Maintenance and Care: Regular upkeep is essential for optimal performance. Familiarizing oneself with the essential components and their functions can lead to more efficient maintenance practices. Ensuring that the equipment remains in top condition not only extends its lifespan but also enhances safety on the job site.

Key Components of Trenchers

The efficiency of excavation machinery relies heavily on its essential elements, each playing a crucial role in overall performance. Understanding these components is vital for optimal operation and maintenance.

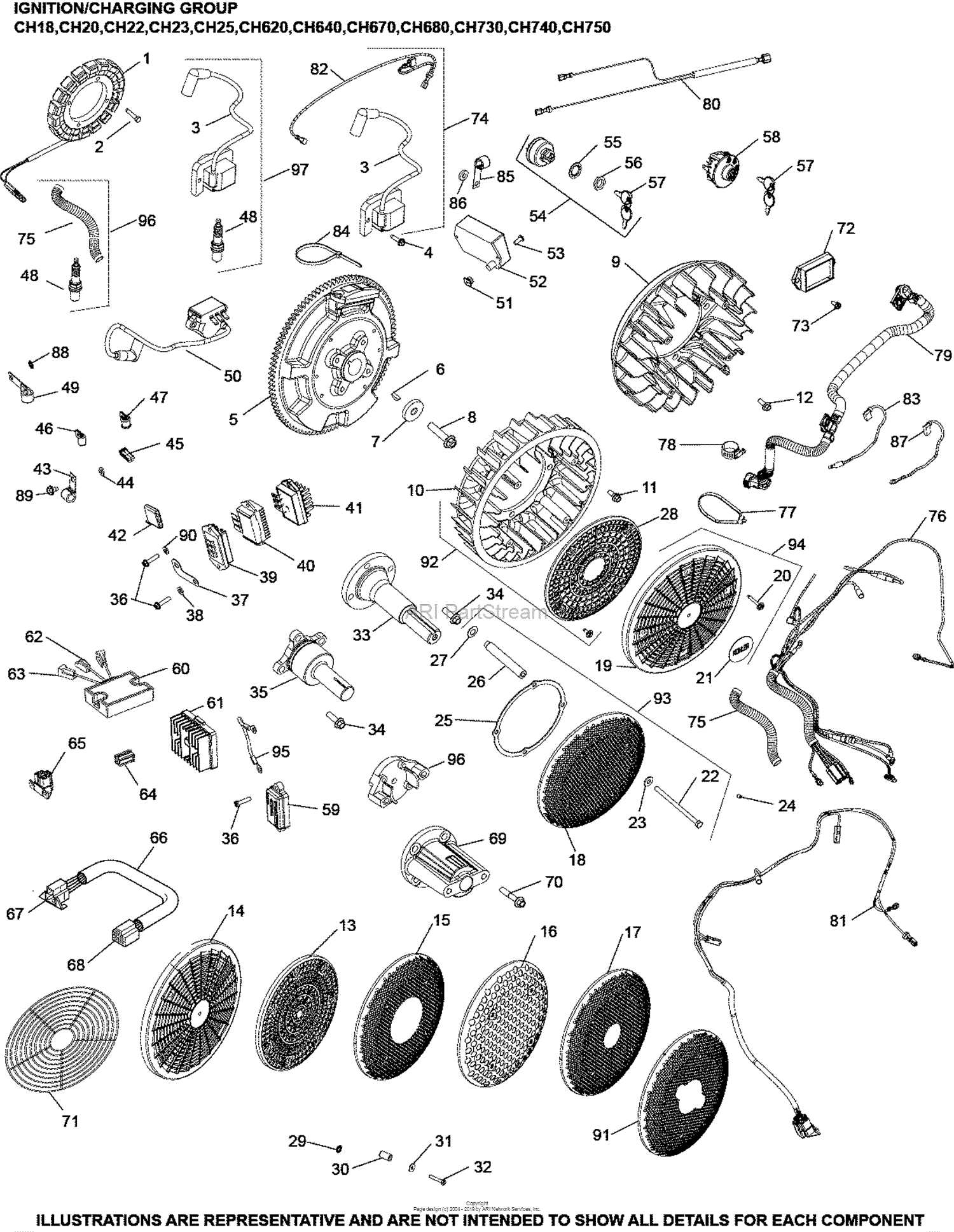

Power Systems

Engines serve as the heart of the machinery, providing the necessary power to perform heavy-duty tasks. These engines can vary in type and output, influencing the machine’s capability and efficiency.

Cutting Mechanisms

The cutter head is integral to the excavation process, designed to break and remove material with precision. Its design and sharpness significantly impact the effectiveness of the operation, making it essential to maintain.

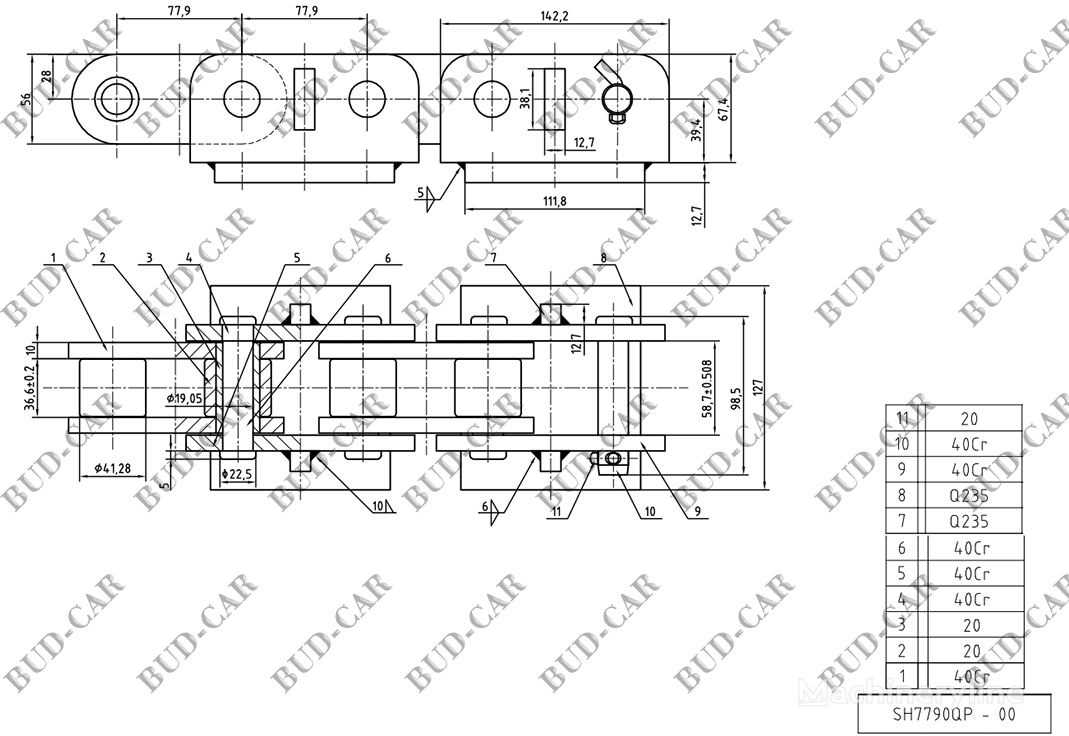

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding of complex systems. Accurate illustrations serve as vital tools for technicians and engineers, enabling them to navigate intricate assemblies with ease. This clarity can significantly reduce errors and enhance productivity in maintenance and repair tasks.

Benefits of Clear Visual Representations

- Facilitates quick identification of components

- Enhances understanding of operational mechanisms

- Reduces time spent on troubleshooting

- Improves safety during assembly and maintenance

Consequences of Inaccuracy

- Increased risk of misassembly

- Higher likelihood of equipment failure

- Extended downtime and associated costs

- Frustration among operators and technicians

Common Issues with Trencher Parts

When operating machinery designed for excavation, various challenges can arise that impact performance and efficiency. Understanding these common difficulties is essential for maintaining optimal functionality and ensuring longevity.

Wear and Tear: Over time, components may experience significant degradation due to constant use. Regular inspection and timely replacement are crucial to prevent operational failures.

Hydraulic Failures: Hydraulic systems can encounter issues such as leaks or pressure drops, which may hinder the effectiveness of the equipment. Addressing these problems swiftly is vital to avoid extensive downtime.

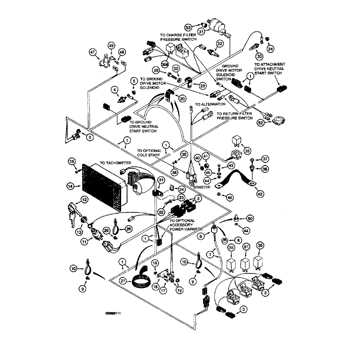

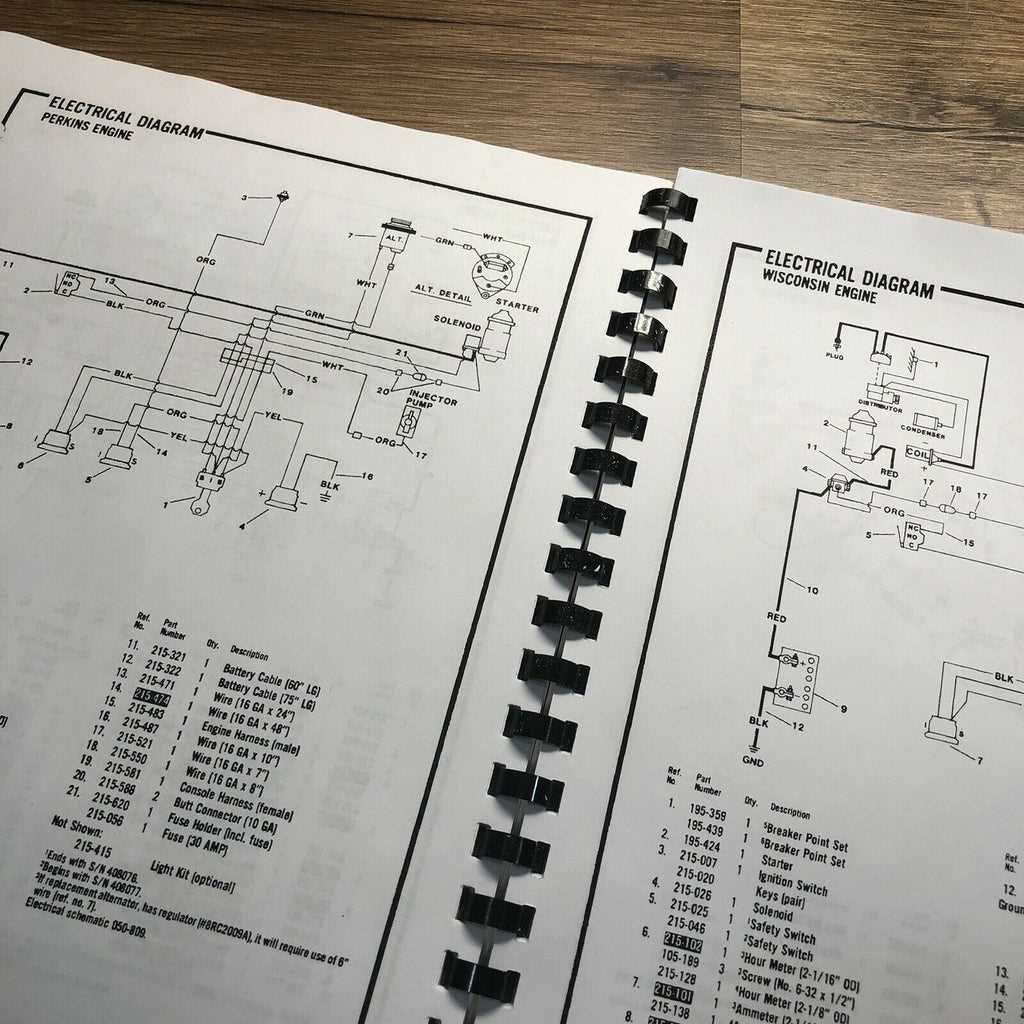

Electrical Malfunctions: Electrical components can fail due to various reasons, including corrosion or short circuits. Maintaining proper connections and monitoring electrical systems is necessary for reliable operation.

Misalignment: Components that are not correctly aligned can cause excessive strain and lead to premature breakdown. Regular adjustments and calibrations help in maintaining proper alignment and efficiency.

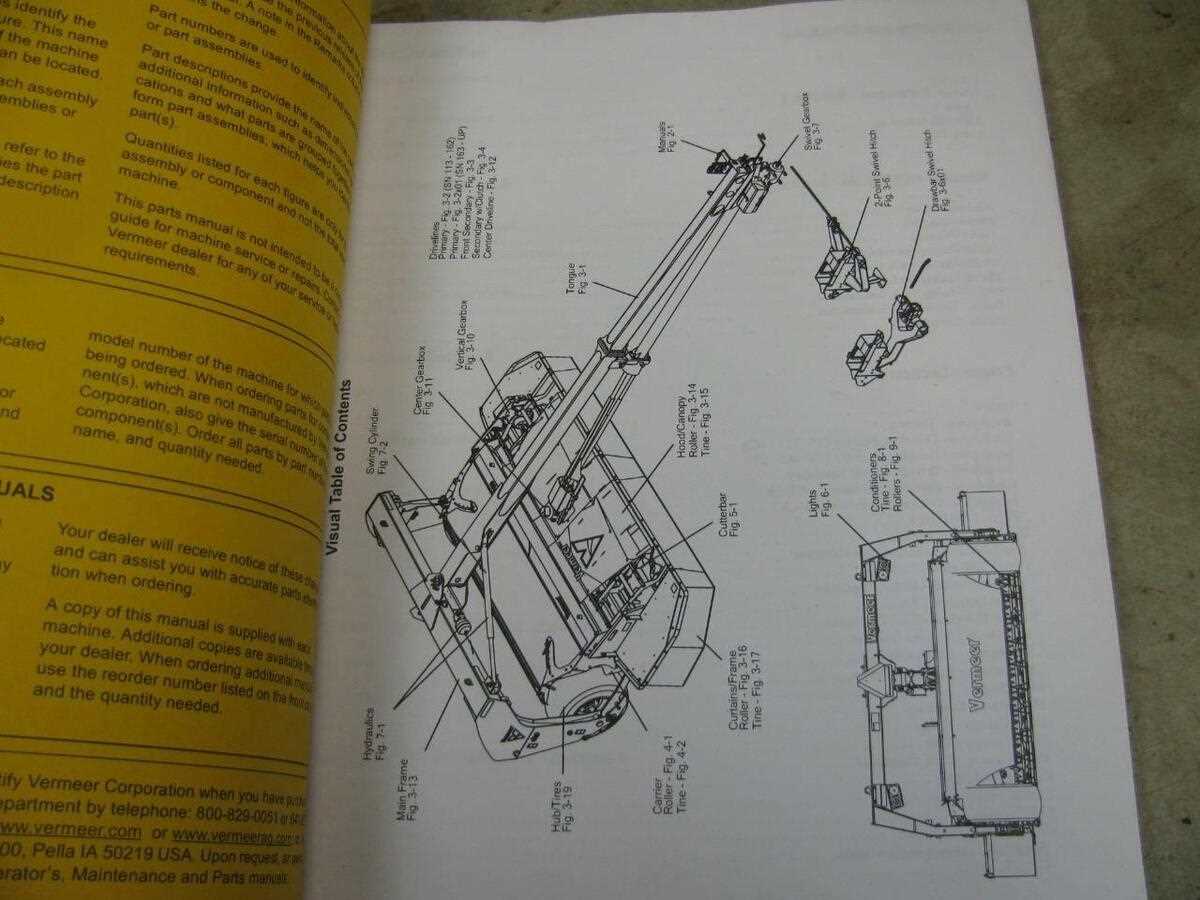

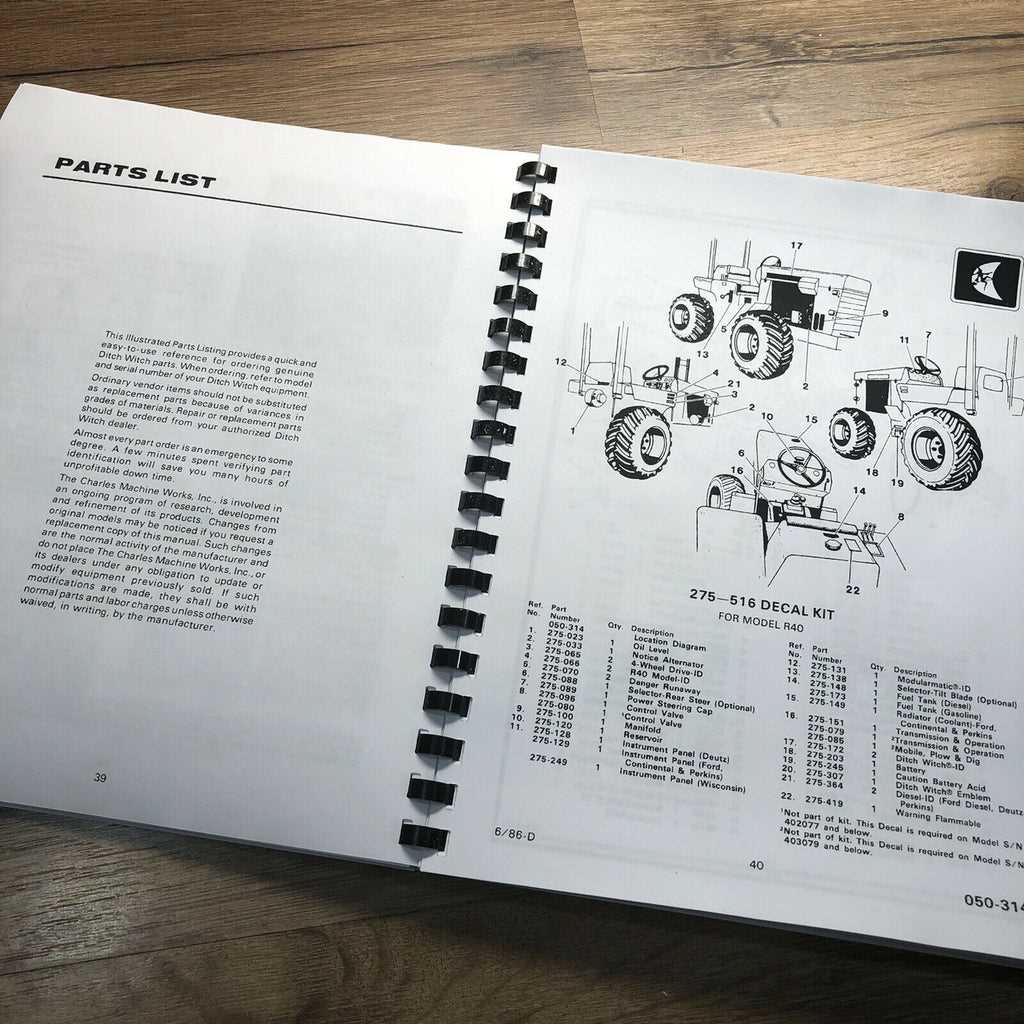

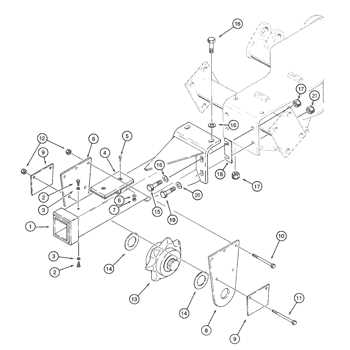

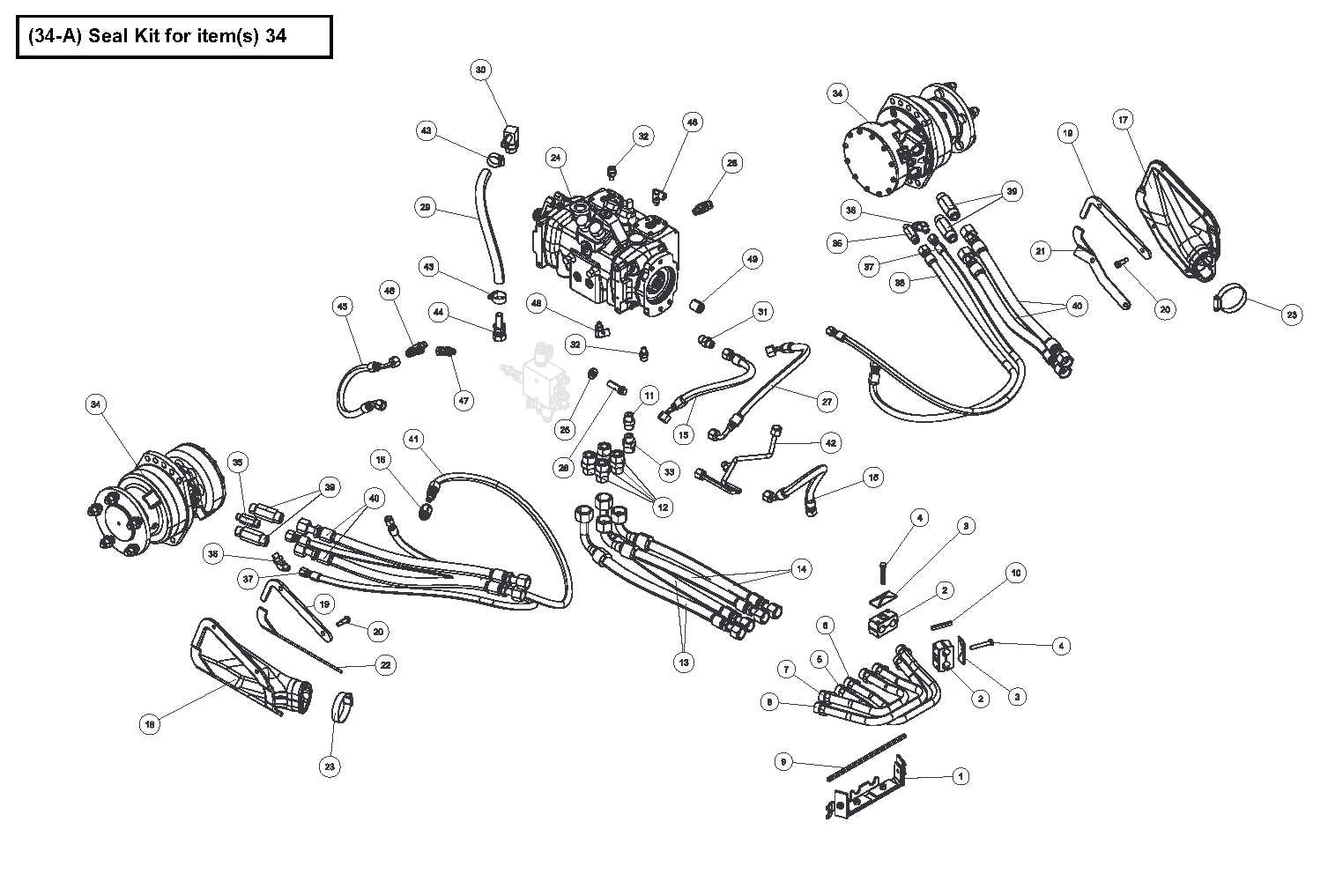

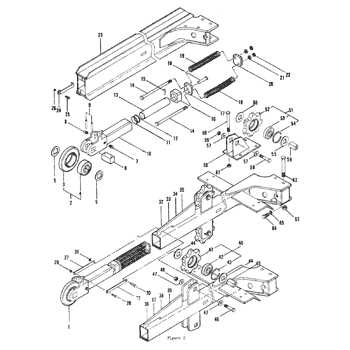

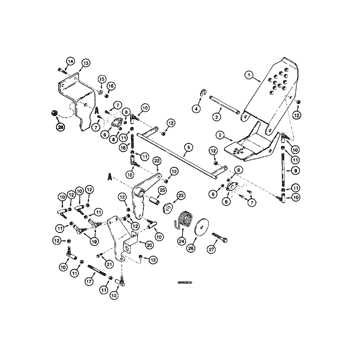

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visuals serve as a roadmap, guiding users through complex assemblies and components. Familiarity with these representations enhances comprehension and ensures proper identification of each element involved.

To interpret these illustrations effectively, consider the following aspects:

| Element | Description |

|---|---|

| Labels | Each part typically features a label indicating its name or number, facilitating easy identification. |

| Numbering | Sequential numbers often correspond to a list or catalog, providing a quick reference for ordering replacements. |

| Connections | Lines or arrows illustrate how components interconnect, offering insights into assembly and disassembly procedures. |

| Views | Different perspectives may be included to showcase components from various angles, enhancing overall understanding. |

By focusing on these elements, individuals can efficiently navigate and utilize technical illustrations, leading to successful repairs and maintenance tasks.

Replacement Parts Overview

Understanding the various components of heavy machinery is essential for maintaining optimal performance. This section provides an insight into the essential items that may require substitution over time, ensuring that your equipment operates smoothly and efficiently.

Common Components Needing Replacement

Over time, certain elements of machinery can wear out due to prolonged use. Among the most frequently replaced items are the cutting tools, drive systems, and hydraulic elements. Regular checks and timely replacements can prevent breakdowns and enhance productivity.

Importance of Quality Components

When it comes to substitutions, the quality of the items is paramount. Utilizing high-grade replacements can significantly impact the longevity and performance of your machinery. Investing in superior components not only ensures reliability but also enhances the overall efficiency of operations.

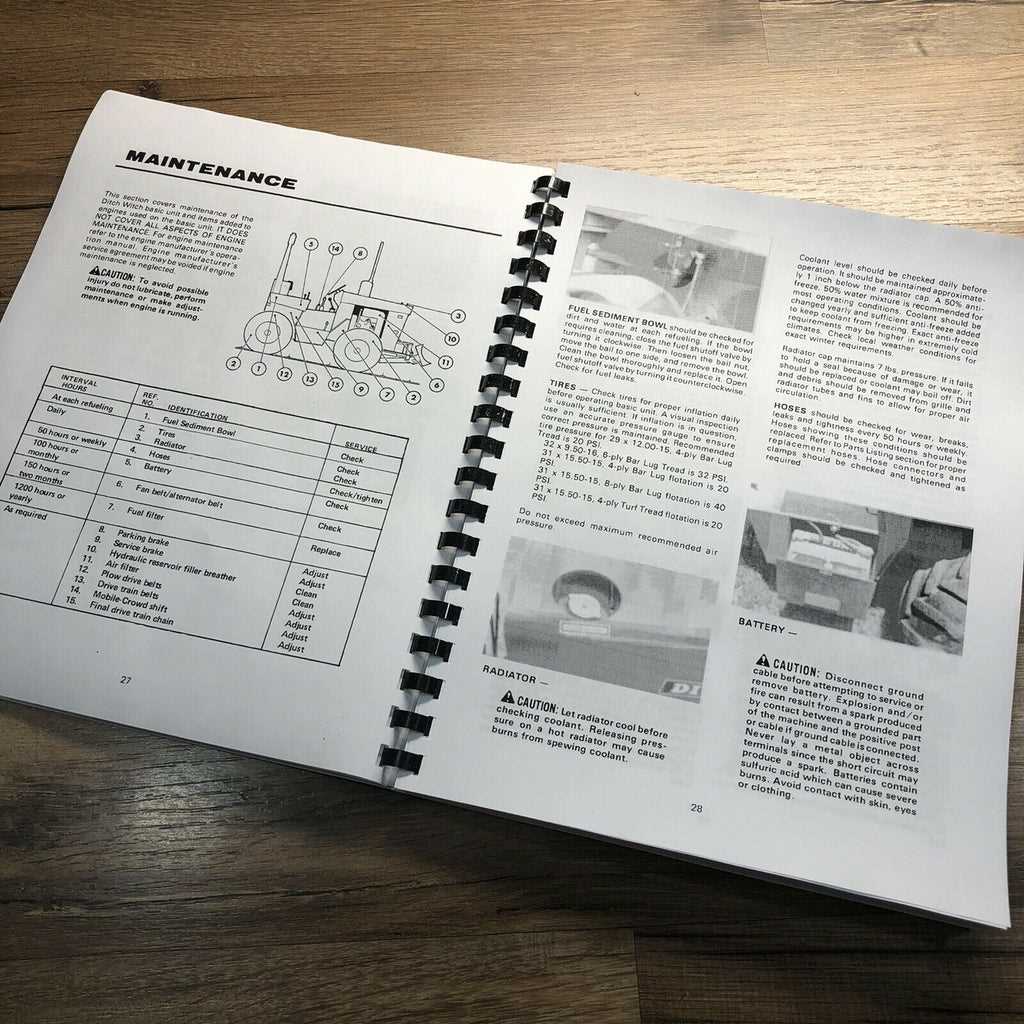

Maintenance Tips for Trenchers

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular maintenance not only enhances efficiency but also prevents costly breakdowns and repairs. By following a systematic approach to care, operators can significantly extend the lifespan of their machinery.

1. Regular Inspection: Conduct frequent checks of all components to identify wear and tear early. Focus on critical areas such as blades, chains, and hydraulic systems. Look for signs of damage or abnormal wear that could affect performance.

2. Lubrication: Keep moving parts well-lubricated to reduce friction and prevent premature wear. Use the manufacturer-recommended lubricant and ensure that all grease points are adequately serviced.

3. Cleanliness: Maintain a clean working environment by regularly removing debris and dirt from the machine. A clean unit operates more efficiently and is less prone to corrosion and other damage.

4. Fluid Levels: Check and maintain appropriate fluid levels, including oil, coolant, and hydraulic fluid. Regularly change fluids as recommended to ensure optimal performance and protection of internal components.

5. Blade Maintenance: Sharpen and replace blades as necessary to ensure effective cutting. Dull blades can lead to increased strain on the machine and reduced efficiency.

6. Tire and Track Care: Inspect tires or tracks for proper inflation and wear. Maintaining the correct pressure and addressing any damage promptly can enhance traction and stability during operation.

7. Storage: When not in use, store the equipment in a sheltered area to protect it from the elements. Covering the machine can prevent rust and deterioration caused by exposure to moisture.

By adhering to these maintenance guidelines, operators can ensure their equipment remains in peak condition, enhancing productivity and minimizing unexpected downtime.

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right tools at your disposal is crucial for effective and efficient work. A well-equipped toolkit can significantly simplify the process, ensuring that repairs are carried out smoothly and without unnecessary delays. Understanding which instruments are essential for specific tasks can save both time and effort.

Essential Hand Tools

Basic hand tools are the backbone of any repair job. Wrenches, screwdrivers, pliers, and hammers are fundamental for tackling various issues. A good set of sockets and ratchets will allow you to reach tight spaces and loosen stubborn fasteners. Additionally, a torque wrench is vital for ensuring that bolts are tightened to the manufacturer’s specifications, preventing future mechanical failures.

Specialized Equipment

In addition to standard hand tools, specialized equipment may be required for more complex repairs. Diagnostic tools, such as multimeters and pressure gauges, help identify underlying problems that may not be immediately visible. Furthermore, having access to lifting equipment, like jacks or hoists, facilitates the safe handling of heavy components, making it easier to conduct thorough inspections and repairs.

Safety Considerations During Repairs

Ensuring a secure environment during maintenance activities is crucial for preventing accidents and injuries. Adhering to established safety protocols not only protects the technician but also prolongs the lifespan of the machinery being serviced. A thorough understanding of potential hazards and the implementation of safety measures can significantly mitigate risks.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves, goggles, and helmets to shield against debris and chemical exposure. Always ensure that the equipment fits properly and is in good condition to maximize safety.

Tool Safety and Equipment Handling

When using tools, it’s important to follow manufacturer guidelines and handle equipment with care. Ensure that tools are maintained and stored correctly to prevent malfunctions. Additionally, never bypass safety features or operate machinery without proper training.

Where to Find Parts Diagrams

Locating detailed illustrations of equipment components can greatly enhance maintenance and repair processes. These resources provide invaluable visual guides that clarify the structure and arrangement of individual elements. Whether you’re troubleshooting or performing routine upkeep, having access to accurate schematics is essential.

One of the most reliable sources for these visuals is the manufacturer’s official website, where you can often find downloadable resources specific to your model. Additionally, specialized forums and community groups dedicated to machinery can be treasure troves of shared knowledge, offering both diagrams and practical advice from experienced users. Local dealers and repair shops may also have printed materials available for reference.

Online retailers frequently provide resources alongside their product listings, ensuring you have the information needed for precise ordering. Lastly, consider consulting service manuals, which typically include comprehensive illustrations as part of their maintenance guidance.

Benefits of Using Original Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These genuine elements are specifically designed to meet the exact specifications of the equipment, providing reliability and efficiency that aftermarket alternatives often lack.

Enhanced Reliability

Original components are manufactured under stringent quality controls, ensuring that each piece functions as intended. This reliability translates to reduced downtime and maintenance costs, ultimately enhancing productivity.

Cost-Effectiveness in the Long Run

While the initial investment may be higher, genuine parts often lead to lower repair expenses over time. Their durability minimizes the risk of breakdowns, allowing operators to focus on their tasks without interruptions.