Comprehensive Guide to Hayward Northstar Pump Parts Diagram

In the realm of swimming pool maintenance, having a comprehensive grasp of the various elements involved in circulation systems is essential for optimal performance and longevity. This knowledge enables pool owners and technicians alike to effectively troubleshoot issues and ensure smooth operation. A detailed exploration of these components reveals their intricate connections and functionalities, highlighting the importance of each piece in the overall system.

Familiarity with the structural layout and individual roles within the assembly can greatly enhance one’s ability to maintain and repair the system. By recognizing how each unit interacts, users can more easily identify wear and tear, as well as anticipate potential failures. Understanding the specifics not only empowers individuals to make informed decisions but also enhances their overall confidence in managing pool operations.

Furthermore, being aware of replacement options and the latest innovations in the market allows for improved efficiency and performance. This knowledge is invaluable, especially in a field where technology is continually evolving. Thus, an in-depth examination of these components is crucial for anyone looking to ensure the reliability and effectiveness of their aquatic setup.

Understanding Hayward Northstar Pumps

This section explores the fundamental aspects of a widely used water circulation system in pools and spas. These systems are essential for maintaining clean and clear water, ensuring optimal performance, and prolonging the life of the entire setup. A comprehensive understanding of their components and functionality will empower users to make informed decisions regarding maintenance and repairs.

The effectiveness of these circulation systems is largely dependent on the various elements that work together to achieve efficient water flow and filtration. Familiarity with these components allows for better troubleshooting and optimization of performance.

| Component | Description |

|---|---|

| Motor | Drives the impeller, creating the necessary flow of water. |

| Impeller | Moves water through the system, crucial for circulation. |

| Strainer Basket | Collects debris, preventing clogging and ensuring smooth operation. |

| Seal | Prevents leaks, maintaining system efficiency and safety. |

| Diffuser | Helps to evenly distribute water flow, enhancing performance. |

Understanding these essential components will greatly aid in the proper maintenance and operation of the system, ultimately contributing to a more enjoyable experience for users.

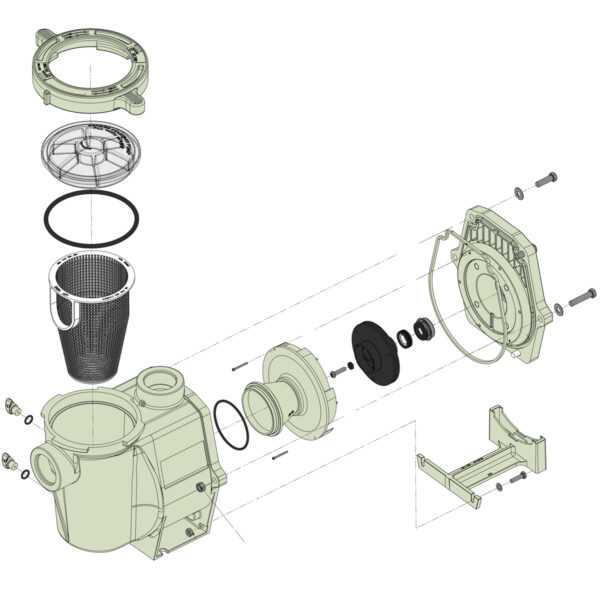

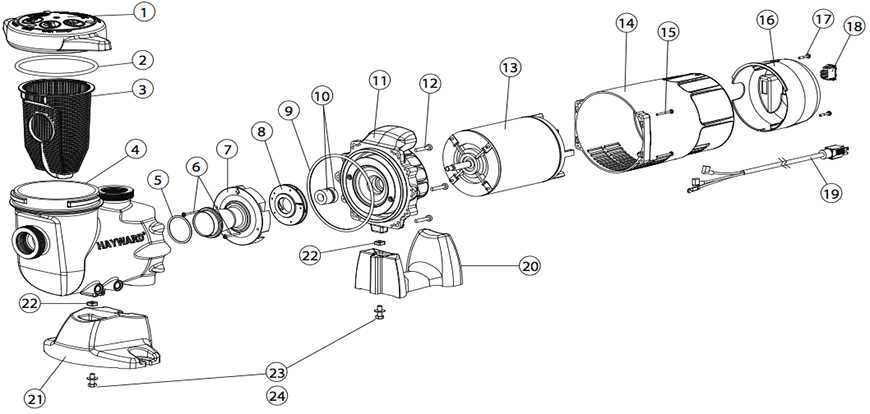

Key Components of Northstar Pumps

The effective operation of any fluid circulation system relies on a few essential elements that work in harmony. Understanding these crucial components can significantly enhance maintenance and troubleshooting efforts, ensuring optimal performance and longevity.

Main Elements

- Motor: The driving force behind the entire mechanism, responsible for generating the required energy to facilitate fluid movement.

- Impeller: A rotating component that increases the velocity of the fluid, playing a vital role in creating flow.

- Volute: A stationary structure that helps convert the kinetic energy of the fluid into pressure energy, directing it toward the outlet.

- Strainer: This component filters out debris and particles, protecting the internal mechanisms from damage and clogging.

Additional Features

- Seal: Prevents leaks by maintaining pressure and ensuring that the fluid remains contained within the system.

- Base: Provides stability and support, anchoring the unit to the ground or mounting surface.

- Control Panel: Facilitates user interaction, allowing for adjustments and monitoring of system performance.

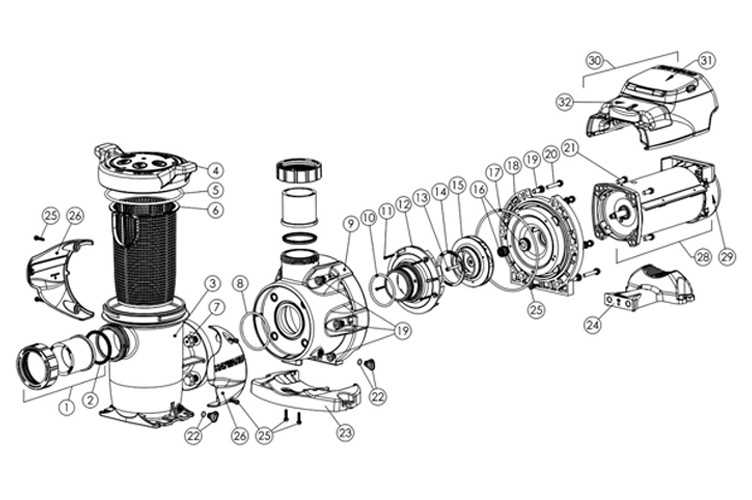

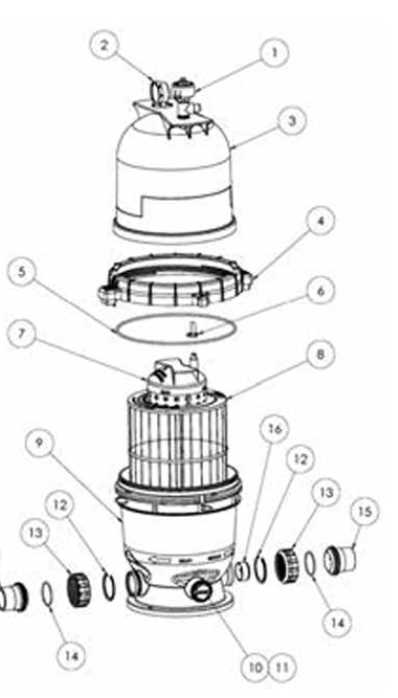

Importance of Pump Diagrams

Understanding the layout and components of a fluid circulation system is crucial for efficient operation and maintenance. Visual representations of these systems serve as essential tools for both professionals and DIY enthusiasts, ensuring that all elements are correctly identified and understood.

Here are several reasons why these visual aids are vital:

- Facilitates Troubleshooting: Clear illustrations help in pinpointing issues quickly, reducing downtime.

- Enhances Maintenance: Knowing where each component is located simplifies routine checks and repairs.

- Improves Communication: Standardized visuals allow for better collaboration among technicians and engineers.

- Educational Value: They serve as excellent resources for training new personnel in the field.

Overall, having access to accurate visual schematics is indispensable for anyone involved in the upkeep and functioning of fluid circulation mechanisms.

Common Issues with Northstar Pumps

Many users encounter a variety of challenges with these devices, which can impact their efficiency and functionality. Understanding these common problems can help in troubleshooting and maintaining optimal performance.

1. Leaks: One of the most frequent issues observed is water leakage. This can arise from worn seals or loose fittings, leading to decreased efficiency and potential water damage.

2. Noise: Unusual sounds during operation may indicate underlying mechanical issues. This can stem from loose components or worn bearings, necessitating immediate attention to prevent further damage.

3. Overheating: Excessive heat generation is another concern, often resulting from blocked intake filters or inadequate airflow. Overheating can lead to significant operational failures if not addressed promptly.

4. Reduced Flow Rate: A noticeable decrease in water flow can signal clogs within the system. Regular cleaning and maintenance of filters and impellers are essential to restore proper functionality.

5. Electrical Failures: Malfunctions in the electrical components, such as faulty wiring or blown fuses, can disrupt operation. Ensuring all electrical connections are secure is crucial for uninterrupted performance.

By being aware of these typical complications, users can take proactive measures to ensure longevity and efficiency in their equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the smooth operation and extended lifespan of any mechanical system. Proper care can prevent common issues, reduce the need for frequent repairs, and keep the equipment running efficiently over time. By following a consistent maintenance routine, you can maximize the durability and functionality of your system, ensuring reliable performance for years to come.

Begin by inspecting the device for signs of wear, such as loose connections or unusual noises, and address any issues promptly. Cleaning external components and ensuring that all moving parts remain lubricated will help prevent unnecessary strain. Additionally, it’s important to monitor the system’s overall efficiency, adjusting settings and replacing worn-out components as necessary to maintain optimal performance.

Regularly checking for blockages or debris in areas prone to buildup is also crucial. Accumulated particles can cause the system to work harder than it should, leading to overheating or damage over time. Routine flushing and cleaning of these areas can prevent costly breakdowns and extend the lifespan of your equipment.

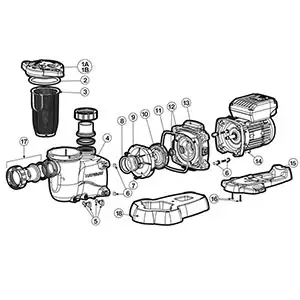

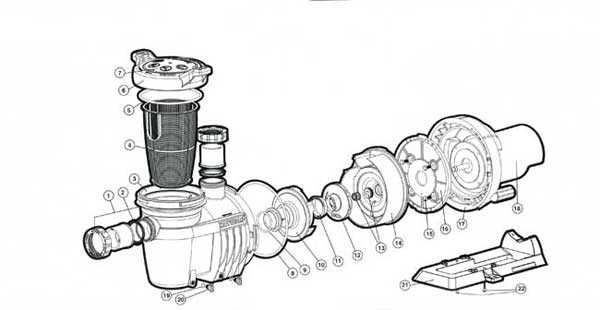

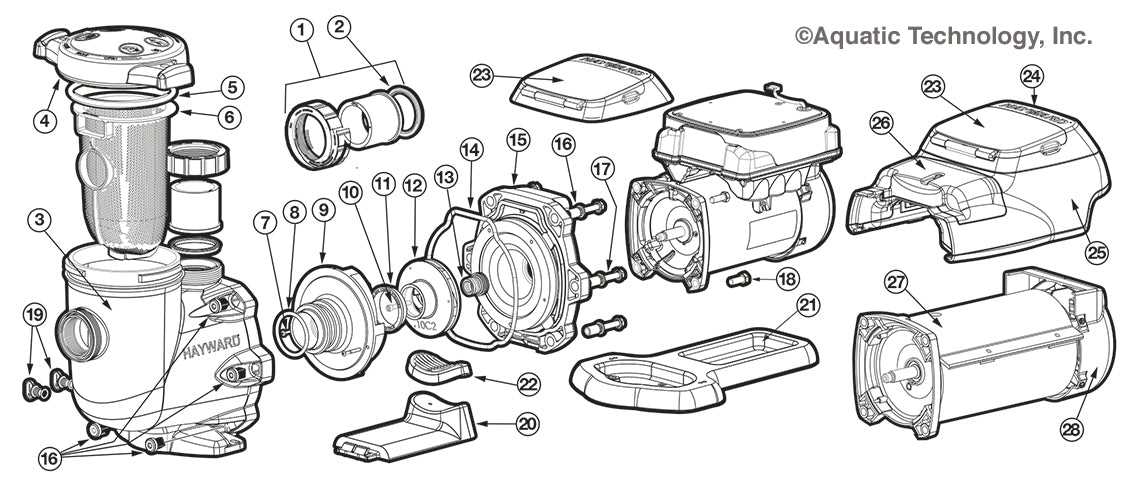

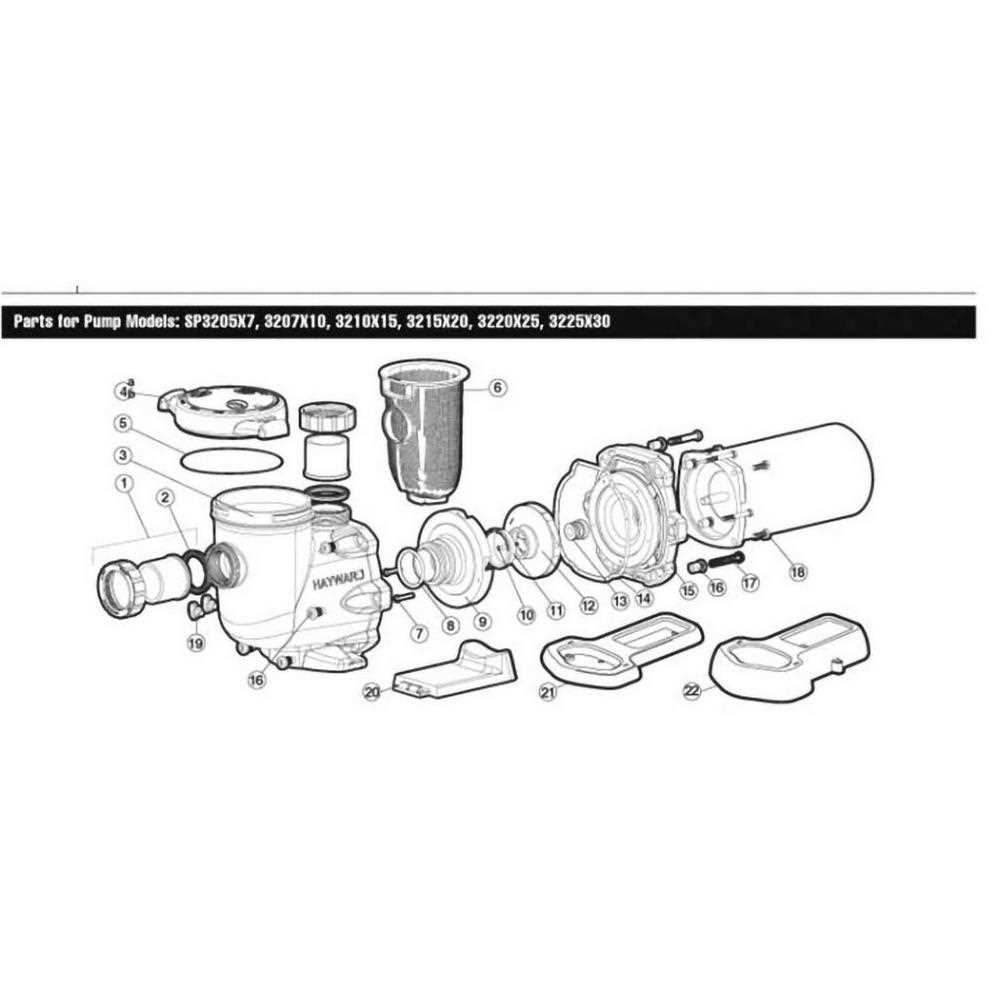

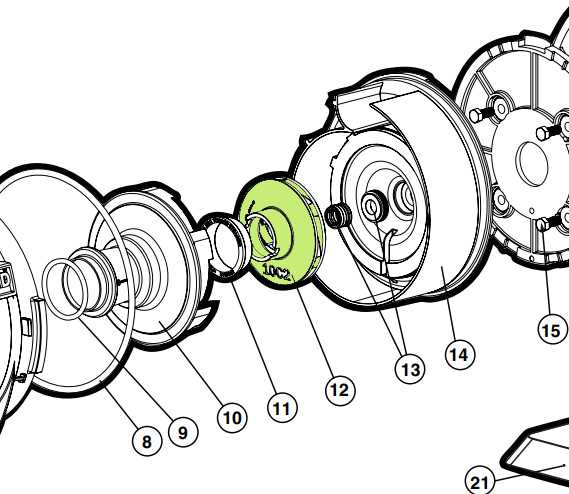

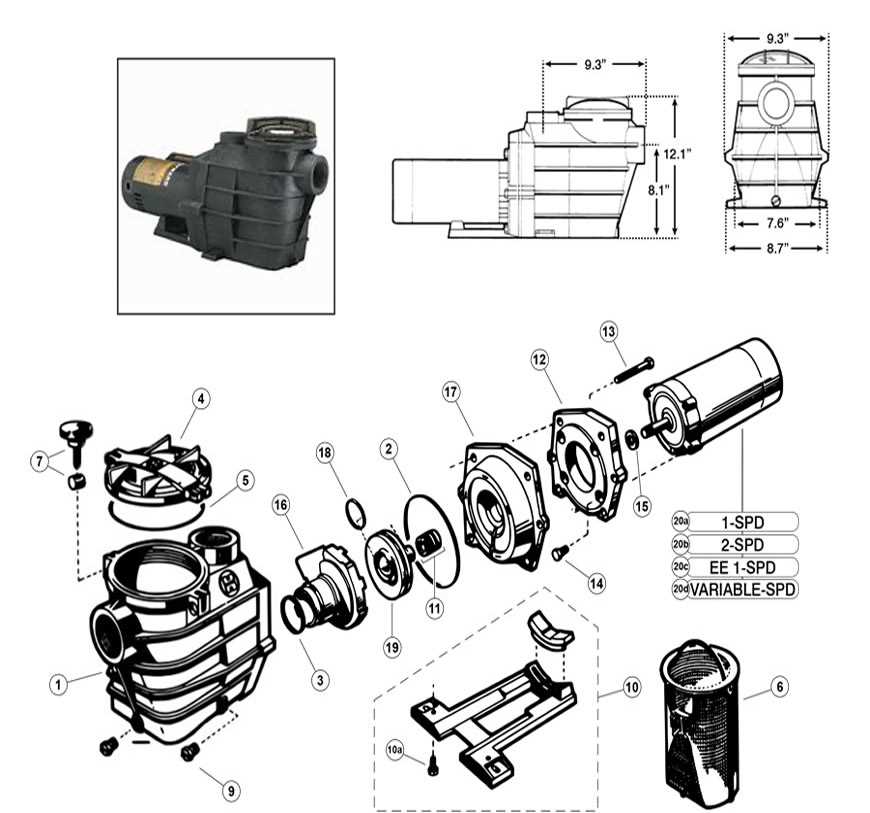

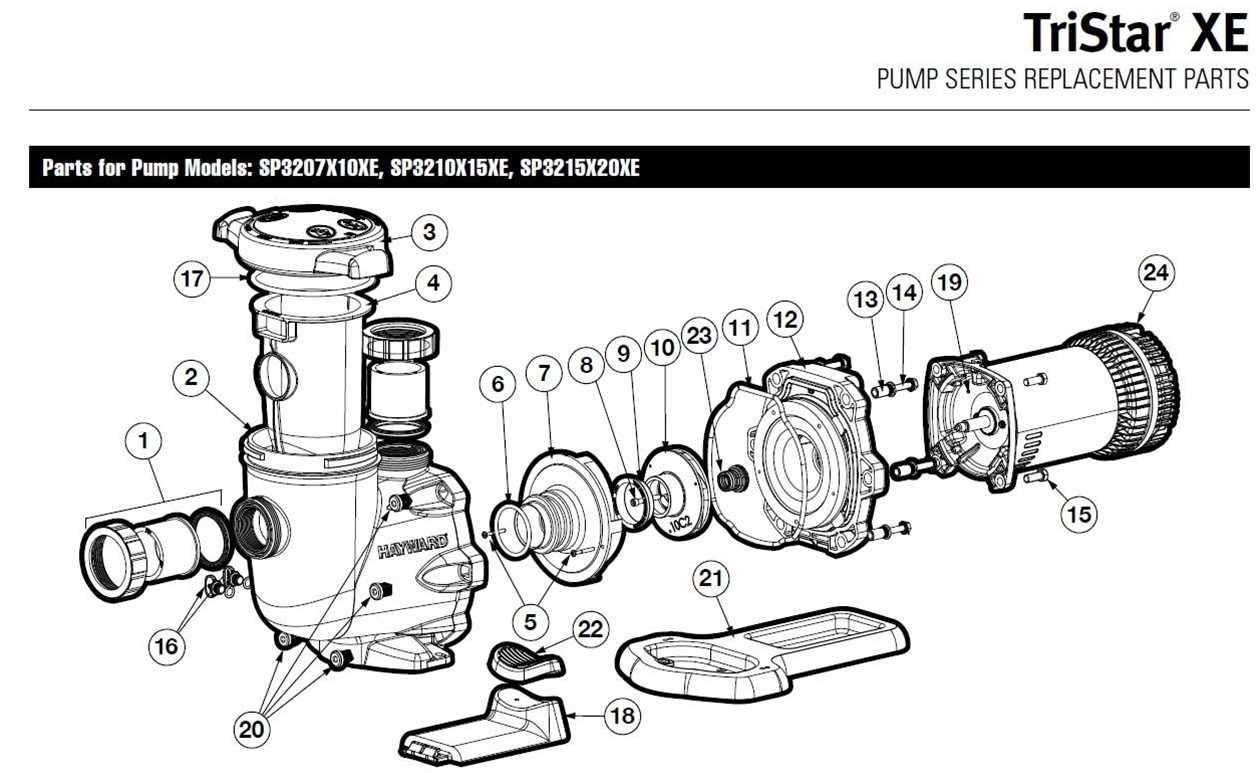

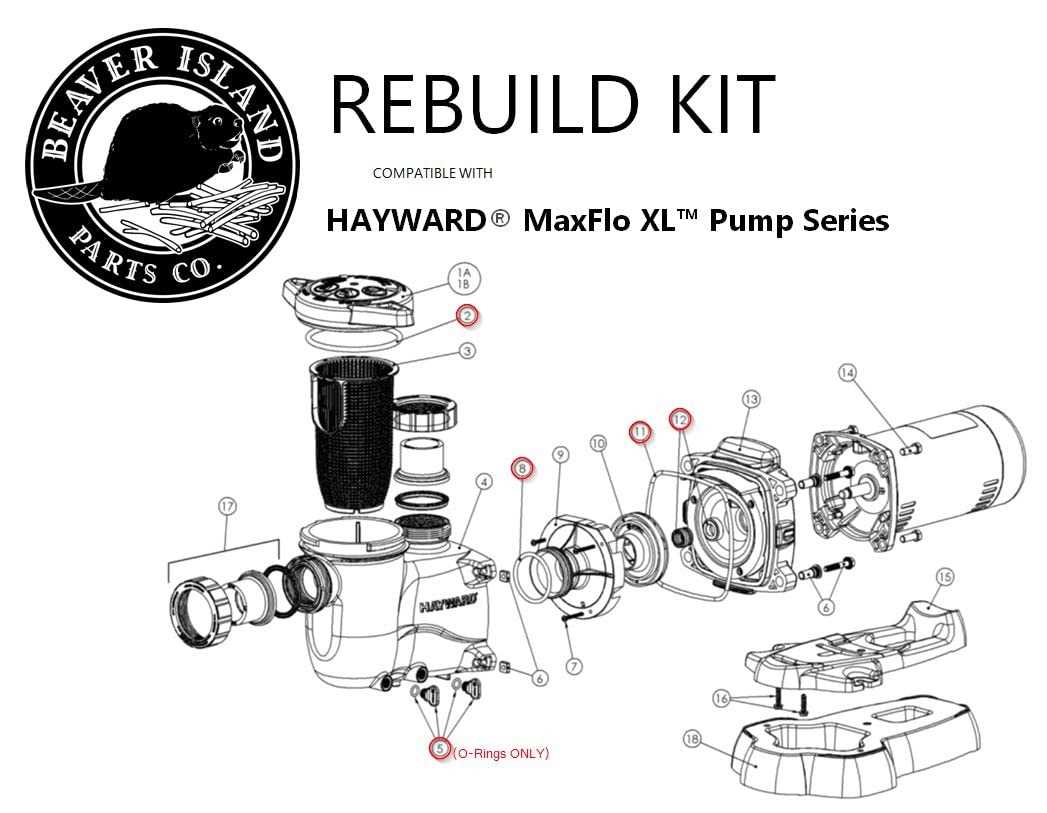

Identifying Pump Parts by Diagrams

When working with technical systems, visual guides offer a practical way to understand the components and their placement within a mechanism. Detailed illustrations help to differentiate between various elements, making it easier to maintain and repair the equipment. Understanding how to interpret these visual aids is essential for anyone involved in technical maintenance or assembly.

Below is a table that outlines key elements typically found in these systems, providing a reference for their identification:

| Component Name | Description |

|---|---|

| Impeller | Responsible for moving fluid through the system, creating flow by centrifugal force. |

| Seal Plate | Acts as a barrier to prevent leakage where components connect. |

| Motor | Powers the mechanism, converting electrical energy into mechanical motion. |

| Diffuser | Guides the fluid into a controlled flow, ensuring efficient operation. |

| Housing | Encloses internal components, offering protection and structural support. |

Where to Find Replacement Parts

When your equipment requires new components, knowing where to source the right pieces is crucial. Whether you’re dealing with regular wear or an unexpected issue, having access to reliable suppliers will ensure your setup continues to function optimally.

Authorized Distributors and Retailers

For the highest quality and compatibility, it’s recommended to look for authorized distributors. These sellers often provide certified items and may offer warranties, ensuring long-term use. Many also offer expert advice to help you select the right item for your specific needs.

Online Marketplaces

Numerous online platforms offer a wide range of components, often at competitive prices. While these options can be convenient, always check seller ratings and product reviews to ensure you receive the right fit for your system. A little research can go a long way in avoiding delays or incompatible replacements.

Understanding Pump Performance Ratings

Performance ratings are crucial for assessing the efficiency and capability of any motorized system designed for fluid movement. They provide insights into how well the system can handle varying demands, offering key data points that help determine energy use, output levels, and overall reliability. By understanding these metrics, one can optimize the operation, reduce costs, and extend the lifespan of the system.

Key Factors Affecting Efficiency

The efficiency of fluid-moving systems is influenced by several factors, such as flow rate, pressure levels, and energy consumption. These aspects are typically measured in specific units, allowing users to gauge the system’s ability to meet their needs. It’s important to balance all these factors to ensure optimal performance without unnecessary energy expenditure.

Evaluating the Right Metrics

When analyzing performance ratings, it’s essential to focus on the most relevant metrics, such as flow capacity and energy efficiency. Systems that maintain consistent flow rates while using minimal power are often the most desirable. Understanding these performance indicators can help users select the right equipment for their needs, ensuring both reliability and cost-effectiveness.

Comparing Northstar Models and Features

When evaluating different models, it’s essential to consider the specific capabilities and characteristics each version offers. Whether you’re focused on performance, durability, or specialized features, each variation has distinct advantages. Understanding these differences can help you make an informed decision that suits your individual needs and requirements.

Performance and Efficiency

One of the key factors in comparing models is their overall efficiency. While some versions are designed for maximum energy savings, others may prioritize raw power. It’s important to assess which option aligns better with your operational demands, especially if you’re looking for long-term reliability in high-demand environments.

Durability and Maintenance

Another critical aspect to explore is the build quality and ease of maintenance. Certain models are crafted with enhanced materials, offering greater resistance to wear and tear, while others may feature streamlined designs that simplify regular upkeep. This can significantly reduce the total cost of ownership over time, especially in challenging conditions.

Step-by-Step Installation Guide

Installing a new system requires attention to detail and proper preparation to ensure seamless functionality. The following guide outlines the process in clear, manageable steps, making it easy to set up your system and avoid common pitfalls. Carefully follow each stage to guarantee successful installation.

| Step | Description |

|---|---|

| 1 | Begin by positioning the main unit on a stable surface, ensuring it is level and securely anchored. This prevents any movement during operation. |

| 2 | Connect the input line to the designated port, making sure all seals are tight to avoid any leakage. A proper connection is essential for optimal performance. |

| 3 | Attach the output line to its corresponding outlet. Ensure the line is free from obstructions, and the connection is firm. |

| 4 | Next, verify all electrical connections are secure and properly insulated. Double-check for any exposed wires to prevent short circuits. |

| Benefit | Impact |

|---|---|

| Increased Efficiency | Ensures machinery operates at peak performance. |

| Cost Savings | Reduces the likelihood of expensive repairs or replacements. |

| Extended Lifespan | Prolongs the usability of essential equipment. |

| Safety | Minimizes the risk of accidents caused by mechanical failures. |

Resources for Further Learning

For those looking to deepen their understanding and explore similar systems, there are numerous materials and tools available that offer in-depth guidance. Whether you prefer reading technical manuals, watching tutorials, or accessing interactive platforms, the following resources provide valuable insights and practical advice.

- Technical guides covering system maintenance and upgrades

- Online video tutorials for step-by-step troubleshooting

- Community forums where experts discuss common issues and solutions

- Interactive tools and apps designed for system optimization

- Manufacturers’ websites offering downloadable manuals and updates

By taking advantage of these resources, you can expand your knowledge and ensure that your system continues to operate smoothly and efficiently.