Wilden Pump Components Overview

In various industrial settings, the efficiency of machinery heavily relies on the intricate arrangements of their individual components. A comprehensive understanding of these layouts is essential for troubleshooting and maintenance, ensuring optimal performance. Each segment serves a specific function, contributing to the overall effectiveness of the system.

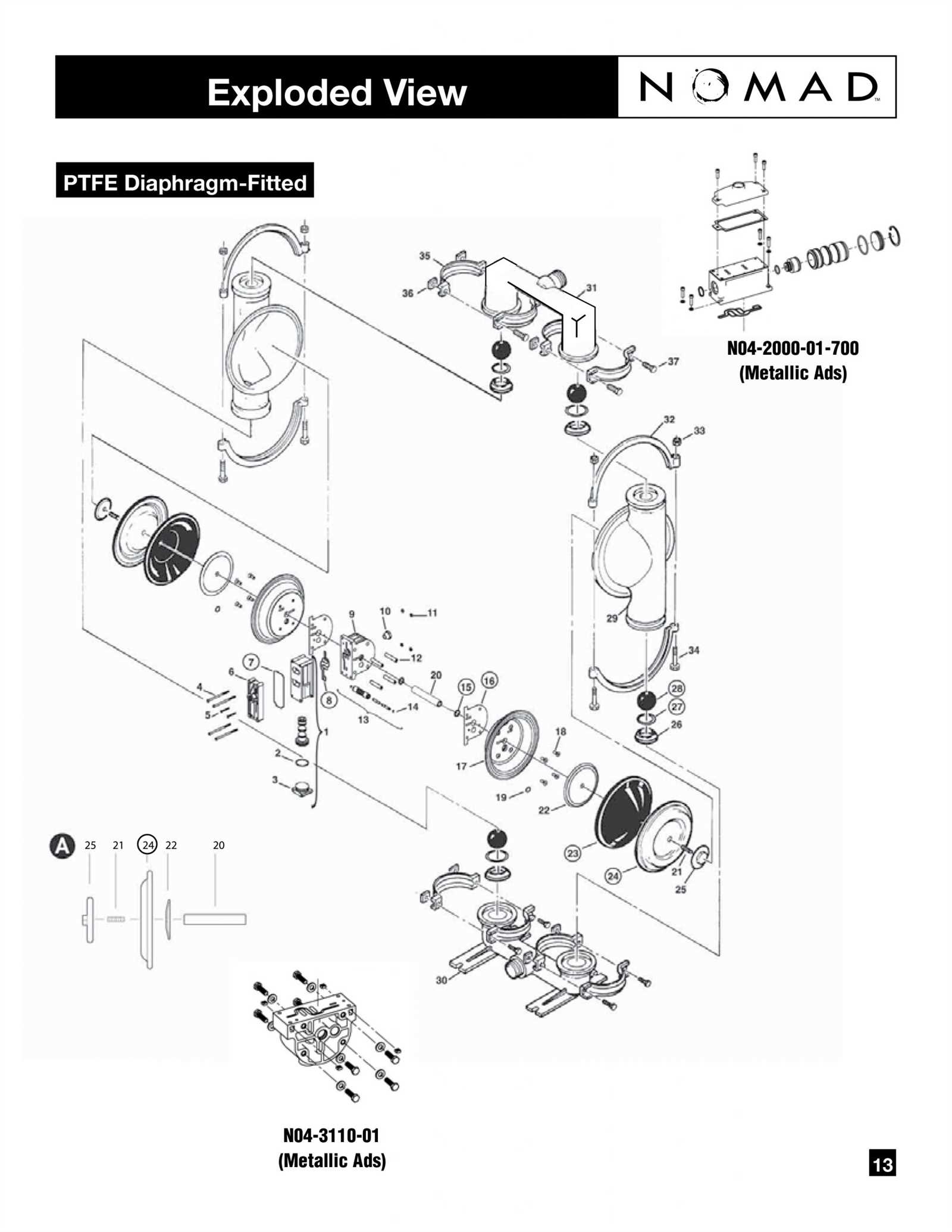

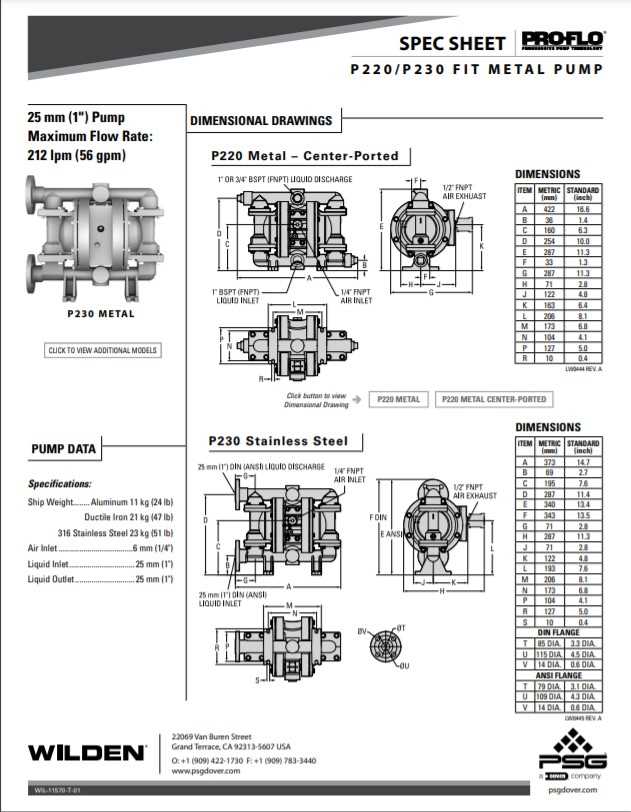

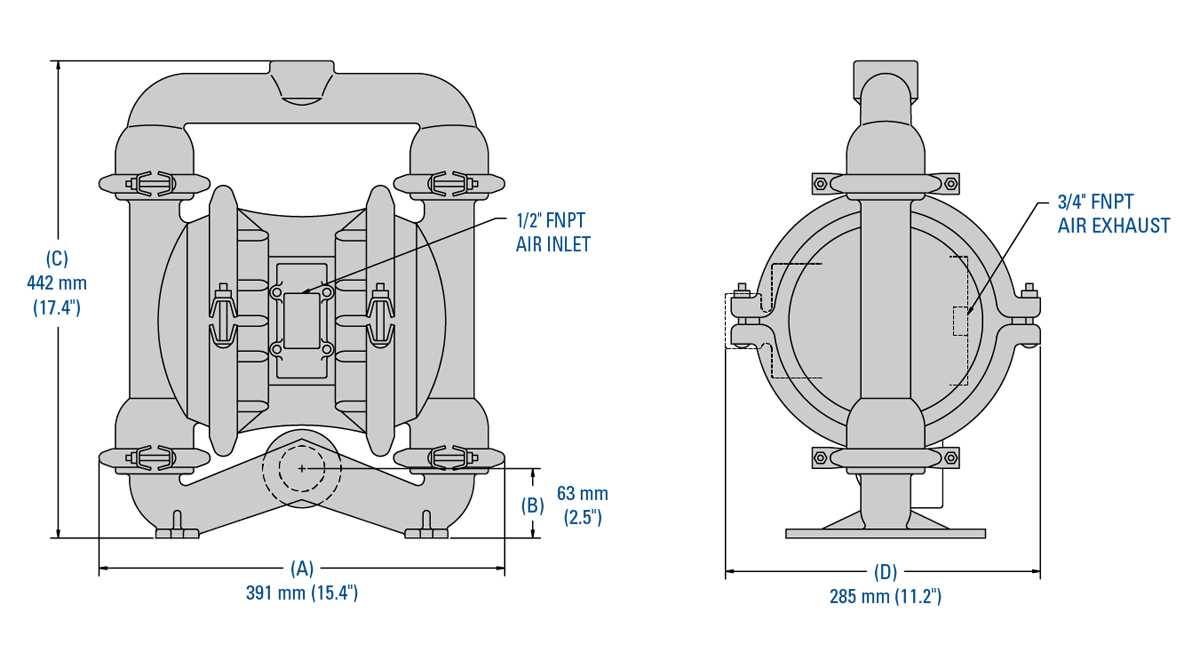

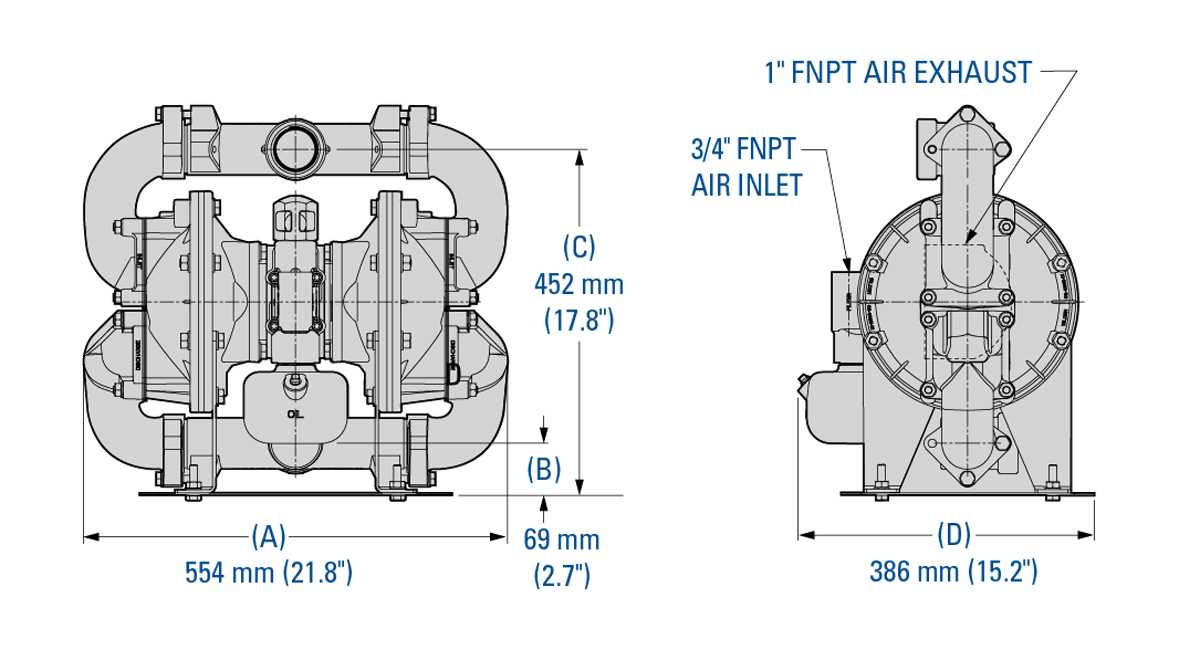

To facilitate better insights, visual representations of these configurations can be invaluable. Such illustrations enable users to quickly identify and comprehend the roles of different elements. By examining these layouts, operators can gain clarity on assembly, identify potential issues, and make informed decisions regarding repairs or upgrades.

Utilizing accurate visual aids not only streamlines operations but also enhances safety protocols. When personnel are well-acquainted with the structure and functionality of the machinery, they can execute their tasks with confidence and precision. This understanding ultimately leads to improved productivity and reduced downtime in various applications.

Key Elements of Wilden Pumps

The efficient operation of fluid transfer systems relies on several crucial components that work in harmony. Understanding these essential elements is vital for optimal functionality and maintenance of these systems.

Core Components

- Diaphragm: This flexible membrane is essential for creating pressure changes within the system, allowing for effective fluid movement.

- Air Valve: A critical element that controls the flow of air, enabling the diaphragm to alternate its movement.

- Fluid Chamber: This enclosure houses the fluid, ensuring it is securely contained during transfer processes.

- Check Valves: These one-way valves prevent backflow, ensuring the fluid moves in the intended direction.

- Inlet and Outlet Ports: These openings facilitate the entry and exit of fluids, playing a vital role in the system’s overall efficiency.

Maintenance Considerations

- Regular inspection of the diaphragm for wear and tear to ensure uninterrupted operation.

- Monitoring the air valve for proper function to prevent inefficiencies.

- Checking fluid chambers for leaks that could compromise system integrity.

- Cleaning check valves to avoid blockages that may hinder performance.

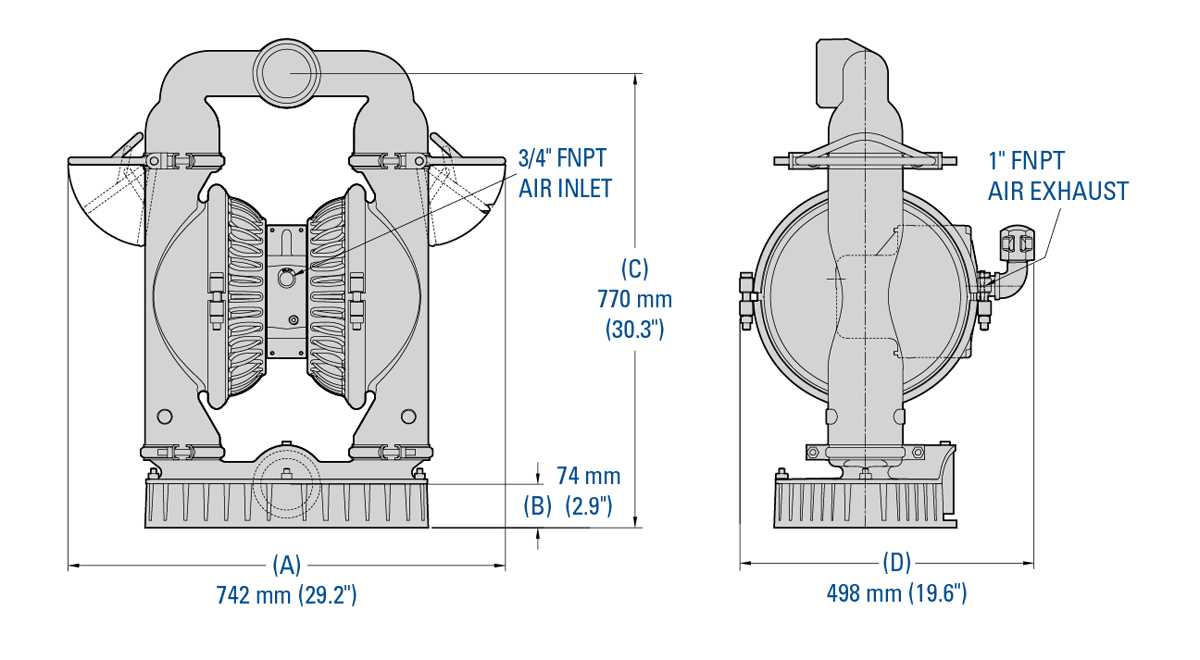

How to Read Pump Diagrams

Understanding schematics is essential for effective maintenance and troubleshooting of fluid transfer systems. This section provides insights into interpreting these technical representations, enabling users to grasp the layout and functionality of various components involved in fluid movement.

Identifying Key Elements

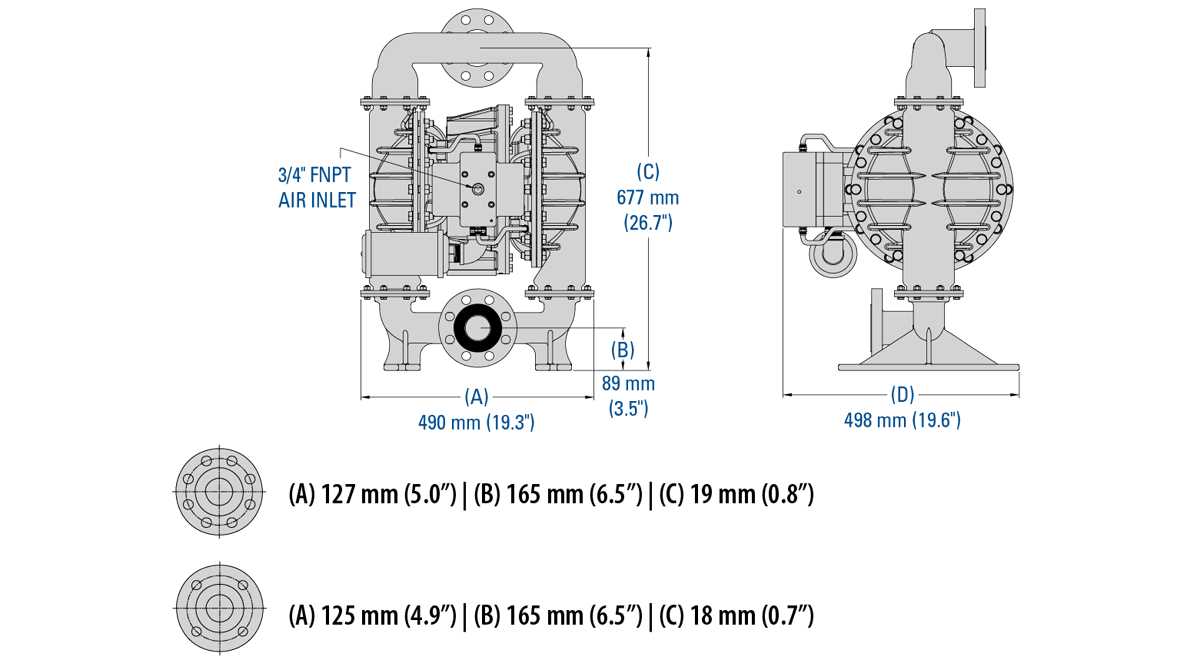

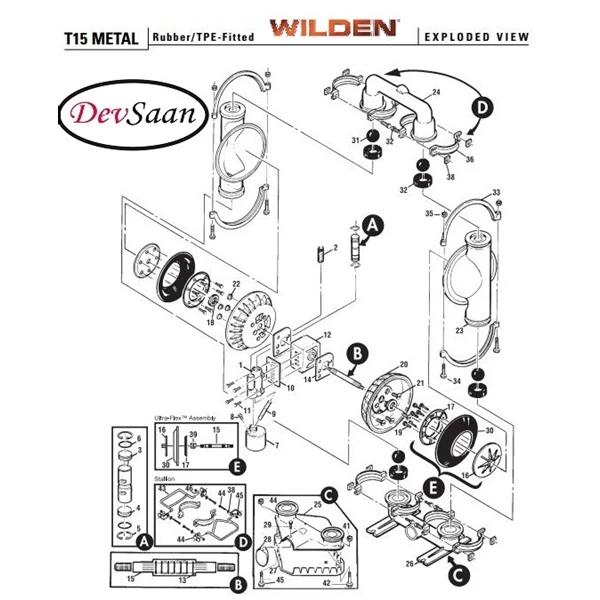

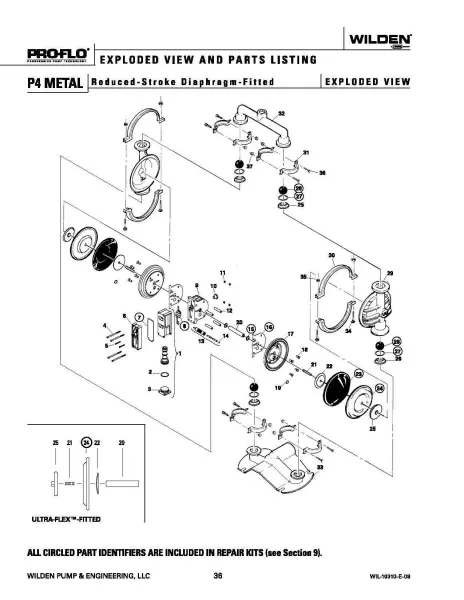

Each illustration typically features several crucial components, such as inlets, outlets, and control mechanisms. Recognizing these elements and their respective roles is fundamental. Often, annotations and labels accompany these visuals, offering additional context and details to clarify the function of each part.

Interpreting Flow Directions

Another vital aspect is understanding flow pathways. These illustrations usually indicate the direction in which the fluid travels, often represented by arrows. Familiarizing yourself with these indicators allows for better comprehension of how the system operates, helping identify potential issues or inefficiencies in the setup.

Common Parts and Their Functions

Understanding the key components and their roles is essential for the effective operation of fluid transfer equipment. Each element plays a significant part in ensuring optimal performance and longevity of the system.

| Component | Description |

|---|---|

| Diaphragm | This flexible membrane facilitates the movement of fluids by creating pressure changes within the chamber. |

| Valves | These mechanisms control the flow direction and prevent backflow, ensuring that the fluid moves in the intended path. |

| Check Valve | This type of valve allows fluid to pass in one direction while preventing reverse flow, safeguarding the system. |

| Fluid Chamber | This housing contains the liquid being transferred, providing the necessary space for operation and pressure buildup. |

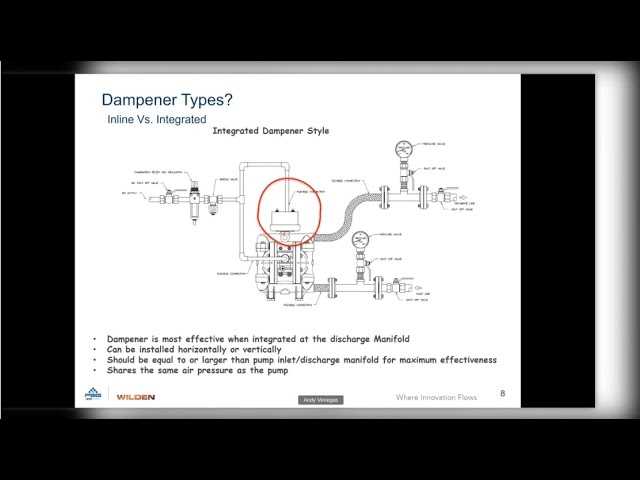

| Pulsation Dampener | This component minimizes pressure fluctuations, ensuring a smooth and consistent flow of liquid through the system. |

Maintenance Tips for Wilden Pumps

Regular upkeep is crucial for ensuring the longevity and optimal performance of fluid transfer systems. By following a few key practices, users can minimize downtime and enhance efficiency in their operations. This section provides essential guidelines to maintain these systems effectively.

Routine Inspection

Conducting periodic evaluations is vital. Look for signs of wear, leaks, or unusual noises during operation. Early detection of potential issues can prevent costly repairs and ensure smooth functioning.

Proper Lubrication

Ensure that all moving components are adequately lubricated. Use the manufacturer-recommended lubricants to reduce friction and wear. Regularly check lubrication levels and replenish as necessary to maintain peak performance.

Incorporating these maintenance practices into your routine will lead to improved reliability and efficiency, ultimately extending the lifespan of your fluid transfer systems.

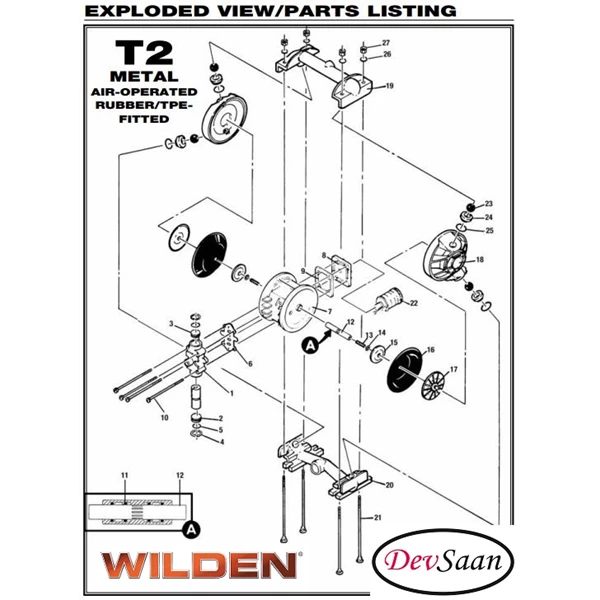

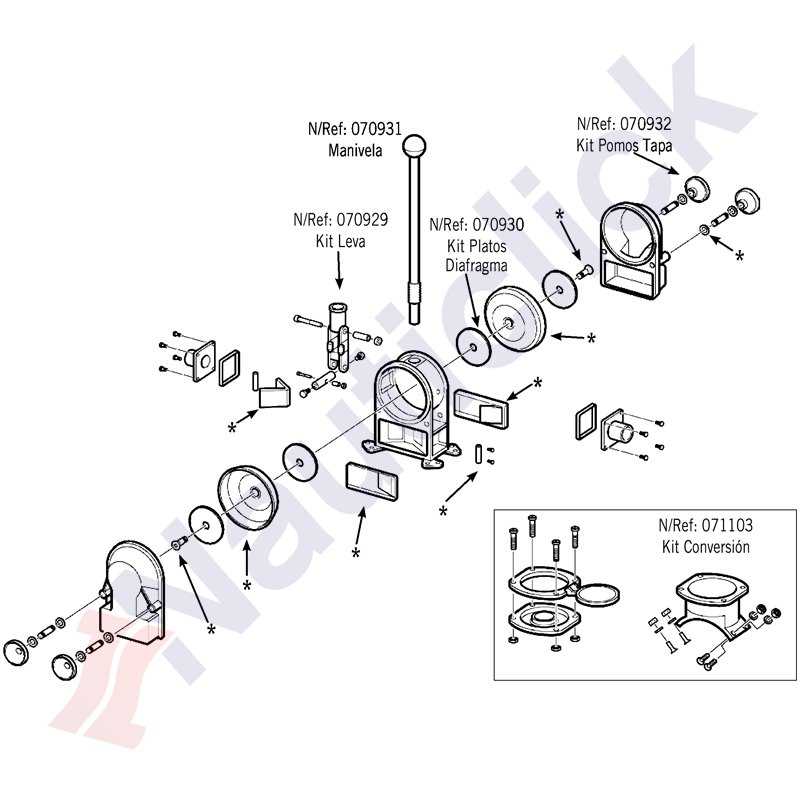

Identifying Replacement Parts Easily

Understanding how to pinpoint necessary components can streamline maintenance and repair processes. When equipment experiences issues, knowing how to identify the appropriate substitutes is crucial for efficient resolutions. This section explores strategies for recognizing and sourcing the correct elements to ensure optimal functionality.

Utilizing Reference Materials

Leveraging manuals and reference guides can significantly aid in identifying components. These resources typically offer detailed descriptions and visuals, making it easier to match items accurately. Regularly consulting these materials can enhance familiarity with the system, leading to quicker identification of needed replacements.

Engaging with Expert Communities

Connecting with knowledgeable forums and communities can provide valuable insights. Many enthusiasts and professionals share their experiences and advice on locating specific components. Engaging with these networks can also lead to recommendations for reliable suppliers, ensuring access to high-quality items.

Advantages of Wilden Pump Design

The innovative design of these fluid handling devices offers a multitude of benefits that enhance performance and reliability. Their unique construction allows for efficient operation across various applications, making them a preferred choice in many industries.

Durability is one of the key advantages, as these devices are built to withstand harsh environments and demanding conditions. The materials used in their manufacturing ensure long-lasting performance, reducing the need for frequent replacements.

Moreover, the versatile configuration allows for customization based on specific requirements, enabling seamless integration into existing systems. This adaptability is crucial for optimizing workflows and enhancing productivity.

Another significant benefit is the ease of maintenance. The design facilitates straightforward access to internal components, allowing for quick inspections and repairs, which minimizes downtime and operational costs.

Additionally, the energy efficiency of these devices contributes to cost savings over time. Their ability to operate effectively at lower energy consumption levels makes them an environmentally friendly option.

In conclusion, the advanced engineering of these fluid handling solutions provides a reliable and efficient means of managing various substances, ensuring superior functionality and satisfaction for users.

Typical Issues with Pump Parts

When dealing with fluid transfer mechanisms, several common challenges can arise, often linked to the individual components involved. Understanding these issues is crucial for maintaining efficiency and preventing operational failures.

Frequent problems may include wear and tear, leaks, and improper functioning of various elements. Regular inspection and timely replacement can help mitigate these concerns, ensuring optimal performance over time.

| Issue | Description | Solution |

|---|---|---|

| Wear | Components may deteriorate over time due to friction and pressure. | Regular maintenance and timely replacement of affected elements. |

| Leaks | Fluid may escape from seals or connections, causing efficiency loss. | Inspect seals regularly and replace as necessary to prevent leaks. |

| Blockages | Debris can obstruct flow, reducing effectiveness. | Routine cleaning and checking for obstructions can help maintain flow. |

| Noise | Unusual sounds may indicate misalignment or malfunctioning parts. | Investigate noise sources and address any misalignments or faults. |

Upgrading Wilden Pump Components

Enhancing the efficiency and longevity of your equipment involves upgrading key components. These improvements not only optimize performance but also reduce maintenance costs and downtime. It is essential to evaluate and select high-quality replacements to ensure smooth operation.

Benefits of Upgrading Components

- Improved efficiency and performance

- Reduced energy consumption

- Increased reliability and durability

- Enhanced safety features

- Cost savings on maintenance and repairs

Considerations for Component Upgrades

- Material Quality: Choose components made from durable materials to withstand operational demands.

- Compatibility: Ensure that new parts are compatible with existing systems for seamless integration.

- Supplier Reputation: Select reputable suppliers known for high-quality offerings.

- Installation: Consider professional installation to guarantee proper fitting and function.

Best Practices for Parts Replacement

Replacing components in any mechanical system is crucial for maintaining optimal performance and extending the lifespan of the equipment. Proper execution of this task ensures that the system operates efficiently, reduces downtime, and prevents potential failures. Following a systematic approach is essential for achieving the best outcomes during the replacement process.

Preparation and Planning

Before starting the replacement process, it is vital to gather all necessary tools and new components. Reviewing the manufacturer’s guidelines can provide insights into recommended practices and specifications. Additionally, creating a detailed plan helps streamline the process, minimizing interruptions and ensuring that all steps are followed accurately.

Inspection and Testing

Once the new components are installed, conducting thorough inspections and tests is important. This step verifies that the new parts are functioning correctly and that there are no leaks or malfunctions. Regular monitoring and maintenance can help identify any issues early, ensuring the system remains in excellent condition.

Finding Authentic Wilden Parts

When it comes to sourcing genuine components for your equipment, it’s crucial to ensure quality and reliability. Authenticity in replacements not only guarantees optimal performance but also extends the lifespan of your machinery. This section explores the best practices for identifying and procuring legitimate items that meet industry standards.

Importance of Quality Components

Utilizing high-quality replacements is essential for maintaining operational efficiency. Genuine items are designed to fit seamlessly and function optimally within your system, reducing the risk of malfunctions and costly downtime. Ensuring that you acquire verified components safeguards your investment and enhances productivity.

Where to Source Authentic Components

Finding reliable suppliers is key to obtaining genuine replacements. Trusted vendors often provide certifications and warranties, which can help in verifying authenticity. Additionally, researching online reviews and seeking recommendations from industry professionals can guide you towards reputable sources.

| Supplier Type | Benefits | Considerations |

|---|---|---|

| Authorized Distributors | Genuine components, warranties | Potentially higher prices |

| Reputable Online Retailers | Convenience, often competitive pricing | Check for authenticity guarantees |

| Local Machinery Shops | Personalized service, expert advice | Limited inventory compared to larger suppliers |