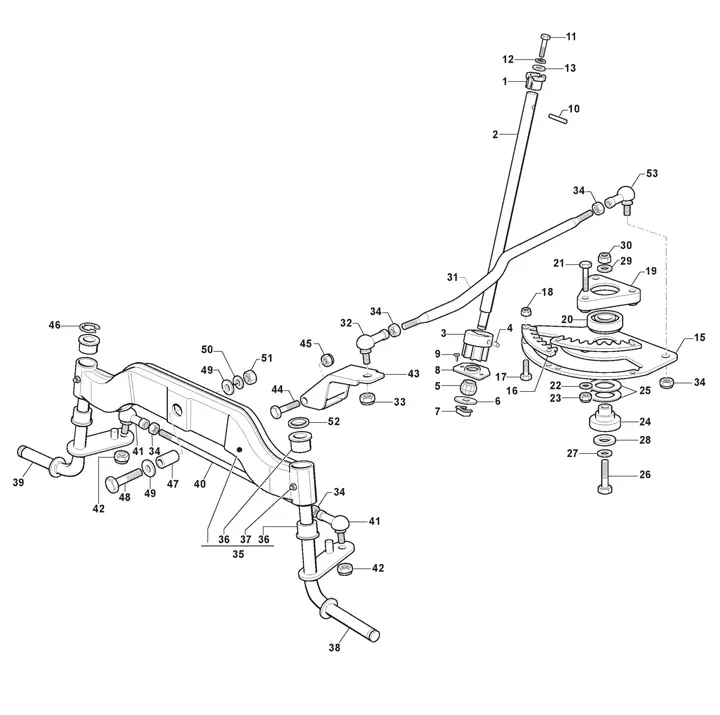

Understanding the Diagram of Craftsman Riding Mower Steering Parts

When it comes to maintaining and operating outdoor machinery, having a clear grasp of the control components is essential for optimal performance. These mechanisms play a vital role in ensuring smooth navigation and precise handling, allowing users to maneuver their equipment effectively across various terrains.

In this section, we will explore the intricate relationships between different elements that contribute to the overall functionality of these devices. By breaking down each component, we aim to provide a comprehensive overview that will help enthusiasts and operators alike enhance their understanding and troubleshooting skills.

Additionally, a detailed visual representation will aid in identifying each section, making it easier to recognize potential wear or damage. With this knowledge, users can ensure their equipment remains in peak condition, ultimately improving their outdoor experience.

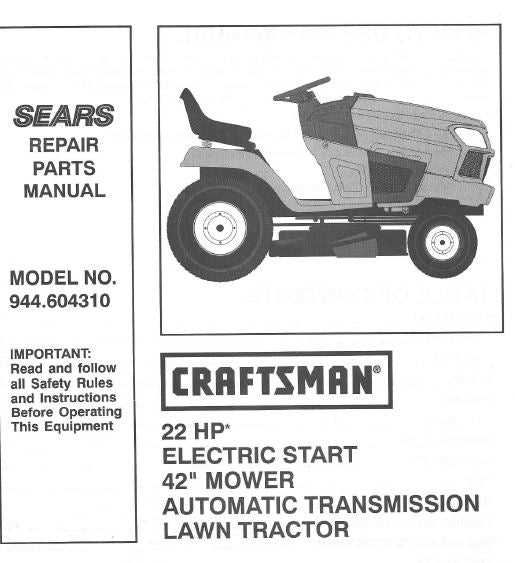

Understanding Craftsman Riding Mowers

This section delves into the intricacies of lawn maintenance machinery designed for efficient maneuverability and control. These powerful tools have transformed how enthusiasts and professionals approach yard care, offering a blend of performance and ease of use.

The mechanisms within these machines are crafted to provide a seamless experience, allowing users to navigate various terrains with precision. Familiarizing oneself with the components involved in steering and navigation enhances the overall understanding and operational proficiency of these devices.

Maintenance and troubleshooting of the steering system are essential for optimal performance. Recognizing the key elements and their functions aids in preventing issues and ensuring longevity. A thorough comprehension of the assembly not only empowers users but also enhances the enjoyment of yard work.

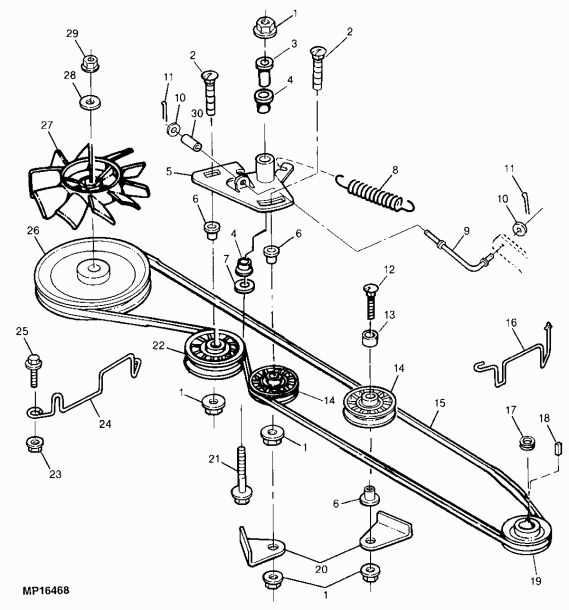

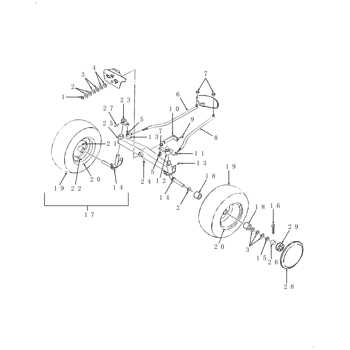

Key Components of Steering Systems

Understanding the fundamental elements that govern directional control is essential for maintaining optimal performance. Each component plays a vital role in ensuring smooth operation and precise maneuverability.

Essential Elements

- Wheel Assembly: Facilitates movement and provides traction.

- Linkage System: Connects various parts, translating motion effectively.

- Column Mechanism: Houses controls for user input, allowing for directional adjustments.

- Pivot Points: Enable rotational movement, crucial for changing direction.

Supportive Structures

- Frame: Provides stability and support to all components.

- Bearings: Reduce friction, ensuring smooth operation.

- Hydraulic System: Offers enhanced control and responsiveness.

Importance of Steering Maintenance

Regular upkeep of directional control mechanisms is crucial for optimal performance and safety in various machinery. Neglecting this aspect can lead to diminished functionality, increased wear, and potential hazards during operation. Ensuring that these systems are well-maintained not only enhances maneuverability but also extends the lifespan of the equipment.

Frequent inspections are essential to identify any signs of wear or damage early on. Components such as linkages, joints, and bushings may experience stress over time, and addressing these issues promptly can prevent more significant problems in the future. Lubrication plays a vital role as well, reducing friction and facilitating smooth operation, which is particularly important during extended use.

Moreover, maintaining proper alignment and calibration is necessary for efficient control. Misalignment can result in uneven handling, leading to discomfort for the operator and potential accidents. Therefore, investing time and resources into maintaining directional systems is a wise decision that promotes safety and enhances overall performance.

Common Issues with Steering Parts

Many users encounter various challenges related to the directional control mechanism in their lawn equipment. These complications can significantly affect maneuverability and overall performance, leading to frustration and potential safety hazards.

Wear and Tear

Over time, components can experience degradation due to regular use, resulting in decreased responsiveness. It’s essential to inspect for signs of wear, such as loose connections or frayed links, to maintain optimal functionality.

Alignment Problems

Miscalibration of the directional system can lead to uneven handling. Regular checks and adjustments are vital to ensure that all elements are correctly aligned, enhancing the user experience and extending the lifespan of the equipment.

How to Identify Steering Problems

Understanding how to recognize issues with your vehicle’s directional control is crucial for ensuring safe operation. A range of symptoms may indicate a malfunction, and early detection can prevent more severe damage.

Listen for Unusual Noises: If you hear grinding or popping sounds while maneuvering, this could signal a problem with the mechanism.

Check for Vibration: Excessive shaking during navigation may indicate misalignment or worn components, necessitating further examination.

Observe Responsiveness: If the control system feels sluggish or unresponsive, it might suggest issues with the internal system or connections.

Inspect for Wear: Regularly examine the components for signs of wear or damage, as this can help pinpoint potential problems before they escalate.

Identifying these signs promptly can lead to effective repairs, ensuring smoother and safer operation.

Step-by-Step Steering Repair Guide

Maintaining the control system of your machine is essential for smooth operation. This guide provides a comprehensive approach to fixing any issues that may arise, ensuring that your vehicle remains easy to maneuver. Follow these steps to identify and resolve common problems effectively.

-

Identify the Issue:

Begin by assessing the symptoms. Common signs include difficulty in turning or unusual noises. Take note of any irregularities while operating.

-

Gather Necessary Tools:

Collect the following items before starting your repair:

- Wrench set

- Screwdriver

- Pliers

- Lubricant

- Replacement components, if needed

-

Disassemble the Control Assembly:

Carefully remove the cover and detach any components that may be obstructing access to the control mechanism. Keep track of all screws and parts for reassembly.

-

Inspect the Components:

Examine all elements for wear and tear. Look for:

- Cracks or breaks in structural parts

- Loose connections or fasteners

- Corrosion or rust

-

Replace Damaged Parts:

If you find any damaged components, replace them with new ones. Ensure that all replacements are compatible with your model.

-

Reassemble the Control Assembly:

Carefully reattach all components in the reverse order of disassembly. Ensure that everything is secure and correctly aligned.

-

Lubricate Moving Parts:

Apply a suitable lubricant to the joints and pivots to ensure smooth operation. Avoid over-lubrication as it may attract dirt.

-

Test the System:

Before using the vehicle, perform a test to ensure that the control system operates smoothly. Make any necessary adjustments if issues persist.

By following these detailed steps, you can effectively address issues with the control mechanism of your machine, ensuring a safe and enjoyable experience.

Tools Needed for Steering Repairs

When addressing issues with maneuverability in outdoor machinery, having the right tools is essential for effective troubleshooting and repairs. This section outlines the necessary equipment that will help ensure a smooth repair process.

- Wrenches: Various sizes to fit different bolts and nuts.

- Screwdrivers: Both flathead and Phillips for different screw types.

- Pliers: Useful for gripping and twisting components.

- Socket Set: For easier access to tight spaces.

- Torque Wrench: To ensure proper tightening of bolts.

- Jack Stands: For safely elevating the machine during repairs.

- Grease Gun: To apply lubrication where needed.

- Safety Gear: Including gloves and goggles for protection.

Gathering these tools will facilitate a more efficient and safe repair experience.

Replacing Worn Steering Components

Over time, various control elements can degrade, affecting maneuverability and overall performance. Recognizing the signs of wear and addressing them promptly can enhance your vehicle’s handling and extend its lifespan. This section will explore the essential steps for identifying and substituting these crucial components.

Begin by inspecting the relevant mechanisms for any signs of damage or excessive play. Common indicators include difficulty in turning or unusual noises during operation. Once you have pinpointed the worn pieces, gather the necessary tools and replacement items. Ensure that you follow the manufacturer’s guidelines for proper installation to guarantee optimal functionality.

After replacing the components, conduct a thorough test to confirm that the adjustments have restored smooth operation. Regular maintenance checks will help prevent future issues, ensuring a more enjoyable experience while operating your equipment.

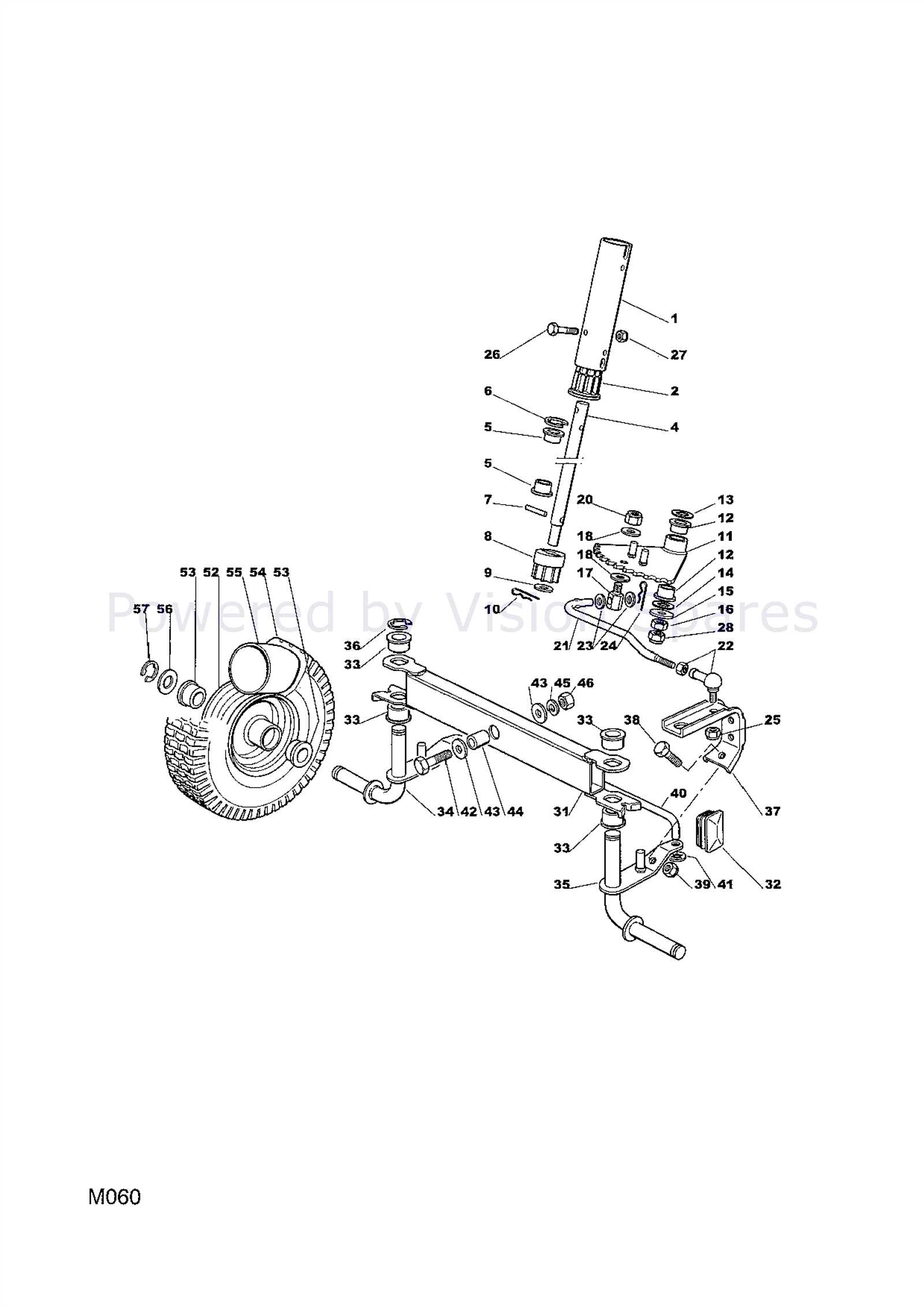

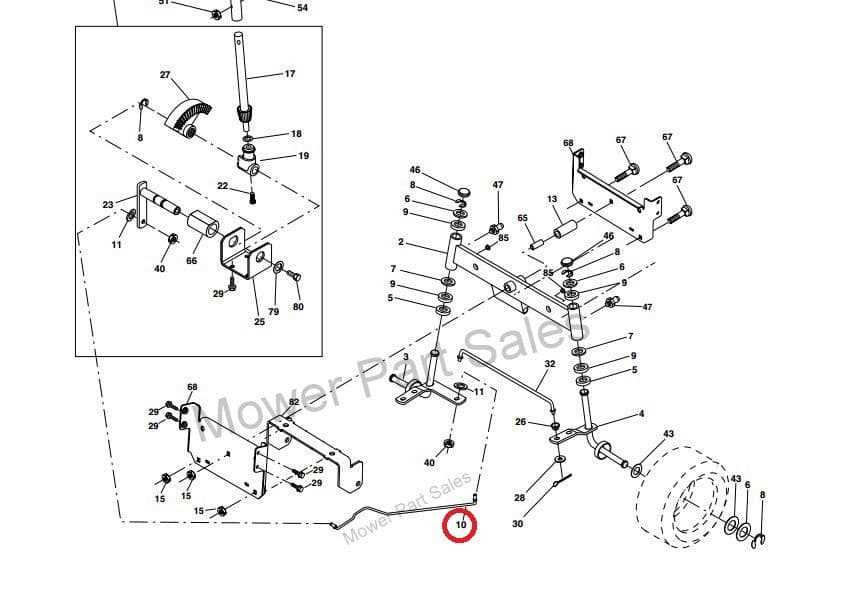

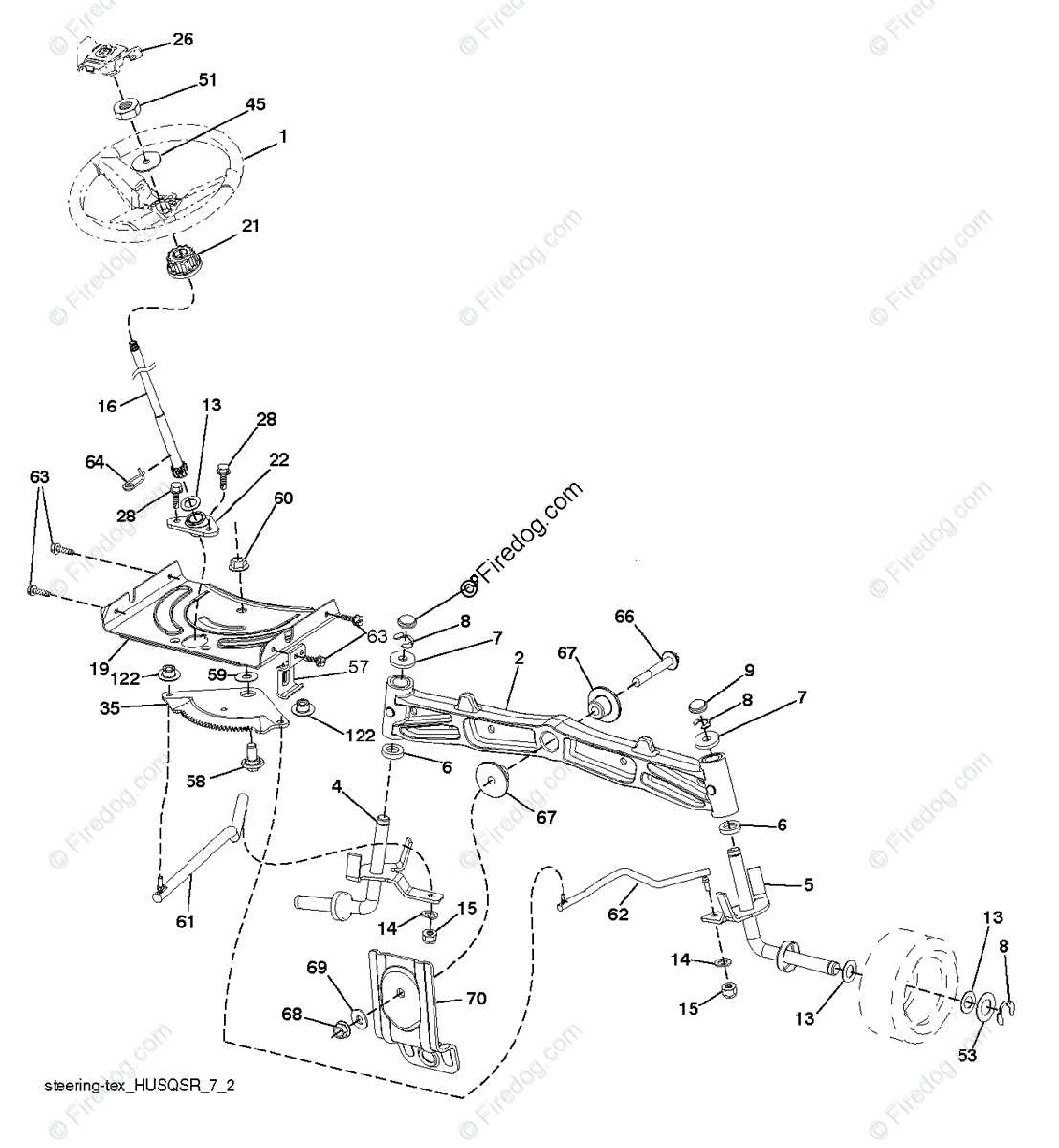

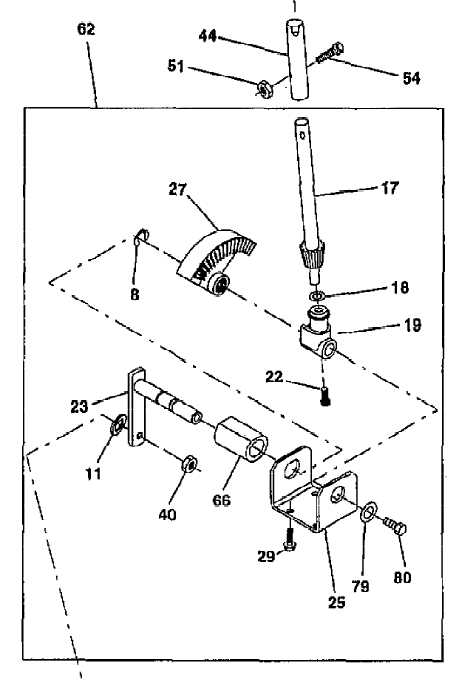

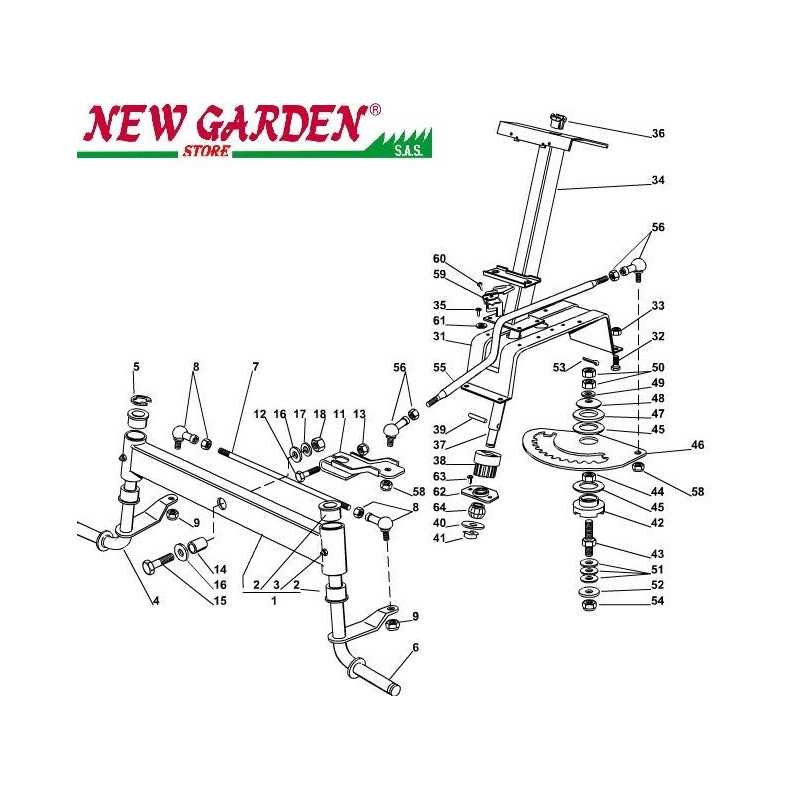

Craftsman Steering Diagram Explained

This section delves into the intricate layout and functionality of the control system for your garden vehicle. Understanding this configuration is essential for effective operation and maintenance, ensuring smooth navigation and precise handling during use.

The schematic representation outlines various components that contribute to the maneuverability of the machine. Each element plays a vital role, from the central column to the linkages, allowing for fluid movement and responsiveness to the operator’s commands.

By familiarizing yourself with the arrangement and interaction of these elements, you can troubleshoot issues, perform repairs, or enhance performance. A thorough grasp of how these components work together can significantly improve your overall experience with your equipment.

In summary, comprehending this essential layout not only empowers users with knowledge but also facilitates better care for their machinery, ensuring longevity and efficiency in the field.

Preventive Measures for Steering Longevity

Ensuring the durability of your equipment’s maneuvering system is crucial for optimal performance and longevity. Regular maintenance and mindful practices can significantly enhance its lifespan, minimizing the risk of breakdowns and costly repairs.

Regular Inspection and Maintenance

Conduct periodic checks to identify any signs of wear or damage. Lubrication of moving components is essential to reduce friction and prevent premature deterioration. Replace worn-out elements promptly to maintain efficiency.

Proper Usage Techniques

Adopting correct handling methods can prevent unnecessary strain. Avoid abrupt turns and excessive speed, which can lead to uneven wear. Consistent operation within recommended limits will foster longevity and reliability.

Where to Find Replacement Parts

When seeking components for your outdoor machinery, it’s essential to know the best sources available. Various options exist that cater to both common and unique requirements, ensuring you can keep your equipment in optimal condition.

Online Retailers

One of the most convenient ways to obtain necessary components is through online retailers. Websites like Amazon and specialized equipment sites offer a vast selection of items, often with customer reviews to help guide your choice.

Local Hardware Stores

Don’t overlook your neighborhood hardware stores. Many of these establishments carry a range of supplies for lawn equipment. Additionally, the staff can provide valuable advice and assistance in locating specific items.