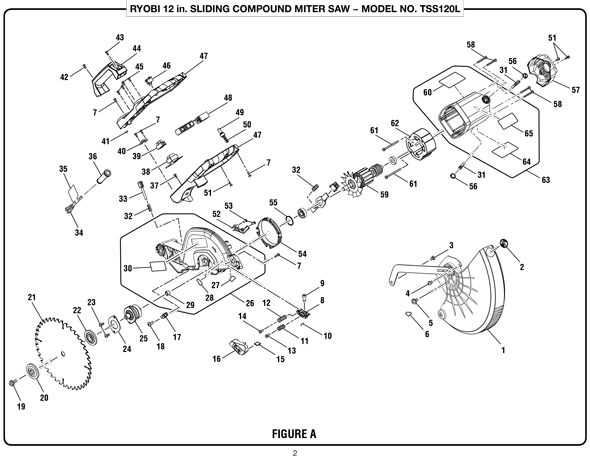

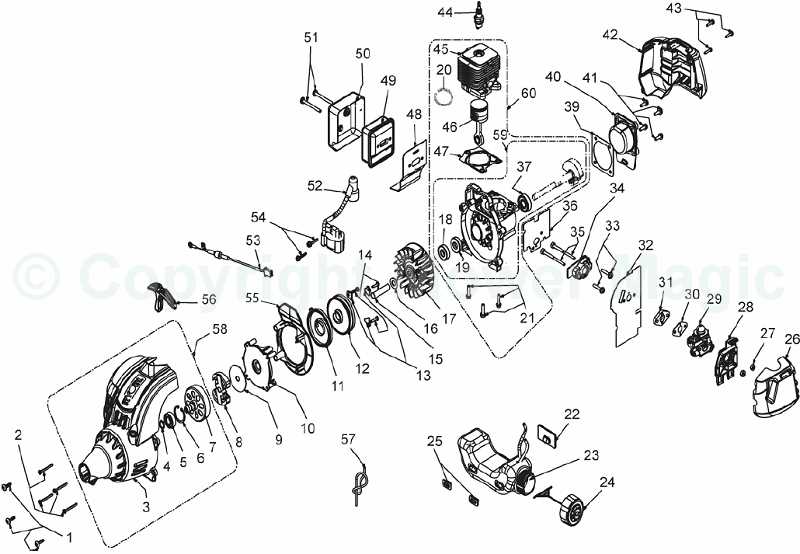

Understanding the Parts Diagram for Ryobi TSS102L

When it comes to maintaining and optimizing your cutting equipment, grasping the layout and function of its various elements is crucial. Each component plays a pivotal role in ensuring efficiency and precision during operation. By familiarizing yourself with these parts, you can enhance the longevity and performance of your device.

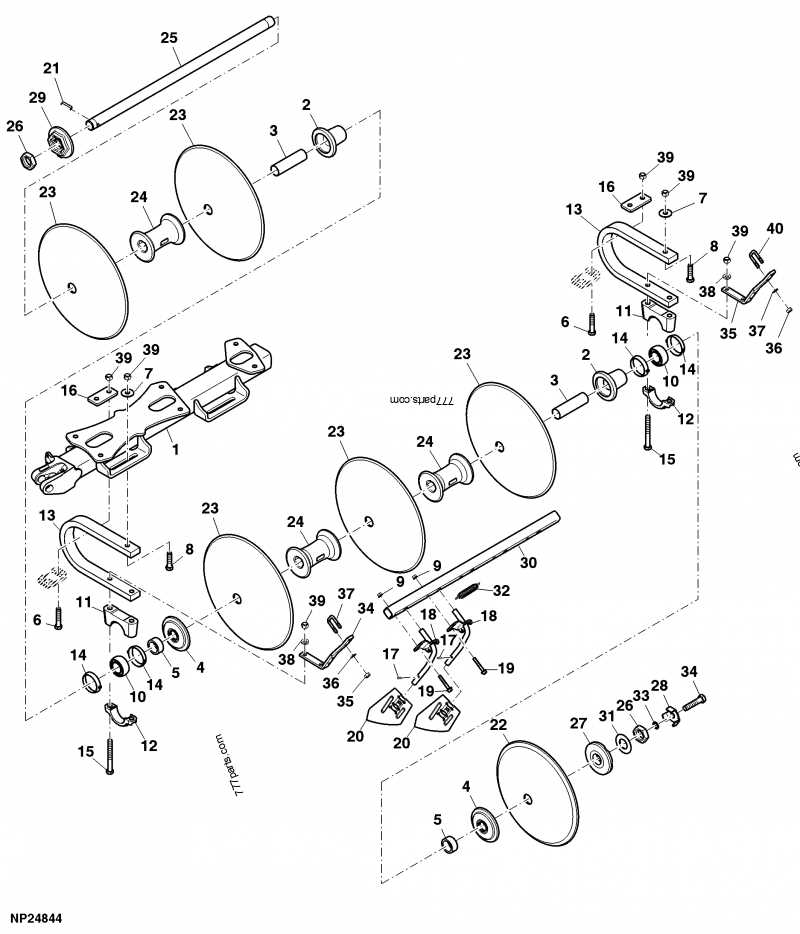

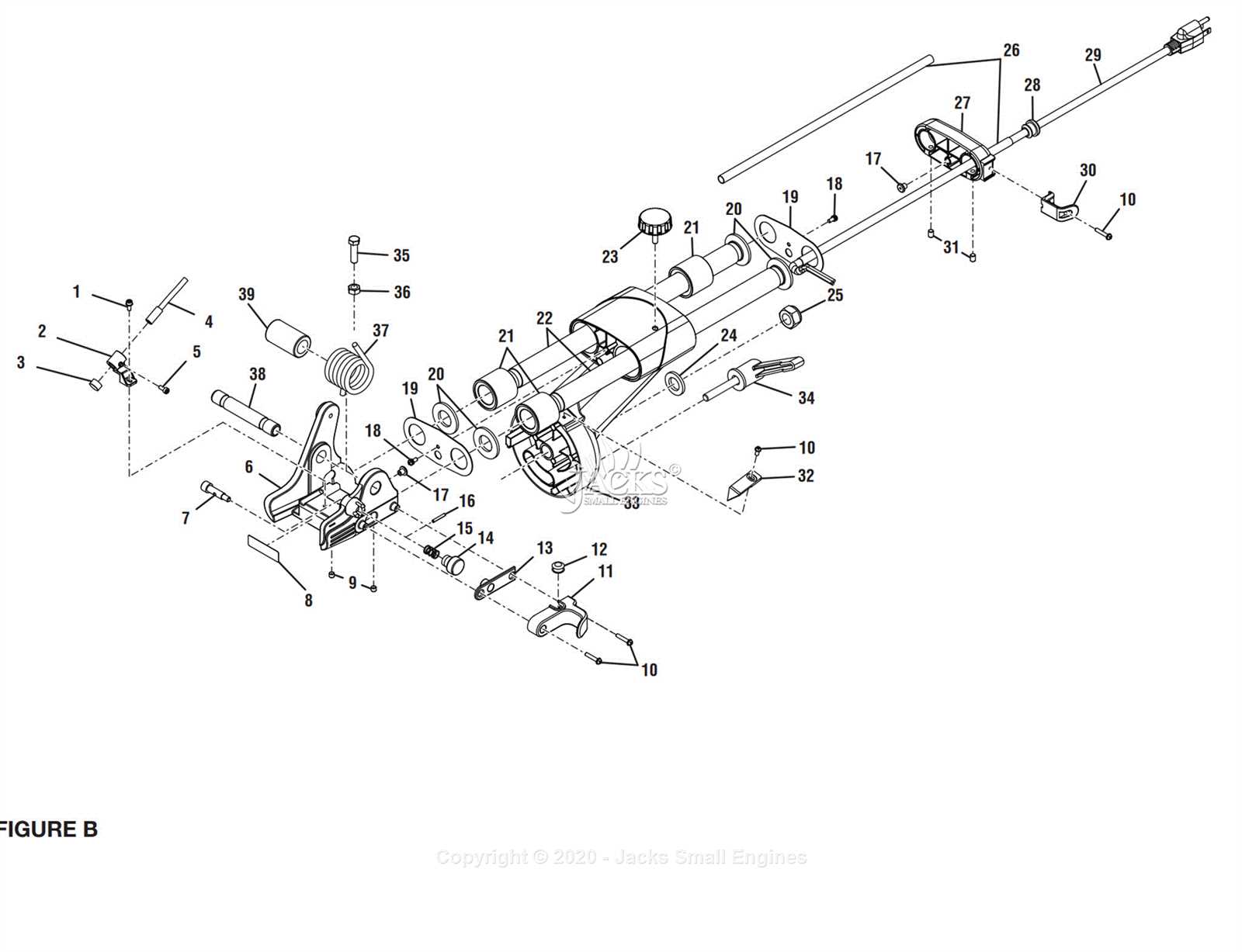

Visualization of the arrangement and connection of these elements can significantly aid in troubleshooting and repairs. A clear representation can help you quickly identify the specific areas that require attention. This understanding not only streamlines maintenance but also empowers you to tackle any issues that arise.

Ultimately, having a detailed overview of your tool’s structure can make all the difference in effective usage. Whether you’re a hobbyist or a professional, taking the time to delve into the intricacies of your equipment ensures that you achieve the best results consistently.

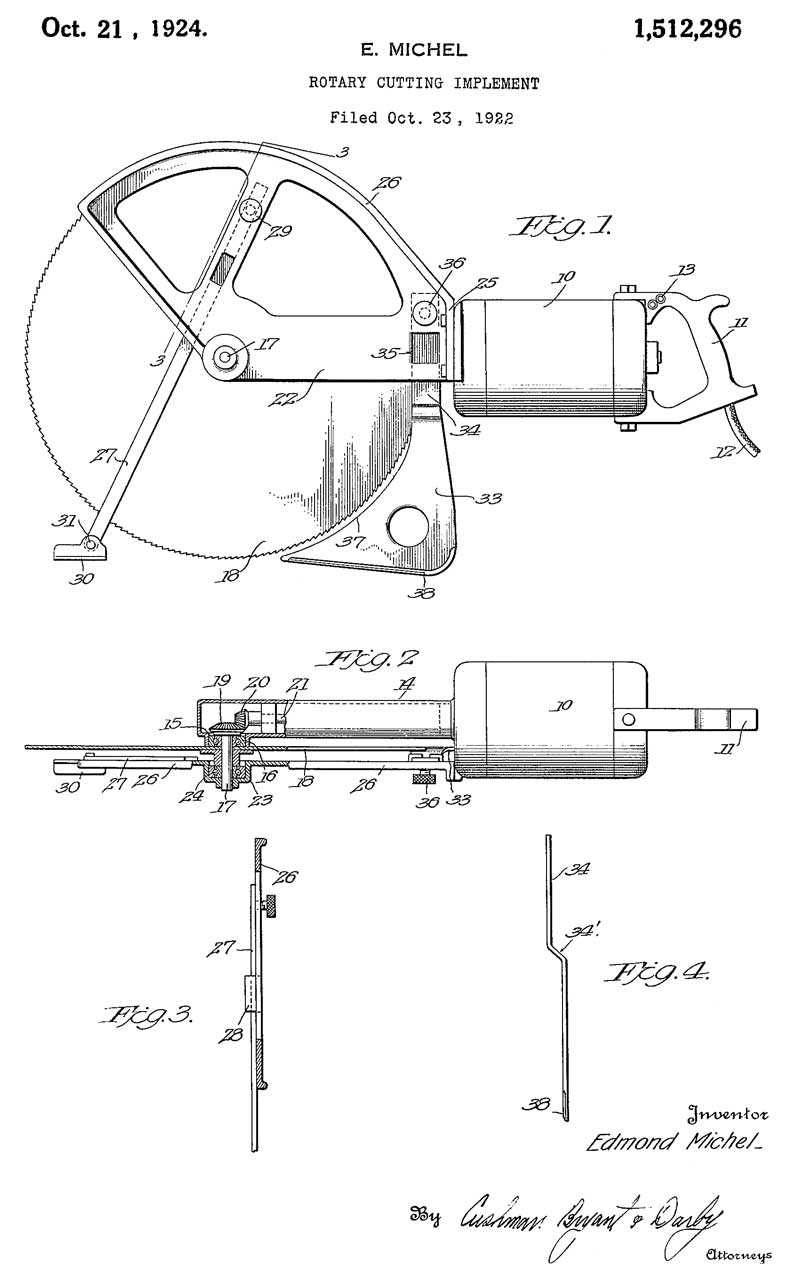

Understanding the Ryobi TSS102L

This section explores a popular tool designed for precision cutting and versatility in various projects. It combines ease of use with robust performance, making it a favorite among DIY enthusiasts and professionals alike.

Key Features

- Compact design for easy transport and storage.

- Powerful motor ensuring efficient cutting.

- Adjustable settings for customized performance.

- Durable construction for long-lasting use.

Applications

- Ideal for woodworking projects.

- Useful in home improvement tasks.

- Suitable for crafting and hobby activities.

Importance of Parts Diagrams

Understanding the intricacies of a machine requires a clear visual representation of its components and their relationships. Such illustrations serve as invaluable tools for maintenance, repair, and assembly, ensuring users can navigate the complexities of mechanical systems with ease.

Enhancing Efficiency in Repairs

When issues arise, having access to a detailed visual reference streamlines the troubleshooting process. It allows technicians to quickly identify malfunctioning elements and understand how they interact with other parts. This efficiency not only saves time but also reduces the likelihood of errors during repairs.

Facilitating Accurate Assembly

For those involved in constructing or reassembling equipment, these visual guides are crucial. They provide step-by-step instructions, highlighting the correct placement and orientation of each component. By following these illustrations, users can achieve a seamless assembly process, minimizing the risk of misalignment or improper installation.

In summary, visual representations of machinery play a critical role in maintenance and assembly tasks. They enhance understanding, improve efficiency, and ultimately contribute to the longevity and reliability of the equipment.

Key Components of the TSS102L

The essential elements of this cutting tool play a crucial role in its overall functionality and performance. Understanding these components can significantly enhance the user experience and ensure optimal results during operation.

Motor: The powerhouse of the machine, the motor is responsible for delivering the necessary torque and speed. A high-quality motor ensures efficient cutting and can handle various materials with ease.

Base: The sturdy base provides stability and support, allowing for precise cuts. A well-designed base minimizes vibrations and helps maintain accuracy, particularly during extended use.

Blade: The cutting edge of any tool, the blade must be sharp and durable to effectively slice through different materials. Selecting the right type of blade can greatly impact the quality of the finished work.

Fence: This component acts as a guide for making straight cuts. An adjustable fence allows users to set the desired width for repetitive cuts, improving efficiency and consistency.

Dust Collection: Effective dust management is essential for maintaining a clean workspace. A built-in dust collection system helps keep the area tidy and reduces cleanup time, promoting a safer environment.

Each of these vital components contributes to the overall performance and user satisfaction of the tool. Proper maintenance and understanding of their functions can extend the lifespan of the equipment and enhance its effectiveness.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to repair or assemble machinery. These visual guides provide a clear representation of individual components, allowing users to identify and locate each piece effectively. Familiarity with the symbols and layout can significantly enhance the repair process, making it more efficient and straightforward.

To interpret these illustrations accurately, follow these steps:

| Step | Description |

|---|---|

| 1 | Begin by examining the overall layout to grasp the structure and organization of the items. |

| 2 | Identify the legend or key, which explains symbols and reference numbers used throughout the visual. |

| 3 | Look closely at each component’s position to understand how they connect and function together. |

| 4 | Cross-reference the identified elements with a list of specifications for further clarity on dimensions and compatibility. |

By mastering these techniques, you’ll ultimately enhance your ability to navigate and utilize technical illustrations, paving the way for successful repairs and maintenance tasks.

Common Replacement Parts Overview

Maintaining equipment in optimal condition often requires replacing certain components. Understanding the most frequently needed elements can enhance performance and extend the lifespan of your tool. This overview provides insights into those key pieces that are essential for efficient operation.

Blades: Sharp, quality blades are crucial for precision cutting. Regular replacement ensures clean cuts and minimizes strain on the motor.

Motors: Over time, motors can wear down due to heavy use. Identifying signs of decline early allows for timely upgrades, keeping your device running smoothly.

Switches: A malfunctioning switch can halt operation entirely. Keeping a spare can be a practical solution to avoid downtime during projects.

Bearings: These components help reduce friction, ensuring that moving parts operate seamlessly. Replacing worn bearings can significantly improve performance.

Feet: Feet provide stability and support. Regular checks can prevent damage and ensure your equipment stays secure during use.

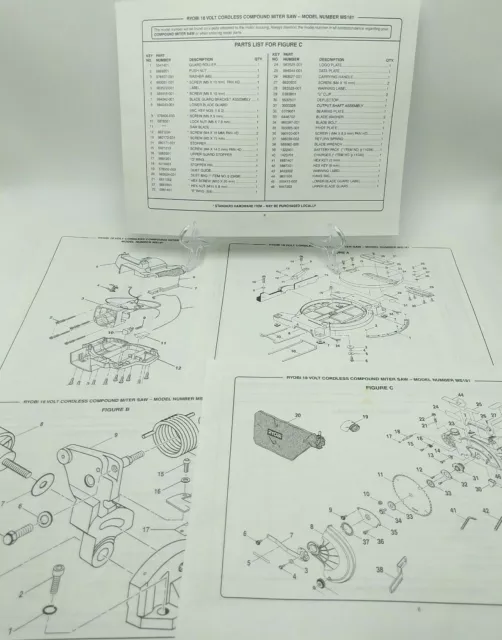

Finding Official Ryobi Diagrams

Accessing authentic schematics for power tools can significantly enhance maintenance and repair efforts. By utilizing reliable sources, users can ensure they have the most accurate information, allowing for efficient troubleshooting and part replacement. This guide will outline the best methods for locating these essential resources.

| Method | Description |

|---|---|

| Manufacturer’s Website | Visit the official site for comprehensive resources and downloadable illustrations. |

| Authorized Dealers | Contact local retailers or service centers for printed guides and support. |

| Online Forums | Engage with community discussions where enthusiasts share resources and insights. |

| Manuals and Documentation | Search for product manuals, which often include detailed breakdowns of components. |

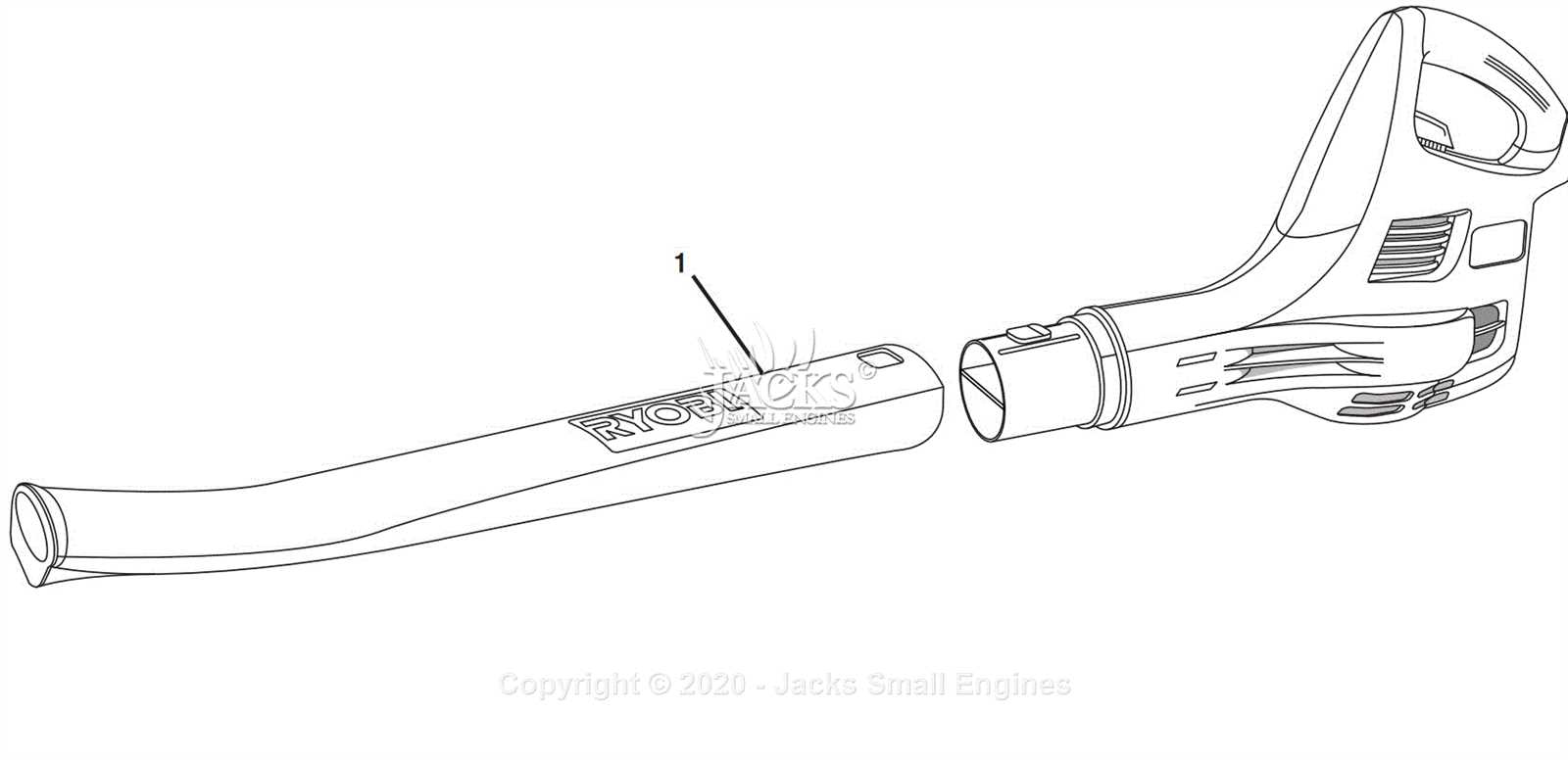

Aftermarket Parts and Accessories

Exploring alternatives in the market can significantly enhance performance and versatility. These supplementary items often provide improved durability, functionality, and tailored solutions for specific needs.

Benefits of Upgraded Components

Investing in quality enhancements can lead to better efficiency and extended longevity. Superior materials and design improvements frequently translate to a more satisfying user experience.

Popular Add-ons

Among the sought-after enhancements are precision blades, improved bases, and advanced safety features. Choosing the right accessories can greatly influence the effectiveness of your equipment.

Tips for Maintaining Your Tool

Proper care of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance can prevent issues and enhance efficiency, making your work easier and more enjoyable. Below are some valuable tips to help you keep your tools in top shape.

| Tip | Description |

|---|---|

| Clean Regularly | Remove dust and debris after each use to prevent buildup and corrosion. |

| Inspect Components | Regularly check for wear and tear to identify any parts that may need replacement. |

| Lubricate Moving Parts | Use appropriate lubricants to ensure smooth operation and reduce friction. |

| Store Properly | Keep your tools in a dry, organized space to protect them from damage. |

| Follow Manufacturer Guidelines | Refer to the user manual for specific maintenance recommendations tailored to your equipment. |

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration is essential for maintaining the longevity and efficiency of your tools. By regularly checking for specific signs, users can ensure that equipment operates optimally and avoid unexpected failures. This guide outlines key features to inspect during routine maintenance.

Common Indicators

Several noticeable signs can indicate wear and tear. These may include unusual noises during operation, decreased performance, and visible damage to components. Understanding these signs can help in timely interventions.

Inspection Checklist

| Sign | Description |

|---|---|

| Frayed Cables | Check for any exposed wires or wear on the insulation that could pose safety risks. |

| Worn Bearings | Listen for grinding sounds, indicating that the bearings may need replacement. |

| Cracks in Housing | Inspect for visible cracks that could affect the structural integrity of the tool. |

| Dull Blades | Examine cutting edges for dullness, as this can lead to inefficient performance. |

Where to Purchase Replacement Parts

Finding the right components for your tools is essential for maintaining their performance and longevity. There are several avenues to explore when seeking to acquire these necessary items, ensuring you have access to quality replacements that meet your needs.

Online retailers offer a vast selection, often with detailed descriptions and customer reviews to aid in your decision-making. Popular e-commerce platforms typically stock a variety of options, allowing for easy comparison of prices and features.

Additionally, local hardware stores and specialized tool shops can provide personalized assistance and immediate access to parts. Engaging with knowledgeable staff can also help you identify the correct components and any compatible alternatives.

Manufacturer websites frequently feature direct sales or links to authorized dealers, ensuring authenticity and proper fit. Signing up for newsletters may also alert you to exclusive promotions and new arrivals.

Lastly, consider exploring online marketplaces and community forums where users share experiences and resources, potentially leading you to reliable sellers and hard-to-find items.

DIY Repair vs. Professional Help

When it comes to fixing or maintaining equipment, many individuals face the dilemma of whether to tackle the task themselves or seek assistance from a professional. This choice often hinges on factors such as skill level, complexity of the job, and budget constraints. Understanding the pros and cons of each approach can help you make an informed decision.

Advantages of DIY Repair

- Cost Savings: Handling repairs yourself can significantly reduce expenses associated with labor costs.

- Skill Development: Engaging in hands-on work enhances your knowledge and abilities, making future repairs easier.

- Flexibility: You can work at your own pace and schedule, allowing for greater convenience.

Benefits of Professional Assistance

- Expertise: Professionals bring experience and specialized knowledge, ensuring that repairs are done correctly and efficiently.

- Time Efficiency: Experts can complete tasks more quickly, saving you time and effort.

- Warranty Protection: Using a professional may help preserve any existing warranties on the equipment.

Ultimately, the choice between DIY and professional help depends on the specific situation and personal preference. Evaluating the complexity of the repair, your own capabilities, and the potential risks involved can guide you toward the best decision.

Benefits of Using Original Parts

Choosing components from the original manufacturer offers numerous advantages that enhance the overall performance and longevity of your equipment. These elements are specifically designed to fit perfectly and operate seamlessly with your tools, ensuring optimal functionality.

Quality Assurance: Original components are crafted with high standards of quality control, resulting in superior durability and reliability. This commitment to excellence minimizes the risk of malfunctions and extends the lifespan of your machinery.

Compatibility: Utilizing parts from the original source guarantees perfect compatibility with your device. This not only ensures smooth operation but also reduces the likelihood of damage caused by improper fitting or mismatched specifications.

Warranty Protection: When you use genuine components, you often maintain the warranty coverage of your equipment. This protection can save you significant costs in repairs or replacements in the event of a malfunction.

Performance Optimization: Original parts are engineered to work in harmony with your tool’s system, delivering optimal performance. This integration enhances efficiency and productivity, allowing you to achieve the best results in your tasks.

Support and Assistance: Purchasing components from the original manufacturer typically comes with access to customer support and guidance. This can be invaluable for troubleshooting and ensuring that you are using the right parts for your equipment.