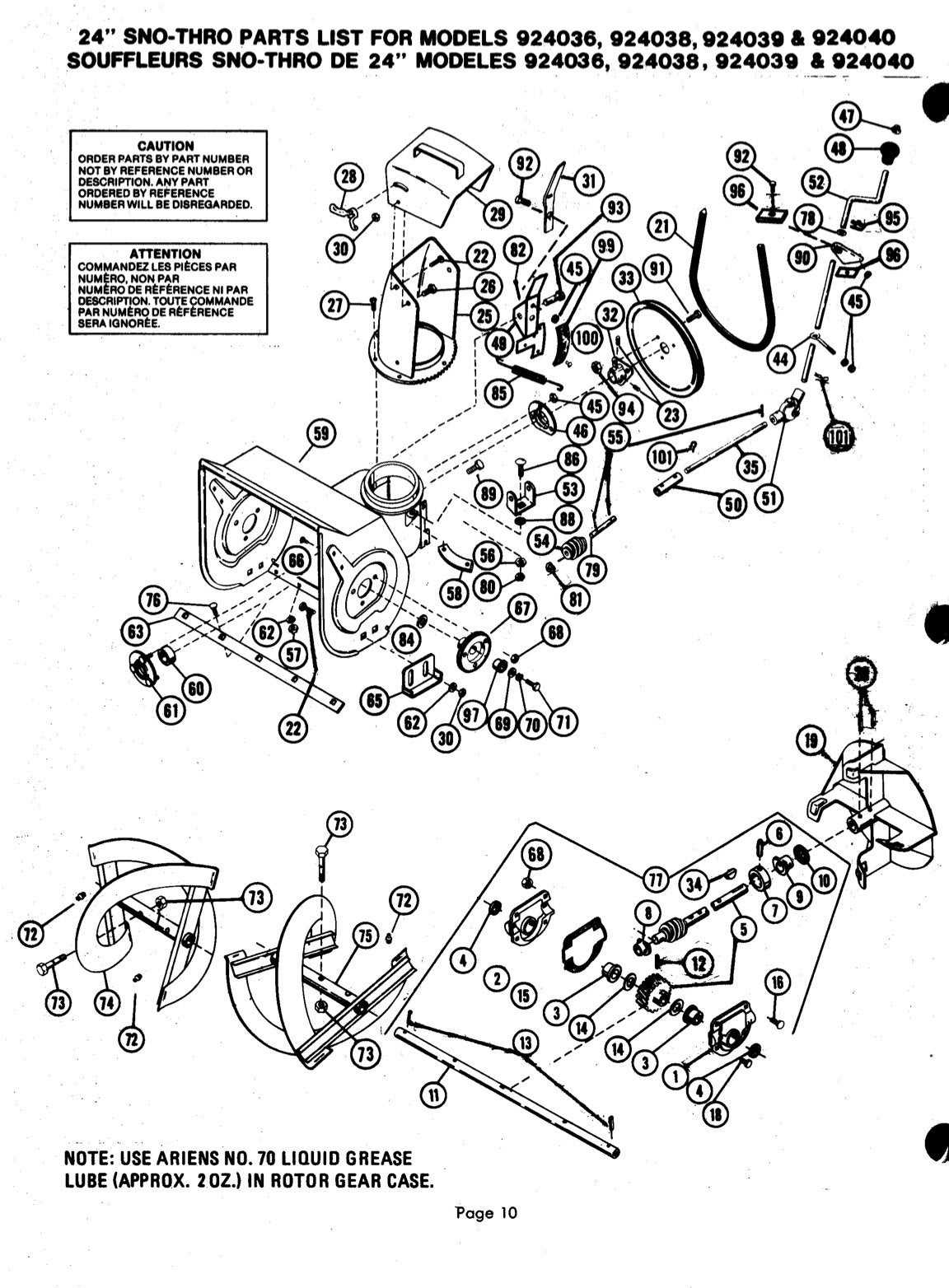

Ariens Snowblower Parts Overview

Maintaining winter machinery is crucial for effective snow management. Knowing the individual elements that contribute to the functionality of these machines ensures they operate smoothly during harsh weather conditions. Each component plays a significant role in enhancing performance and reliability.

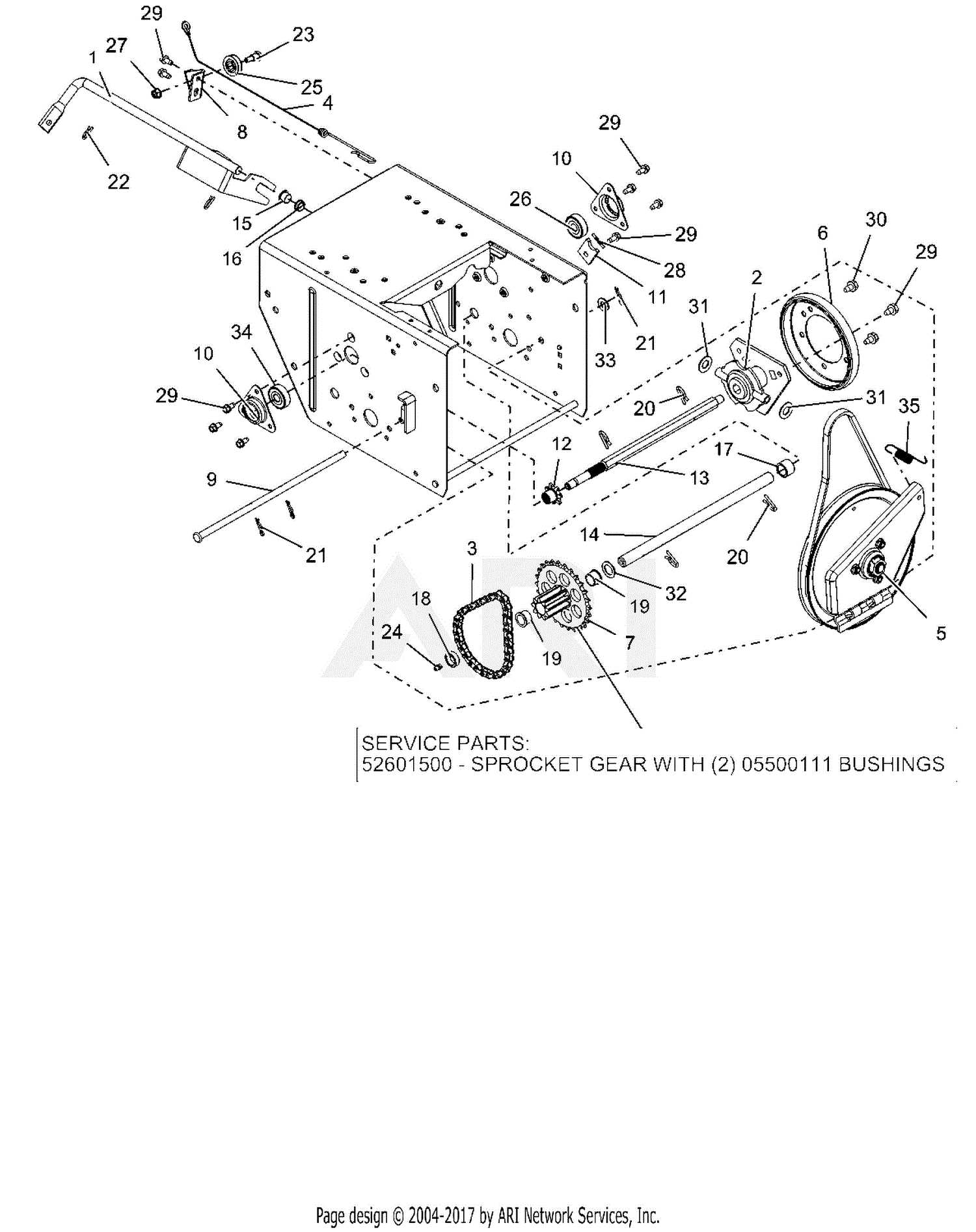

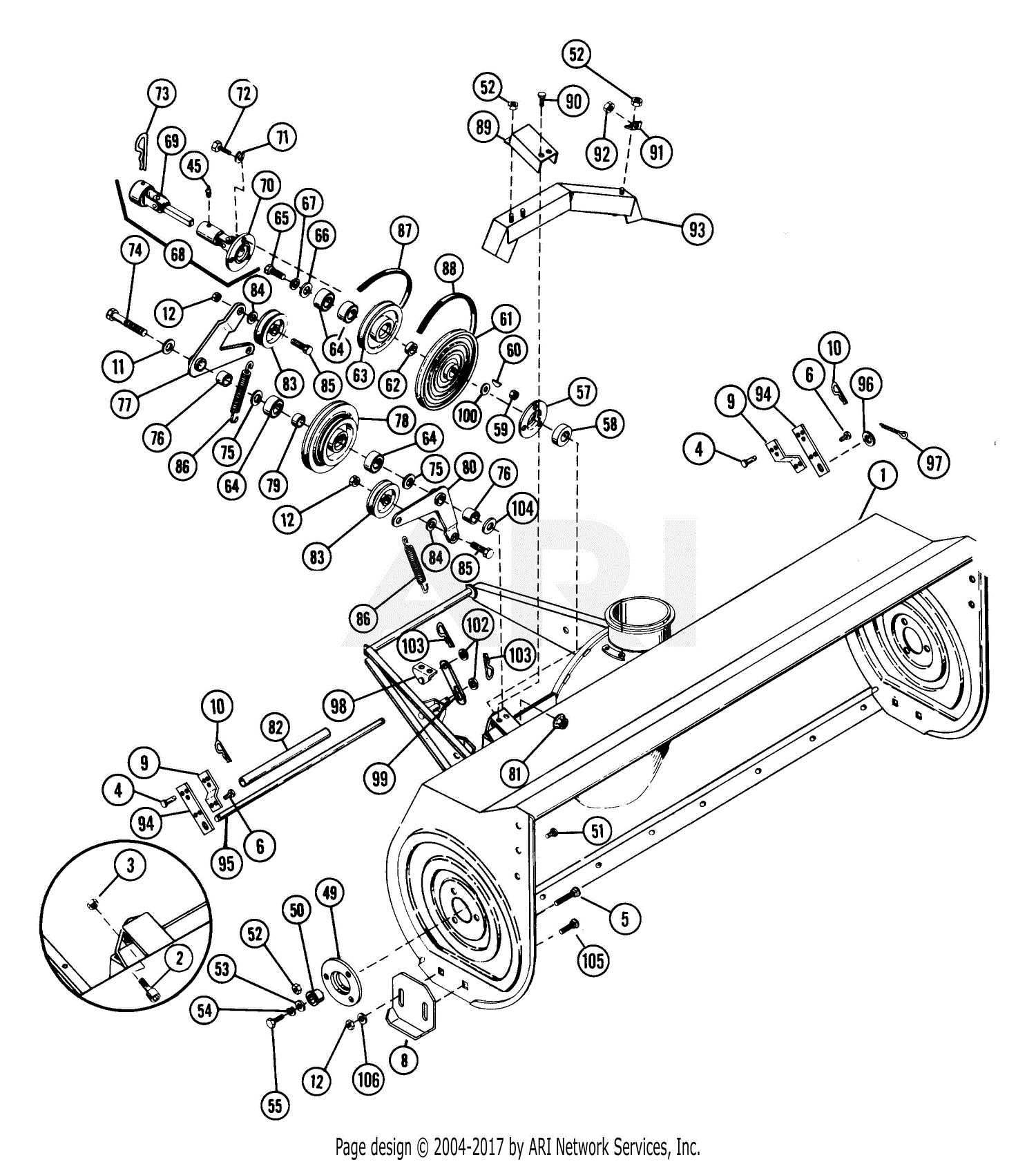

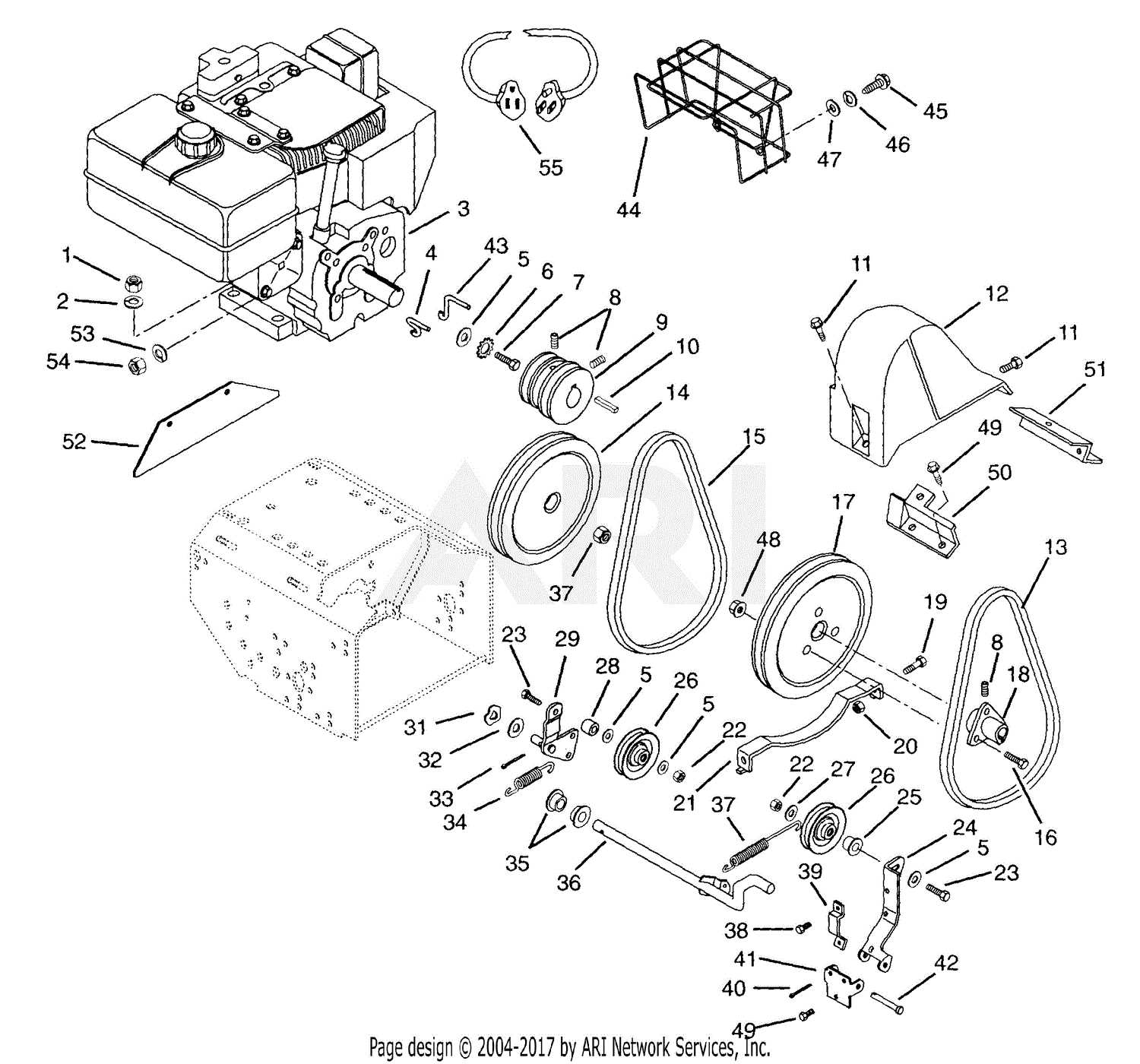

For anyone involved in the upkeep of snow-clearing machines, having a clear view of how these elements are organized can greatly facilitate repairs and replacements. Familiarity with the layout and interaction between parts can save time and effort when addressing issues or performing routine maintenance.

Furthermore, understanding the structure of the equipment allows users to make informed decisions regarding upgrades or modifications. This knowledge not only enhances the machine’s efficiency but also prolongs its lifespan, making it a valuable asset for any winter enthusiast.

Overview of Components for Snow Removal Equipment

This section provides a comprehensive look at the essential elements of equipment designed for clearing snow. Understanding the various components is crucial for effective maintenance and efficient operation. By familiarizing oneself with these parts, users can ensure their machinery functions optimally during the winter months.

Main Components

- Engine: The power source that drives the entire mechanism.

- Chassis: The structural framework that supports all other parts.

- Auger: The rotating blade that collects snow and moves it towards the discharge chute.

- Discharge Chute: The exit point through which snow is expelled.

- Control Panel: The interface for operating various functions of the machine.

Maintenance Tips

- Regularly inspect all components for wear and damage.

- Ensure the engine is properly lubricated to avoid overheating.

- Clean the auger and discharge chute after each use to prevent clogging.

- Check the control panel connections to ensure all functions are responsive.

- Store the equipment in a dry place to protect it from rust and corrosion.

Understanding Snowblower Components

To effectively operate and maintain winter clearing equipment, it is essential to grasp the various elements that contribute to its functionality. Each component plays a critical role in ensuring optimal performance, facilitating tasks such as snow removal with efficiency and ease.

Typically, these machines consist of multiple sections, including the engine, drive system, and the mechanism responsible for displacing snow. The engine serves as the powerhouse, providing the necessary energy for operation. Meanwhile, the drive system allows for mobility across different terrains, making it easier to navigate through snow-covered areas.

Another significant aspect is the clearing mechanism, which directly engages with the snow. This system includes various tools that enhance effectiveness in breaking up and moving snow aside. Understanding the interplay of these components will enable users to troubleshoot issues and optimize the use of their equipment.

Common Issues and Solutions

Operating a snow removal machine can present various challenges. Understanding these frequent problems and their corresponding remedies can enhance efficiency and extend the lifespan of the equipment. This section addresses common malfunctions that users may encounter, along with practical solutions to resolve them.

Starting Difficulties

Many users experience issues when attempting to start their equipment. Factors contributing to this problem may include fuel-related issues, electrical failures, or mechanical malfunctions. To troubleshoot, check the fuel level and quality, inspect the battery and wiring connections, and ensure all controls are in the correct position.

Poor Performance

Machines may not perform optimally due to clogging, inadequate maintenance, or improper adjustments. If the machine fails to remove snow effectively, consider examining the intake and discharge areas for blockages. Regular maintenance, such as oil changes and filter replacements, is essential for peak performance.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Starting Difficulties | Low fuel, dead battery, faulty wiring | Check fuel levels, charge or replace battery, inspect wiring |

| Poor Performance | Blockages, lack of maintenance | Clear clogs, perform regular maintenance |

Maintenance Tips for Longevity

Ensuring the durability of outdoor machinery requires consistent care and attention. By implementing a regular maintenance routine, you can significantly enhance the performance and lifespan of your equipment. This section offers practical suggestions to help you keep your machine in top condition throughout its use.

Regular Inspections

Conducting frequent assessments is crucial for identifying potential issues early. Check for any signs of wear, damage, or loose components that may affect functionality. Addressing these problems promptly can prevent more significant repairs down the line.

Proper Storage Techniques

When not in use, store your equipment in a clean, dry place. Shielding it from extreme weather conditions can prevent rust and corrosion. Additionally, removing any debris and ensuring that the machine is free from snow or moisture will help maintain its overall condition.

Identifying Replacement Parts

Understanding the components of your equipment is crucial for effective maintenance and repairs. Recognizing the specific elements that require substitution can enhance performance and prolong the lifespan of your machine. This section outlines the essential steps to identify the necessary components for your equipment efficiently.

Begin by examining the user manual, which often includes a detailed overview of each component and its function. If the manual is unavailable, online resources or manufacturer websites can provide valuable information. Additionally, you can consult diagrams that illustrate the arrangement and labeling of various components.

| Component | Description | Common Issues |

|---|---|---|

| Drive Belt | Transfers power from the engine to the auger and impeller. | Worn or frayed belts can lead to reduced efficiency. |

| Auger | Helps in breaking up and moving snow. | Dents or bends may hinder its performance. |

| Shear Pins | Protect the auger from damage by breaking under excessive stress. | Broken pins can cause the auger to become inoperative. |

| Skid Shoes | Adjust the height of the machine to avoid scraping the ground. | Worn shoes may result in uneven clearing. |

Importance of Genuine Parts

Utilizing authentic components is crucial for maintaining the longevity and performance of your machinery. Original elements are designed specifically to fit and function seamlessly within the system, ensuring optimal efficiency and reliability. By choosing genuine replacements, users can prevent premature wear and reduce the likelihood of malfunction.

Benefits of Authentic Components

- Enhanced Durability: Genuine items are manufactured to meet strict quality standards, providing greater resistance to wear and tear.

- Improved Performance: Original parts are engineered to work harmoniously with your equipment, ensuring consistent operation and peak performance.

- Warranty Protection: Many manufacturers require the use of genuine components to maintain warranty coverage, safeguarding your investment.

Risks of Using Imitation Components

- Increased Breakdowns: Non-genuine parts may not fit properly, leading to inefficiencies and frequent malfunctions.

- Higher Long-term Costs: The use of inferior items often results in more frequent replacements and repairs, ultimately costing more.

- Safety Concerns: Imitation components may not adhere to safety regulations, posing potential hazards to users.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right tools is essential for ensuring efficiency and effectiveness. A well-prepared toolkit not only simplifies the repair process but also enhances safety and reduces the risk of damage to the machinery. Understanding which tools are necessary can greatly facilitate troubleshooting and repair tasks.

Essential Hand Tools

Basic hand tools are fundamental for any repair job. These typically include wrenches, screwdrivers, and pliers. A variety of sizes and types will be needed to address different components effectively. Additionally, socket sets can provide added versatility, allowing for quicker adjustments and removals.

Power Tools and Accessories

For more complex repairs, power tools can significantly speed up the process. Drills and impact wrenches are invaluable for loosening stubborn fasteners. Always ensure you have the proper bits and attachments for compatibility. Furthermore, having an angle grinder or saw can be beneficial for cutting or reshaping parts as needed.

Step-by-Step Repair Guide

This section provides a comprehensive approach to diagnosing and fixing common issues encountered in outdoor machinery. Following a systematic method can help ensure that all necessary adjustments and replacements are made efficiently, restoring functionality and enhancing performance.

Identifying the Problem

Begin by assessing the symptoms of malfunction. Listen for unusual noises, check for leaks, and observe any irregularities in operation. Documenting these observations will aid in pinpointing the exact cause of the issue.

Gathering Necessary Tools

Before commencing repairs, assemble all required tools and materials. Common tools may include wrenches, screwdrivers, and replacement components. Having everything on hand will streamline the repair process and reduce downtime.

Seasonal Preparation for Snowblowers

Properly preparing your equipment for the winter season ensures optimal performance and longevity. This involves a series of essential steps that should be taken to ready your machine for snowy conditions. Adhering to these guidelines can help you avoid potential issues when the snow begins to fall.

Essential Maintenance Steps

- Check and change the oil to ensure smooth operation.

- Inspect the fuel system, replacing old fuel with fresh gasoline if necessary.

- Examine the spark plug and clean or replace it to ensure efficient ignition.

- Sharpen or replace the cutting blades for effective snow removal.

- Test the electrical system, including the battery and lights, to confirm functionality.

Storage and Protection

Proper storage techniques can significantly extend the life of your equipment. Consider the following:

- Store the machine in a dry, sheltered area to protect it from moisture and corrosion.

- Cover the equipment with a tarp or specific cover to prevent dust accumulation.

- Disconnect the battery if the equipment will not be used for an extended period.

Upgrading Your Snowblower

Enhancing your winter equipment can significantly improve its performance and longevity. Investing in quality upgrades not only boosts efficiency but also ensures a smoother operation during heavy snowfall. Whether you’re looking to increase power, enhance maneuverability, or simply update older components, there are various options available to elevate your machine’s capabilities.

Evaluate Your Current Equipment: Before proceeding with upgrades, assess the condition of your existing machine. Identify any worn-out components or features that may hinder performance. A thorough evaluation will help you prioritize which enhancements will yield the best results.

Consider Engine Modifications: Upgrading the engine can provide a notable boost in power. Look for high-performance models or components that can enhance fuel efficiency and increase torque. Proper installation and tuning are essential for optimal performance.

Improve Maneuverability: Enhancements such as larger or specialized tires can significantly improve traction and control. Additionally, consider modifying the chassis for better stability and ease of handling in challenging conditions.

Optimize Performance with Attachments: Adding specific attachments can greatly expand the functionality of your equipment. Consider options like additional blades or specialized hoppers that can enhance your machine’s versatility and efficiency during use.

Regular Maintenance and Upkeep: Maintaining your equipment is crucial for longevity and optimal performance. Regularly inspect and replace any worn parts, and follow a strict maintenance schedule to ensure your machine operates at its best, especially after upgrades.

Safety Precautions During Repairs

When undertaking maintenance on equipment, ensuring personal safety and preventing accidents should be the foremost priority. Adhering to essential precautions not only protects the individual performing the repairs but also extends the lifespan of the machinery involved.

Essential Safety Gear

- Protective eyewear: Always wear goggles to shield your eyes from debris and flying particles.

- Gloves: Use durable gloves to protect your hands from sharp edges and harmful substances.

- Non-slip footwear: Ensure proper footing to avoid slips and falls during the repair process.

Work Environment Considerations

- Ensure the workspace is well-lit to facilitate visibility and reduce the risk of accidents.

- Keep tools organized and within reach to prevent unnecessary movements that could lead to injuries.

- Clear the area of any obstructions or hazards that could impede movement or cause accidents.

Where to Find Diagrams and Manuals

Finding visual guides and instructional documents for your outdoor equipment can significantly enhance your understanding and maintenance capabilities. Various resources are available to help users locate these essential materials.

One reliable option is the manufacturer’s official website, where you can often access a wealth of resources, including manuals and assembly illustrations. Additionally, online forums and communities dedicated to equipment enthusiasts can provide valuable insights and shared resources. YouTube also serves as an excellent platform for instructional videos that can visually guide you through various processes.

Moreover, local hardware stores and specialty retailers may have printed materials or can order specific manuals on your behalf. Finally, don’t overlook the possibility of third-party websites that specialize in equipment resources, as they might host downloadable guides and diagrams that cater to your needs.