Understanding the Trs27 Snowblower Parts Diagram for Optimal Maintenance

When the cold season arrives, having the right tools can make all the difference in maintaining a clear and safe environment. Knowing the intricate elements of your equipment is essential for effective operation and maintenance. This section aims to provide clarity on the various elements that contribute to the overall functionality of your winter apparatus.

By delving into the specifics of these components, users can enhance their understanding of how each part interacts within the larger system. Recognizing these connections not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and replacements.

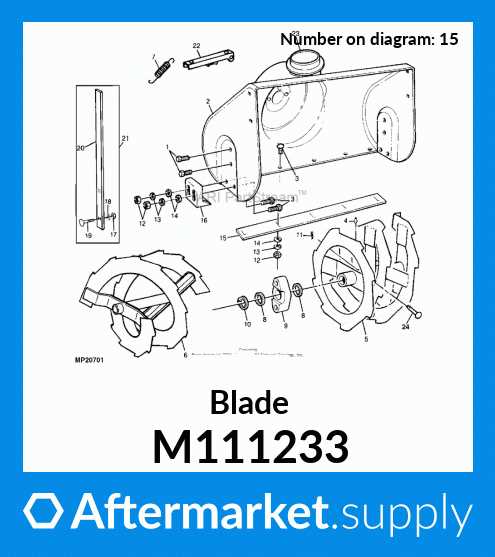

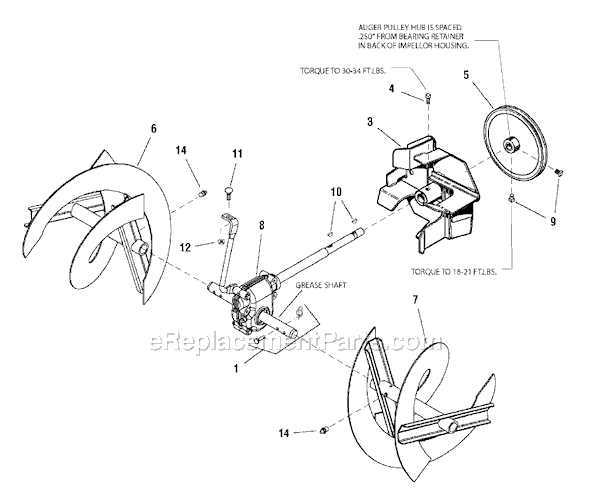

Moreover, visual references play a crucial role in this learning process. Illustrative guides can significantly simplify the comprehension of complex assemblies, making it easier for operators to identify and manage the various pieces. This understanding ultimately leads to improved performance and longevity of your winter tool.

Understanding Trs27 Snowblower Components

Gaining insight into the various elements of a winter clearing machine is essential for effective maintenance and operation. Each component plays a pivotal role in ensuring that the equipment functions smoothly during harsh conditions, enabling users to tackle snow with ease.

Key Elements of the Machine

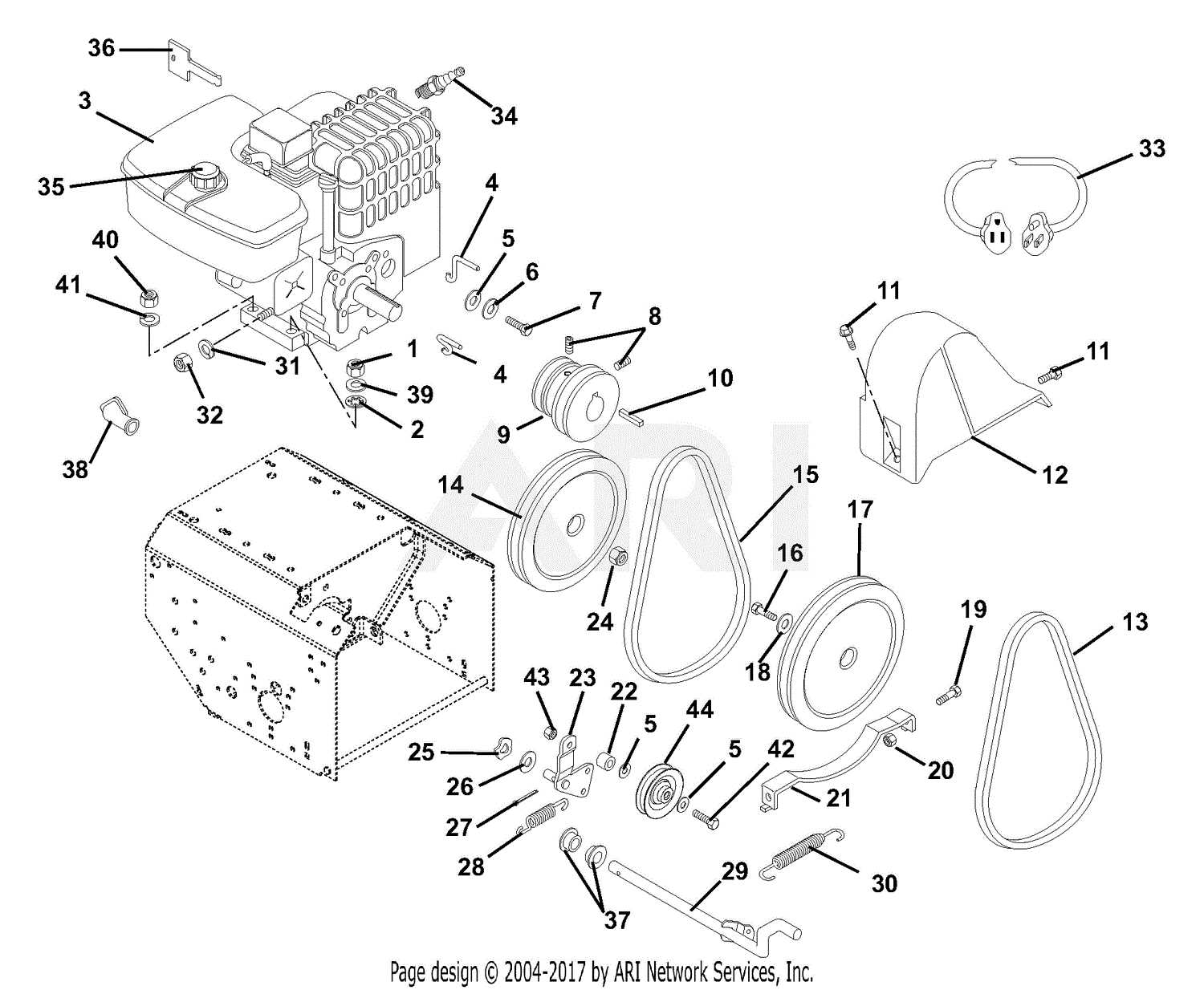

The primary features of this clearing device include the engine, auger assembly, and chute. Each part has a specific function that contributes to the overall efficiency and performance during use.

Component Overview

| Component | Function |

|---|---|

| Engine | Powers the entire system, providing necessary force for operation. |

| Auger Assembly | Collects and moves snow towards the chute for expulsion. |

| Chute | Directs snow away from the path of the machine. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining machinery. They serve as essential tools for both professionals and enthusiasts, ensuring clarity in identification and assembly.

- Enhances comprehension of complex structures.

- Aids in efficient troubleshooting and repairs.

- Facilitates accurate ordering of replacements.

- Improves safety by highlighting critical areas.

Overall, these visual guides are indispensable for ensuring the longevity and optimal performance of equipment.

Key Features of the Trs27 Model

This model stands out due to its robust design and efficiency in handling winter challenges. It combines user-friendly features with powerful performance, making it an essential tool for maintaining clear pathways during snowy conditions.

- Powerful Engine: Equipped with a high-performance engine that ensures reliable operation even in heavy snowfall.

- Adjustable Chute: Features an adjustable chute for directing snow exactly where needed, enhancing maneuverability.

- Ergonomic Controls: Designed with user comfort in mind, allowing for easy handling and reduced fatigue.

- Durable Construction: Built with high-quality materials to withstand harsh winter conditions and provide longevity.

- Easy Maintenance: Engineered for straightforward upkeep, ensuring optimal performance throughout the season.

These characteristics contribute to an ultimate snow-clearing experience, making it an indispensable asset for homeowners in winter climates.

Common Issues with Snowblower Parts

Understanding the typical problems that can arise with winter machinery is essential for effective maintenance and operation. Identifying these issues early can prevent larger failures and ensure smooth functionality during harsh weather conditions.

Frequent Problems Encountered

- Engine Difficulties: Issues such as hard starting, stalling, or reduced power output can occur, often linked to fuel quality or ignition system failures.

- Auger Blockages: Debris accumulation can lead to poor performance, requiring regular checks and clearing to maintain optimal operation.

- Drive System Malfunctions: Gear slippage or failure can hinder movement, often caused by wear and tear or improper adjustments.

- Electrical Failures: Faulty wiring or corroded connections can result in operational disruptions, demanding thorough inspections.

Preventative Measures

- Regular Maintenance: Schedule routine check-ups to ensure all components are functioning properly.

- Quality Fuel Use: Always opt for high-grade fuel to prevent engine-related issues.

- Proper Storage: Store the equipment in a dry, sheltered area to protect against weather damage.

- Timely Repairs: Address any signs of wear or malfunction immediately to avoid larger issues down the line.

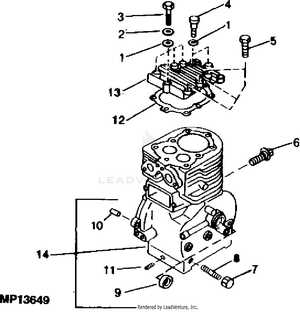

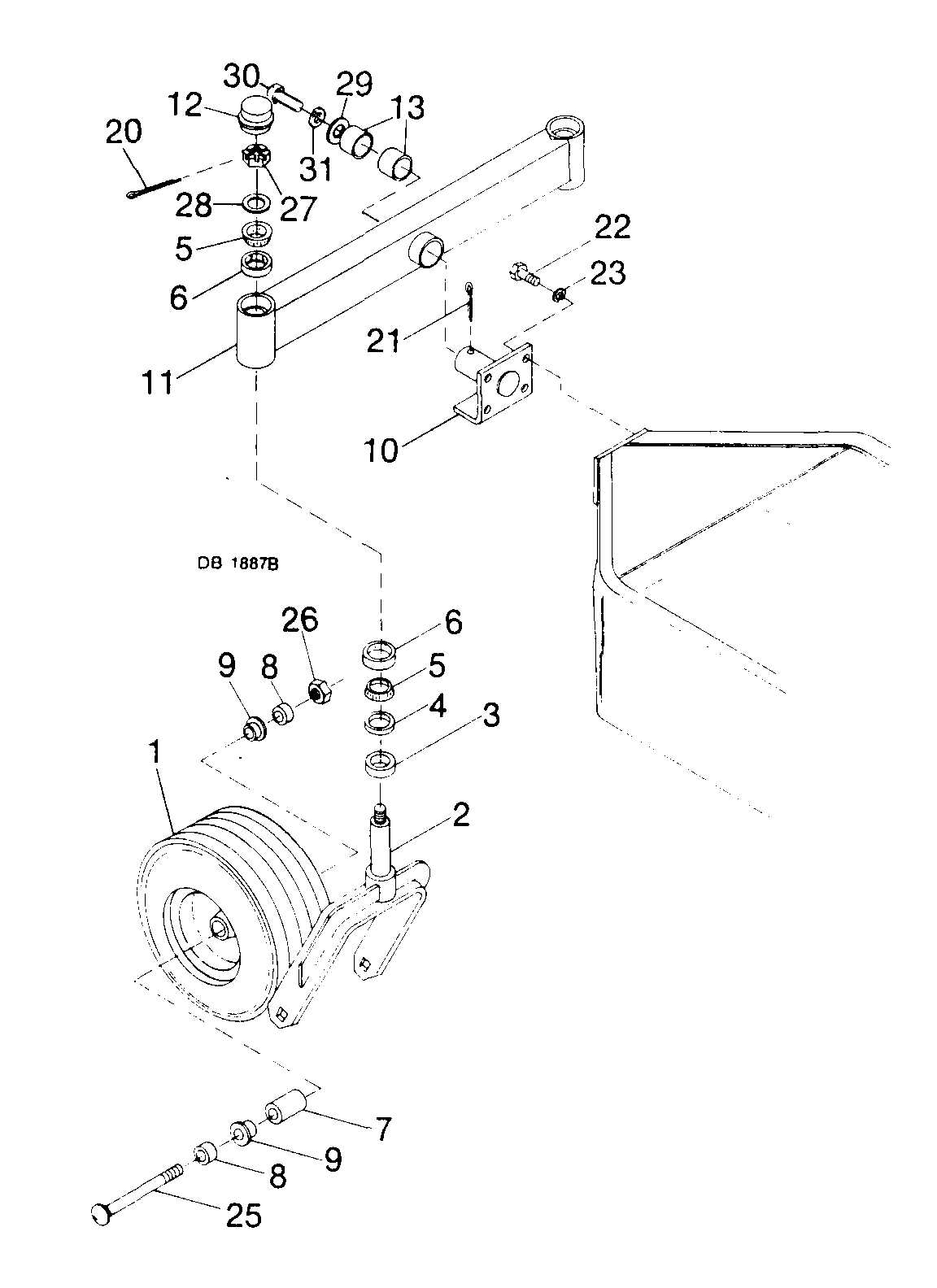

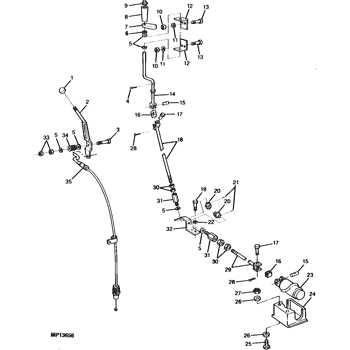

How to Interpret the Diagram

Understanding the layout of components is crucial for effective maintenance and repairs. Each element is represented visually, allowing users to identify specific sections and their relationships with one another. Mastering this representation can enhance efficiency and simplify troubleshooting processes.

Identifying Key Components

Start by familiarizing yourself with the various symbols and labels. Each icon corresponds to a particular part, often accompanied by a reference number. Pay close attention to these identifiers as they guide you in locating and ordering necessary replacements.

Understanding Relationships

Next, examine how the elements interact. Lines or arrows typically indicate connections, illustrating how parts work together. Recognizing these associations can help you pinpoint potential issues and understand the assembly better.

Maintenance Tips for Longevity

Proper care is essential for ensuring the durability and efficiency of your outdoor equipment. Regular maintenance not only enhances performance but also extends the lifespan, allowing you to maximize your investment.

| Task | Frequency | Description |

|---|---|---|

| Inspect belts | Monthly | Check for wear and tear; replace if frayed or damaged. |

| Clean air filter | Every season | Ensure optimal airflow by cleaning or replacing the filter. |

| Check oil levels | Every use | Maintain proper lubrication for smooth operation. |

| Sharpen blades | Every season | Keep cutting edges sharp for efficient performance. |

| Store properly | Off-season | Store in a dry place to prevent rust and damage. |

Replacing Worn Out Components

Maintaining equipment is crucial for optimal performance and longevity. Over time, certain elements may experience wear and tear, impacting efficiency and functionality. Regular inspections help identify these issues early, allowing for timely replacements and ensuring your machinery operates smoothly.

Common Signs of Wear: Look for decreased performance, unusual noises, or visible damage. Addressing these indicators promptly can prevent further complications and costly repairs.

Replacement Process: Begin by consulting the user manual for guidance on compatible replacements. Gather necessary tools and safely disassemble the affected area. Carefully install the new components, ensuring everything is securely fastened and aligned.

Final Check: After replacing components, conduct a thorough test to confirm everything is functioning correctly. This final step ensures that your efforts yield the ultimate results in efficiency and reliability.

Essential Tools for Repairs

Having the right equipment is crucial for efficient and effective maintenance tasks. A well-stocked toolkit can significantly streamline the repair process, ensuring that you are prepared for any challenge that arises. Below are some key tools that will enhance your ability to perform various fixes with confidence.

Basic Hand Tools

- Screwdrivers: A set of both flat-head and Phillips screwdrivers is essential for assembling and disassembling components.

- Wrenches: Adjustable wrenches and socket sets are vital for tightening and loosening nuts and bolts.

- Pliers: Needle-nose and slip-joint pliers provide versatility in gripping and bending various materials.

Specialized Equipment

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Diagnostic Tools: Multi-meters and diagnostic scanners help in identifying electrical issues effectively.

- Lubricants and Cleaners: High-quality lubricants and cleaning agents are essential for maintaining optimal performance and longevity.

Identifying Genuine Parts vs. Alternatives

When maintaining outdoor equipment, distinguishing between authentic components and substitutes is crucial for ensuring optimal performance and longevity. Authentic items often promise higher reliability and compatibility, while alternatives may appeal due to lower costs but can compromise efficiency.

Key indicators to assess include packaging quality, manufacturer branding, and available warranties. Authentic components typically feature clear labeling and thorough documentation, while alternatives may lack these details. Additionally, researching vendor reputations can provide insights into the reliability of the offered products.

Ultimately, investing in genuine components can enhance overall performance and reduce the risk of malfunction, making it a wise choice for serious users.

Safety Precautions During Maintenance

Ensuring safety while performing upkeep on equipment is paramount to prevent accidents and injuries. Proper precautions help create a secure environment, allowing for efficient work and the longevity of machinery.

Before starting any maintenance tasks, always disconnect power sources to eliminate the risk of unexpected activation. This step is essential for safeguarding both the operator and the equipment.

Wearing appropriate personal protective equipment (PPE) is crucial. Items such as gloves, goggles, and sturdy footwear can protect against potential hazards during repairs or inspections.

Keep the workspace organized and free of clutter. A tidy environment reduces the chances of trips or falls, ensuring that tools and parts are easily accessible when needed.

Finally, always consult the manufacturer’s guidelines for specific maintenance instructions and safety measures, as they provide the ultimate resource for safe practices.

Where to Find Replacement Parts

When seeking components for machinery maintenance, it’s essential to know where to look. Various sources can provide the necessary items to ensure optimal performance and longevity. Utilizing the right resources will save both time and effort in the search process.

Online Retailers: Numerous websites specialize in aftermarket components, offering detailed catalogs and often competitive pricing. These platforms enable users to filter results based on specific requirements, making it easier to find what is needed.

Local Dealers: Visiting authorized dealers can yield reliable options. These establishments often carry original equipment, ensuring compatibility and quality. Additionally, staff can offer valuable advice on maintenance and selection.

Second-Hand Markets: Exploring thrift stores, garage sales, and online marketplaces can uncover hidden gems. Many individuals sell unused or gently used components, providing an economical solution for those on a budget.

Forums and Community Groups: Engaging with online communities can lead to recommendations and insights from experienced users. Such platforms often feature discussions about sourcing and troubleshooting, helping to connect individuals with viable suppliers.

By utilizing these diverse avenues, individuals can effectively locate the necessary components to keep their machinery running smoothly.

Customer Support and Resources Available

Access to reliable assistance and informative resources is essential for users seeking to maintain and repair their equipment. Ensuring that customers have the support they need contributes significantly to overall satisfaction and efficient operation.

- Online Manuals: Comprehensive guides detailing assembly, maintenance, and troubleshooting procedures.

- Customer Service Hotline: Dedicated representatives available for immediate assistance and inquiries.

- FAQs Section: A collection of frequently asked questions addressing common concerns and issues.

- Community Forums: Interactive platforms where users can share experiences and solutions.

- Video Tutorials: Step-by-step visual guides for various repair and maintenance tasks.

By utilizing these resources, customers can effectively address their needs and enhance their overall experience with their equipment.