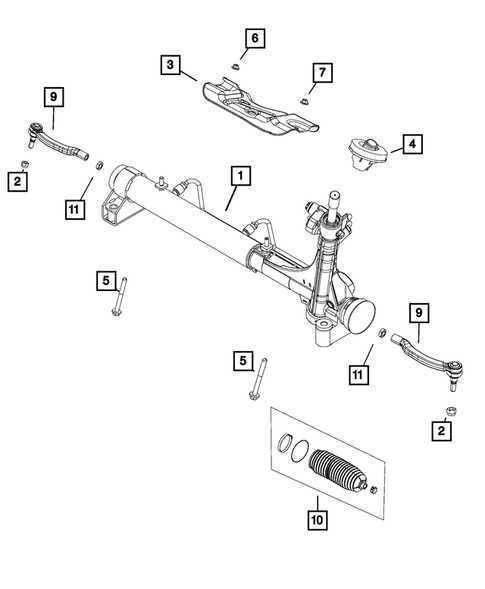

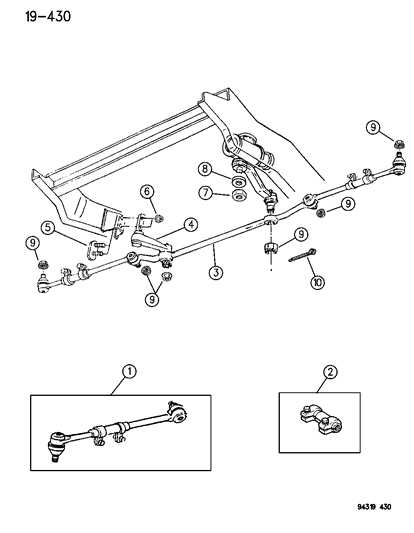

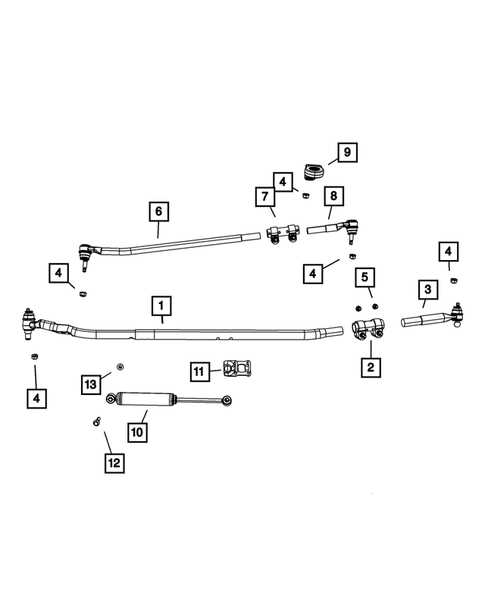

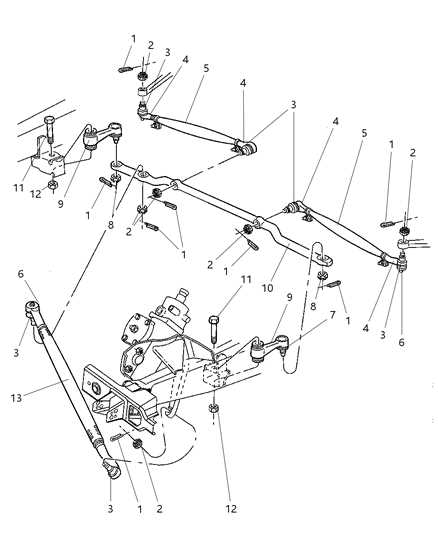

Dodge Ram Steering Parts Overview

In any vehicle, the ability to navigate effectively relies heavily on the intricate components that govern movement. These mechanisms work in unison, ensuring that the driver maintains control while enhancing overall safety and performance. A comprehensive examination of these elements reveals their essential roles and how they contribute to a seamless driving experience.

Delving into the specifics of the assembly, one can uncover a wealth of information about each individual element, their functions, and interrelations. Understanding these relationships is vital for anyone looking to perform maintenance or upgrades. Moreover, knowledge of these components can significantly enhance a driver’s awareness of their vehicle’s capabilities and limitations.

Through careful analysis and visualization of these crucial mechanisms, enthusiasts and professionals alike can develop a deeper appreciation for the engineering marvels that allow vehicles to function optimally. This section aims to provide a clear representation of these critical components, facilitating a better understanding for all interested parties.

The effectiveness of a vehicle’s maneuverability largely relies on the fundamental elements of its control system. These critical components work in unison to ensure precise handling and driver responsiveness. Understanding their functions and interconnections is essential for maintaining optimal performance.

Central Linkage

Central linkage serves as the core element, connecting various elements and enabling fluid communication between the driver and the wheels. This component plays a vital role in translating the driver’s input into directional movement, thereby enhancing overall vehicle control.

Control

Understanding Steering Gear Mechanism

The mechanism responsible for guiding a vehicle’s direction plays a critical role in its overall performance and safety. It transforms the rotational motion of the driver’s input into the lateral movement needed for navigating various terrains. By comprehending the fundamentals of this assembly, one can appreciate how it contributes to both handling and responsiveness.

At its core, this mechanism consists of several key components that work in unison to facilitate smooth directional changes. The primary elements include the following:

| Component | Description |

|---|---|

| Gearbox | A vital unit that converts rotational input into linear output, enabling wheel movement. |

| Linkage | Connects the gearbox to the wheels, transferring force to initiate turning. |

| Rack and Pinion | A common setup that aids in the conversion of rotational motion to linear motion. |

| Column | The shaft that houses the controls and provides a path for the driver’s input. |

Understanding the function of each component enhances the overall knowledge of how vehicles respond to steering commands. Proper maintenance and awareness of the mechanism’s workings are essential for ensuring safety and efficiency on the road.

How Power Steering Works

Power-assisted control systems play a vital role in enhancing the ease of maneuvering vehicles. These systems employ hydraulic or electric mechanisms to reduce the effort needed for directional changes, making driving a smoother experience. The primary function is to amplify the driver’s input, allowing for effortless navigation, especially at lower speeds or during tight turns.

Components of Power Assistance

Central to this functionality is a pump, which generates pressure to assist in the movement of the control mechanism. In hydraulic systems, fluid is directed through hoses, transmitting force from the pump to the control mechanism, thereby enabling easier turning of the wheels. Electric systems, on the other hand, utilize sensors and motors to provide assistance, adapting to driving conditions and enhancing efficiency.

Benefits of Power Assistance

The advantages of power assistance are manifold. It significantly reduces the physical strain on the driver, particularly in larger vehicles, allowing for improved comfort and control. Additionally, these systems can contribute to better handling and responsiveness, ensuring that the vehicle reacts promptly to driver input, thus enhancing overall safety on the road.

Identifying Common Steering Issues

Recognizing prevalent difficulties in vehicle handling can significantly enhance safety and performance. Various symptoms can indicate underlying problems that need prompt attention. Awareness of these issues allows for timely intervention, preventing more severe complications.

Common Symptoms of Malfunction

Drivers may experience unusual noises, such as grinding or squeaking, which often suggest wear in components. Additionally, difficulty in maneuvering the vehicle or a noticeable pull to one side can signal an imbalance or misalignment. Addressing these indicators promptly is crucial for maintaining optimal function.

Causes of Steering Problems

Several factors can lead to handling difficulties. Worn-out elements, inadequate lubrication, or damaged linkages are common culprits. Furthermore, environmental factors, such as rough terrain or debris on the road, can exacerbate these concerns. Regular inspections and maintenance can help mitigate these risks.

Maintenance Tips for Steering System

Ensuring optimal performance of the directional control system is crucial for vehicle safety and functionality. Regular care and attention can prolong the lifespan of these components while enhancing driving comfort. Following a few key practices can help prevent potential issues and maintain the efficiency of the mechanism.

Regular Inspections

Conducting periodic evaluations of the directional control system is essential. Look for signs of wear, leaks, or damage to critical components. Early detection of issues can prevent costly repairs and ensure a smoother operation.

Fluid Checks and Replacements

Monitoring and maintaining the hydraulic fluid levels are vital for the proper function of the system. Regularly check the fluid quality and replace it as recommended by the manufacturer. Contaminated or low fluid levels can lead to reduced responsiveness and increased wear on the components.

Replacing Dodge Ram Steering Parts

Replacing components that facilitate the direction of your vehicle can enhance handling and improve overall safety. Understanding the process of substitution is crucial for both experienced mechanics and DIY enthusiasts. This guide will walk you through the essential steps and considerations involved in this important task.

Identifying the Need for Replacement

Before proceeding with any substitutions, it is vital to diagnose the specific issues affecting the functionality of the directional system. Symptoms such as unusual noises, loose control, or excessive play in the wheel can indicate that components require attention. Regular inspections and maintenance can help catch problems early, preventing more extensive damage.

Step-by-Step Replacement Process

Once you’ve identified the components that need to be replaced, gather the necessary tools and materials. Ensure that you have the correct replacements on hand, as using incompatible components can lead to further complications. Follow a systematic approach to remove the old components carefully and install the new ones. Always refer to the manufacturer’s guidelines for specifications and torque settings to ensure proper assembly.

Tools Needed for Steering Repairs

Repairing the directional control system of a vehicle requires a variety of specialized tools. Each tool serves a distinct purpose, ensuring that adjustments and replacements can be carried out effectively and safely. Having the right equipment on hand can significantly streamline the repair process and enhance overall efficiency.

Essential Equipment

Below is a list of fundamental tools necessary for effective maintenance and repair work:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening various fasteners |

| Wrench Set | For gripping and turning nuts and bolts |

| Pliers | For gripping, twisting, and cutting wires |

| Torque Wrench | For applying precise torque to fasteners |

| Ball Joint Separator | For separating ball joints from the control arms |

| Jack and Stands | For lifting and securely supporting the vehicle |

| Alignment Tools | For checking and adjusting wheel alignment |

Safety Gear

In addition to standard tools, personal protective equipment is crucial. This includes gloves, safety glasses, and steel-toed boots to protect against potential injuries while working. Ensuring safety while conducting repairs not only safeguards the technician but also promotes a more efficient workflow.

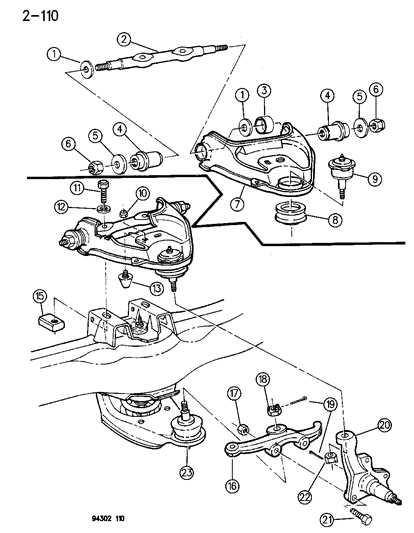

Step-by-Step Steering Diagram Guide

This section provides a comprehensive walkthrough for understanding the components involved in vehicle navigation systems. By exploring each element methodically, you will gain insights into how these mechanisms work together to ensure smooth handling and control.

To effectively navigate this guide, follow these steps:

-

Identify the Core Components:

Begin by familiarizing yourself with the main elements that contribute to vehicle maneuverability. Key components include:

- Control unit

- Connecting rods

- Pivot points

- Linkages

-

Locate Each Component:

Next, pinpoint the location of each element within the assembly. Knowing where each part is situated helps in understanding its function and relation to others.

-

Examine the Interactions:

Investigate how these components interact with one another. Look for:

- Movement patterns

- Load distribution

- Mechanical advantages

-

Consult the Reference Materials:

Use reliable sources, such as manuals or service guides, to cross-reference information and ensure accuracy.

By following these steps, you will develop a thorough understanding of the essential elements involved in vehicle control systems, enhancing your knowledge and skills in maintenance and troubleshooting.

Importance of Accurate Steering Alignment

Proper alignment of the vehicle’s directional control system is crucial for optimal performance and safety. When the angles of the wheels are correctly adjusted, it ensures that the vehicle travels straight and true on the road. This precision reduces tire wear and improves fuel efficiency, leading to lower operating costs over time.

Misalignment can result in various issues, including uneven tire wear, decreased handling responsiveness, and compromised safety. When the angles are not set according to the manufacturer’s specifications, the vehicle may pull to one side or experience difficulty maintaining a straight path. Regular checks and adjustments of these angles can help prevent costly repairs and enhance overall driving comfort.

Furthermore, accurate adjustments contribute to better control of the vehicle, especially during high-speed maneuvers and emergency situations. Ensuring the proper orientation of the wheels promotes stability and responsiveness, ultimately enhancing the driving experience. Therefore, routine maintenance that includes alignment checks is essential for every vehicle owner.