Comprehensive Guide to Jeep YJ Steering Parts Diagram

The intricacies of vehicle maneuvering systems play a vital role in ensuring a smooth and safe driving experience. Understanding these components can enhance one’s knowledge and facilitate effective maintenance and upgrades. This section aims to provide clarity on the various elements involved in the directional control of off-road vehicles.

By dissecting the arrangement and functionality of these mechanisms, enthusiasts and owners alike can delve into the ultimate guide for enhancing performance. Whether tackling rugged terrains or navigating urban landscapes, familiarity with these crucial elements can empower drivers to make informed decisions.

In this exploration, we will cover the essential components that contribute to the overall stability and responsiveness of your vehicle. Gaining insight into their layout and interaction will ultimately lead to a more proficient handling experience.

Understanding Jeep YJ Steering Components

This section explores the crucial elements that contribute to vehicle maneuverability and control. A well-functioning system is vital for ensuring smooth navigation across various terrains, enhancing both safety and performance.

Key Elements

- Control mechanism: This regulates the direction of travel.

- Linkage: Connects the control mechanism to the wheels.

- Assistance devices: Aid in reducing effort needed for turning.

- Support structures: Provide stability during operation.

Maintenance Tips

- Regularly inspect all components for wear and tear.

- Ensure lubrication of moving parts to prevent friction.

- Check alignment to maintain optimal performance.

- Replace damaged or worn elements promptly to avoid complications.

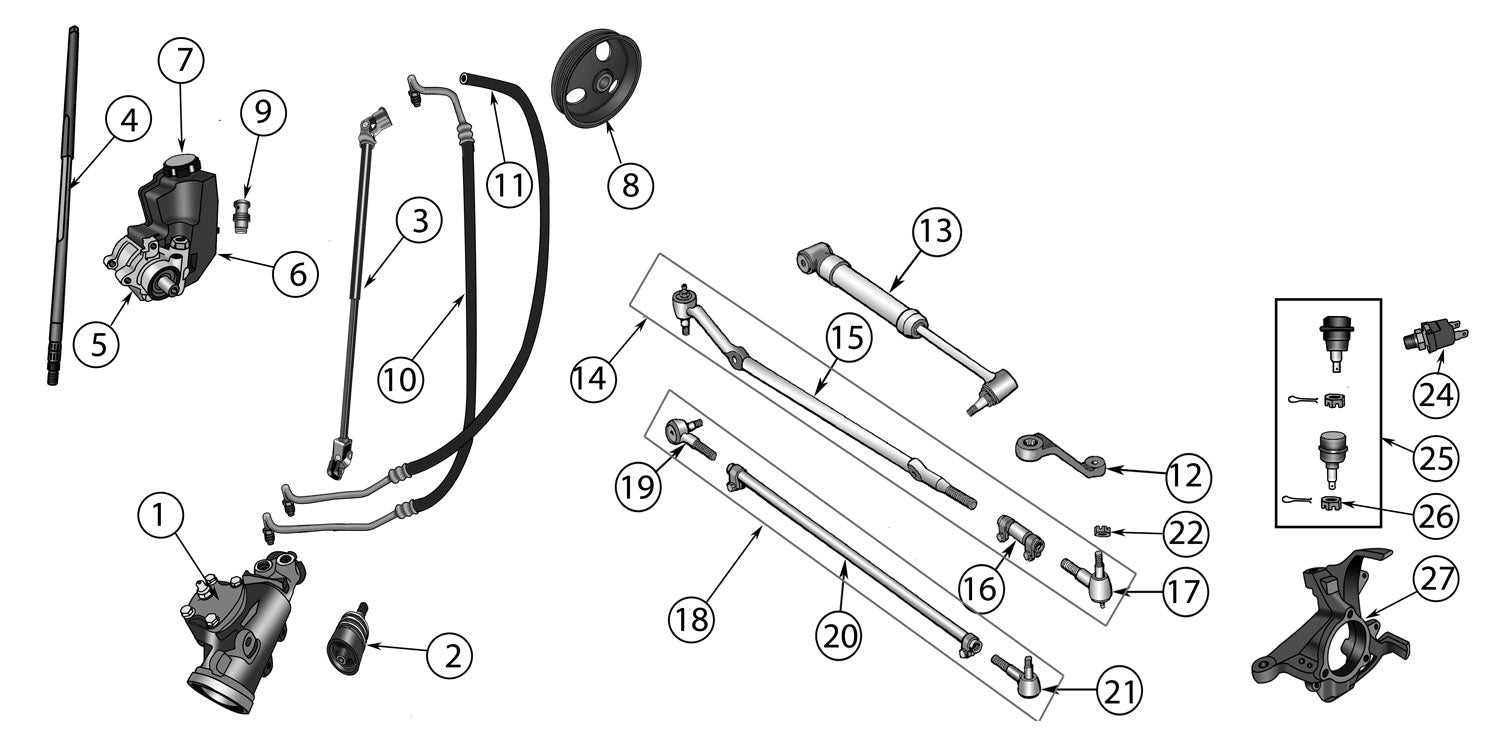

Overview of Jeep YJ Steering System

The functionality of the directional control mechanism in vehicles is crucial for safety and maneuverability. This system is designed to provide precise handling and stability, ensuring a smooth driving experience across various terrains. Understanding its components and their interactions is essential for maintenance and upgrades.

| Component | Description |

|---|---|

| Column | Connects the driver’s input to the mechanism. |

| Linkage | Transmits motion from the column to the wheels. |

| Box | Converts rotational movement into lateral movement. |

| Rods | Connects various components for coordinated movement. |

| Wheel Assembly | Controls the angle of the wheels for directional change. |

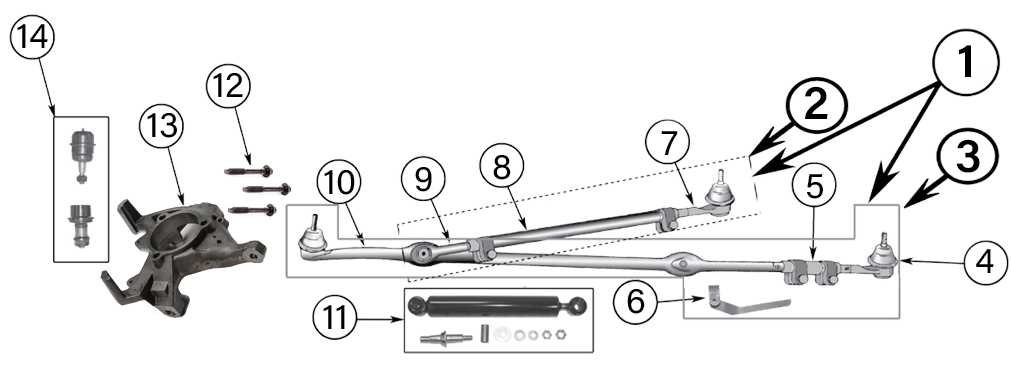

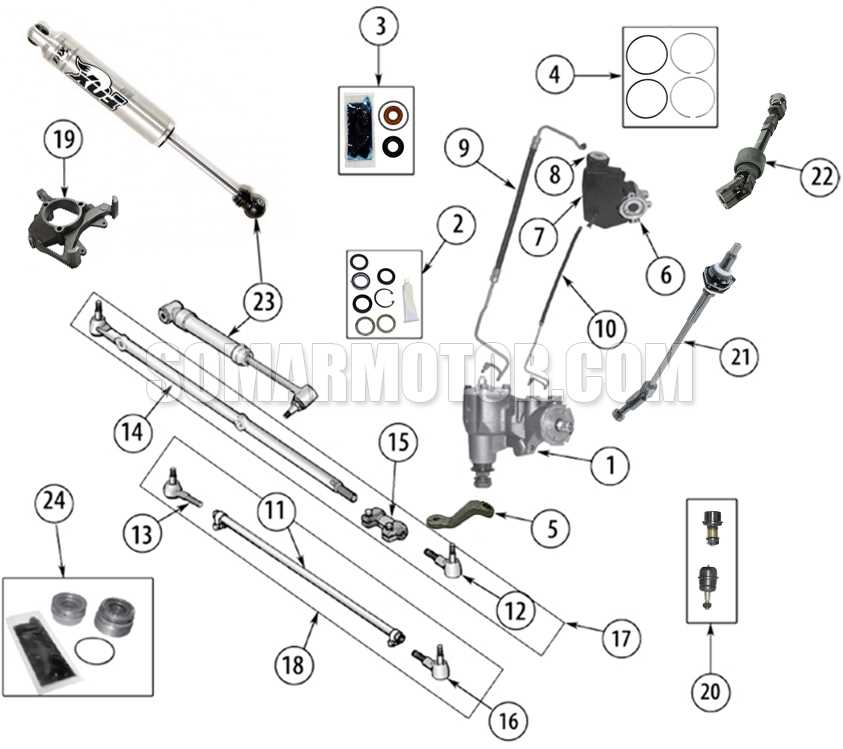

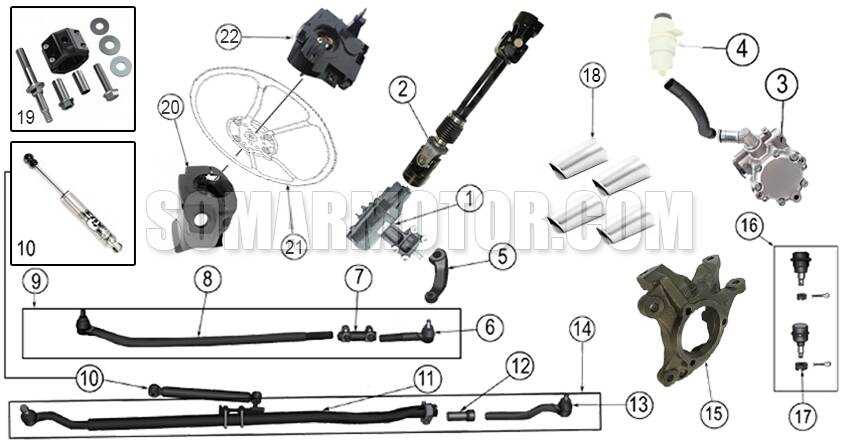

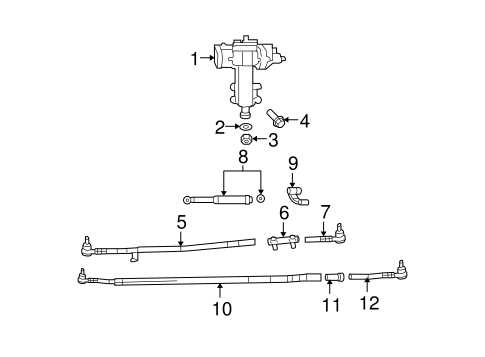

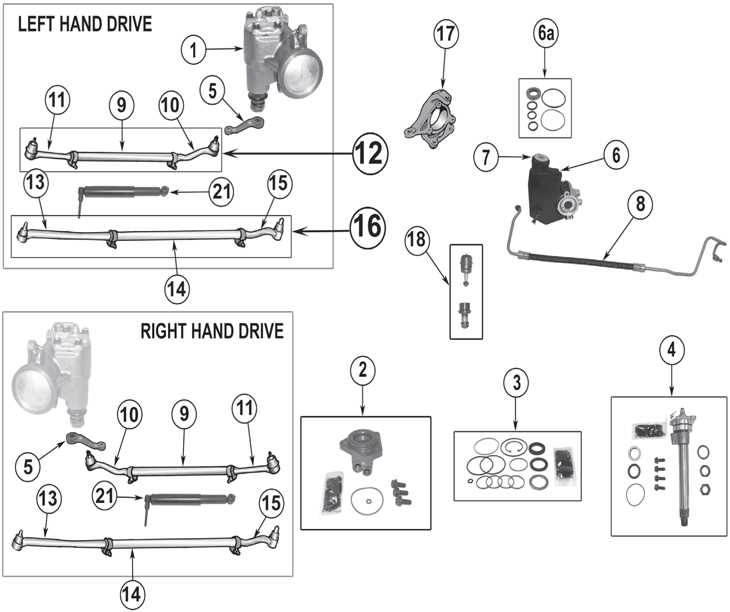

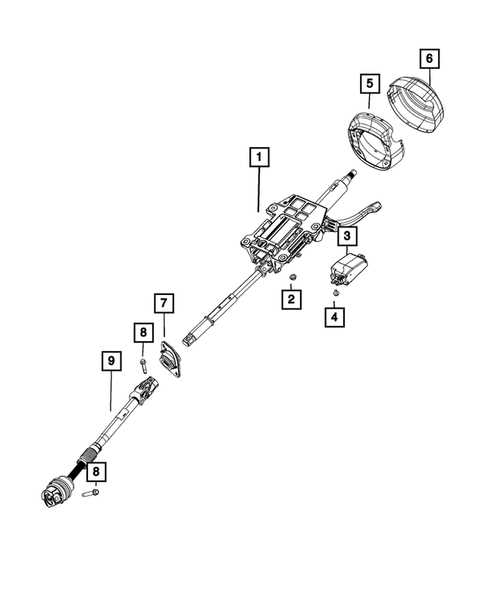

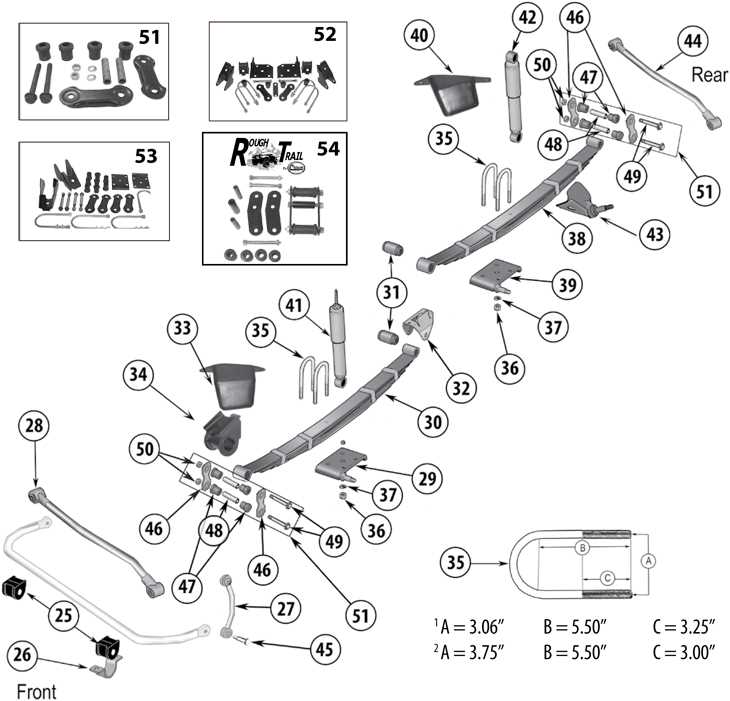

Key Parts in YJ Steering Diagram

This section focuses on the essential components that contribute to the control and maneuverability of the vehicle. Understanding these elements is crucial for effective maintenance and enhancement of performance.

Major Components

- Column Assembly

- Linkage System

- Control Box

- Connecting Rods

Functionality Overview

- Column Assembly: Acts as the central hub for directing motion.

- Linkage System: Transmits force from the driver’s input to the wheels.

- Control Box: Houses mechanisms for adjustment and response.

- Connecting Rods: Ensure smooth communication between parts.

Importance of Steering Alignment

Proper alignment of the vehicle’s directional system is crucial for maintaining optimal performance and safety. When all components are accurately positioned, it enhances handling, reduces tire wear, and improves fuel efficiency. This process not only contributes to a smoother ride but also extends the lifespan of the vehicle’s components.

Benefits of Accurate Alignment

When the directional system is aligned correctly, it ensures that the wheels are pointed in the right direction, which enhances overall stability. Improved traction is a significant advantage, especially in challenging conditions. Additionally, accurate alignment minimizes unnecessary strain on the vehicle’s components, leading to lower maintenance costs over time.

Consequences of Poor Alignment

Neglecting alignment can lead to serious issues, such as uneven tire wear and compromised handling. Over time, this misalignment can cause safety hazards and significantly impact the driving experience. Regular checks are essential to ensure that everything remains in harmony, preventing costly repairs and enhancing safety on the road.

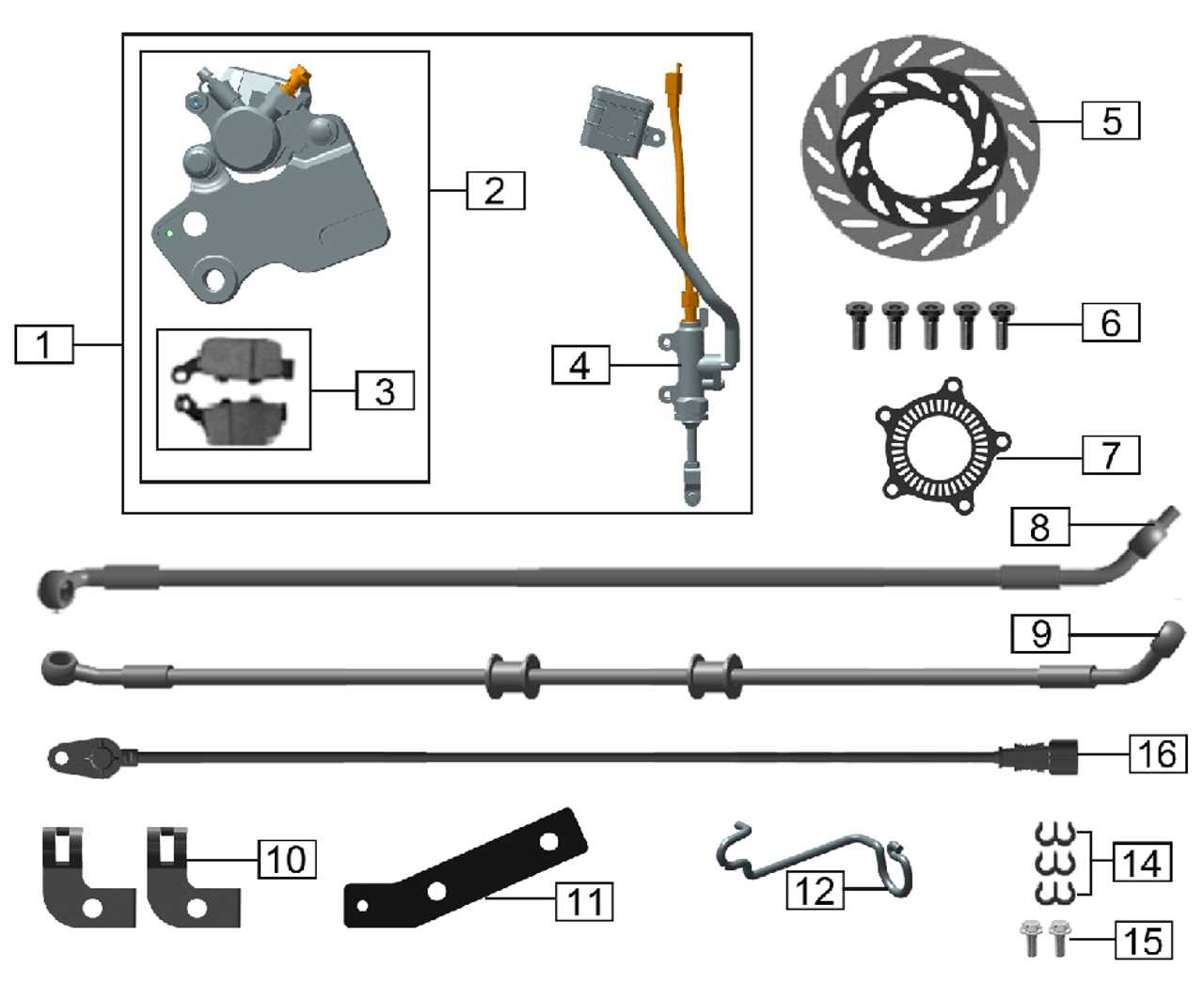

Common Issues with YJ Steering Parts

When it comes to vehicle control systems, certain problems frequently arise that can compromise performance and safety. Understanding these challenges is essential for maintaining optimal functionality and ensuring a smooth driving experience.

| Issue | Description |

|---|---|

| Worn Bushings | Degradation of rubber components can lead to increased play and instability. |

| Leaking Seals | Fluid loss from deteriorated seals may result in diminished performance. |

| Alignment Problems | Miscalibrated angles can cause uneven tire wear and handling issues. |

| Loose Connections | Fasteners that have come loose can lead to vibrations and steering anomalies. |

| Ball Joint Failure | Worn or damaged joints can affect vehicle maneuverability and safety. |

Maintenance Tips for Steering Components

Ensuring the longevity and reliability of your vehicle’s directional system requires regular attention and care. A well-maintained setup not only enhances performance but also contributes to overall safety. Here are some essential practices to keep these crucial elements in top shape.

Regular Inspections

- Check for visible wear and tear on components.

- Look for signs of leakage around hydraulic systems.

- Examine joints and bushings for any play or looseness.

Fluid Maintenance

- Inspect and change hydraulic fluid as recommended by the manufacturer.

- Keep fluid levels topped off to prevent system failure.

- Flush the system periodically to remove contaminants.

By following these guidelines, you can significantly enhance the durability and responsiveness of your vehicle’s directional system, ensuring a safer driving experience.

Upgrading Your Jeep YJ Steering

Enhancing the control and handling of your off-road vehicle can significantly improve your driving experience. A well-tuned system ensures better responsiveness, stability, and safety on various terrains. Whether you’re navigating rocky paths or cruising on highways, optimizing this crucial setup is essential for performance and comfort.

Key Benefits of Improvement

Upgrading your vehicle’s control mechanisms offers several advantages. Improved precision allows for better maneuverability, while increased durability ensures longevity under demanding conditions. Additionally, enhanced feedback from the terrain contributes to a more engaging driving experience.

Components to Consider

| Component | Description |

|---|---|

| Control Arm | Helps in maintaining alignment and improving responsiveness. |

| Linkage | Connects various elements for optimal force transfer. |

| Shock Absorbers | Reduces vibrations and enhances stability on uneven surfaces. |

| Brace Kit | Increases strength and rigidity, minimizing flex during tough maneuvers. |

Investing in quality upgrades can transform your vehicle’s capability, making every journey more enjoyable and secure. Prioritize compatibility and performance when selecting enhancements to achieve the best results.

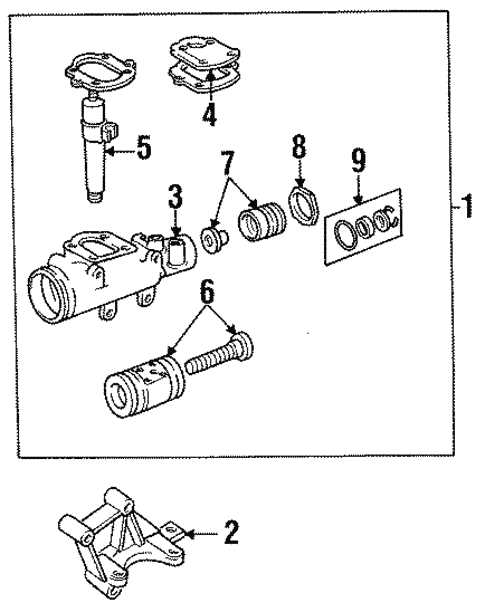

How to Read Steering Diagrams

Understanding schematics is essential for effective maintenance and repair of vehicle control systems. By familiarizing yourself with these illustrations, you can easily identify components and their relationships, which ultimately aids in troubleshooting and enhancing performance.

Familiarize with Symbols

Each component in the illustration is represented by a specific symbol. Recognizing these symbols is crucial, as they provide quick insights into the functionality of each part. Refer to the accompanying legend for accurate interpretations.

Analyze Connections

The lines connecting symbols indicate how various elements interact with one another. Pay attention to the direction and type of lines; solid lines typically denote direct connections, while dashed lines may signify secondary links or dependencies.

Tools Needed for Steering Repair

When it comes to addressing issues related to directional control systems in vehicles, having the right tools is essential for effective and efficient repair. A well-equipped toolkit can make a significant difference in the quality of the work and the time taken to complete the job.

Start with basic hand tools, such as wrenches, sockets, and screwdrivers, which are crucial for loosening and tightening components. A torque wrench is also necessary to ensure that all fittings are secured to the manufacturer’s specifications. Additionally, a ball joint separator and tie rod puller are invaluable for removing stubborn connections without damaging surrounding parts.

Specialized equipment, like a hydraulic jack and jack stands, provides safe access to the undercarriage. A floor creeper can enhance comfort during prolonged work sessions. Lastly, having a good-quality grease gun and lubricant on hand ensures that all moving parts remain functional and long-lasting.

Identifying Wear and Tear in Parts

Recognizing degradation in vehicle components is essential for ensuring optimal performance and safety. Over time, elements can experience stress and deterioration, which can lead to various issues if not addressed promptly. Regular inspection helps in pinpointing problems before they escalate.

Common Signs of Degradation

Look for visible cracks, unusual noises, or misalignment during operation. Components may exhibit excessive play or stiffness, indicating that they are not functioning as intended. Regularly checking these symptoms can prevent further complications.

Maintenance Tips

Implement routine checks and maintenance schedules to prolong the life of your vehicle’s components. Cleaning and lubricating moving parts can significantly reduce wear, while timely replacements of worn elements ensure continued reliability. Stay proactive to avoid unexpected breakdowns and costly repairs.

Replacing Steering Components: A Guide

Maintaining the control system of your vehicle is crucial for ensuring safe and smooth operation. Over time, certain elements may wear out or become damaged, necessitating their replacement. This guide will walk you through the process of updating these components effectively.

Before beginning, gather the necessary tools and materials:

- Socket set

- Wrench set

- Jack and jack stands

- Replacement components

- Grease and lubricant

- Safety goggles and gloves

Follow these steps to replace the worn components:

- Preparation: Ensure your vehicle is parked on a level surface. Engage the parking brake and disconnect the battery to prevent any electrical issues.

- Access the Components: Use the jack to lift the vehicle and secure it with jack stands. Remove any covers or shields that obstruct access to the parts you need to replace.

- Inspection: Examine the current components for signs of wear, damage, or corrosion. Identify which parts require replacement.

- Removal: Carefully detach the old components using the appropriate tools. Take note of how they are connected to facilitate the installation of the new ones.

- Installation: Position the new components in place. Ensure all connections are secure, and apply grease where necessary to promote smooth operation.

- Testing: Once everything is installed, lower the vehicle and reconnect the battery. Take the vehicle for a short test drive to confirm that everything is functioning correctly.

lessCopy code

Regularly checking and replacing these critical elements not only enhances performance but also ensures your safety on the road. Always refer to your vehicle’s manual for specific guidelines related to your model.

Aftermarket vs. OEM Steering Parts

The choice between replacement components from original manufacturers and alternative suppliers can significantly impact performance and reliability. Each option presents distinct advantages and considerations, making it essential for users to evaluate their needs and preferences before making a decision.

Advantages of Aftermarket Components

- Cost-effective alternatives often available at lower prices.

- Variety of options, allowing customization to enhance functionality.

- Potential for improved performance or specialized features not offered by originals.

Benefits of OEM Components

- Guaranteed compatibility with the original design.

- Consistent quality and reliability from established manufacturers.

- Often come with warranties, providing peace of mind.

Ultimately, the decision hinges on individual priorities, whether focusing on budget, customization, or reliability.

Preventative Measures for Steering Longevity

Ensuring the durability of your vehicle’s handling system requires consistent care and attention. By implementing a few key practices, you can significantly extend the life of essential components.

- Regular Inspections: Frequently check all relevant components for wear and tear.

- Fluid Maintenance: Keep hydraulic fluids at optimal levels and replace them as recommended.

- Tire Alignment: Ensure proper alignment to reduce unnecessary strain on the system.

- Protective Coatings: Apply rust-proof treatments to shield metal parts from corrosion.

By incorporating these measures, you will not only enhance performance but also secure the ultimate longevity of your vehicle’s essential mechanisms.