Comprehensive Guide to Saginaw Steering Box Parts Diagram

In the intricate system that guides a vehicle’s directional control, understanding the intricate elements that compose its operational core unveils a world of interconnected parts. Each component plays a crucial role in ensuring smooth maneuverability, reinforcing the synergy between driver intent and mechanical response.

Delving into the anatomy of this essential mechanism, one encounters a network of interdependent elements, each contributing uniquely to the fluidity and precision of steering movements. From foundational structures that provide stability to dynamic elements that translate driver input into nuanced directional adjustments, the assemblage is a testament to engineering finesse.

Examining the interplay between these components reveals a ballet of engineering ingenuity, where even the subtlest alteration can yield significant enhancements in performance and safety. Mastery of these elements empowers both enthusiasts and professionals alike to optimize and tailor vehicle handling to meet diverse demands and conditions.

Overview of the Steering Mechanism

This section provides an in-depth look at a critical component of vehicle handling systems, focusing on its structure and functionality. Understanding this mechanism is essential for anyone involved in automotive maintenance or restoration, as it plays a vital role in ensuring precise maneuverability and stability on the road.

Functionality and Importance

The primary purpose of this assembly is to translate the driver’s input into controlled motion of the vehicle’s wheels. It allows for enhanced driving experience by providing responsiveness and accuracy during navigation. The reliability of this component directly affects overall vehicle performance and safety, making it crucial for both everyday drivers and motorsport enthusiasts.

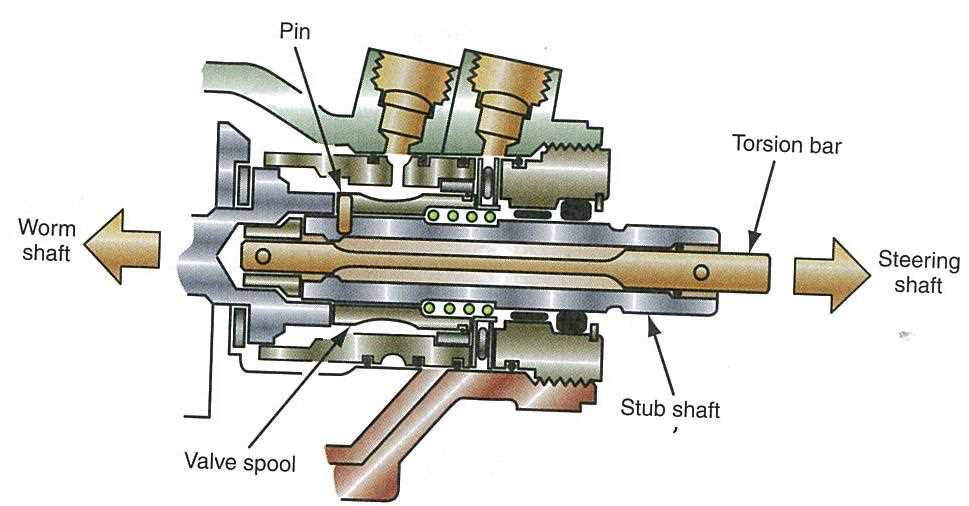

Key Components and Their Roles

Within this assembly, several crucial elements work together seamlessly. The housing encases the internal mechanisms, providing protection and structural integrity. Additionally, the gears and linkages facilitate smooth movement, while the internal fluid system aids in reducing friction and wear. Understanding these components helps in diagnosing issues and performing effective repairs.

In summary, familiarity with this essential assembly is key for anyone looking to enhance their vehicle’s performance and ensure a safe driving experience.

Understanding Steering Mechanism Operational Principles

In the realm of vehicular dynamics, the steering system functions as a pivotal interface between driver intention and vehicle response. It operates through a series of interconnected components that facilitate directional control, ensuring seamless maneuverability on various terrains.

| Component | Function |

| Steering Wheel | Initiates the steering input, translating driver movements into rotational force. |

| Steering Column | Transfers rotational motion from the steering wheel down to the steering box. |

| Steering Gear | Converts rotational input from the steering column into lateral movement. |

| Tie Rods | Transmit lateral movement from the steering gear to the steering knuckles, affecting wheel alignment. |

| Steering Knuckles | Connect the tie rods to the wheels, enabling directional changes in response to steering input. |

This intricate interplay of components ensures precise control over the vehicle’s direction, enhancing safety and maneuvering capabilities across diverse driving conditions.

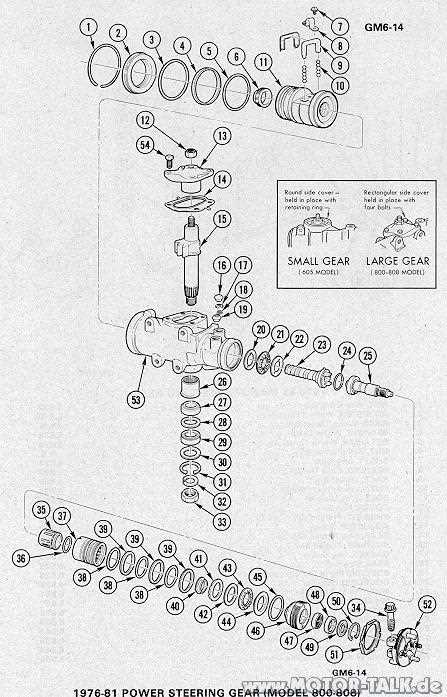

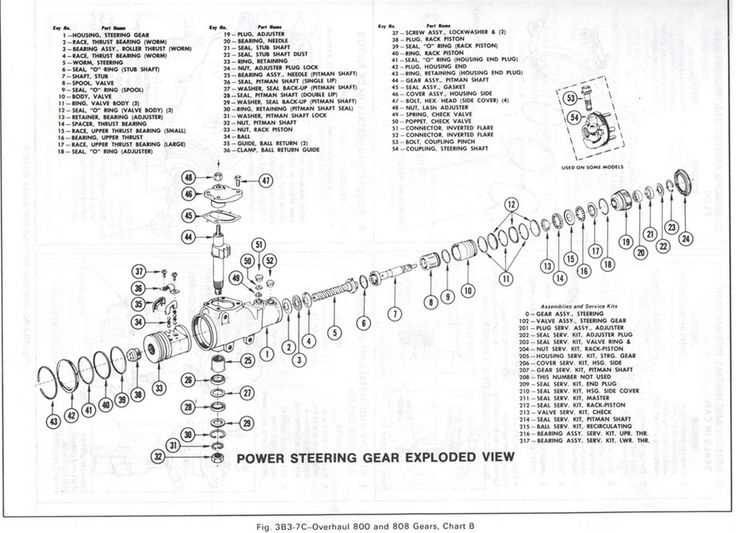

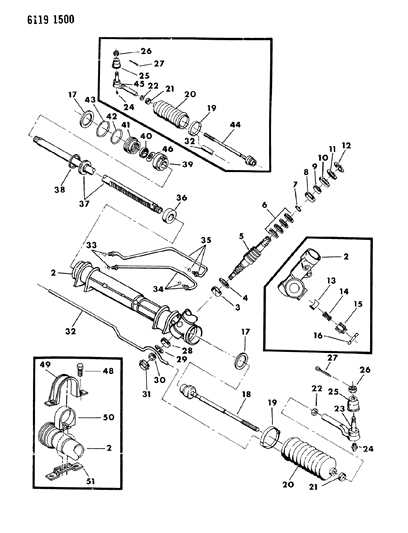

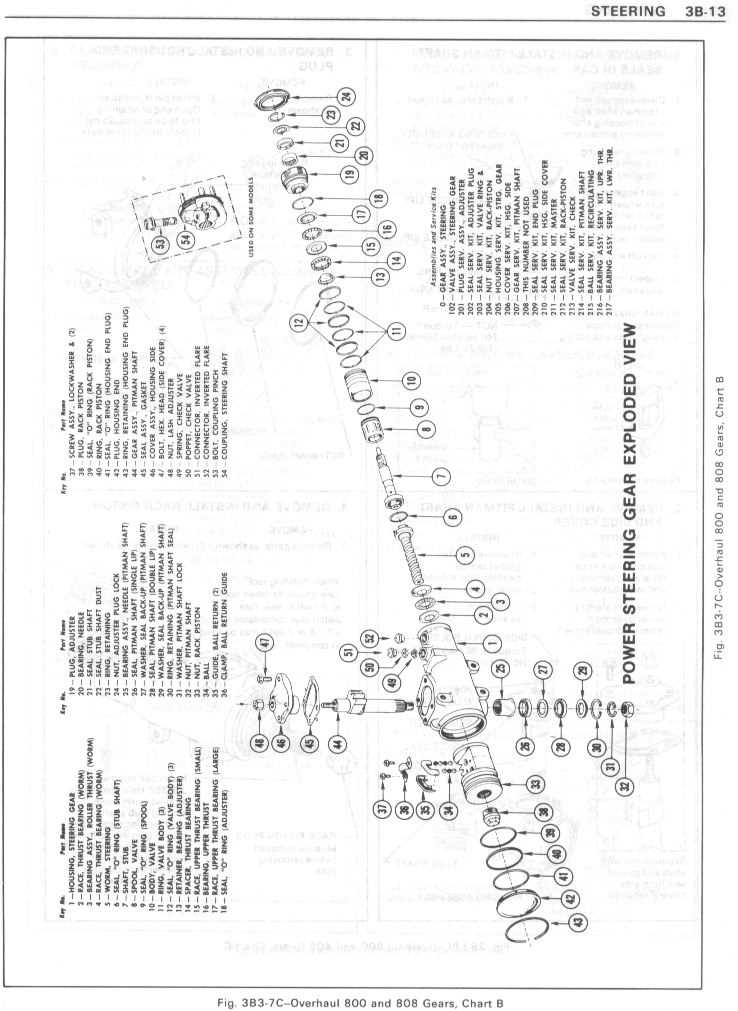

Components of Saginaw Steering Box

This section explores the essential elements that make up a particular type of automotive control mechanism, focusing on how these components interact to ensure smooth maneuverability and response. Each element plays a crucial role in delivering precision and reliability, ultimately enhancing the driving experience.

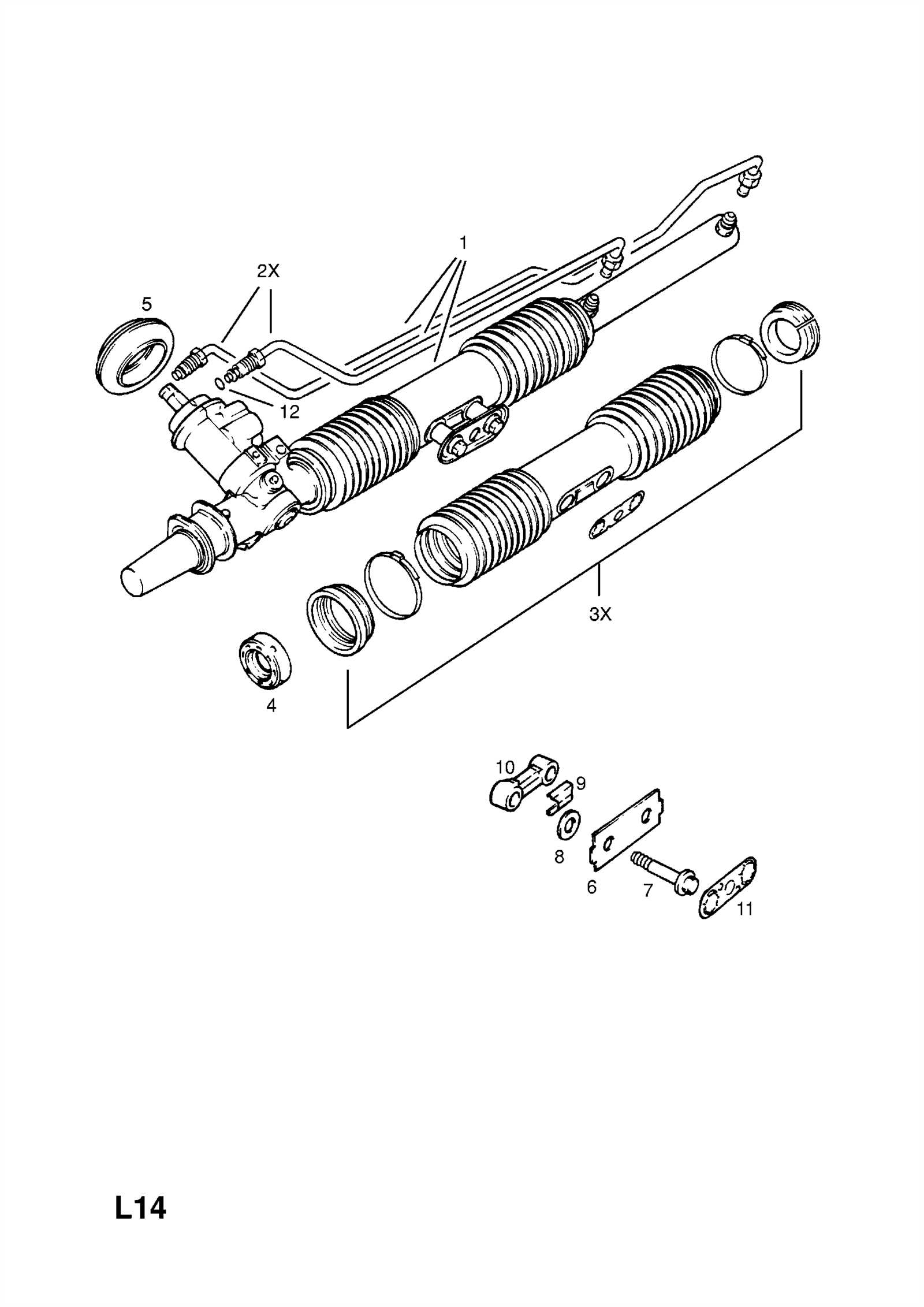

Main Elements

- Housing: The outer shell that encases the internal mechanisms, providing protection and structural integrity.

- Input Shaft: The component through which the driver applies force, initiating the movement of the entire system.

- Output Shaft: This part transmits the rotational motion to the vehicle’s wheels, facilitating direction changes.

- Gearset: A series of interlocking gears that amplify the input force, allowing for easier handling.

Additional Features

- Bearings: These reduce friction between moving parts, ensuring smooth operation and longevity.

- Seal: Prevents fluid leakage and contamination, maintaining optimal performance.

- Control Valve: Regulates the flow of hydraulic fluid, enabling precise control of motion.

Understanding these components provides insight into how this assembly contributes to vehicle dynamics and overall safety on the road.

Common Issues in Steering Boxes

In the realm of vehicle handling mechanisms, certain challenges frequently arise that can affect performance and safety. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth driving experience. This section will explore prevalent complications that can occur, highlighting their causes and potential solutions.

Worn Components

Over time, key elements within the mechanism may experience wear and tear. This degradation can lead to several performance issues, such as increased play in the system and a decrease in responsiveness. Regular inspections can help identify these worn parts before they lead to more significant complications.

Fluid Leaks

Fluid leaks represent another common issue, often caused by damaged seals or hoses. Loss of hydraulic fluid can compromise the effectiveness of the system, making it harder to maneuver the vehicle. Addressing leaks promptly is crucial to maintain proper operation.

| Issue | Possible Causes | Recommended Action |

|---|---|---|

| Worn Components | Age, excessive use | Regular maintenance, timely replacement |

| Fluid Leaks | Damaged seals, cracked hoses | Inspect and replace faulty parts |

Maintenance Tips for Longevity

Ensuring the durability of critical components in your vehicle requires regular upkeep and attention. By following a few essential practices, you can extend the life of these vital mechanisms and enhance overall performance.

- Regular Inspections: Schedule routine checks to identify any wear or damage. Early detection can prevent larger issues down the line.

- Fluid Maintenance: Keep an eye on hydraulic fluids. Regularly check levels and replace them according to the manufacturer’s guidelines to ensure optimal operation.

- Cleaning: Remove dirt and debris from surrounding areas to prevent contaminants from entering and causing damage.

- Proper Alignment: Ensure that your vehicle’s alignment is correct. Misalignment can lead to uneven wear and strain on components.

- Lubrication: Apply appropriate lubricants to moving parts as recommended, reducing friction and wear over time.

By incorporating these practices into your maintenance routine, you can significantly enhance the lifespan and reliability of essential vehicle systems.

How to Diagnose Steering Problems

Identifying issues with vehicle handling can be crucial for safety and performance. Various symptoms may indicate underlying problems that require attention. Understanding these signs and knowing how to address them is essential for any driver.

Here are some common symptoms to look out for:

- Unusual Noises: Listen for grinding, whining, or clunking sounds when turning the wheel.

- Difficulty in Maneuvering: Notice if turning the wheel feels stiff or overly loose.

- Vibrations: Pay attention to any shaking or wobbling sensations in the steering column.

- Uneven Tire Wear: Inspect tires for irregular patterns, which can indicate misalignment.

- Fluid Leaks: Look for puddles or stains under the vehicle, particularly near the front.

To diagnose these issues effectively, follow these steps:

- Visual Inspection: Check for visible damage to components, including hoses and connections.

- Test Drive: Take the vehicle for a slow drive to assess responsiveness and listen for unusual sounds.

- Check Fluid Levels: Ensure that the necessary fluids are at appropriate levels and free from contaminants.

- Consult a Professional: If problems persist, consider seeking assistance from a qualified technician.

By being proactive and attentive to these indicators, you can ensure your vehicle remains safe and reliable on the road.

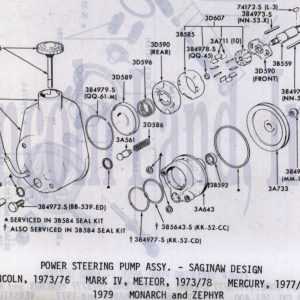

Replacement Parts for Saginaw Systems

When it comes to enhancing the functionality of your vehicle’s directional control system, choosing the right components is essential. Various elements contribute to optimal performance, ensuring reliability and safety during operation. Understanding the available options can aid in making informed decisions regarding replacements.

Quality replacements can improve the efficiency and lifespan of your system. Below is a comprehensive overview of some crucial components you may consider when upgrading or repairing your equipment.

| Component | Description | Function |

|---|---|---|

| Control Valve | Regulates fluid flow within the system. | Ensures smooth operation and responsiveness. |

| Sector Shaft | Connects the steering mechanism to the linkage. | Translates rotational movement into directional change. |

| Pitman Arm | Transmits motion from the sector shaft to the wheels. | Facilitates the turning motion of the vehicle. |

| Coupling | Links various mechanical parts securely. | Maintains connection and alignment between components. |

| Fluid Reservoir | Stores hydraulic fluid necessary for operation. | Provides adequate fluid supply to prevent system failure. |

Choosing high-quality replacements for these critical components ensures your system operates efficiently and enhances the overall driving experience. Regular maintenance and timely upgrades can prevent issues and extend the life of your vehicle’s directional control mechanism.

Step-by-Step Installation Guide

Welcome to our comprehensive guide on setting up your new steering mechanism. This section aims to provide you with clear, sequential instructions for assembling and installing your steering system components. Throughout this guide, we’ll walk you through each phase of the process, ensuring you have a smooth and successful installation experience.

To begin, we’ll start by preparing the necessary components for assembly. This initial step involves gathering all essential parts and verifying their compatibility and condition. Ensuring that each element aligns correctly will lay the foundation for a reliable steering setup.

Next, we’ll move on to the assembly phase. Here, you’ll carefully connect the various parts according to the detailed instructions provided by the manufacturer. This stage requires attention to detail to guarantee that every component fits snugly and functions as intended.

Once the assembly is complete, we’ll proceed with the installation process. This involves mounting the assembled steering unit securely into your vehicle’s designated position. Pay close attention to alignment and attachment points to ensure optimal performance and safety.

After securing the unit, the final step involves testing the steering mechanism. This crucial phase allows you to verify functionality and detect any potential issues early on. Conduct thorough checks of steering responsiveness and smooth operation before finalizing the installation.

Throughout the entire process, refer to the manufacturer’s guidelines and specifications provided with your steering components. These instructions are essential for ensuring proper installation and maximizing the longevity of your steering system.

By following these step-by-step instructions diligently, you’ll be well-equipped to successfully install your steering components and enjoy a reliable driving experience.

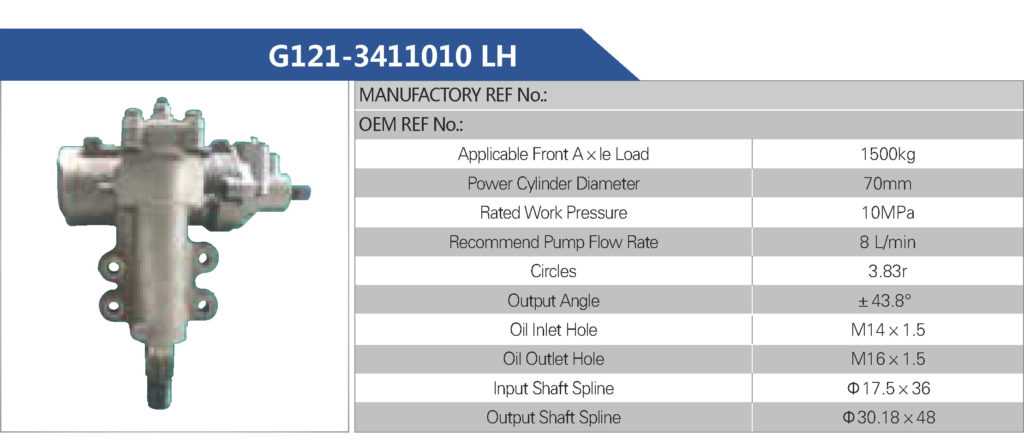

Identifying Different Steering Models

Understanding the various designs of control mechanisms used in vehicles is essential for maintenance and repairs. Each model has unique characteristics that distinguish it from others, influencing performance and handling. By recognizing these differences, you can ensure the right parts are utilized during service or replacement.

First, examine the configuration of the unit. Some models may feature a compact design, while others are more robust. The shape and orientation can indicate the specific type employed in a vehicle, helping you determine compatibility with various applications.

Next, consider the components involved. The presence of certain elements, such as specific gear arrangements or housing shapes, can provide insights into the mechanism’s classification. Take note of the materials used, as different designs may incorporate unique alloys or plastics.

Finally, pay attention to the serial numbers or identifiers usually stamped on the unit. These markings can reveal the manufacturer and model specifics, aiding in accurate identification. Consulting reference guides can also streamline the identification process and ensure that you’re working with the correct specifications.

Tools Needed for Repair

When undertaking a repair project involving a specific mechanical component, having the right tools is essential for achieving a successful outcome. The proper instruments not only facilitate the disassembly and reassembly process but also ensure that adjustments can be made with precision. This section outlines the key tools that will aid in performing repairs effectively.

To start, a basic set of hand tools is vital. This includes wrenches of various sizes, screwdrivers, and pliers, which will assist in loosening and tightening connections. Additionally, a torque wrench is necessary for applying the correct amount of force to bolts, preventing damage from over-tightening.

Incorporating specialized tools can further enhance the repair experience. A puller may be needed to remove stubborn components, while a seal puller can simplify the extraction of old seals without causing damage. It is also advisable to have a set of sockets to tackle different fasteners effectively.

For those delving deeper into the repair, a workbench and a set of high-quality measuring tools can provide the stability and accuracy required for precise work. Keeping a magnetic tray nearby can help prevent small parts from getting lost during the process.

Lastly, safety equipment such as gloves and goggles should not be overlooked. Protecting oneself while working with tools is paramount to ensure a safe and productive repair environment.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the surrounding environment. Adhering to guidelines and being aware of potential hazards can lead to a more efficient and secure repair process.

Use Appropriate Personal Protective Equipment

Before starting any repair, it is essential to wear the correct personal protective equipment (PPE). This includes gloves, safety glasses, and steel-toed boots. Each item plays a vital role in protecting against cuts, debris, and heavy objects that may pose a risk during the procedure.

Maintain a Clean and Organized Workspace

An orderly work area minimizes the chance of accidents. Ensure that tools are easily accessible and that there are no obstacles that could cause tripping. Additionally, be mindful of any hazardous materials that may be present, and dispose of them properly to maintain a safe environment.

Upgrades and Modifications Available

Enhancing the performance and efficiency of your vehicle’s control system can significantly improve your driving experience. Various modifications can be implemented to address specific needs, offering a blend of functionality and reliability. Below are some popular upgrades that enthusiasts often consider.

- High-Performance Components:

Upgrading to high-performance components can improve responsiveness and durability. Look for options such as:

- Reinforced gears

- Heavy-duty seals

- Enhanced fluid systems

- Custom Ratios:

Adjusting the ratio can tailor the feel of your handling, making it more suited to specific driving styles. Consider:

- Quick ratio setups for sporty driving

- Modified ratios for increased stability

- Hydraulic Enhancements:

Upgrading hydraulic systems can provide smoother operation and better feedback. Options include:

- Performance hydraulic fluids

- Advanced pump designs

- Adjustable Features:

Incorporating adjustable elements allows for fine-tuning based on personal preference. This includes:

- Adjustable torque settings

- Customizable travel limits

- Modern Technology Integration:

Integrating modern technology can enhance usability and performance. Explore options such as:

- Electronic assist systems

- Feedback sensors for improved control

Considering these upgrades can lead to a more engaging and efficient driving experience, aligning your vehicle with your personal preferences and performance expectations.