Understanding the Steering Linkage and Parts Diagram for F250

The intricate systems responsible for vehicle navigation are crucial for safe and efficient operation. These assemblies play a vital role in translating driver inputs into precise movements, ensuring that every turn and maneuver is executed with accuracy. A closer look at these components reveals the complexity and engineering behind effective control.

For those seeking to enhance their knowledge of automotive mechanics, familiarizing oneself with the various elements involved in directional guidance is essential. Each component is designed to work harmoniously, contributing to the overall functionality of the vehicle. Understanding how these mechanisms interact can greatly assist in maintenance and troubleshooting.

In this article, we will explore the various components related to vehicle navigation, highlighting their functions and interconnections. By breaking down these assemblies, we aim to provide a comprehensive overview that will aid both enthusiasts and professionals in grasping the essentials of automotive systems.

Understanding F250 Steering Systems

This section explores the essential components that enable vehicle maneuverability and control, highlighting their significance in ensuring a smooth driving experience. By examining the underlying mechanisms, we can appreciate how these elements work together to maintain stability and responsiveness on the road.

Key Components

Several vital elements contribute to the overall functionality of the vehicle’s control system. Each plays a unique role in enhancing performance and driver confidence.

| Component | Function |

|---|---|

| Rack | Converts rotational motion into linear motion. |

| Pitman Arm | Transfers motion from the gear box to the control rods. |

| Idler Arm | Stabilizes the system by supporting the control rods. |

| Ball Joints | Provide pivot points for the linkage system. |

Maintenance Tips

Regular inspection and maintenance of these components are crucial for optimal performance. Addressing wear and tear early can prevent larger issues and ensure a safe driving experience.

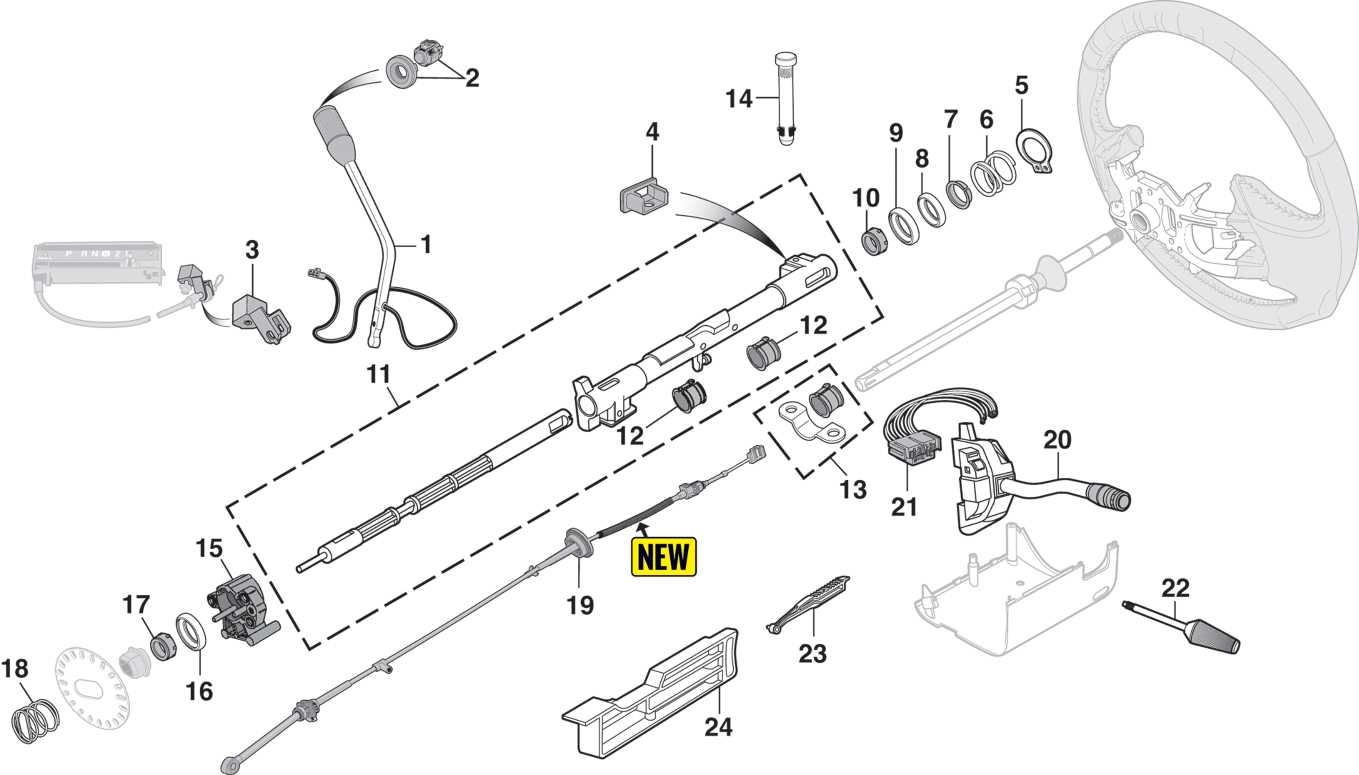

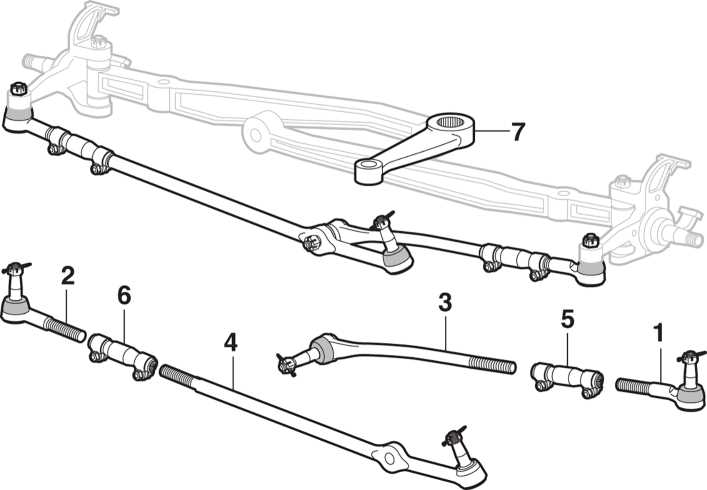

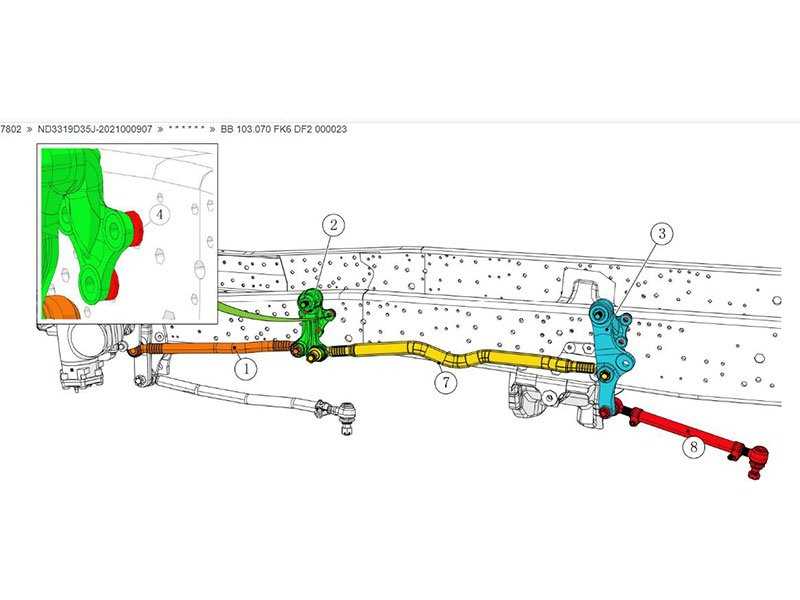

Components of Steering Linkage Explained

This section will explore the essential elements that contribute to the control and direction of a vehicle. Understanding these components is vital for both maintenance and performance optimization.

Key Elements

- Rods: These serve as the primary connections, transmitting motion and force.

- Joints: Allow for flexibility and enable movement between different parts.

- Gear Mechanism: Facilitates the conversion of rotational movement into directional control.

- Connections: Ensure stability and alignment between various elements.

Functionality

- Rods link the steering wheel to the wheels.

- Joints provide necessary movement angles.

- The gear mechanism enhances precision in direction changes.

- Connections maintain structural integrity during operation.

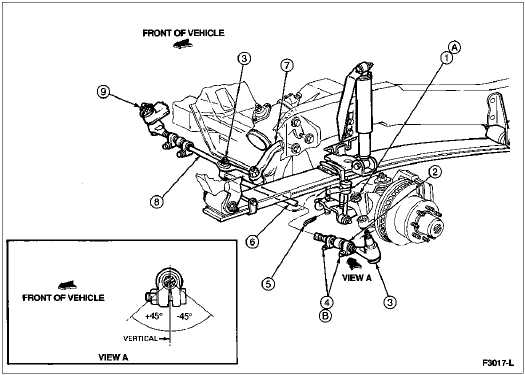

Importance of Proper Alignment

Ensuring that vehicle components are correctly aligned is crucial for optimal performance and safety. Misalignment can lead to uneven wear on tires, compromised handling, and increased fuel consumption. Addressing these issues promptly not only enhances the driving experience but also extends the lifespan of vital components.

Accurate alignment plays a pivotal role in maintaining control over the vehicle. When all elements are functioning harmoniously, the driver experiences improved maneuverability and stability. On the contrary, even slight misalignments can lead to significant challenges, affecting overall driving confidence.

Regular inspections are essential to detect any alignment issues early on. Ignoring these problems can result in costly repairs and safety hazards. By prioritizing proper alignment, vehicle owners can ensure a smoother ride and a more enjoyable journey.

Common Issues in Steering Mechanisms

In the realm of vehicle control systems, several complications can arise that impact handling and safety. These issues may stem from wear and tear, poor maintenance, or design flaws. Understanding these common problems is essential for effective troubleshooting and ensuring a smooth driving experience.

Worn Components

Over time, various components can become worn, leading to increased play and reduced responsiveness. Ball joints, tie rod ends, and bushings are particularly susceptible to deterioration, which can cause misalignment and unpredictable behavior.

Fluid Leaks

Leaks in hydraulic systems can lead to a significant loss of pressure, resulting in decreased performance. Regularly checking for fluid levels and inspecting hoses for cracks can help identify potential issues before they escalate.

Maintenance Tips for Steering Parts

Regular upkeep of your vehicle’s directional system is crucial for safe and reliable operation. Proper maintenance not only enhances performance but also extends the lifespan of the components involved. A proactive approach can help identify potential issues before they escalate into costly repairs.

First and foremost, routine inspections should be conducted to check for signs of wear or damage. Look for any frayed or cracked elements, as these can compromise functionality. Additionally, ensure that all connections are secure and free from rust or corrosion.

Lubrication is another vital aspect. Keeping the moving parts well-greased minimizes friction and wear. Use high-quality lubricant suitable for your vehicle’s specifications, and apply it at regular intervals to maintain optimal performance.

Alignment plays a significant role in the overall handling of the vehicle. Misalignment can lead to uneven tire wear and decreased stability. Regular checks and adjustments by a qualified technician can help maintain proper alignment and ensure a smoother driving experience.

Lastly, pay attention to unusual noises or changes in handling characteristics. These can be early warning signs of underlying issues. Addressing them promptly can prevent more extensive damage and ensure a safer driving experience.

How to Identify Worn Components

Recognizing the signs of deterioration in essential mechanisms is crucial for maintaining optimal performance. Regular inspection can prevent further damage and enhance safety. Here’s how to effectively assess the condition of key elements.

Visual Inspection

- Check for cracks or fractures on visible surfaces.

- Look for excessive rust or corrosion.

- Examine for uneven wear patterns or deformities.

Functional Testing

- Monitor for unusual noises during operation.

- Test for play or looseness when handling components.

- Assess response times and handling precision.

Tools Needed for Steering Repairs

When it comes to maintaining the functionality of your vehicle’s maneuvering system, having the right instruments is essential. Proper tools not only ensure efficient repairs but also enhance safety and precision during the process. Below is a guide to the essential equipment required for effective repairs in this area.

Basic Tools

- Wrenches (various sizes)

- Socket set

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Torque wrench

Specialized Equipment

- Ball joint separator

- Puller tools

- Hydraulic jack and stands

- Alignment tools

- Fluid transfer pump

Having these tools on hand will significantly simplify the repair process, making it more efficient and effective. Proper preparation is key to achieving a smooth and successful outcome.

Step-by-Step Repair Guide

This guide aims to provide a comprehensive approach for addressing issues related to the vehicle’s directional control system. By following these structured steps, you can ensure effective resolution and enhance the overall performance of your ride.

Begin by gathering the necessary tools and safety equipment. This preparation will allow for a smooth repair process without interruptions. Make sure to have a clean workspace to facilitate organization and efficiency.

Next, thoroughly inspect the components for wear and damage. Identifying problematic areas early on will save time and resources later in the process. Document any findings to keep track of what needs attention.

Once you’ve pinpointed the issues, carefully disassemble the components as per the specifications outlined in your manual. Take note of the arrangement for easier reassembly. Use appropriate techniques to avoid causing further damage.

After disassembly, clean all parts to remove debris and buildup. This step is crucial for ensuring proper functioning once everything is reassembled. Replace any damaged components with high-quality replacements to maintain durability.

Finally, reassemble the system following the documentation closely. Once everything is back in place, perform a thorough test to verify that all functions operate smoothly. Regular maintenance checks will help prolong the lifespan of your vehicle’s directional system.

Upgrading Your F250 Steering System

Enhancing the handling and control of your vehicle can significantly improve your driving experience. By upgrading certain components, you can achieve a more responsive and stable ride. This process involves selecting high-quality alternatives that provide better durability and performance.

Benefits of Upgrading

Opting for advanced features can lead to increased safety and efficiency. Enhanced responsiveness allows for smoother turns and better maneuverability, making it easier to tackle various terrains. Additionally, improved durability means fewer maintenance issues down the line.

Choosing the Right Components

When selecting new elements, consider compatibility with your existing setup and the specific demands of your driving style. Research reputable brands and consult with experts to ensure you’re making informed decisions that align with your ultimate performance goals.

Comparative Analysis of Steering Parts

This section delves into the intricacies of different components that facilitate vehicle maneuverability. By examining various elements, we aim to highlight their unique features, performance characteristics, and how they contribute to the overall functionality of a vehicle’s directional system.

One of the most significant factors in evaluating these components is their material composition. For instance, high-strength steel is often favored for its durability, while lightweight alloys can enhance responsiveness. Each material comes with trade-offs, impacting both longevity and handling precision.

Another aspect worth considering is the design variations. Different configurations can lead to distinct performance outcomes, affecting factors such as turning radius and feedback sensitivity. Understanding these nuances can aid in selecting the most appropriate elements for specific driving needs.

Additionally, compatibility plays a crucial role in ensuring seamless integration within the system. Parts must not only fit together physically but also operate harmoniously to provide a reliable driving experience. Mismatched components can lead to inefficiencies and safety concerns.

Ultimately, conducting a thorough comparative analysis of these critical elements enables better decision-making for enhancements, repairs, or replacements, ensuring optimal vehicle performance and driver satisfaction.

Common Modifications and Enhancements

When it comes to improving vehicle control systems, enthusiasts often seek ways to boost performance, responsiveness, and overall reliability. These adjustments can significantly alter the driving experience, offering a blend of comfort and capability tailored to individual preferences.

Popular Upgrades

Upgrading components can enhance maneuverability and precision. Here are some common enhancements:

| Modification | Description |

|---|---|

| High-Performance Bushings | Replace factory bushings with durable options for improved handling and reduced flex. |

| Heavy-Duty Rods | Utilize reinforced rods to withstand greater stress during demanding driving conditions. |

| Adjustable Control Arms | Allow for precise alignment adjustments, enhancing stability and cornering capabilities. |

Benefits of Modifications

Implementing these changes can lead to a more enjoyable driving experience, with better feedback and increased confidence on various terrains. Enhanced durability and performance often translate to longer service life and less frequent repairs.

Resources for Diagrams and Parts Lists

Finding reliable references for components and their arrangements is essential for maintenance and repairs. Numerous resources provide detailed visual aids and inventories to assist enthusiasts and professionals alike. These guides facilitate a deeper understanding of how various elements interact within the system.

Online Databases

Websites dedicated to automotive resources often feature extensive catalogs. Users can explore schematics and component listings, which are frequently updated. These platforms enable quick access to vital information, enhancing repair efficiency.

Manufacturer Manuals

Official documentation from manufacturers serves as a valuable asset. These manuals typically include comprehensive breakdowns of each assembly and its corresponding elements, ensuring accuracy in any restoration or replacement task.