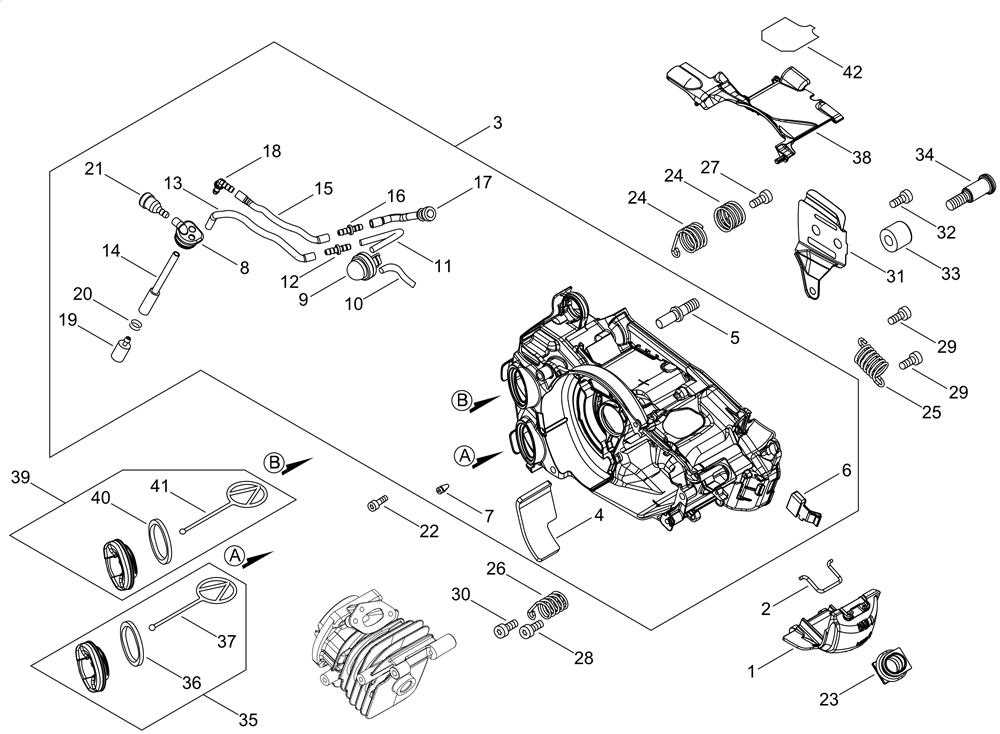

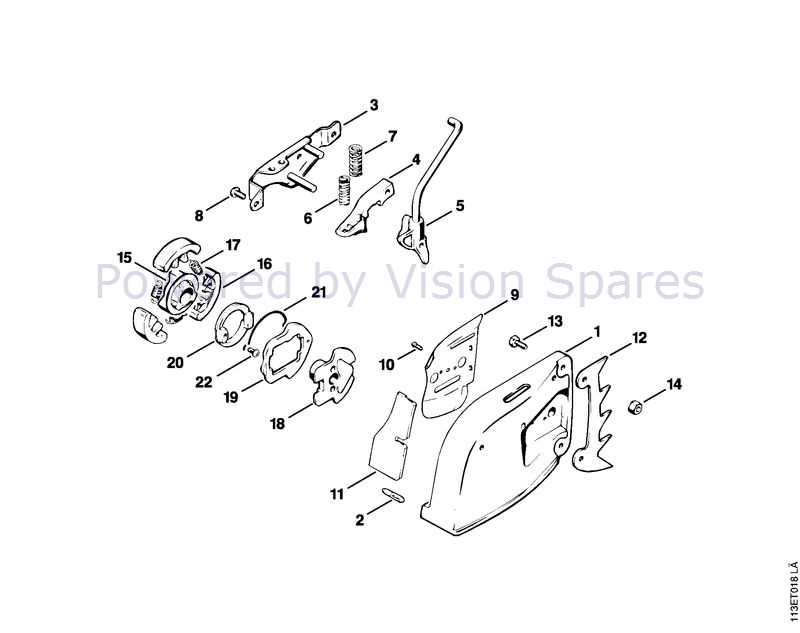

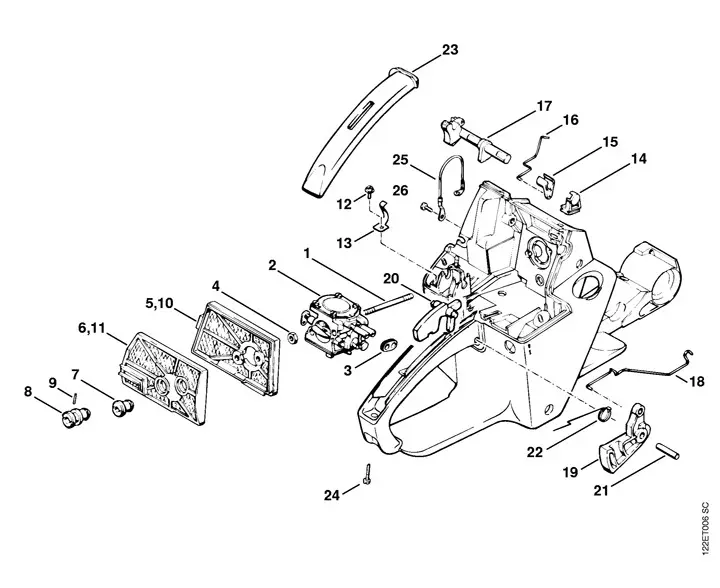

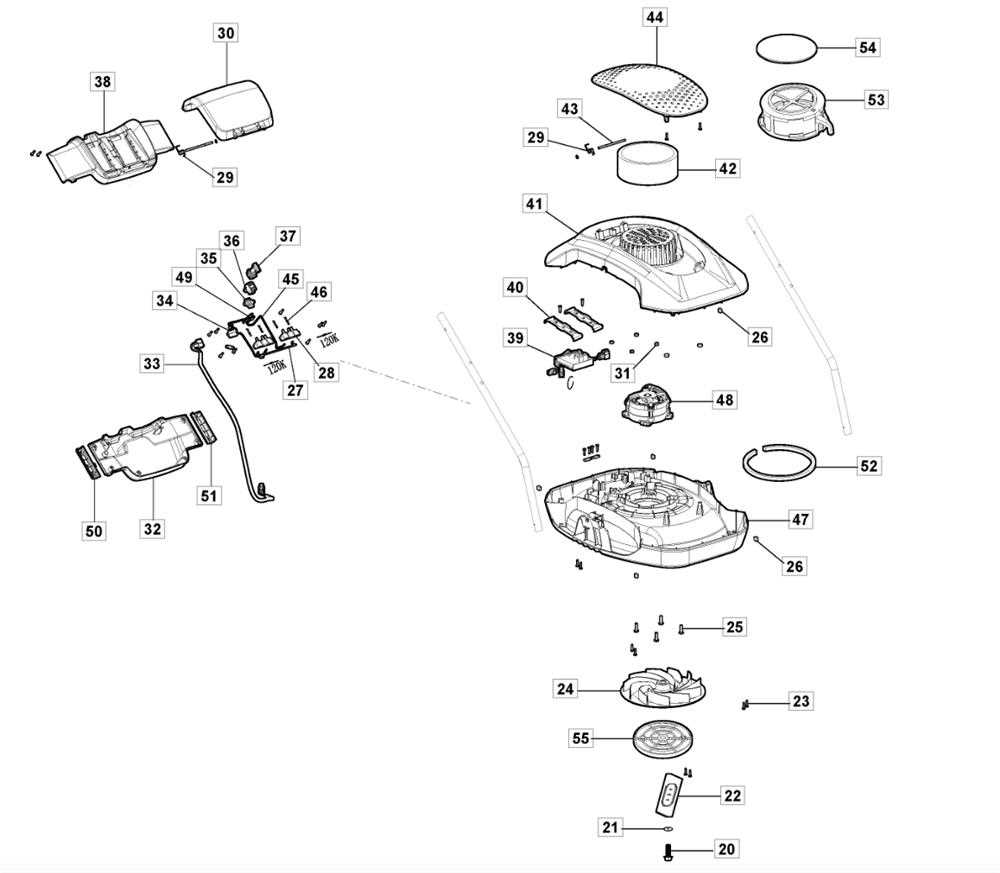

Comprehensive Guide to Stihl 031 Parts Diagram

The intricate design of a beloved outdoor device reflects the synergy between engineering and functionality. Understanding its components not only enhances maintenance practices but also empowers users to appreciate its craftsmanship. Each element plays a vital role in ensuring optimal performance, making familiarity with the structure essential for enthusiasts and professionals alike.

By examining the layout of individual elements, one can uncover the ultimate relationships between various parts. This exploration reveals the interconnectedness that underlies efficient operation, allowing for informed troubleshooting and repairs. As we delve into the specifics, we aim to provide clarity on how these segments work harmoniously to deliver unparalleled reliability.

For those looking to extend the lifespan of their equipment, a thorough grasp of its makeup serves as a foundation for successful upkeep. With each piece serving a distinct purpose, recognizing these roles can lead to improved performance and satisfaction. Let us embark on this journey to decode the essence of a time-tested tool, enhancing our understanding and appreciation along the way.

Overview of Stihl 031 Chainsaw

This powerful cutting tool is designed for both professional and recreational use, offering a reliable performance in various applications. Its robust construction ensures longevity and durability, making it a favorite among enthusiasts and industry workers alike.

Equipped with a reliable engine, this model delivers impressive cutting efficiency and speed. The ergonomic design allows for comfortable handling, reducing fatigue during extended use. Users appreciate its balance and maneuverability, which contribute to precise cutting actions.

Maintenance is straightforward, thanks to its accessible components. Regular upkeep enhances performance and extends the lifespan of the machine. Additionally, a variety of accessories and attachments can be utilized to optimize its functionality for specific tasks.

Whether tackling heavy-duty jobs or light trimming, this cutting tool stands out for its versatility. Its reputation for reliability makes it a trusted choice for anyone looking to manage woodwork efficiently.

Importance of Parts Diagrams

Understanding the layout and components of a machine is essential for effective maintenance and repair. Visual representations provide clarity, enabling users to identify individual elements and their functions within the overall structure.

Here are several key reasons why these illustrations are invaluable:

- Enhanced Clarity: Diagrams simplify complex assemblies, making it easier to understand how different components fit together.

- Efficient Troubleshooting: By pinpointing specific parts, users can quickly diagnose issues and determine necessary replacements.

- Time-Saving: A clear reference reduces the time spent searching for components, streamlining the repair process.

- Improved Safety: Understanding the configuration helps in safely handling and disassembling equipment, minimizing risks of injury.

- Cost-Effective Maintenance: Identifying the right parts helps avoid unnecessary expenditures on incorrect or superfluous components.

Incorporating these visuals into maintenance practices promotes a more efficient and informed approach to equipment care, ultimately leading to improved longevity and performance.

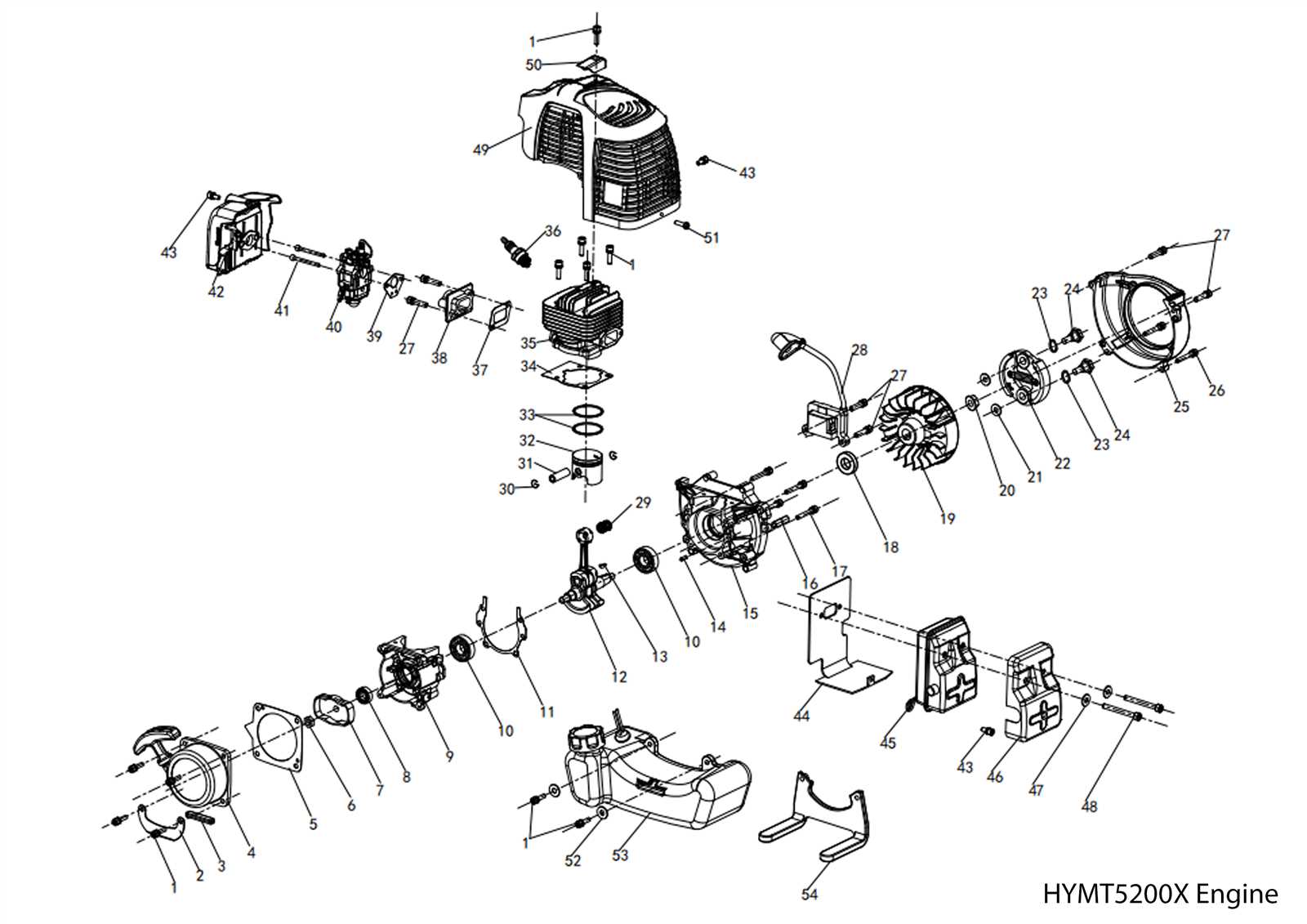

Key Components of Stihl 031

Understanding the essential elements of this tool is crucial for maintenance and optimal performance. Each part plays a significant role in ensuring efficient operation and longevity. By delving into these components, users can gain insights into how to best care for their equipment.

Power System

The heart of the device is its power system, which includes the engine and fuel delivery components. This system is designed to provide maximum output while maintaining fuel efficiency. Regular inspection of filters and spark plugs can enhance performance and reliability.

Cutting Mechanism

The cutting assembly consists of various blades and chains that work in unison to achieve precise cuts. Understanding the different types and their functions allows users to select the right configuration for their tasks. Proper maintenance of these elements is essential to ensure safe and effective operation.

How to Use the Diagram

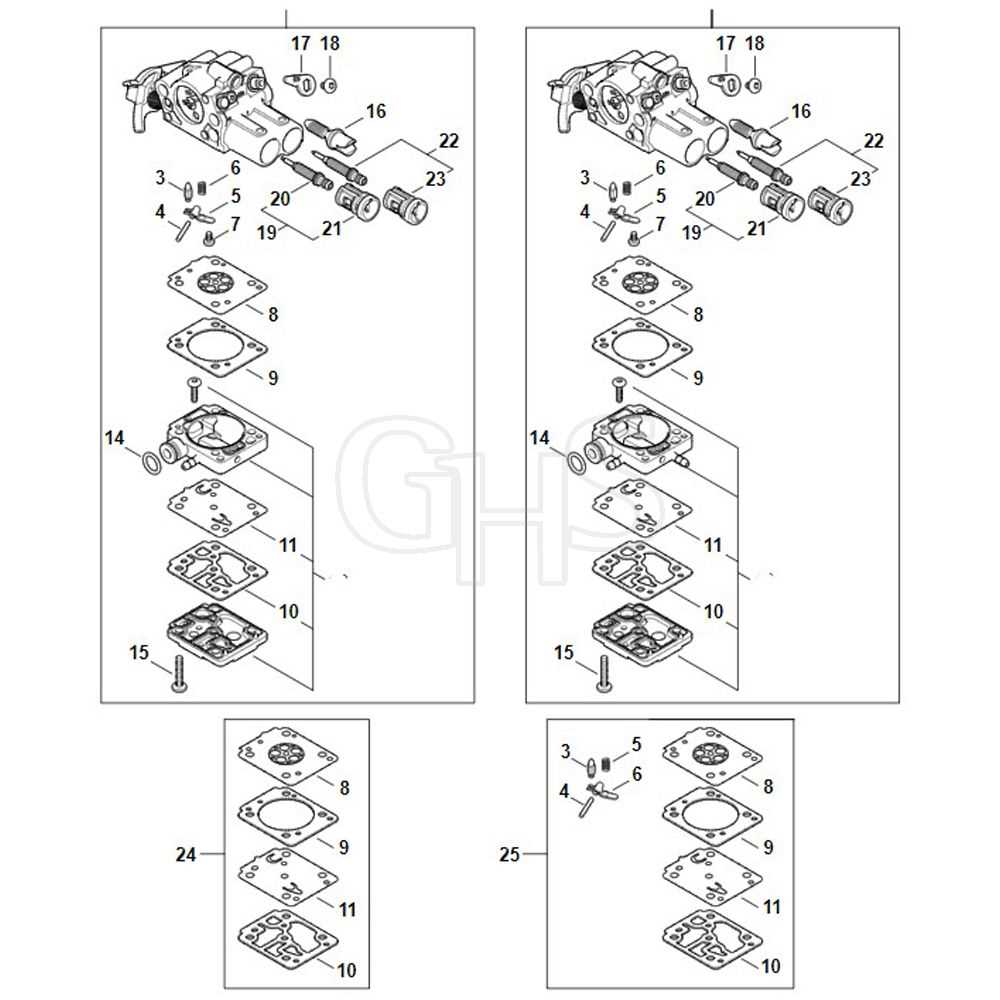

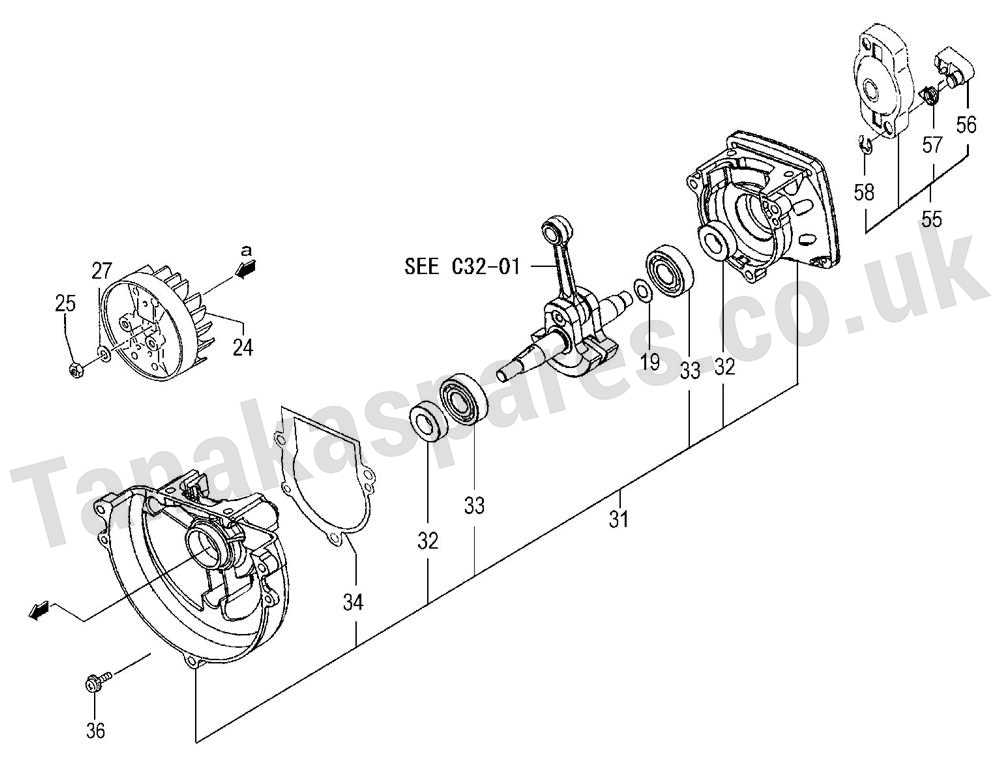

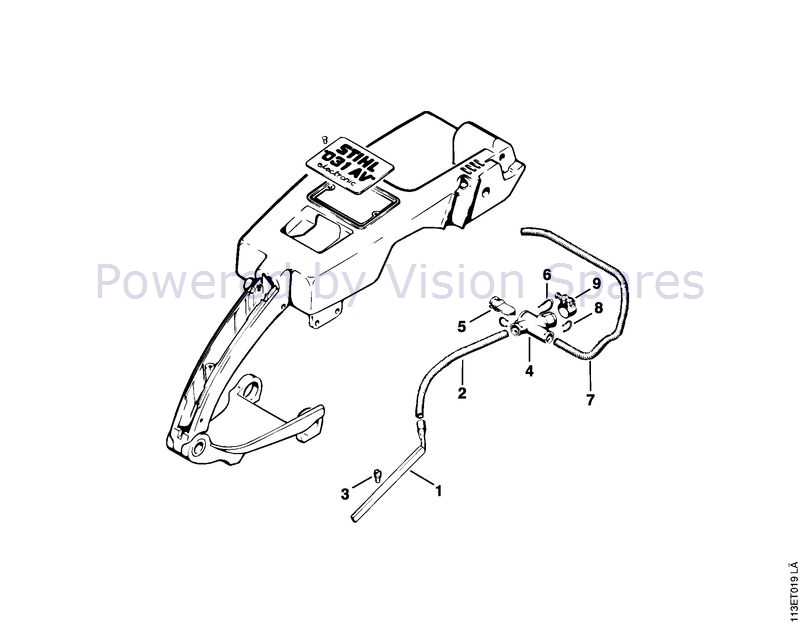

Understanding the visual representation of components is essential for efficient maintenance and repair tasks. This guide will help you navigate the illustration, enabling you to identify and locate various elements easily. By familiarizing yourself with the layout, you can streamline your workflow and ensure that every piece is in its proper place.

Start by referencing the key sections within the image, which often include numbered parts or labeled areas. This organization allows you to cross-reference with the corresponding list of items, making it easier to find specific components needed for replacement or inspection. Pay attention to any notes or legends that clarify the function and relationship of the elements depicted.

Additionally, take advantage of color coding or highlighted areas, which can indicate priority components or frequently serviced items. When disassembling or reassembling equipment, refer back to the illustration to ensure accuracy. This approach will not only help in identifying the right components but also in understanding how they interact within the overall system.

Finally, keep this visual reference handy for future repairs. With regular use, it will enhance your familiarity with the machinery and ultimately improve your repair skills, leading to more efficient and effective maintenance practices.

Common Issues and Solutions

When using outdoor power equipment, various challenges may arise that can hinder performance and efficiency. Understanding these common problems and their respective solutions can significantly improve the longevity and reliability of your machine. Below are some frequently encountered issues and practical tips for addressing them.

Performance Issues

- Difficulty Starting:

- Check the fuel level and quality; stale fuel can cause starting problems.

- Inspect the spark plug for wear or carbon buildup, replacing it if necessary.

- Inconsistent Power:

- Examine the air filter for dirt and debris; clean or replace it as needed.

- Ensure that the fuel line is not clogged, allowing proper fuel flow.

Mechanical Failures

- Excessive Vibration:

- Check for loose screws or components; tighten them to restore stability.

- Inspect the blades or attachments for damage; replace any broken parts.

- Overheating:

- Ensure that the cooling fins are clean and unobstructed.

- Monitor the oil levels; insufficient lubrication can lead to overheating.

By recognizing these issues and applying the suggested remedies, users can maintain optimal functionality and extend the life of their equipment.

Where to Find Replacement Parts

Locating components for your equipment can significantly enhance its performance and longevity. Whether you are looking for original items or compatible alternatives, several reliable sources can cater to your needs.

Online Retailers

- Official manufacturer websites often provide an extensive inventory.

- Third-party e-commerce platforms may offer competitive prices.

- Specialty stores online focus solely on outdoor equipment components.

Local Shops

- Authorized dealers usually stock genuine components.

- Repair shops can have essential items and knowledgeable staff.

- Farm supply stores often carry a range of compatible options.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan and performance of your outdoor equipment. By implementing a few simple practices, you can ensure that your machinery operates efficiently and reliably for years to come.

Regular Cleaning: After each use, take the time to remove dirt and debris from the exterior. This prevents buildup that can lead to overheating and mechanical issues.

Routine Inspections: Periodically check all components for wear and tear. Identifying potential problems early can save you from costly repairs down the line.

Proper Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and helps maintain optimal function.

Fuel Quality: Always use high-quality fuel and avoid old or contaminated gasoline, which can cause performance issues and engine damage.

Storage Practices: Store your equipment in a dry, sheltered area to protect it from the elements. Use covers when possible to prevent dust accumulation.

By following these guidelines, you can significantly enhance the durability and efficiency of your outdoor machinery, ensuring it remains in top condition throughout its lifespan.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your equipment can significantly elevate its overall performance. By focusing on specific enhancements, users can achieve optimal power, reliability, and longevity, allowing for a more effective operation in various tasks.

Engine Enhancements

One of the primary areas to consider for improvement is the engine. Upgrading components such as the air filter and exhaust can lead to better airflow and combustion efficiency. Additionally, implementing a high-performance spark plug can ensure a more reliable ignition, thus maximizing power output.

Handling and Comfort

Another vital aspect involves the handling and user comfort of the machine. Adding ergonomic grips and anti-vibration features can greatly reduce fatigue during prolonged use. Upgrading the fuel system with a more advanced carburetor can also contribute to smoother operation, enhancing the overall experience.

Comparing Stihl Models and Parts

This section explores the similarities and differences among various models of outdoor power equipment, focusing on their components and functionality. Understanding these distinctions can help users make informed decisions based on their specific needs and preferences.

Key Features of Different Models

Each model comes with unique specifications that cater to diverse tasks. Engine capacity, weight, and design often vary, influencing performance and ease of use. Users should consider these aspects when selecting equipment for gardening, forestry, or landscaping.

Component Compatibility

Not all machinery from this brand share interchangeable components. It’s essential to delve into the details of each unit to ensure compatibility when replacing or upgrading. Understanding the ultimate fit of components can enhance functionality and prolong the lifespan of the equipment.

DIY Repairs: A Step-by-Step Guide

Engaging in do-it-yourself repairs can be both rewarding and cost-effective. Whether you’re looking to fix a piece of equipment or simply want to enhance its performance, understanding the basic components and their functions is crucial. This guide will walk you through a structured approach to tackle repairs effectively.

Gathering Necessary Tools and Resources

Before starting any repair, ensure you have the right tools at hand. A toolkit should include basic items like screwdrivers, wrenches, and pliers. Additionally, consult reliable resources such as manuals or online tutorials to familiarize yourself with the assembly and disassembly processes. Having clear instructions will significantly ease your repair journey.

Executing the Repair Process

Begin by disassembling the unit carefully, taking note of each component’s position. It’s advisable to organize parts as you go, possibly using labeled containers. Once disassembled, inspect each piece for wear or damage. If you identify any issues, replace the faulty components with quality alternatives. After replacement, reassemble the unit in reverse order, ensuring that everything is tightened securely. Finally, conduct a test to confirm that the repair was successful and the equipment functions properly.

In summary, with the right tools and a systematic approach, you can effectively handle repairs on your own. This not only saves money but also enhances your understanding of how your equipment operates.