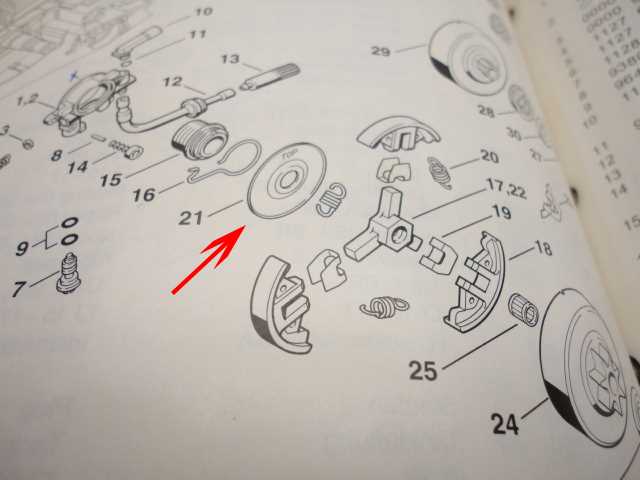

Complete Stihl 039 Parts Diagram for Easy Reference

Maintaining optimal performance of outdoor machinery requires a thorough understanding of its various elements. Each piece plays a critical role in the overall functionality, and knowing how they interconnect can greatly enhance repair and maintenance efforts.

In this section, we will explore the intricate layout of these essential components. By familiarizing yourself with the specific arrangements, you can more effectively troubleshoot issues and streamline your repair processes.

Furthermore, a visual reference can serve as a valuable tool, enabling you to identify parts more easily and ensure that replacements are accurate. Whether you’re an experienced technician or a novice user, having access to a comprehensive guide can simplify your maintenance tasks and prolong the lifespan of your machinery.

Understanding Stihl 039 Chainsaw Components

Familiarizing oneself with the various elements of a cutting tool can significantly enhance its performance and maintenance. Each component plays a crucial role in the efficient operation of the machinery, contributing to both its functionality and longevity. By grasping the purpose of these individual parts, users can make informed decisions regarding repairs and upgrades.

Key Elements of the Equipment

Central to the functioning of this machinery is the engine, which provides the necessary power. Equally important are the cutting assembly and the drive mechanism, which work in tandem to facilitate effective cutting. Understanding the interaction between these components is vital for optimal performance.

Maintenance and Care

Regular upkeep of the various parts is essential for maintaining efficiency. This includes checking the lubrication system, ensuring sharpness of the cutting edge, and monitoring the ignition system. Neglecting these aspects can lead to decreased performance and potential safety hazards. A thorough understanding of the components involved allows for better care and longevity of the tool.

Key Features of Stihl 039

This section highlights the essential characteristics of a renowned power tool designed for efficient cutting tasks. Its robust design and advanced features cater to both professionals and enthusiasts alike.

- Powerful Engine: Delivers exceptional performance for demanding applications.

- Durability: Constructed with high-quality materials to withstand rigorous use.

- Ergonomic Design: Provides comfort during extended operation, reducing fatigue.

- Easy Maintenance: Simplifies upkeep, ensuring longevity and reliability.

- Safety Features: Equipped with mechanisms that prioritize user protection during operation.

These attributes contribute to its reputation as a reliable tool for various cutting tasks, making it a favorite among users seeking ultimate efficiency.

Importance of Parts Diagrams

Understanding the layout and components of a mechanical device is crucial for effective maintenance and repair. Visual representations play a vital role in simplifying complex assemblies, allowing users to identify each element and its function within the system. This clarity is essential for anyone working to restore equipment to optimal performance.

Accurate identification of components helps to streamline the repair process, ensuring that users can quickly locate the necessary pieces and understand their interconnections. This not only saves time but also reduces the risk of errors during reassembly, leading to a more efficient workflow.

Additionally, having a visual guide enhances learning and understanding for individuals new to machinery. By studying these illustrations, users can gain insights into how parts interact, which fosters greater proficiency in troubleshooting and repairs.

Moreover, the availability of visual aids can significantly contribute to better resource management. Knowing precisely what is needed allows for more effective ordering and inventory control, minimizing downtime and unnecessary expenses. In essence, these graphical tools are invaluable for anyone involved in the upkeep of machinery.

Identifying Stihl 039 Parts

Understanding the components of a chainsaw is essential for effective maintenance and repair. Each element plays a critical role in the overall functionality of the tool. By familiarizing yourself with these various segments, you can ensure proper operation and extend the lifespan of your equipment.

Key Components

Familiar components include the engine, guide bar, and chain. Each part has a specific function that contributes to the performance of the machine. Recognizing these elements allows users to troubleshoot issues and perform necessary repairs more efficiently.

Tools for Identification

Using a reference guide or manual can greatly assist in identifying different components. These resources often provide detailed descriptions and illustrations, making it easier to locate and understand the purpose of each segment. Having the right tools on hand for disassembly and inspection is also vital for accurate identification.

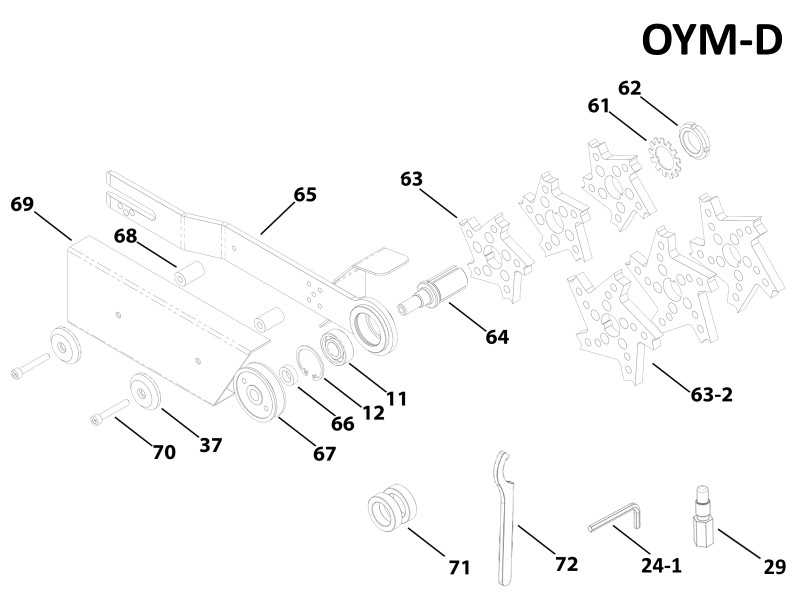

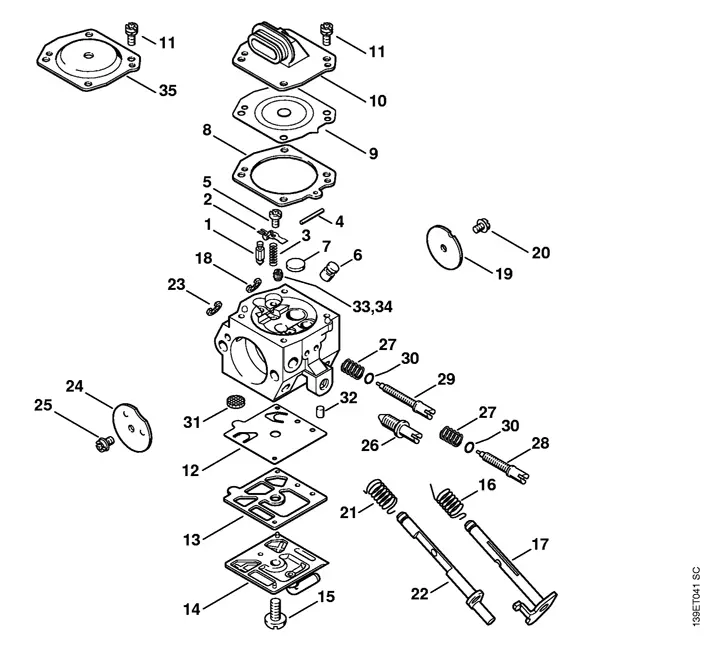

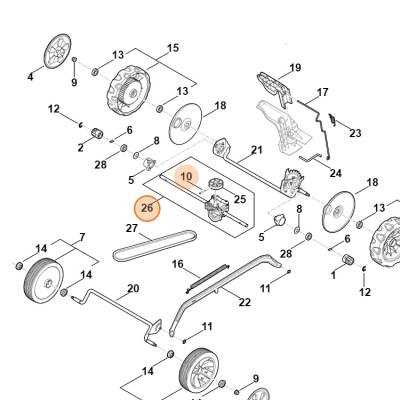

How to Read a Parts Diagram

Understanding a schematic can significantly enhance your ability to maintain and repair machinery. These illustrations serve as visual guides, showcasing components and their interrelations, which is crucial for effective troubleshooting. Grasping the essentials of these representations will empower you to tackle repairs with confidence.

Firstly, familiarize yourself with the layout. Most schematics are organized logically, with similar items grouped together. This helps in quickly locating specific elements. Secondly, pay attention to the labels. Each part is usually numbered or named, corresponding to a list that details specifications or replacement options. This connection is vital for ensuring you acquire the correct components.

Lastly, practice makes perfect. Regularly consulting these visuals during maintenance will deepen your understanding and improve your efficiency. The more you delve into these resources, the more intuitive reading them will become, ultimately aiding your repair efforts.

Common Stihl 039 Issues

When it comes to outdoor power tools, certain challenges can frequently arise, affecting their performance and longevity. Understanding these common problems is essential for effective maintenance and troubleshooting. By identifying the most prevalent issues, users can ensure their equipment operates smoothly and efficiently.

Frequent Mechanical Problems

Mechanical failures often manifest in various forms, ranging from engine struggles to starting difficulties. These issues can stem from multiple factors, including wear and tear, improper maintenance, or environmental conditions.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Hard Starting | Engine won’t turn over or requires multiple attempts | Check spark plug, fuel lines, and carburetor settings |

| Overheating | Excessive smoke or burning smell | Inspect air filter and cooling fins for blockages |

| Poor Performance | Loss of power or irregular operation | Clean or replace the air filter, check fuel quality |

Fuel-Related Issues

Fuel-related problems can significantly affect tool efficiency and functionality. Issues such as contamination or improper fuel mixtures can lead to a range of operational challenges.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Fuel Contamination | Difficulty in starting or stalling | Drain old fuel and replace with fresh fuel |

| Improper Mixture | Excessive smoke or sluggish operation | Adjust fuel mix according to manufacturer specifications |

| Clogged Fuel Filter | Engine sputtering or reduced power | Replace or clean the fuel filter regularly |

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right set of instruments is crucial for ensuring efficiency and accuracy. A well-equipped toolkit can make the difference between a smooth repair process and unnecessary frustration. Below is a list of fundamental tools that every technician should have on hand.

| Tool | Description |

|---|---|

| Wrench Set | Essential for loosening and tightening various bolts and nuts. |

| Screwdriver Set | Includes both flathead and Phillips types for diverse applications. |

| Torque Wrench | Ensures proper tension is applied to fasteners, preventing damage. |

| Pliers | Useful for gripping, twisting, and cutting wires and components. |

| Socket Set | Provides versatility for various sizes of bolts and screws. |

| Multi-tool | A handy device that combines several functions into one compact form. |

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Various options are available to ensure you can find the necessary items to keep your equipment running smoothly. From authorized dealers to online marketplaces, each source offers unique benefits that cater to different needs.

Authorized Dealers provide the highest assurance of quality and compatibility. They often carry a comprehensive selection of genuine components, ensuring that you receive items that meet the manufacturer’s specifications. Visiting a local dealer can also give you access to knowledgeable staff who can offer valuable advice on your specific needs.

Online Retailers have gained popularity due to their convenience and vast inventory. Websites specializing in machinery supplies can be excellent resources for finding hard-to-get components. Make sure to check customer reviews and ratings to ensure you are purchasing from a reputable seller.

Aftermarket Options can be a cost-effective alternative. Many manufacturers produce compatible items that are often less expensive than original ones. However, it’s crucial to verify the quality and reliability of these alternatives, as they may vary significantly in performance.

For those who enjoy DIY projects, local salvage yards or second-hand marketplaces can be treasure troves for finding used components at a fraction of the cost. Just ensure you inspect the items carefully to confirm they are in good condition and fit your equipment correctly.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your equipment and ensuring optimal performance. Regular maintenance not only prevents breakdowns but also enhances efficiency, allowing users to enjoy a smoother experience. By implementing a few simple practices, you can significantly prolong the lifespan of your machine.

Routine Checks

Establishing a schedule for routine inspections can help identify potential issues before they escalate. Key areas to focus on include:

| Component | Check Frequency | Notes |

|---|---|---|

| Air Filter | Every 10 hours | Clean or replace as necessary to maintain airflow. |

| Oil Levels | Every use | Ensure proper lubrication to prevent overheating. |

| Fuel System | Monthly | Inspect for leaks and clean fuel lines regularly. |

| Blade Condition | After each use | Sharpen or replace as needed for efficiency. |

Seasonal Maintenance

Seasonal maintenance is equally crucial, as it prepares your machine for different operating conditions. Tasks to consider include:

- Draining old fuel before long-term storage.

- Checking spark plugs for wear and replacing them if necessary.

- Inspecting all belts and cables for signs of wear.

By adhering to these guidelines, you can ensure that your equipment remains reliable and performs at its best for years to come.

Aftermarket vs. Original Parts

When it comes to equipment maintenance, the choice between alternative and manufacturer-specific components can significantly impact performance and longevity. Understanding the differences can help users make informed decisions that align with their needs and budget.

Quality and Performance

Original components are designed to meet the manufacturer’s exact specifications, often resulting in superior performance and reliability. In contrast, aftermarket options may vary in quality, with some providing comparable results while others might compromise efficiency or durability.

Cost Considerations

Price is a crucial factor in this decision. While alternative components often come at a lower price point, it’s essential to evaluate whether the potential savings outweigh the risks associated with reduced quality. Ultimately, the right choice depends on individual preferences and how often the equipment is used.

Understanding Warranty Coverage

Warranty coverage is an essential aspect of purchasing equipment, ensuring that users are protected against manufacturing defects and other issues. It provides peace of mind by guaranteeing that if problems arise within a specified timeframe, the manufacturer will address them without additional cost to the consumer. Understanding the specifics of this coverage is crucial for maximizing the investment made in any tool or machine.

Typically, warranty agreements outline the conditions under which repairs or replacements are applicable. Consumers should familiarize themselves with the terms, including duration, limitations, and the process for claiming warranty services. It’s also important to note that proper maintenance and care are often prerequisites for warranty validity.

| Aspect | Description |

|---|---|

| Duration | Time period during which the warranty is active. |

| Coverage | Types of issues that are included under warranty. |

| Exclusions | Specific conditions or damages that are not covered. |

| Claim Process | Steps required to initiate a warranty claim. |

In summary, understanding warranty coverage helps ensure that consumers are well-informed about their rights and the responsibilities of the manufacturer. This knowledge empowers users to make better decisions and maintain their equipment effectively.

Safety Considerations When Repairing

When undertaking maintenance or repairs on power tools, safety should always be the top priority. Proper precautions can prevent accidents and injuries, ensuring a smooth and efficient repair process. Here are essential considerations to keep in mind.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hearing protection.

- Ensure the equipment is turned off and disconnected from any power source before beginning any work.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

In addition to personal safety, consider the environment in which you are working:

- Keep your workspace organized and free from clutter to prevent trips and falls.

- Ensure that all tools are in good condition and appropriate for the tasks at hand.

- Be aware of your surroundings and avoid distractions while working.

Finally, always consult the manufacturer’s guidelines and instructions before proceeding with repairs. This helps ensure you understand the specifics of the device and can perform maintenance safely and effectively.

Resources for Further Learning

To deepen your understanding of machinery maintenance and repair, a variety of educational materials are available. These resources can enhance your skills and provide valuable insights into the workings of power tools and equipment.

- Online Tutorials: Websites and video platforms offer comprehensive guides that cover troubleshooting and repair techniques.

- User Manuals: Official manuals provide detailed instructions and diagrams, essential for understanding assembly and function.

- Community Forums: Engaging in discussions with other enthusiasts can yield tips and advice from experienced users.

- Workshops and Classes: Local vocational schools or community colleges often host hands-on courses to develop practical skills.

- Books and E-books: Literature focusing on equipment mechanics can serve as excellent reference materials.

Utilizing these resources will not only improve your technical abilities but also increase your confidence in handling various machinery tasks.