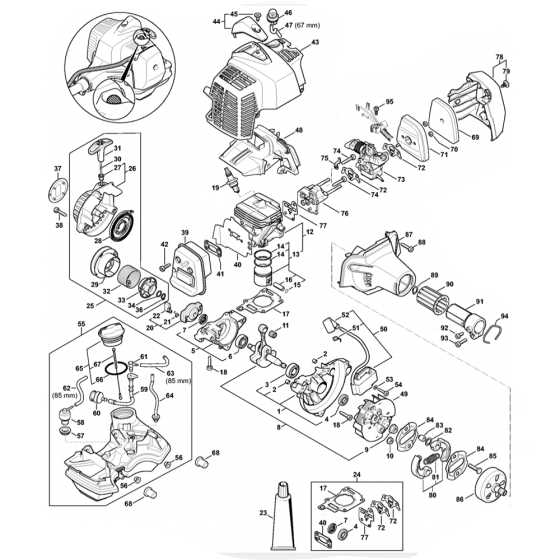

Stihl FS 90 Parts Diagram Overview

The efficient operation of a brushcutter relies on a well-designed assembly of its individual elements. Each component plays a crucial role in ensuring the device performs optimally, making it essential for users to grasp how these parts interact within the overall framework. Knowledge of these components aids in maintenance and troubleshooting, enhancing the longevity and functionality of the equipment.

Identifying the elements involved in the assembly can significantly simplify repair processes. By familiarizing oneself with the layout and function of these components, users can tackle any issues that arise during operation. This understanding is particularly valuable for those who perform their own repairs, enabling them to identify malfunctioning elements swiftly and accurately.

Moreover, having a comprehensive overview of the assembly can guide users in making informed decisions when replacing or upgrading specific parts. Knowing the role of each section can assist in selecting the appropriate replacements or enhancements, ultimately leading to improved performance. With this foundational knowledge, users are better equipped to maintain their brushcutters effectively.

Overview of FS 90 Components

The FS 90 is a robust machine designed for efficient cutting and trimming tasks. Understanding its various elements is essential for optimal performance and maintenance. Each component plays a crucial role in the overall functionality, ensuring that users can achieve desired results with ease.

Key components of this equipment include:

- Engine: The powerhouse responsible for driving the tool’s cutting mechanism.

- Handle: Designed for comfort and control, allowing the user to maneuver the device effectively.

- Blade: The cutting tool that determines the efficiency and quality of the work.

- Fuel Tank: Stores the necessary fuel for operation, crucial for uninterrupted use.

- Throttle Trigger: Provides control over the engine speed and cutting power.

- Guard: A safety feature that protects the user from debris during operation.

Familiarity with these components will aid in troubleshooting and performing maintenance tasks. Regular checks and replacements ensure the equipment remains in top condition, ultimately extending its lifespan.

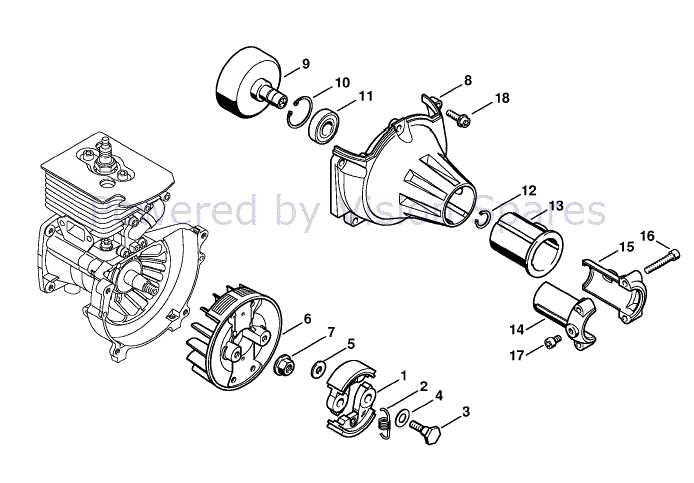

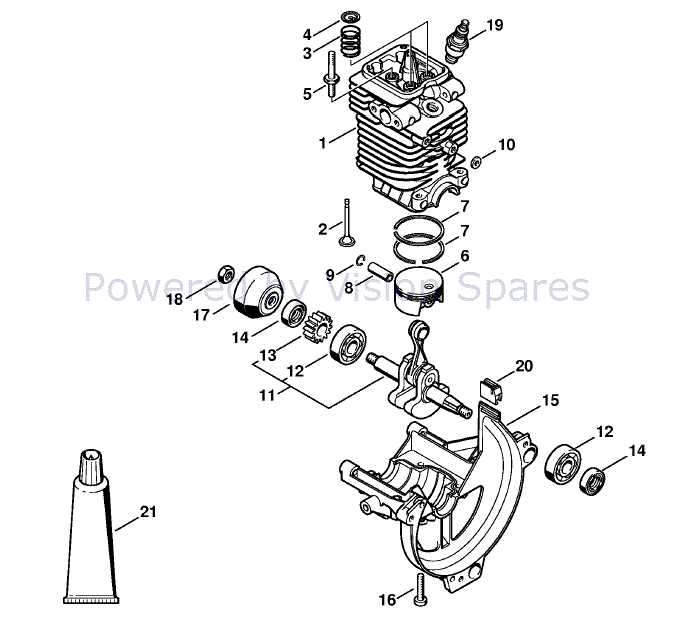

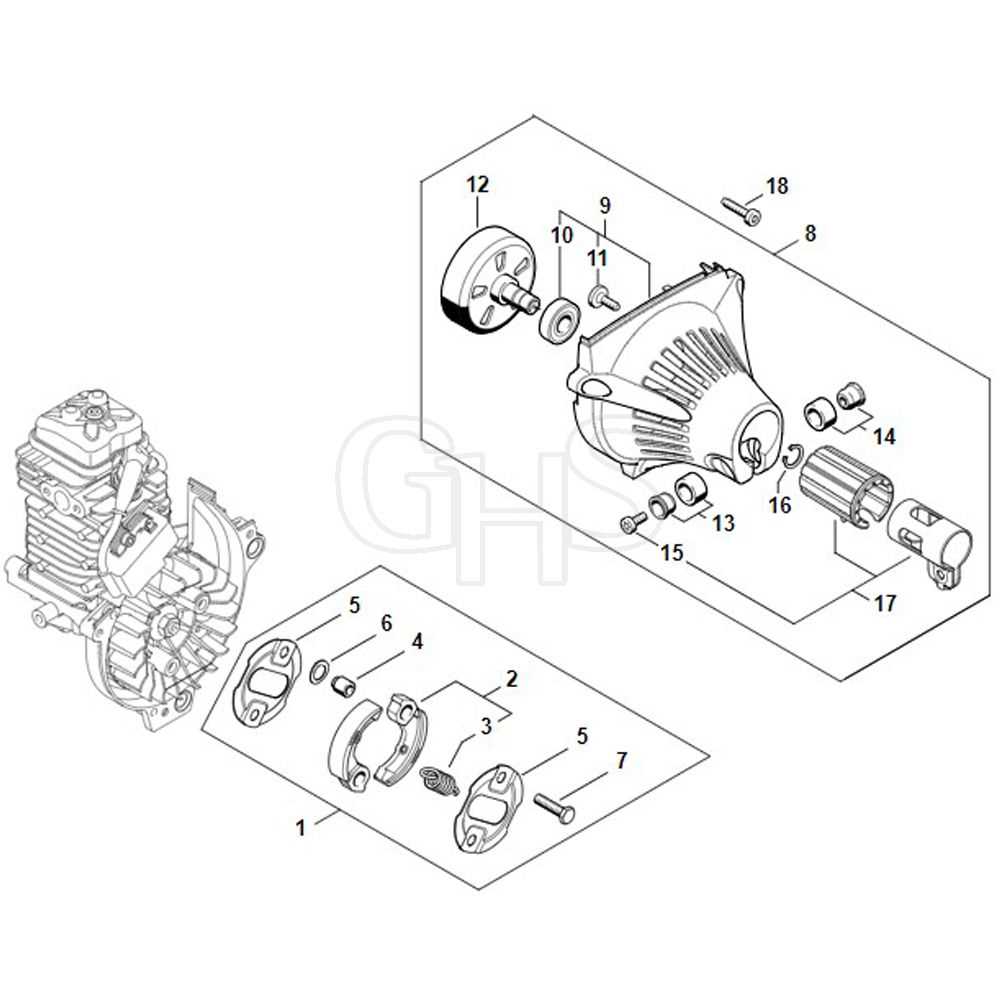

Understanding the Parts Breakdown

The breakdown of components within a mechanical device is essential for effective maintenance and troubleshooting. By familiarizing oneself with each element, users can enhance their understanding of the overall functionality and ensure optimal performance of the equipment. This knowledge empowers individuals to identify issues, perform repairs, and execute routine checks with confidence.

Components are often categorized based on their function and location, allowing for a systematic approach to comprehension. For instance, elements responsible for power generation, movement, and control are typically organized in a logical sequence. This organization aids in visualizing how each part interacts with others, leading to a more profound grasp of the machinery’s operation.

Additionally, having a clear representation of the various components can be invaluable during maintenance tasks. When users can pinpoint specific sections, it simplifies the process of ordering replacements or seeking technical assistance. Ultimately, understanding the configuration and role of each part is a foundational step in achieving long-lasting equipment reliability.

Key Features of FS 90 Model

The FS 90 model stands out due to its remarkable design and efficient performance, making it a preferred choice for various landscaping tasks. This unit is engineered to provide users with exceptional reliability and ease of operation, enhancing the overall experience for both professionals and enthusiasts.

- Powerful Engine: The unit is equipped with a high-performance engine that ensures robust operation, enabling it to tackle tough vegetation with ease.

- Lightweight Construction: Designed with a lightweight frame, the model offers improved maneuverability, reducing user fatigue during extended use.

- Ergonomic Design: Features an ergonomic handle that promotes comfort and control, allowing for precise handling during operation.

- Versatile Attachments: Compatible with various attachments, the unit can adapt to different tasks, making it a versatile tool for any gardener.

- Easy Maintenance: The design facilitates straightforward maintenance, ensuring that users can keep the equipment in optimal condition with minimal effort.

Overall, the FS 90 model exemplifies a perfect blend of performance, comfort, and versatility, making it an excellent choice for users seeking efficiency in their landscaping endeavors.

Importance of Genuine Parts

Using authentic components for your equipment is crucial for maintaining optimal performance and longevity. Quality materials and precise engineering ensure that the machinery operates smoothly and efficiently, reducing the risk of malfunctions and prolonging its lifespan. When you invest in reliable elements, you are not just protecting your equipment but also enhancing its overall functionality.

Quality Assurance

Authentic components are manufactured to meet strict quality standards, guaranteeing that they will fit perfectly and function as intended. This level of assurance helps prevent potential issues that can arise from using inferior substitutes, such as wear and tear or mechanical failures. By prioritizing quality, users can ensure their machinery performs at its best.

Cost-Effectiveness

While genuine components may come with a higher upfront cost, they often prove to be more economical in the long run. Investing in high-quality items reduces the need for frequent replacements and repairs, ultimately saving you money over time. Furthermore, authentic components can enhance fuel efficiency and reduce overall operational costs.

Common Replacement Parts Explained

In any machinery, understanding the elements that may require replacement is essential for maintaining optimal performance. Regular maintenance and timely substitutions can prevent extensive damage and ensure longevity. This section delves into the frequently replaced components that users should be aware of, emphasizing their roles and importance.

Engine Components

Among the vital elements are those directly related to the engine’s functionality. These include the spark plug, which ignites the fuel-air mixture, and the fuel filter, essential for keeping contaminants away from the engine. Replacing these components regularly ensures efficient operation and reduces the likelihood of breakdowns.

Cutting Equipment

Another crucial area involves the cutting mechanism. The blades and line heads are particularly susceptible to wear and tear. Over time, they may dull or become damaged, necessitating their replacement. Keeping these parts in good condition is key to achieving effective cutting performance and enhancing the overall user experience.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the durability and efficiency of your equipment. Implementing a routine maintenance schedule can significantly enhance performance and extend the lifespan of the machine.

Regular Inspections: Conduct frequent checks to identify any wear or damage. Look for signs of corrosion, loose components, or fluid leaks. Early detection of issues can prevent more significant problems later.

Cleaning: Keep the exterior and interior of the equipment clean. Remove dirt, debris, and other contaminants that may affect functionality. Use a soft brush and mild soap to avoid damaging any surfaces.

Lubrication: Ensure that moving parts are adequately lubricated. Use the recommended lubricant to reduce friction and wear. This practice not only enhances performance but also minimizes the risk of overheating.

Storage: When not in use, store the machine in a dry and protected area. Avoid exposure to extreme temperatures or moisture, as these conditions can lead to deterioration. If necessary, cover the equipment to shield it from dust and debris.

Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations regarding maintenance intervals and procedures. This guidance is vital for maintaining warranty coverage and ensuring optimal functionality.

By following these maintenance tips, you can ensure that your equipment remains in excellent working condition, ultimately contributing to its longevity and reliability.

Assembly Instructions for Users

When assembling your equipment, it’s essential to follow a systematic approach to ensure all components are fitted correctly and securely. Proper assembly not only guarantees the longevity of the device but also enhances its performance. Below are guidelines to assist you in the assembly process, making it efficient and straightforward.

Essential Steps for Assembly

Begin by gathering all necessary components and tools before starting. Familiarizing yourself with each piece will help in understanding how they fit together. It is advisable to lay out all parts in an organized manner to streamline the assembly process.

Assembly Table

| Component | Description | Installation Tips |

|---|---|---|

| Handle | The part that users hold while operating the device. | Ensure it is securely fastened and positioned for comfort. |

| Engine | The power source for the machine. | Align it properly with the mounting points before tightening. |

| Guard | Protective shield around the cutting area. | Check that it is firmly attached to prevent accidents. |

| Fuel Tank | Container for the operating fluid. | Ensure it is sealed correctly to avoid leaks. |

Following these assembly instructions carefully will lead to a successful setup of your equipment, allowing for optimal usage and safety during operation.

Identifying Compatible Accessories

Choosing the right additional components for your equipment is essential for optimizing its performance and extending its lifespan. Understanding compatibility between various attachments and the main device can significantly enhance your experience and efficiency.

When seeking out suitable accessories, consider the following aspects:

- Manufacturer Specifications: Always refer to the guidelines provided by the manufacturer to ensure compatibility.

- Accessory Types: Familiarize yourself with different accessory categories, such as cutting tools, harnesses, and protective gear.

- Reviews and Recommendations: Check user feedback and expert opinions to gauge the effectiveness and reliability of specific accessories.

Taking the time to identify compatible components will lead to better results and a more satisfying user experience.

Diagram Utilization for Repairs

The effective use of schematics is crucial in maintaining and fixing various equipment. Understanding the visual representation of components and their arrangement can significantly enhance the repair process. This section explores how these illustrations aid technicians in diagnosing issues and replacing elements accurately.

Benefits of Using Visual Guides

- Facilitates quick identification of parts and functions.

- Streamlines the disassembly and reassembly process.

- Reduces the risk of errors during repairs.

- Improves the overall efficiency of maintenance tasks.

Steps for Effective Utilization

- Gather the necessary tools and equipment.

- Study the visual representation to understand the layout.

- Follow the indicated steps for disassembly, ensuring careful handling of components.

- Refer back to the guide when reassembling to ensure all elements are correctly positioned.

- Test the equipment after repairs to confirm proper functionality.

Troubleshooting Common Issues

When operating outdoor power equipment, encountering certain difficulties can be quite common. Understanding the typical challenges and their resolutions can enhance the user experience and prolong the lifespan of the device. This section addresses frequent problems faced by users and offers practical solutions to rectify them.

Engine Does Not Start

If the engine fails to ignite, it may stem from various causes. Ensure that there is an adequate fuel supply, and inspect the fuel lines for any blockages or leaks. Additionally, verify that the spark plug is in good condition and properly connected. Replacing a worn or damaged spark plug can often resolve ignition issues.

Unusual Noise During Operation

Should you notice an unusual sound while the equipment is in use, it is crucial to address it promptly. Such noises may indicate a loose component or an internal malfunction. Begin by checking for loose screws or bolts and tighten them as necessary. If the sound persists, consider consulting a professional for further inspection and repair.

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its functionality and longevity. There are various resources available to help you locate the necessary items without any hassle. From authorized dealers to online platforms, options abound for sourcing what you need.

One effective method is to visit local retailers that specialize in outdoor equipment and accessories. These establishments often carry a wide range of items that match the specifications of your machinery. Additionally, they can provide valuable insights into compatible components and alternative solutions.

Online marketplaces present another convenient avenue for obtaining these essential items. Websites dedicated to selling equipment components often feature detailed descriptions and customer reviews, making it easier to ensure compatibility. Furthermore, many online suppliers offer competitive pricing, allowing you to find what you need at a reasonable cost.

Lastly, engaging with community forums or groups dedicated to machinery can yield beneficial recommendations. Fellow users frequently share their experiences and insights on where to acquire specific components, providing you with trustworthy leads.