Comprehensive Stihl FS250 Parts Diagram for Easy Reference

Maintaining machinery requires a clear comprehension of its individual elements and their functions. A thorough exploration of the intricate relationships between each component can significantly enhance the performance and longevity of your tools. Knowing how these parts interact is essential for any operator aiming to achieve ultimate efficiency.

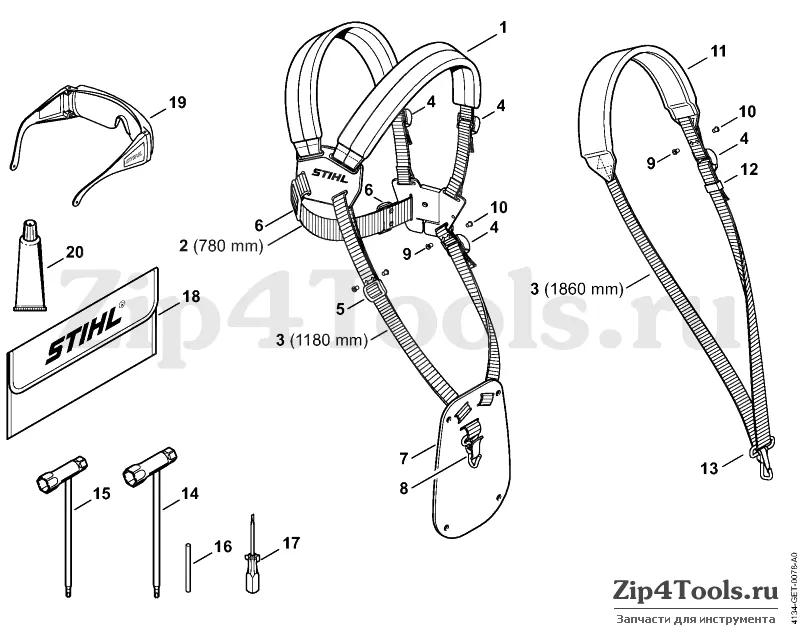

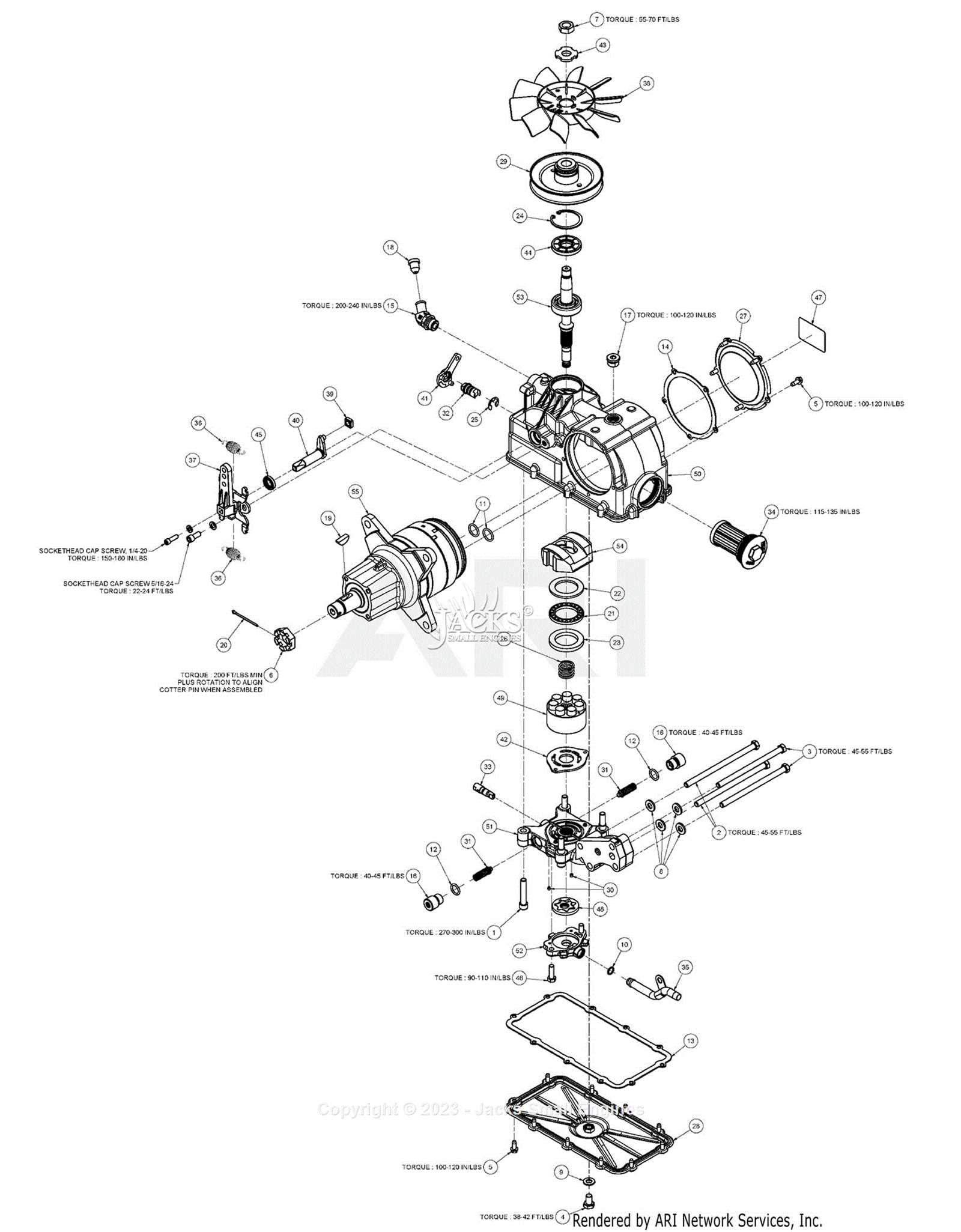

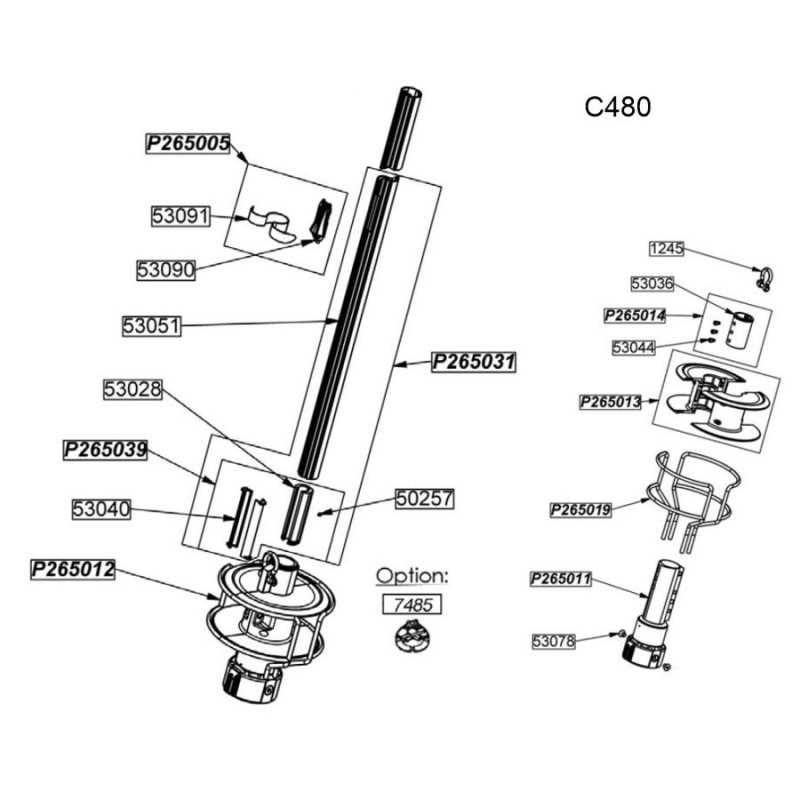

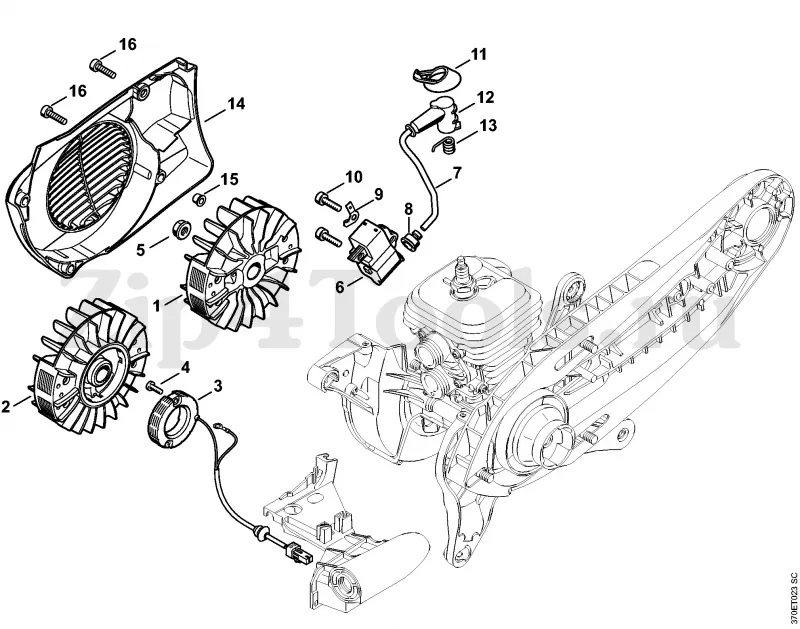

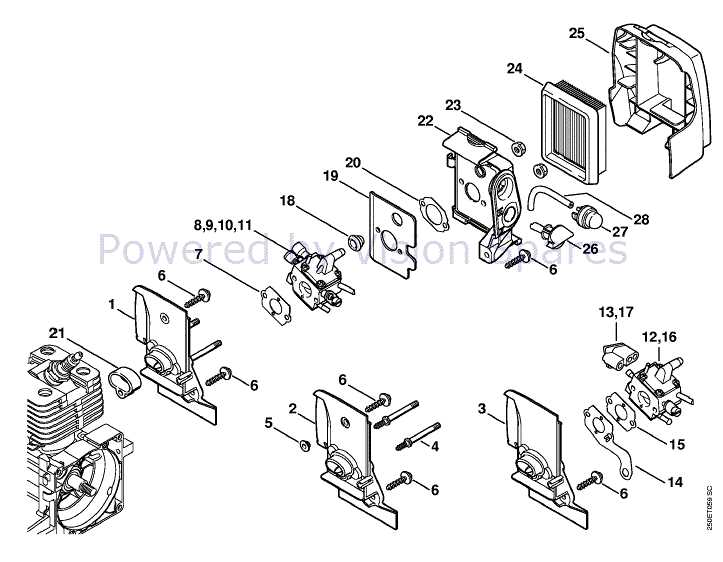

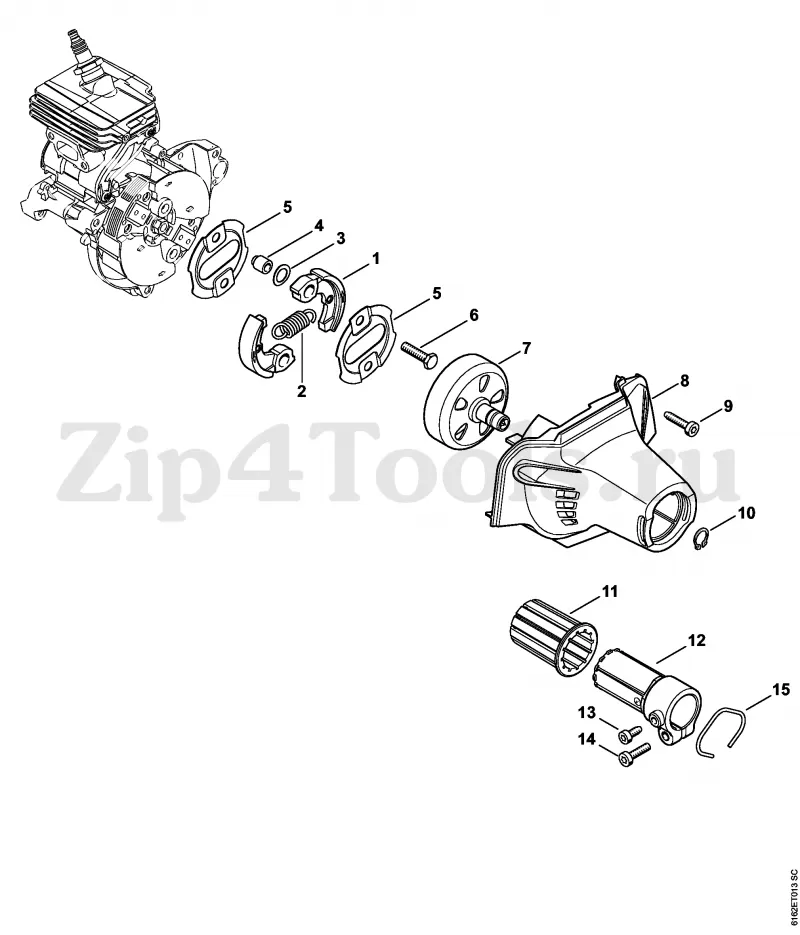

In this section, we will delve into the visual representation of the various elements that comprise your outdoor power equipment. Such illustrations serve as a valuable resource for identifying necessary replacements or repairs, ensuring that your machinery operates at peak performance. A detailed look at these components will provide insights into their roles and importance in the overall functionality.

Equipping yourself with this knowledge empowers you to make informed decisions regarding maintenance and upgrades. As you familiarize yourself with the configuration and layout, you’ll be better prepared to tackle any issues that may arise, keeping your equipment in prime condition for years to come.

Understanding Stihl FS250 Components

Grasping the various elements of a brush cutter is essential for effective maintenance and operation. Each part plays a critical role in ensuring the equipment runs smoothly and efficiently. Familiarity with these components not only aids in troubleshooting but also enhances overall performance.

The primary assembly consists of several key parts that contribute to the functionality of the tool. These elements work in tandem to facilitate tasks such as trimming and clearing overgrowth. Knowing their individual purposes can empower users to optimize their equipment use and maintenance routines.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives the cutting mechanism. |

| Fuel Tank | Holds the fuel needed for engine operation. |

| Cutting Head | Contains the line or blade that performs the cutting action. |

| Handlebar | Provides control and stability during operation. |

| Throttle Trigger | Regulates engine speed and cutting power. |

| Air Filter | Ensures clean air intake for optimal engine performance. |

By understanding these components, users can make informed decisions regarding maintenance, repairs, and upgrades, ensuring their tool remains in top condition for any landscaping challenge.

Overview of the FS250 Model

The FS250 is a powerful tool designed for efficiency and performance in vegetation management. This machine combines advanced engineering with user-friendly features, making it suitable for both professional landscapers and home users alike. Its robust design allows for tackling various tasks, from trimming grass to clearing dense underbrush.

Equipped with a reliable engine, this model ensures consistent power delivery and optimal cutting performance. Its lightweight construction contributes to ease of handling, enabling operators to work for extended periods without fatigue. Additionally, the adjustable components provide versatility, allowing users to customize the tool for specific applications.

Maintenance is straightforward, ensuring longevity and peak functionality. The accessible design facilitates routine checks and part replacements, making it a practical choice for those who prioritize reliability in their equipment. Overall, this model stands out for its blend of durability, efficiency, and ease of use, catering to a wide range of outdoor tasks.

Importance of Parts Diagrams

Understanding the intricate design of any machinery is crucial for effective maintenance and repair. Visual representations that detail each component provide invaluable guidance for users and technicians alike. These illustrations simplify complex structures, making it easier to identify and address issues.

Clarity in Maintenance: Clear visuals aid in recognizing specific elements, allowing for efficient troubleshooting. Users can pinpoint the exact location of a malfunction, which saves time and minimizes frustration during repairs.

Enhanced Learning: For those new to machinery, these representations serve as educational tools. They help users grasp how different components interact, fostering a deeper understanding of overall functionality.

Streamlined Ordering Process: When it comes to procuring replacements, having a visual reference ensures accuracy. Users can confidently identify and order the necessary items without ambiguity.

Improved Safety: By providing a clear view of assembly and disassembly, these visuals promote safe practices. Users can follow step-by-step instructions, reducing the risk of accidents during maintenance.

In summary, visual guides play a pivotal role in effective machinery management, enhancing understanding, safety, and efficiency in maintenance processes.

Main Components of FS250

The functionality of a brush cutter relies on several essential elements that work in harmony to achieve optimal performance. Understanding these key components can greatly enhance maintenance and repair efforts, ensuring the equipment operates smoothly.

Engine: The heart of the machine, providing the necessary power to drive the cutting mechanism. It is crucial for overall efficiency and performance.

Cutting Head: This part is responsible for trimming and clearing vegetation. Various types of attachments can be used, depending on the task at hand.

Fuel System: Comprising the tank and lines, this system delivers fuel to the engine, playing a vital role in its operation. Proper maintenance is essential to avoid clogs and leaks.

Handle and Shaft: Designed for user control and comfort, these components facilitate maneuverability, allowing the operator to navigate various terrains with ease.

Safety Features: Includes guards and shields that protect the user from debris and accidental contact, highlighting the importance of safety during operation.

By familiarizing oneself with these primary elements, users can better appreciate the intricacies of their equipment and ensure its longevity.

Identifying Common Issues

Understanding the typical problems that arise in gardening equipment can significantly enhance performance and longevity. By recognizing early signs of wear and tear, users can address issues promptly and maintain their tools effectively.

Common Symptoms

Users often encounter difficulties such as inconsistent operation, excessive vibration, or starting failures. These symptoms can indicate underlying mechanical issues, necessitating careful inspection and troubleshooting.

Preventive Measures

Regular maintenance plays a crucial role in preventing common malfunctions. Cleaning filters, checking spark plugs, and ensuring proper lubrication are essential steps that contribute to optimal performance. Proactive care can save time and resources in the long run.

How to Read a Parts Diagram

Understanding the layout of a component illustration is essential for effective maintenance and repair. These visual guides provide a clear representation of various elements, helping users identify each piece and its function within the assembly.

Step 1: Begin by familiarizing yourself with the overall structure. Each section usually corresponds to different areas of the device, so take note of how parts are grouped together.

Step 2: Look for labels and numbers that indicate specific items. These references are crucial for locating the exact components you need.

Step 3: Pay attention to the lines connecting pieces, as they often illustrate how components interact with each other. This will deepen your understanding of the assembly’s mechanics.

Step 4: Finally, cross-reference the visual with your user manual for additional insights on installation and maintenance procedures.

By following these steps, you’ll be able to effectively interpret the illustration and tackle repairs with confidence.

Essential Tools for Maintenance

Proper upkeep of outdoor equipment requires a selection of fundamental instruments that ensure efficiency and longevity. These tools enable users to perform routine checks, repairs, and adjustments effectively, making maintenance a straightforward task.

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Adjusting screws in various components |

| Fuel Container | Storing and transporting fuel safely |

| Cleaning Brush | Removing debris from air filters and other parts |

| Protective Gloves | Ensuring safety while handling machinery |

Replacement Parts Availability

When it comes to maintaining equipment, having access to essential components is crucial for optimal performance and longevity. Ensuring the availability of these items can significantly reduce downtime and enhance efficiency during operations. Various suppliers and online platforms offer a range of options, making it easier to find what is needed for repairs or upgrades.

Many authorized dealers provide not only genuine components but also alternatives, catering to diverse preferences and budgets. It’s advisable to explore multiple sources to compare prices and availability, ensuring you make informed choices. Additionally, consulting user forums and community resources can lead to discovering reliable vendors and recommendations on compatible options.

Overall, understanding the landscape of component availability empowers users to effectively maintain their equipment and keep it running smoothly for years to come.

Comparing FS250 to Other Models

When evaluating different models in the same category, it’s essential to highlight key differences and similarities that can influence performance and user experience. This analysis aims to provide insights into how a specific model stacks up against its peers, focusing on efficiency, durability, and usability.

Performance is a crucial factor; some models may excel in power output, while others are designed for fuel efficiency. Users should consider what is most important for their specific tasks. Durability also varies; certain models might incorporate more robust materials, ensuring longevity in challenging conditions.

Lastly, usability can differ significantly, with some designs offering enhanced ergonomics or ease of maintenance. Understanding these distinctions allows users to make informed choices that best suit their needs.

Safety Precautions During Repairs

When performing maintenance on equipment, ensuring safety is of utmost importance. Following proper guidelines can prevent accidents and injuries. Familiarizing oneself with potential hazards and adopting necessary precautions is essential for a successful repair process.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, goggles, and masks to protect against debris and chemicals. |

| Work Area | Maintain a clean and organized workspace to avoid tripping hazards and ensure easy access to tools. |

| Disconnect Power | Before starting repairs, ensure the equipment is unplugged or the power source is turned off to prevent accidental starts. |

| Use Tools Properly | Familiarize yourself with the tools being used and ensure they are in good condition to avoid malfunctions. |

| Follow Instructions | Adhere to the manufacturer’s guidelines and manuals to avoid errors during the repair process. |

By following these safety measures, individuals can minimize risks and enhance the overall efficiency of their repair tasks. Prioritizing safety not only protects the individual but also extends the longevity of the equipment being serviced.

Tips for Effective Troubleshooting

Troubleshooting machinery can often feel daunting, but with a systematic approach, the process becomes much more manageable. Understanding common issues and applying logical steps can lead to swift resolutions and improved performance. This guide offers practical insights to help you navigate the troubleshooting landscape effectively.

Identify the Symptoms

Before delving into repairs, it’s crucial to pinpoint the specific symptoms of the problem. Listen for unusual sounds, watch for erratic behavior, and observe any warning signs. Documenting these indicators can provide valuable clues when seeking solutions. Create a checklist of the issues encountered to help narrow down the possible causes.

Systematic Inspection

Conduct a thorough examination of the equipment, focusing on one area at a time. Check components for wear, damage, or obstructions. Utilizing a methodical approach allows for easier identification of faults. Additionally, consult the manufacturer’s guidelines for reference points, as these can assist in verifying that each part is functioning as intended. Remember, patience is key when troubleshooting; rushing can lead to oversight and further complications.

Maintaining Your FS250 Equipment

Routine Checks: Schedule frequent inspections to assess components such as the engine, fuel system, and cutting mechanisms. Look for signs of wear and tear that could affect functionality.

Cleaning: Keeping your equipment clean is vital. Remove debris from air filters and cooling vents to maintain airflow and prevent overheating. A clean machine operates more effectively.

Lubrication: Regularly lubricate moving parts to reduce friction and wear. This simple step can significantly extend the lifespan of your equipment.

Storage: Proper storage is key when not in use. Store your machinery in a dry place, and consider using protective covers to shield it from dust and moisture.

Replacement Parts: Be proactive about replacing worn components. Using high-quality substitutes will ensure your tool remains efficient and safe to operate.

By adhering to these maintenance tips, you can maximize the performance and durability of your outdoor equipment, allowing you to focus on your tasks without worry.

Frequently Asked Questions About FS250

This section addresses common inquiries related to a popular outdoor power equipment model. Here, we aim to provide clear and concise answers to help users understand the functionality, maintenance, and troubleshooting of their machinery.

What type of fuel should I use?

It is essential to use a high-quality fuel that meets the manufacturer’s specifications. Typically, a mixture of gasoline and oil is required to ensure optimal performance.

How often should I perform maintenance?

Regular maintenance is crucial for longevity. It is advisable to check and clean the air filter, spark plug, and cutting head every few weeks, depending on usage.

What should I do if the equipment won’t start?

If the unit fails to start, check the fuel level, inspect the spark plug for damage, and ensure that the choke is in the correct position. If issues persist, further troubleshooting may be necessary.

Can I replace components myself?

Yes, many users can replace parts independently, provided they follow the manual’s guidelines. However, if you are unsure, seeking professional assistance is recommended.

What are the safety precautions I should take?

Always wear appropriate protective gear, including gloves and eye protection. Familiarize yourself with the safety features of your equipment and ensure that all users are trained in safe operating procedures.