Comprehensive Guide to Ts 420 Stihl Parts Diagram

Every intricate piece of machinery relies on a well-structured assembly of elements, each playing a vital role in its overall functionality. Grasping the layout and connection of these components can significantly enhance your maintenance skills and troubleshooting abilities. Whether you’re a seasoned technician or a DIY enthusiast, having a clear understanding of how each part fits into the larger system is essential.

Visual representations of these assemblies serve as invaluable resources, providing insight into the arrangement and interaction of the various sections. These illustrations not only simplify the process of identification but also help in recognizing the specific areas that may require attention or replacement. By familiarizing yourself with these diagrams, you empower yourself to make informed decisions when it comes to repairs and upgrades.

In the following sections, we will explore the various elements that comprise this particular model, highlighting their functions and interrelationships. Understanding the anatomy of your equipment will enable you to maintain it more effectively, ensuring its longevity and optimal performance.

Understanding the Ts 420 Stihl Model

This section provides an overview of a specific cutting tool renowned for its efficiency and reliability in various applications. It’s essential to grasp the design elements and functionalities that make this model a favorite among professionals and enthusiasts alike.

Key Features

- Robust engine for high performance

- Ergonomic design for user comfort

- Versatile cutting capabilities

Applications

- Landscaping and garden maintenance

- Construction and demolition tasks

- Tree trimming and pruning

Understanding these aspects can help users make informed decisions about their cutting tool needs and optimize their work efficiency.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations not only clarify the relationships between elements but also streamline the identification process during troubleshooting.

Benefits of Visual Guides

- Simplifies complex systems

- Enhances communication among technicians

- Facilitates quick decision-making during repairs

Practical Applications

- Streamlined assembly processes

- Efficient inventory management

- Improved training for new personnel

Key Components of Ts 420

The efficiency and performance of this cutting tool rely heavily on its essential elements. Each component plays a significant role in ensuring optimal functionality and durability.

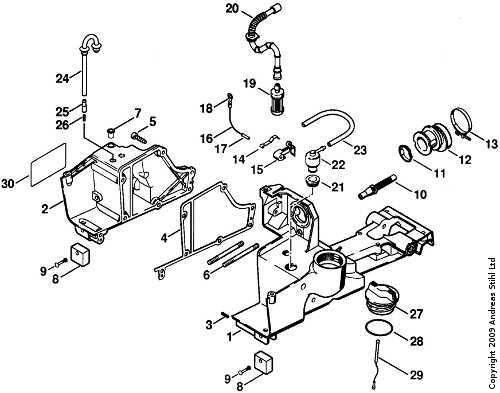

Engine: The heart of the device, providing the necessary power for cutting tasks. A robust engine translates into enhanced performance and reliability.

Cutting Wheel: This critical part is responsible for the actual cutting action. The right size and material determine the effectiveness and precision of the work.

Handle System: Ergonomically designed for user comfort, this aspect influences control and maneuverability during operation.

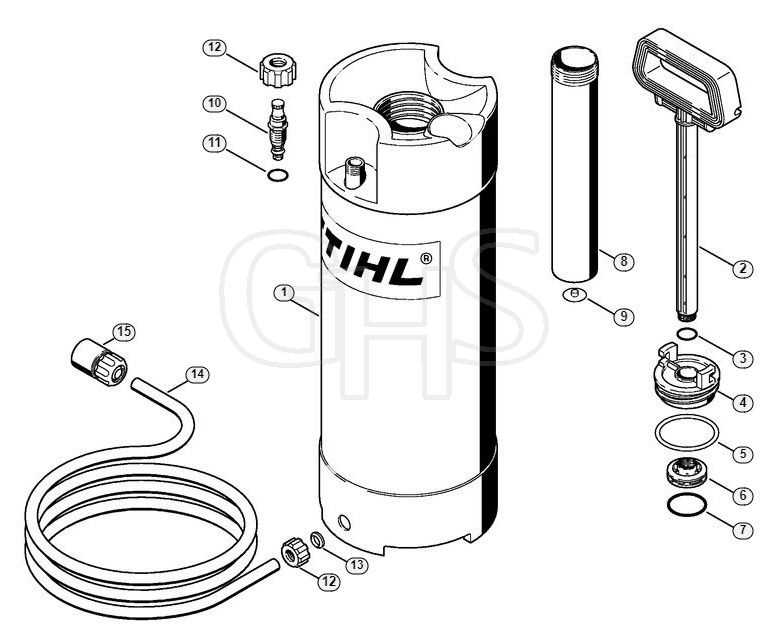

Fuel System: A well-engineered fuel delivery mechanism ensures consistent power output, impacting overall efficiency and longevity.

Air Filter: Vital for maintaining engine health, a clean filter prevents debris from entering the system, thus enhancing performance and lifespan.

Starter Mechanism: A reliable starting system is essential for quick operation, allowing users to begin tasks without delay.

By understanding these key components, users can better appreciate the design and functionality of this versatile tool.

How to Read Parts Diagrams

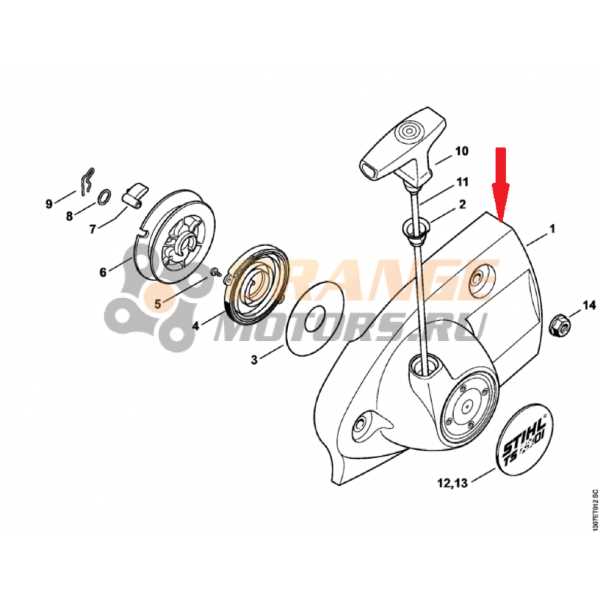

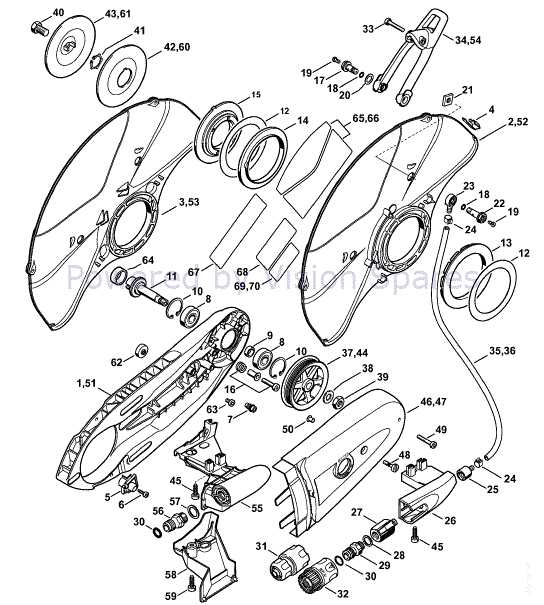

Understanding illustrations that depict components of machinery is essential for effective maintenance and repairs. These visual aids serve as a guide, offering insights into the arrangement and function of various elements within a device. Familiarity with these visuals can enhance your ability to identify specific pieces and facilitate the troubleshooting process.

To interpret these illustrations accurately, start by recognizing the numbering system used to label each part. Each number corresponds to a specific item, which can typically be cross-referenced with a detailed list or catalog. This list usually includes descriptions and, in some cases, pricing information, allowing for informed decision-making when acquiring replacements.

Next, pay attention to the overall layout. Components are often arranged in a manner that reflects their assembly order or functional relationships. This organization helps in understanding how individual parts interact and contribute to the operation of the machinery. By following the connections shown, one can grasp the assembly process more clearly.

Moreover, look for indicators of orientation or positioning. Some illustrations will include arrows or lines that signify how parts fit together or how they should be oriented during installation. Recognizing these cues can prevent mistakes and ensure a smoother repair experience.

Finally, take note of any notes or legends that accompany the visuals. These annotations can provide crucial information regarding specifications, installation tips, or maintenance recommendations. Being attentive to these details can significantly improve your comprehension and effectiveness when working with the equipment.

Common Issues with Ts 420

Understanding the frequent challenges faced by users can enhance performance and longevity. Below are typical problems that may arise with this equipment and suggestions for resolution.

- Starting Difficulties:

Users often report issues when trying to initiate operation. Possible causes include:

- Insufficient fuel or improper fuel mixture.

- Clogged air filter.

- Defective spark plug.

- Power Loss:

A noticeable decrease in power can be frustrating. Consider the following:

- Worn-out cutting tools.

- Dirty or damaged fuel lines.

- Improperly adjusted carburetor.

- Excessive Vibration:

Excessive shaking can lead to operator discomfort and equipment wear. Check for:

- Loose or damaged components.

- Imbalance in the cutting attachment.

- Poorly maintained rubber mounts.

- Overheating:

This issue can cause serious damage. Ensure:

- Proper ventilation during use.

- Regular cleaning of cooling fins.

- Quality of lubricants is maintained.

Addressing these common concerns promptly can lead to an ultimate improvement in functionality and user satisfaction.

Where to Find Authentic Parts

Locating genuine components for your equipment is essential for maintaining optimal performance and longevity. Ensuring that you choose reliable sources not only guarantees quality but also enhances the overall efficiency of your machinery.

Authorized Dealers

One of the most reliable places to acquire genuine items is through authorized retailers. These establishments are recognized by the manufacturer and provide assurance that the components meet strict quality standards.

Online Marketplaces

In addition to local stores, various online platforms specialize in authentic products. Always check the seller’s reputation and reviews to confirm the legitimacy of the items being offered.

Maintenance Tips for Ts 420

Regular upkeep is essential for optimal performance and longevity of your cutting equipment. Implementing a few key practices can enhance efficiency and prevent issues over time.

- Check and clean the air filter regularly to ensure proper airflow.

- Inspect the cutting blade for wear and replace it as needed for effective cutting.

- Lubricate moving parts to reduce friction and prevent damage.

- Examine fuel lines for cracks or leaks, and replace them if necessary.

By following these guidelines, you can maintain your tool in peak condition and achieve the ultimate performance during use.

Upgrading Components for Better Performance

Enhancing the efficiency of your equipment can significantly improve its overall functionality. By focusing on specific elements, you can achieve greater power output, increased durability, and improved user experience. This section explores various upgrades that can transform your machinery into a high-performance tool.

Key Areas for Upgrades

- Engine Efficiency

- Fuel Delivery System

- Air Filtration

- Ignition System

Benefits of Upgrading

- Increased Power: Enhanced components lead to a more robust output.

- Improved Fuel Economy: Efficient systems reduce overall consumption.

- Extended Lifespan: Upgraded parts often provide better durability.

- Enhanced Reliability: Quality components reduce the likelihood of failures.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the process involved in assembling and disassembling the equipment. Understanding these procedures is essential for maintenance, repair, and ensuring the longevity of the tool. Proper techniques not only enhance performance but also promote safety during operation.

Step 1: Begin by gathering all necessary tools and components. Having everything organized will streamline the process and reduce the risk of misplacing parts.

Step 2: For disassembly, start with the removal of any covers or casings. Use appropriate tools to avoid damage to the unit. Carefully note the order of component removal, as this will aid in reassembly.

Step 3: Once disassembled, inspect each component for wear or damage. It is advisable to clean the parts before reassembly to ensure optimal functionality.

Step 4: During reassembly, follow the reverse order of disassembly. Ensure that all fasteners are securely tightened, and verify that each piece fits correctly without excessive force.

Step 5: After completing the assembly, conduct a thorough check to confirm that everything is in its designated place. Performing a test run will help identify any issues before the equipment is put to regular use.

By adhering to this guide, users can effectively manage the assembly and disassembly processes, leading to improved performance and reliability of their equipment.

Comparing Ts 420 with Other Models

This section explores the differences and similarities among various models in the same category, focusing on performance, features, and user experience. Understanding these aspects can help potential buyers make informed decisions.

- Power and Performance:

- Assess the engine capacity and cutting power.

- Compare speed and efficiency in various applications.

- Weight and Maneuverability:

- Evaluate how the weight affects handling and fatigue.

- Consider the design for ease of use in tight spaces.

- Features and Technology:

- Highlight unique features that enhance functionality.

- Discuss technological advancements across models.

- Cost and Value:

- Compare price points and warranty options.

- Analyze long-term value based on durability and maintenance.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and functionality of specific equipment. Here, we aim to provide clear and concise answers to help users navigate their concerns effectively.

What should I do if my equipment is not functioning properly?

Check for any visible issues such as blockages or wear. If problems persist, refer to the user manual for troubleshooting steps or consult a professional.

How can I ensure the longevity of my machine?

Regular maintenance is key. Clean components, replace worn items, and follow the manufacturer’s guidelines to keep your device in optimal condition.