Complete Guide to 19 HP Briggs and Stratton Engine Parts Diagram

The intricate design of a 19 HP power unit encompasses a variety of essential elements that work harmoniously to deliver optimal performance. A thorough examination of these components provides valuable insights into their functions and interrelations. This knowledge is crucial for anyone looking to maintain or enhance the efficiency of their machinery.

In this guide, we will delve into a detailed exploration of the various sections that constitute this robust power source. Each segment plays a vital role, from the fundamental structures to the intricate mechanisms that facilitate operation. Understanding these aspects can significantly aid in troubleshooting and repair processes, ensuring longevity and reliability.

Furthermore, having a clear visual representation of these components can greatly enhance comprehension. By dissecting the configuration, one can better appreciate how each piece contributes to the overall functionality. This not only empowers users to make informed decisions but also fosters a deeper appreciation for the engineering marvels behind modern power equipment.

Understanding the 19 HP Engine

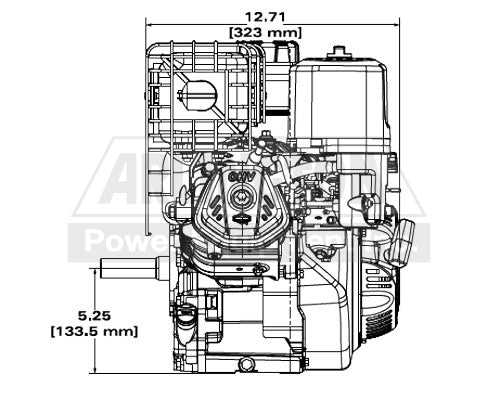

This section explores the essential features and components that define the 19 HP model. Designed for reliability and efficiency, this unit plays a crucial role in various applications, from lawn care to heavy-duty tasks.

Performance is a key attribute, as the 19 HP unit delivers consistent power output, making it ideal for both residential and commercial use. The combination of durability and efficiency ensures that it can handle demanding operations without compromising on functionality.

Delving into the core attributes, one can appreciate the engineering that allows for optimal fuel consumption while maintaining robust performance. Understanding these elements is vital for anyone looking to maximize the potential of this powerhouse.

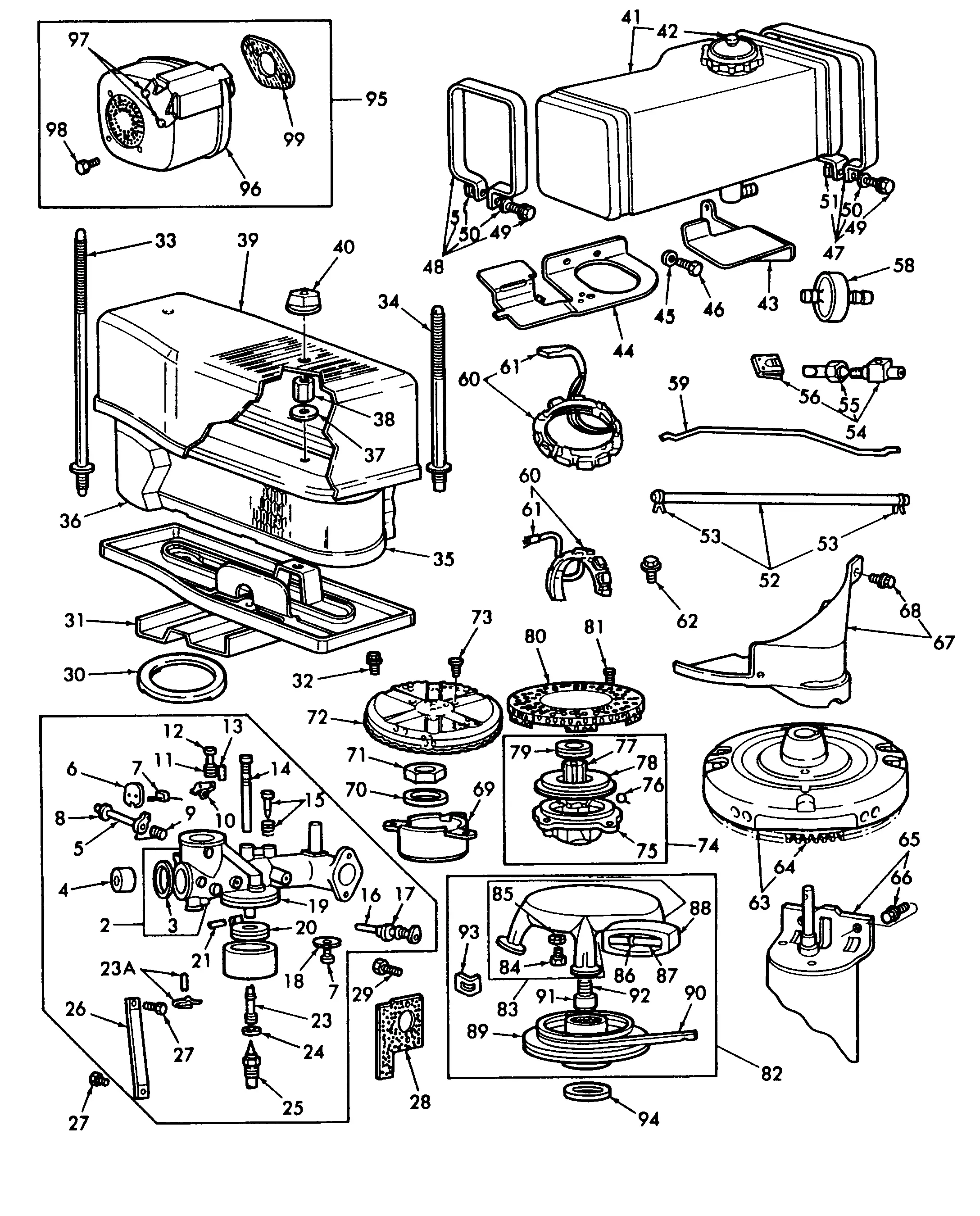

Components of Briggs and Stratton Engines

Understanding the various elements that make up small power units is essential for maintenance and repair. Each component plays a crucial role in the overall functionality, contributing to performance, efficiency, and longevity. Familiarity with these individual pieces allows users to troubleshoot issues effectively and ensure optimal operation.

Key components include the combustion chamber, where the fuel-air mixture ignites, and the crankshaft, which transforms linear motion into rotational power. The carburetor regulates the mixture of fuel and air, ensuring proper combustion. Additionally, the ignition system initiates the combustion process, while the cooling system prevents overheating, maintaining safe operating temperatures.

Furthermore, the fuel system delivers the necessary energy source, and the exhaust system manages byproducts of combustion. Understanding how these parts interact provides insight into troubleshooting potential problems and performing maintenance. Each element’s efficiency directly influences the performance and reliability of the machine, making it vital to keep them in optimal condition.

Importance of Engine Diagrams

Visual representations play a crucial role in understanding the components and mechanisms of mechanical systems. They serve as essential tools for both professionals and enthusiasts, facilitating better comprehension and maintenance.

Here are several reasons why these visuals are invaluable:

- Enhanced Clarity: Diagrams simplify complex structures, making it easier to identify individual components and their functions.

- Efficient Troubleshooting: With a clear view of how elements are arranged, diagnosing issues becomes more straightforward, saving time and effort.

- Guided Assembly: For those involved in construction or repairs, these visuals provide step-by-step guidance, ensuring that each part is correctly installed.

- Educational Resource: They serve as an excellent teaching aid, helping learners grasp fundamental concepts and practices in mechanical design.

- Improved Communication: Sharing these representations can facilitate discussions among technicians, ensuring everyone is on the same page regarding specific tasks.

In summary, these visual aids are indispensable for anyone working with machinery, as they promote efficiency, understanding, and collaboration.

Key Parts of the 19 HP Engine

This section explores the essential components of a 19 horsepower machine, highlighting their functions and significance in overall performance. Understanding these elements can enhance maintenance and troubleshooting, ensuring optimal operation and longevity.

Cylinders and Pistons

The cylinders and pistons form the heart of the power generation process. They work together to convert fuel into mechanical energy, driving the entire system effectively.

Fuel System

The fuel system is crucial for delivering the right mixture of air and fuel to the combustion chamber. Proper functioning ensures efficient operation and maximizes power output, making it vital for overall efficiency.

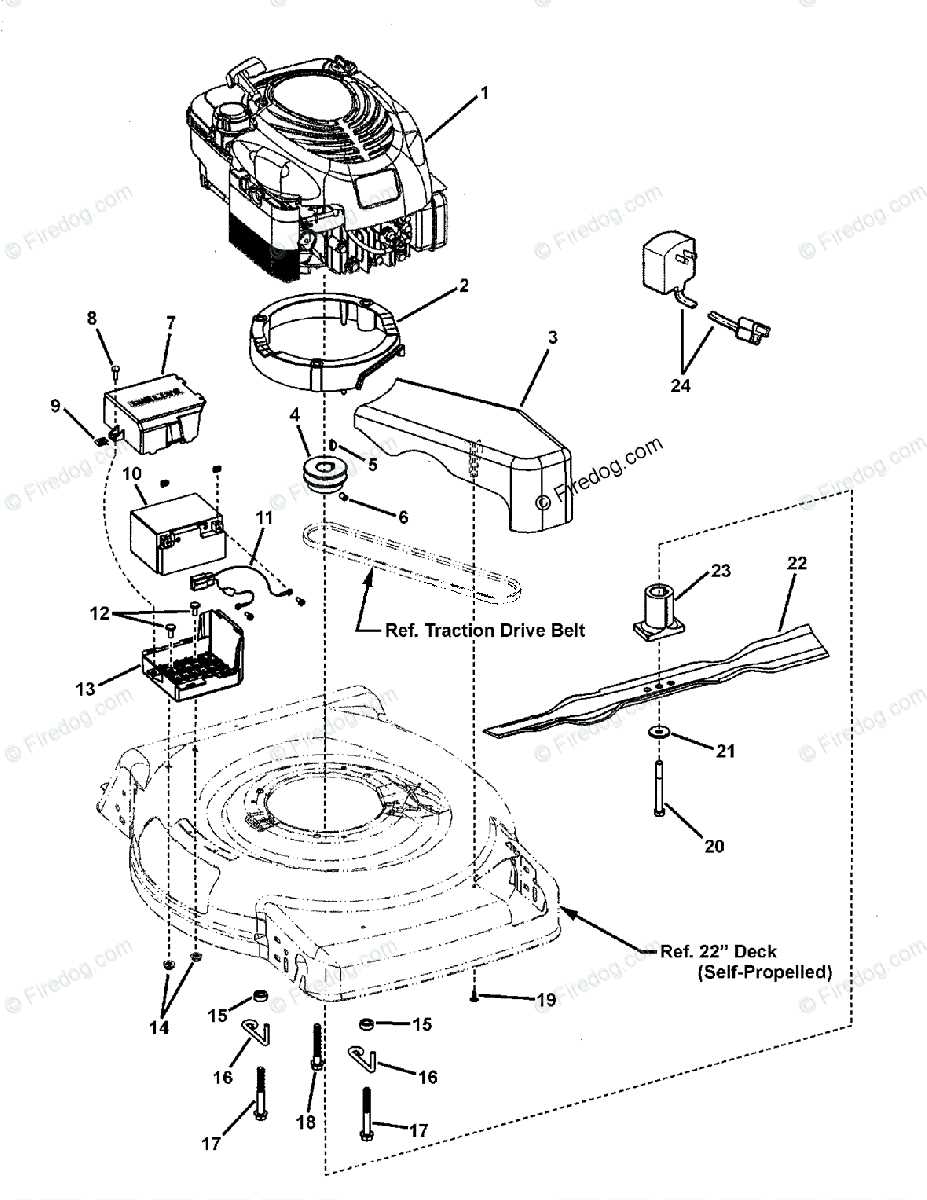

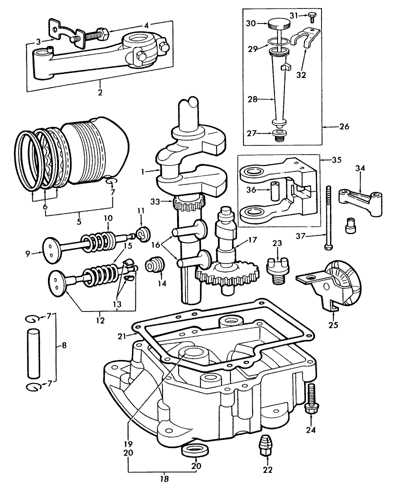

Visual Breakdown of Engine Components

This section offers a comprehensive overview of various elements found within a small motor, highlighting their roles and interactions. Understanding these components provides valuable insight into the functionality and maintenance of the machinery.

Key Components Overview

Each element plays a crucial part in the overall performance. Here’s a brief summary of the most significant sections:

| Component | Description |

|---|---|

| Cylinder | The chamber where combustion occurs, driving the piston. |

| Piston | A cylindrical piece that moves within the cylinder, converting combustion energy. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Carburetor | Mixes air and fuel to create a combustible mixture. |

| Ignition System | Generates a spark to ignite the air-fuel mixture. |

Importance of Each Element

Recognizing the significance of each section aids in troubleshooting and enhances the ability to perform necessary repairs. This understanding ultimately leads to more efficient operation and longevity of the small motor.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any mechanical device. Regular attention to various components ensures optimal performance and reduces the likelihood of unexpected failures. Implementing a consistent maintenance routine can significantly enhance reliability and efficiency.

Regular Inspections

Frequent examinations of critical components help identify wear and tear early on. Pay close attention to seals, belts, and filters. Replace any parts showing signs of damage to avoid larger issues.

Fluid Management

Maintaining appropriate fluid levels is crucial for smooth operation. Regularly check oil levels and replace fluids as recommended by the manufacturer. Clean filters periodically to ensure optimal flow and efficiency.

Common Issues with Briggs and Stratton

Understanding the frequent challenges faced by small power units can help users maintain optimal performance and longevity. Many owners encounter specific problems that may arise during operation, leading to decreased efficiency or complete failure.

Typical Problems

- Starting difficulties: Units may struggle to ignite due to fuel delivery issues or spark plug failure.

- Overheating: Insufficient cooling or blocked vents can cause excessive heat buildup.

- Noisy operation: Unusual sounds may indicate wear in internal components or loose parts.

Preventative Measures

- Regular maintenance: Schedule frequent inspections to identify potential issues early.

- Proper storage: Ensure the unit is stored in a dry, clean environment to avoid rust and damage.

- Fuel quality: Use fresh, appropriate fuel to prevent clogs and ensure smooth operation.

Identifying Engine Part Numbers

Understanding the identification of component numbers is crucial for anyone involved in maintenance or repair tasks. Accurate recognition of these identifiers not only simplifies the process of sourcing replacements but also ensures compatibility with various models. Familiarity with these numbers empowers users to effectively troubleshoot and enhance performance.

Importance of Accurate Identification

Accurate identification plays a pivotal role in achieving optimal functionality. Using the correct component can prevent issues that arise from mismatches, such as inefficient operation or damage. Hence, knowing how to locate and interpret these identifiers is beneficial for longevity and reliability.

How to Locate Part Numbers

Part numbers are typically found on the components themselves or within the documentation provided with the machinery. Users should look for labels, engravings, or printed codes that denote specific identifiers. Additionally, consulting the official manuals can provide valuable insights into the correct numbers for different components.

Where to Find Replacement Parts

When it comes to maintaining outdoor machinery, sourcing the correct components is crucial for optimal performance. Whether you need a specific element for repairs or general upkeep, knowing where to look can save time and ensure you have quality replacements.

Online Retailers

The internet offers a vast array of retailers specializing in outdoor equipment. Websites dedicated to these tools often have extensive catalogs, allowing you to search by model or component type. Make sure to check customer reviews to gauge reliability and service quality before making a purchase.

Local Dealers and Service Centers

For those who prefer a more hands-on approach, local dealers can provide valuable support. Visiting a nearby service center not only allows you to find components directly but also gives you access to expert advice. Establishing a relationship with these professionals can enhance your maintenance experience.

How to Read Engine Diagrams

Understanding technical illustrations can significantly enhance your ability to perform maintenance and repairs. These visuals serve as crucial guides, providing detailed representations of components and their interconnections. Familiarity with these schematics will help you navigate through various systems effectively.

To read these illustrations efficiently, follow these key steps:

- Familiarize Yourself with Symbols:

- Identify common symbols used for different components.

- Learn the meaning of lines indicating connections or flow.

- Study the Layout:

- Observe how components are arranged, noting the relationships between them.

- Pay attention to the grouping of related parts for better comprehension.

- Reference Labels and Numbers:

- Look for part numbers or labels that indicate specific items.

- Utilize these identifiers to locate and order replacements if necessary.

- Follow Flow Directions:

- Trace any directional arrows or flow lines to understand the sequence of operations.

- Recognize how different elements interact within the system.

By mastering these techniques, you will enhance your technical skills and increase your confidence in handling repairs and maintenance tasks.

Tools Needed for Engine Repairs

Effective maintenance and repair of machinery require a variety of specialized instruments. Having the right tools on hand ensures that tasks can be completed efficiently and safely. Here’s a breakdown of essential equipment for successful repairs.

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening fasteners.

- Screwdrivers: A set of flathead and Phillips screwdrivers will tackle different types of screws.

- Pliers: Needle-nose and slip-joint pliers assist in gripping and manipulating components.

- Torque wrench: This tool ensures that bolts are tightened to the manufacturer’s specified tension.

In addition to basic tools, some specialized equipment may be necessary for more complex repairs.

- Compression tester: Evaluates the compression of cylinders, helping diagnose issues.

- Fuel pressure gauge: Measures fuel delivery pressure to ensure optimal performance.

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Parts cleaner: Keeps components free from dirt and debris, which is vital for proper functioning.

Equipping yourself with these tools not only aids in repairs but also enhances overall mechanical proficiency.

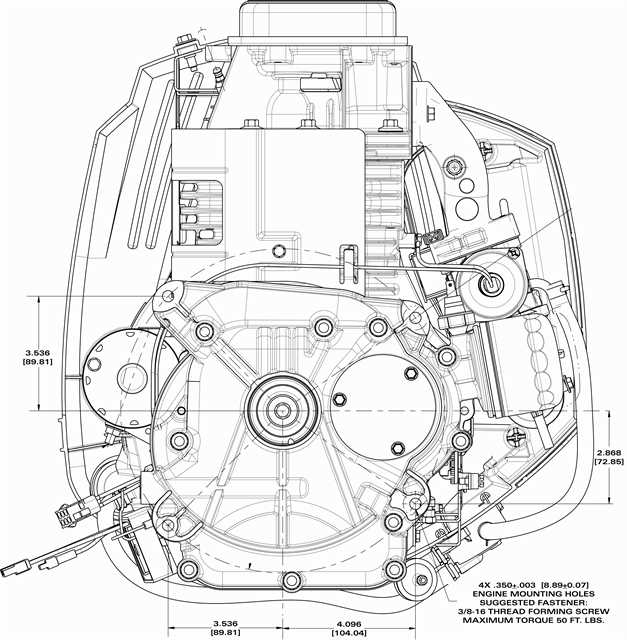

Assembly Process of the Engine

The assembly of a power unit involves a systematic approach to ensure optimal functionality and performance. Each component plays a crucial role, and careful attention to detail is essential during this process.

Preparation Steps

- Gather all necessary components.

- Ensure a clean workspace to avoid contamination.

- Review the assembly manual for specific instructions.

Assembly Procedure

- Begin with the base assembly, securing the foundation.

- Install the crankshaft, ensuring proper alignment.

- Add the piston and connect it to the crankshaft.

- Assemble the cylinder head, making sure all seals are in place.

- Connect the fuel delivery system for efficient operation.

- Finalize by checking all fasteners and conducting a quality control inspection.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both personal well-being and the longevity of the equipment. Following proper protocols helps prevent accidents and injuries while working with mechanical systems. Understanding potential hazards and implementing precautionary measures can create a safer work environment.

Proper Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves to protect hands from sharp edges and chemicals, safety glasses to shield eyes from debris, and steel-toed boots to safeguard feet from heavy objects. Additionally, consider using hearing protection if working with loud machinery.

Safe Workspace Practices

Maintain a clean and organized workspace to reduce the risk of accidents. Ensure tools are stored properly, and remove any unnecessary items that could cause tripping. Always work in a well-ventilated area, especially when dealing with potentially harmful substances. Furthermore, make sure to disconnect power sources before starting any repair work to avoid electrical shocks.