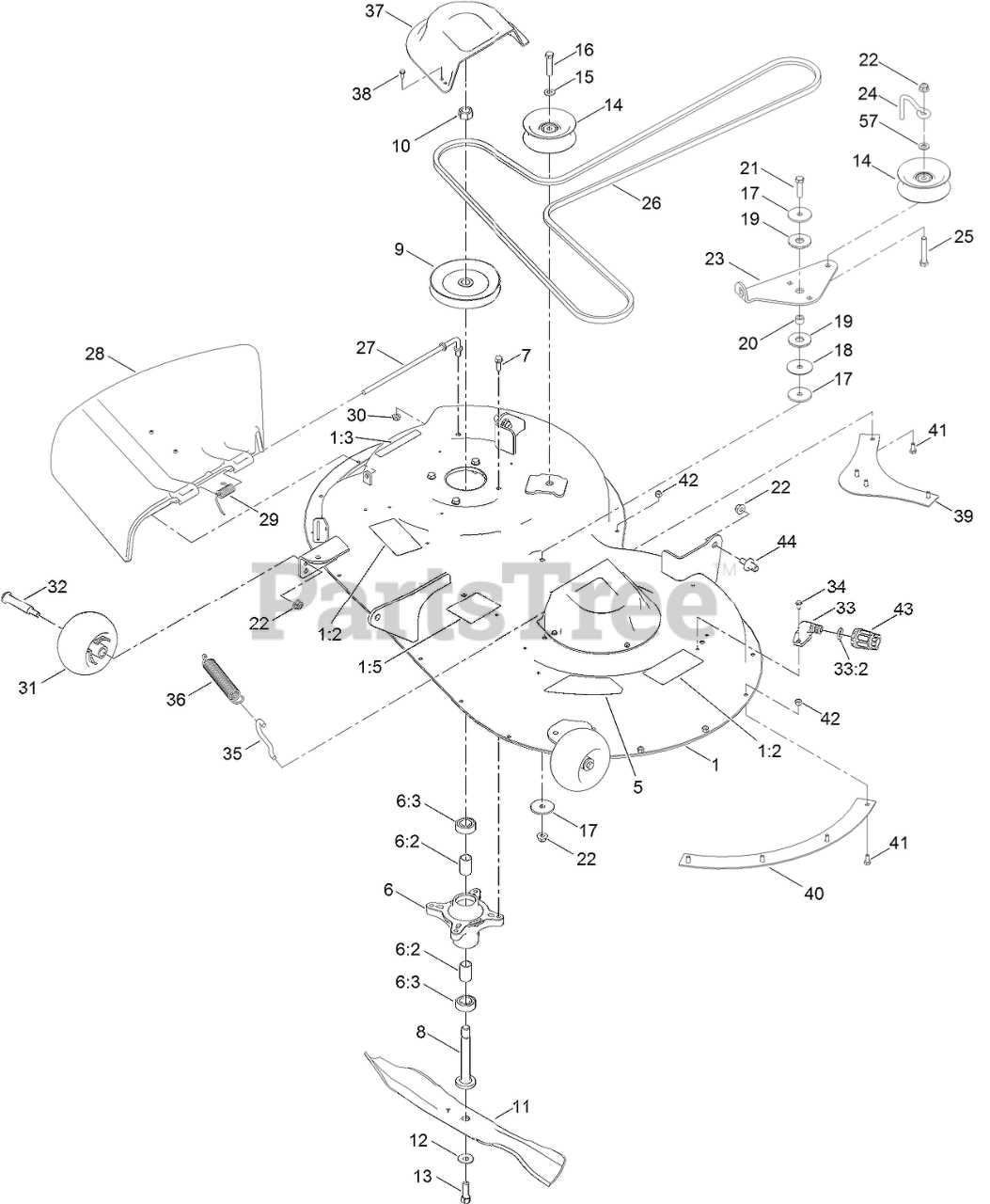

Toro 75742 Parts Diagram Overview

When it comes to maintaining your outdoor space, having a clear grasp of the various elements involved in your machinery can significantly enhance its performance. Each piece plays a crucial role in ensuring that the equipment operates smoothly and efficiently.

In this section, we will explore the intricate relationships between these components, allowing enthusiasts and professionals alike to optimize their tools. By understanding how each part fits into the larger system, users can troubleshoot issues and carry out necessary maintenance with confidence.

As we delve into the specifics, readers will discover the ultimate guide to enhancing their knowledge of the essential features and functions that contribute to the effectiveness of lawn care tools. This insight is invaluable for anyone looking to extend the lifespan and efficiency of their equipment.

Overview and Features

This section provides an insight into a popular model known for its reliability and efficiency in lawn care. Designed for both residential and commercial use, it combines advanced technology with user-friendly features.

Key Features

- Durable construction for long-lasting performance

- Efficient engine that maximizes power and minimizes fuel consumption

- Ergonomic design for ease of use and comfort

- Adjustable settings for various lawn conditions

Benefits

- Enhances lawn appearance with precision cutting

- Saves time and effort with its innovative design

- Offers versatility for different terrains and grass types

- Backed by reliable customer support and warranty

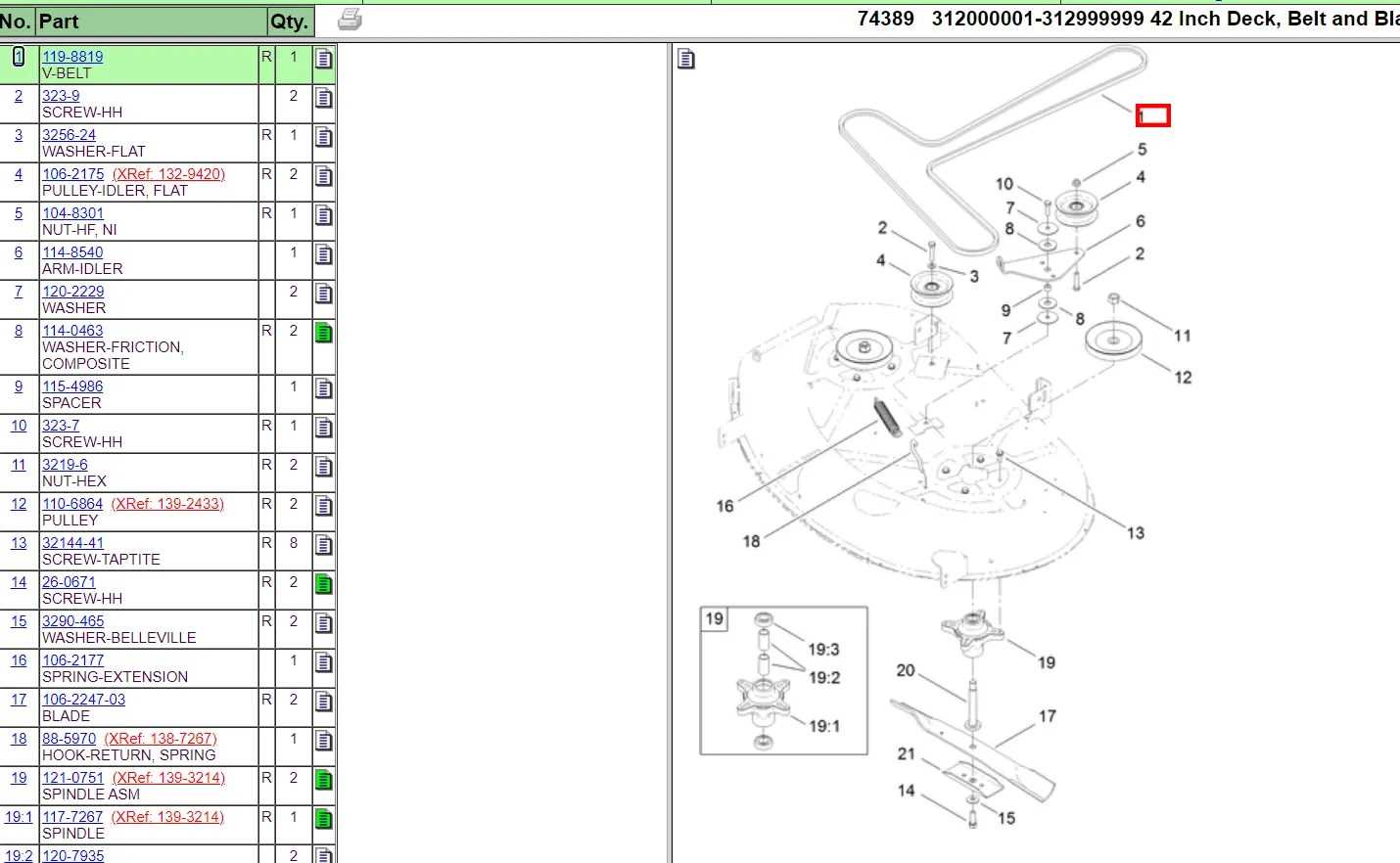

Understanding Toro 75742 Components

This section aims to provide insight into the various elements that comprise a specific model, helping users identify and comprehend each component’s function. A thorough understanding can enhance maintenance and repair efforts, ensuring optimal performance.

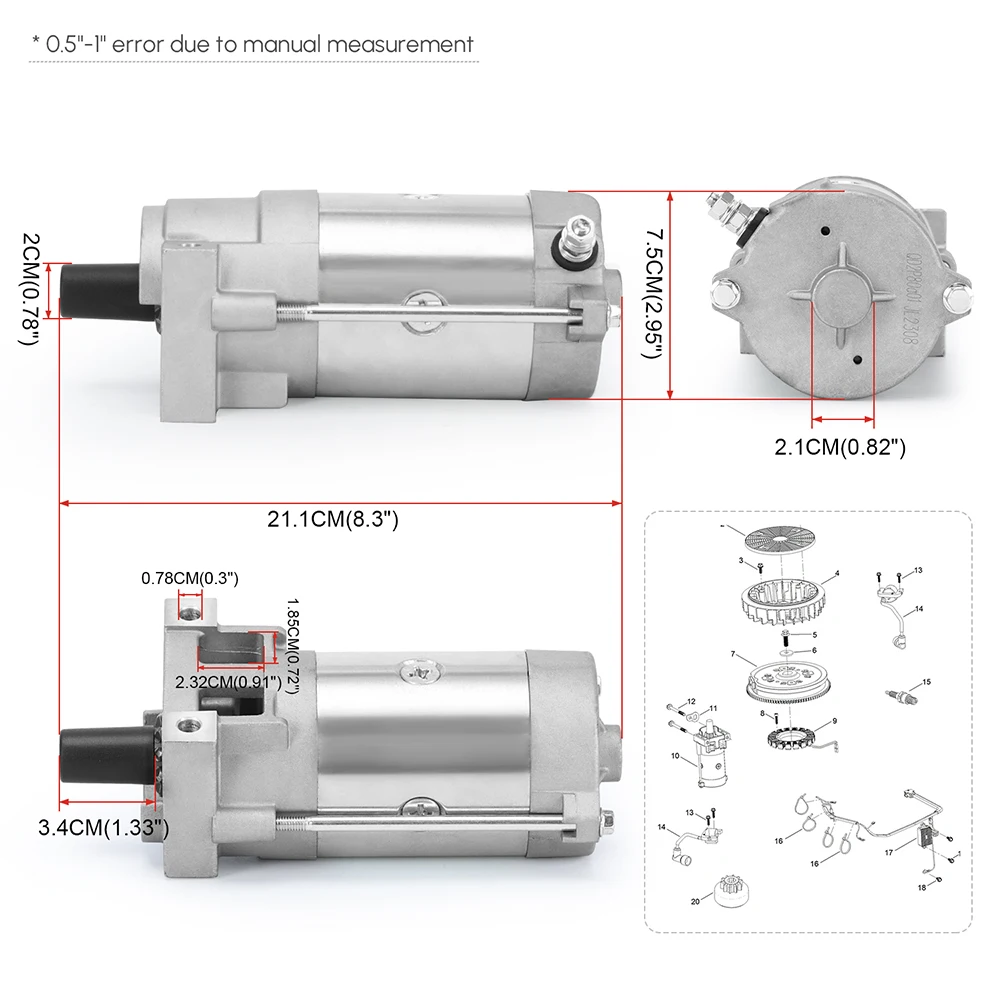

- Engine: The powerhouse that drives the machine.

- Transmission: Responsible for power distribution and speed regulation.

- Chassis: The framework that supports all other components.

- Blades: Essential for cutting, with varying types available for different tasks.

- Control Panel: The interface for operation, allowing for user adjustments.

Understanding these elements is crucial for effective troubleshooting and performance enhancement.

Importance of Parts Diagrams

Understanding the intricate details of machinery is crucial for effective maintenance and repair. Visual representations that outline components enhance comprehension, allowing users to identify and locate necessary items swiftly. This clarity aids in minimizing downtime and ensuring optimal functionality.

Streamlined Maintenance

Visual guides facilitate a smoother maintenance process. They provide clear insights into assembly and disassembly, helping technicians avoid common pitfalls. With precise references, the risk of errors decreases significantly.

Enhanced Troubleshooting

When issues arise, having a detailed visual reference can be the ultimate advantage. It enables users to delve into specific areas of concern quickly, identifying faulty components and expediting repairs. This efficiency ultimately prolongs the lifespan of the equipment.

How to Read the Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. This guide will help you navigate through the intricate details, ensuring you grasp the relationships between various elements and their functions.

Start by familiarizing yourself with the overall layout. Identify the main sections and take note of any labels that provide context. These annotations often indicate the purpose of each part and how they connect to one another.

Next, pay attention to the numbering or lettering used throughout the illustration. This system is designed to correlate with a list of components, enabling you to locate specific items quickly. Refer to this list frequently to enhance your understanding of each part’s role.

Additionally, look for color coding or shading, as these can signify different categories or functions of the parts. Understanding these visual cues can simplify complex information and assist in troubleshooting issues effectively.

Finally, take your time to analyze the connections between parts. Understanding how they interact will deepen your comprehension of the overall system and empower you to perform tasks with confidence.

Common Issues with Toro 75742

When operating machinery designed for landscaping and maintenance, users may encounter several recurring challenges that can affect performance and efficiency. Understanding these common problems can help in timely troubleshooting and ensure smooth operation over time.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Starting Problems | Difficulty in starting the engine can stem from various factors, such as fuel issues or battery failures. | Check fuel levels, replace the battery, or inspect ignition components. |

| Uneven Cutting | When the cutting blades do not operate uniformly, it results in an uneven lawn appearance. | Ensure blades are sharp and properly aligned; adjust height settings if necessary. |

| Excessive Vibration | Vibrations during operation can indicate loose components or imbalanced parts. | Tighten loose screws and bolts; balance the blades if needed. |

| Overheating | Machines may overheat due to blocked air intakes or low oil levels. | Clean air filters, ensure proper oil levels, and allow the machine to cool down. |

| Clogged Deck | Grass and debris can accumulate in the cutting deck, hindering performance. | Regularly clean the deck after use to prevent buildup. |

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward task when you know where to look. With the right resources and methods, you can ensure that your machinery remains in optimal condition without unnecessary delays.

Here are some effective strategies to simplify your search for replacements:

- Online Retailers: Many websites specialize in equipment components. Use specific model numbers for accurate results.

- Manufacturer’s Website: Check the official site for a dedicated section on replacements, which often includes helpful tools and resources.

- Local Dealers: Visit nearby retailers that focus on outdoor or garden machinery; they may have what you need in stock.

- Community Forums: Engage with other users in online communities. They can provide valuable insights and recommendations.

By utilizing these approaches, you can streamline the process and ensure that your equipment is always functioning at its best. Regular maintenance and timely replacements can significantly extend the lifespan of your machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. By following a few key practices, you can significantly extend the lifespan of your machinery and enhance its efficiency. Consistent attention to maintenance not only prevents potential issues but also saves time and resources in the long run.

Regular Cleaning: Keeping your equipment clean is crucial. Dirt and debris can accumulate and lead to wear and tear. Schedule routine cleanings to remove any buildup, especially in hard-to-reach areas. This simple step can help maintain optimal performance.

Fluid Checks: Monitoring and replacing fluids at appropriate intervals is vital. Fluids lubricate moving parts and prevent overheating. Regularly inspect oil, coolant, and other necessary fluids to ensure they are at the correct levels and in good condition.

Inspecting Components: Frequent inspections of essential components can help identify wear early. Check belts, filters, and other critical parts for signs of damage or deterioration. Addressing minor issues promptly can prevent them from escalating into major problems.

Following Manufacturer Guidelines: Adhering to the recommended maintenance schedule outlined by the manufacturer is essential. This includes following specific procedures and using appropriate replacement parts when necessary. Staying compliant with these guidelines ensures your equipment operates efficiently and safely.

Proper Storage: When not in use, store your equipment in a clean, dry place to protect it from environmental factors. Covering machinery can also prevent dust accumulation and exposure to moisture, which can lead to rust and corrosion.

By implementing these maintenance tips, you can enjoy a reliable and efficient performance from your equipment for many years to come. A proactive approach to upkeep is key to maximizing your investment and ensuring optimal functionality.

Comparative Analysis with Other Models

This section explores the distinctive features and functionalities of a specific model in relation to similar offerings in the market. By evaluating key aspects such as performance, durability, and user satisfaction, we can uncover the unique advantages and potential drawbacks that set it apart from its competitors.

Performance Metrics

When assessing operational efficiency, various models exhibit different levels of power and speed. The chosen model stands out due to its robust motor and optimized design, which enhances its overall effectiveness compared to others. Efficiency is paramount, as users seek machines that not only perform well but also conserve energy.

User Experience

The user interface and ease of maintenance play crucial roles in customer satisfaction. Many alternatives may lack the intuitive controls found in this model, making it simpler for users to operate and maintain. Feedback from users consistently highlights the convenience and reliability of this choice, further solidifying its reputation in the competitive landscape.

Frequently Asked Questions on Parts

This section aims to address common inquiries related to components and their maintenance, ensuring users have the information they need to make informed decisions. Understanding the nuances of various elements is essential for proper upkeep and functionality.

What should I do if I can’t find a specific component?

If a certain element is not readily available, consider checking authorized distributors or contacting customer support for assistance. They may provide alternatives or recommend compatible options.

How can I ensure I am purchasing the correct item?

To verify compatibility, always refer to the model specifications and manuals. Cross-referencing with online resources can also help confirm you are selecting the right piece.

What maintenance steps should I follow for longevity?

Regular inspections and cleanings can significantly enhance the lifespan of components. Make sure to follow the manufacturer’s guidelines for maintenance routines.

Are there any warranties available for these components?

Many manufacturers offer warranties on their products. Check the details before purchasing to understand the coverage and duration of protection provided.

Can I install components myself, or should I hire a professional?

This depends on your skill level and the complexity of the installation. If you are confident in your abilities, you may attempt it; however, for more intricate setups, hiring an expert is advisable.

Where to Buy Genuine Parts

When seeking high-quality components for your equipment, it’s essential to source them from reputable suppliers. Authentic items ensure optimal performance and longevity, reducing the risk of malfunction and enhancing the overall efficiency of your machinery. Below are some reliable options for acquiring original components.

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official retailers recognized by the manufacturer. | Genuine products, expert advice, warranty support. |

| Manufacturer’s Website | The official online store of the brand. | Direct access to new releases, secure purchases. |

| Specialized Retail Stores | Shops that focus on equipment and machinery components. | Knowledgeable staff, broad selection, immediate availability. |

| Online Marketplaces | Websites that connect buyers and sellers for a variety of goods. | Competitive prices, convenience, customer reviews. |

Utilizing these avenues will help ensure that you acquire the right items, ultimately prolonging the life of your equipment and maintaining its peak performance.