Toro 75755 Parts Diagram Overview

Maintaining your outdoor machinery is essential for optimal performance and longevity. Whether you are a professional landscaper or a dedicated homeowner, knowing the intricacies of your equipment can make a significant difference in efficiency. This section delves into the intricate components that make up these machines, providing valuable insights for users seeking to enhance their understanding.

By familiarizing yourself with the individual elements of your lawn equipment, you can troubleshoot issues more effectively and make informed decisions when repairs or replacements are necessary. A clear visualization of these components will aid in recognizing how they interact, ensuring that you can keep your machinery running smoothly.

In this guide, we aim to provide a detailed overview of the essential elements, enabling you to navigate through maintenance tasks with confidence. Whether you’re looking to perform routine upkeep or addressing specific malfunctions, having access to a comprehensive resource can be incredibly beneficial. Equip yourself with knowledge to ensure your equipment operates at its best.

Toro 75755 Parts Overview

This section provides a comprehensive look at the components associated with a popular outdoor equipment model. Understanding these elements is essential for maintenance, repair, and optimal performance. Each piece plays a crucial role in the overall functionality and efficiency of the machinery.

Key components include:

- Engine assembly: The heart of the machine, providing the necessary power.

- Blade system: Designed for effective cutting and trimming.

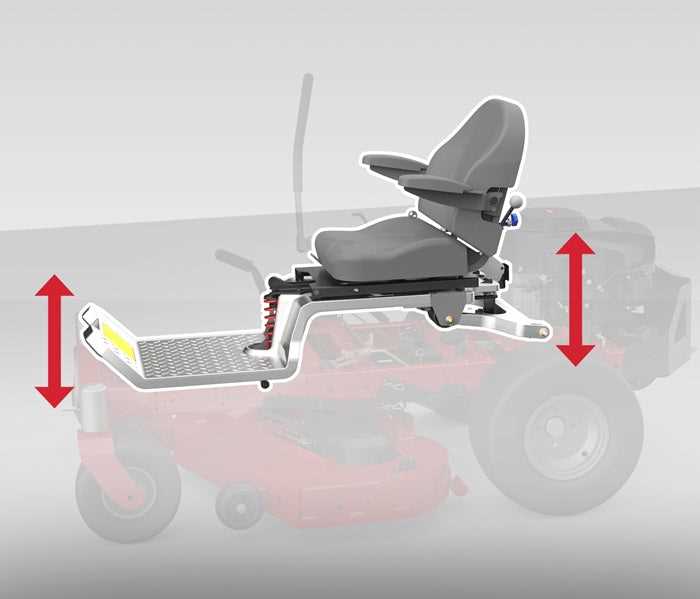

- Drive mechanism: Responsible for movement and maneuverability.

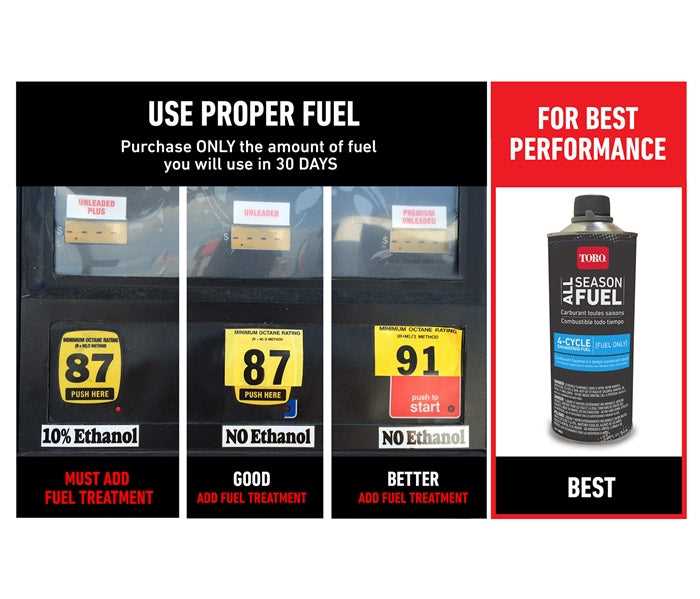

- Fuel system: Ensures efficient operation by delivering energy to the engine.

- Electrical components: Includes wiring and ignition systems that enhance usability.

Each of these elements can be categorized based on their functions:

- Power Generation:

- Engine components

- Fuel filters

- Cutting Mechanism:

- Blades

- Spindle assemblies

- Mobility Features:

- Wheels

- Transmissions

- Control Systems:

- Handles

- Throttle controls

By familiarizing yourself with these components, you can ensure effective upkeep and troubleshooting for your outdoor machinery.

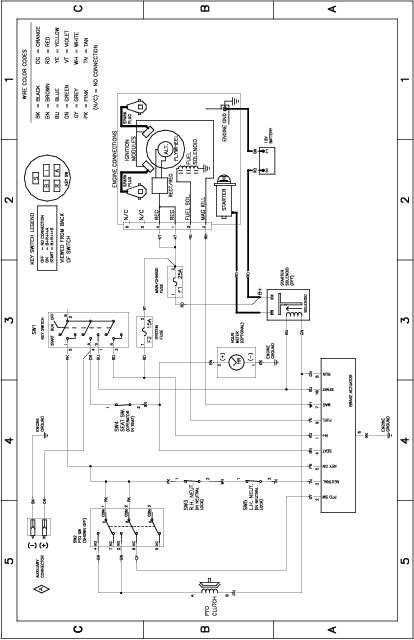

Understanding the Parts Diagram

Comprehending a schematic representation of components is essential for effective maintenance and repair of any machinery. Such illustrations provide a visual breakdown of various elements, helping users identify, locate, and understand the function of each piece within the system. Mastery of these visuals enhances the ability to troubleshoot and ensure optimal performance.

Benefits of Familiarity with Component Illustrations

By becoming acquainted with these visual aids, users can quickly determine the necessary replacements or adjustments needed. This knowledge not only saves time during repairs but also minimizes the risk of misinterpretation of parts, leading to more efficient work processes. Understanding the arrangement and connection of components can significantly enhance one’s ability to carry out repairs confidently.

How to Read the Visual Representation

To effectively utilize these illustrations, one should start by recognizing the labeling system used to denote each component. Typically, numbers or letters correspond to a list that outlines detailed descriptions and specifications. Pay attention to the layout, as it often reflects the assembly sequence or logical connections between parts. Familiarizing yourself with this format can facilitate smoother repair experiences and better-informed decisions regarding maintenance.

Common Components in Toro 75755

This section delves into the essential elements that contribute to the functionality and performance of this particular model. Understanding these components helps users maintain and troubleshoot effectively, ensuring optimal operation.

Key Elements

The primary components include the engine, cutting deck, and transmission system. Each part plays a vital role in the overall performance. The engine provides the necessary power, while the cutting deck ensures precision in lawn care. The transmission system facilitates smooth movement, enhancing user experience.

Maintenance Considerations

Regular upkeep of these components is crucial for longevity. Checking oil levels, cleaning filters, and inspecting belts can prevent common issues. Being proactive in maintenance not only extends the life of the equipment but also ensures efficient performance. Knowledge of these key elements empowers users to take charge of their equipment care.

Importance of Replacement Parts

When it comes to maintaining machinery and equipment, the availability of quality components is crucial for optimal performance. Over time, wear and tear can lead to inefficiencies and potential breakdowns, making it essential to replace worn elements to ensure longevity and reliability.

Utilizing high-quality replacement components can offer several advantages:

- Enhanced Performance: New elements can restore equipment to its original efficiency, improving overall functionality.

- Cost-Effectiveness: Investing in replacements can prevent costly repairs or complete overhauls in the future.

- Safety: Properly functioning machinery reduces the risk of accidents caused by malfunctions.

- Environmental Impact: Well-maintained equipment operates more efficiently, contributing to reduced energy consumption and waste.

Moreover, understanding the specific requirements for replacements helps in making informed decisions, ensuring compatibility and durability. Regularly assessing the condition of components can facilitate timely replacements, ultimately leading to smoother operations and a more productive environment.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. It provides a visual guide that helps identify individual elements and their relationships within a system. Here are some key strategies to effectively interpret such illustrations.

- Familiarize Yourself with Symbols: Different illustrations use various symbols to represent components. Take time to learn these symbols, as they are crucial for understanding the overall layout.

- Identify Key Sections: Often, these visuals are divided into sections based on functionality. Focus on one section at a time to avoid feeling overwhelmed.

- Check the Legend: A legend or key is usually included, explaining each symbol and component. Refer to it frequently to clarify any uncertainties.

By following these strategies, you will enhance your ability to navigate and comprehend the schematic effectively.

- Take Notes: Jot down important points as you study the illustration. This can help reinforce your understanding.

- Cross-Reference with Manuals: If available, use accompanying manuals or documentation to gain further insights into each component’s function.

- Practice: The more you work with these visuals, the more comfortable you will become. Regular practice can significantly improve your skills.

With these tips, you can confidently approach any schematic and utilize it to enhance your repair and maintenance tasks.

Finding OEM vs. Aftermarket Parts

When maintaining or repairing machinery, the choice between original equipment manufacturer components and alternative options is crucial. Each category offers distinct advantages and potential drawbacks, impacting performance, durability, and cost. Understanding these differences can help you make informed decisions that align with your needs and budget.

OEM components are designed specifically for your equipment, ensuring compatibility and adherence to the original specifications. This often translates to better performance and reliability over time. However, they can come with a higher price tag, which might not always be feasible for everyone.

On the other hand, aftermarket options provide a wider range of choices, often at more accessible prices. While some alternatives can match or even exceed the quality of original parts, others may compromise on durability or performance. It’s essential to research the manufacturer and read reviews to ensure you’re selecting a reliable substitute.

Ultimately, the decision between OEM and alternative components will depend on your specific situation, including budget constraints, desired longevity, and the importance of maintaining original specifications. Careful consideration can lead to a satisfying and effective solution for your machinery needs.

Maintenance Tips for Toro Equipment

Proper upkeep of outdoor machinery is essential for optimal performance and longevity. Regular maintenance not only ensures efficient operation but also prevents costly repairs and extends the life of your equipment. Here are some key practices to keep in mind.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Regularly replace engine oil to keep components lubricated and functioning smoothly. |

| Air Filter Inspection | Every 25 hours | Check and clean or replace air filters to ensure proper airflow and engine efficiency. |

| Blade Sharpening | Every 25 hours | Keep blades sharp for effective cutting and to reduce stress on the engine. |

| Tire Pressure Check | Monthly | Maintain correct tire pressure for improved traction and reduced wear. |

| Battery Maintenance | Monthly | Inspect battery connections and charge levels to ensure reliable starting. |

Following these maintenance guidelines will help you keep your equipment in peak condition, ensuring that it operates effectively throughout the seasons. Remember to consult your user manual for specific recommendations and details unique to your model.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration in machinery is crucial for maintaining optimal performance and extending the lifespan of your equipment. Regular inspection can prevent minor issues from escalating into major problems, ensuring efficient operation and safety.

Common Indicators of Wear

- Unusual Noises: Listen for grinding, squeaking, or rattling sounds that may indicate internal damage or lack of lubrication.

- Visible Damage: Look for cracks, dents, or worn-out areas on the equipment’s surface.

- Decreased Performance: Notice any reduction in efficiency or power output, which may suggest wear on critical components.

- Fluid Leaks: Check for any signs of leaking fluids, which can indicate seal failure or other issues.

- Overheating: Monitor temperature levels; excessive heat can be a sign of mechanical problems.

Regular Maintenance Tips

- Schedule routine inspections to catch issues early.

- Replace worn parts promptly to prevent further damage.

- Keep machinery clean to avoid dirt accumulation that can lead to wear.

- Follow manufacturer guidelines for lubrication and maintenance.

- Train operators to recognize and report signs of wear immediately.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring equipment effectively and efficiently. Whether you are dealing with minor issues or significant malfunctions, following a structured method can simplify the repair process and enhance your chances of success.

Before beginning any repair, ensure you have the necessary tools and a clear understanding of the components involved. Here’s a step-by-step outline to guide you through the process:

| Step | Description |

|---|---|

| 1 | Gather all required tools, including wrenches, screwdrivers, and replacement elements. |

| 2 | Disconnect the equipment from any power source to ensure safety during repairs. |

| 3 | Carefully disassemble the unit, noting the location and orientation of each part. |

| 4 | Inspect each component for wear or damage, identifying those that require replacement. |

| 5 | Replace any faulty parts with new ones, ensuring a secure fit and proper alignment. |

| 6 | Reassemble the equipment meticulously, following the reverse order of disassembly. |

| 7 | Reconnect the power source and perform a thorough test to ensure everything operates smoothly. |

By adhering to this structured guide, you can navigate the repair process with confidence and ensure optimal performance of your machinery.

Where to Purchase Toro Parts

When seeking components for your outdoor equipment, it’s essential to know the best sources for reliable replacements. Quality and availability are key factors that can impact your maintenance routine and overall equipment performance.

Local authorized dealers often provide an extensive selection of genuine items, ensuring compatibility and durability. Additionally, many of these retailers offer knowledgeable staff who can assist you in identifying the correct components for your specific model.

Online marketplaces present another convenient option, often featuring a wide range of products at competitive prices. Be sure to check seller ratings and reviews to ensure you are purchasing from a reputable source.

Specialty websites dedicated to outdoor machinery can also be valuable resources. These platforms typically provide detailed product information and may offer diagrams to help you locate the parts you need more efficiently.

Lastly, consider checking with local repair shops or service centers. They may have spare components available for sale or can assist you in ordering the right items, sometimes even offering installation services for your convenience.

Frequently Asked Questions About Toro 75755

This section addresses common inquiries regarding a specific model and its components. Understanding the features, maintenance, and availability of replacement items is essential for effective usage and longevity. Below are answers to frequent questions that can help users make informed decisions.

General Information

Many users often seek clarity on the functionalities and specifications of the equipment. It is crucial to know the best practices for maintaining the performance and efficiency of the machine.

Replacement Components

Access to quality replacements is a common concern. Below is a table highlighting essential details regarding various replacements and their compatibility:

| Component | Description | Compatibility |

|---|---|---|

| Blade | Durable cutting blade for efficient grass trimming | Compatible with various models |

| Filter | High-quality air filter for optimal engine performance | Fits multiple configurations |

| Wheel Assembly | Sturdy wheel set for smooth mobility | Universal fit for selected units |