Comprehensive Parts Diagram for John Deere X320 Lawn Tractor

Maintaining your outdoor machinery requires a solid grasp of its essential elements. Knowing the configuration of each part can enhance your efficiency and extend the lifespan of your equipment. By delving into the intricacies of these components, users can ensure smooth operation and timely repairs.

Familiarity with the various sections and how they interconnect can be the ultimate key to successful maintenance. Whether you’re troubleshooting an issue or performing routine checks, having a clear overview is invaluable. This knowledge empowers users to tackle challenges confidently and effectively.

Moreover, understanding how different elements contribute to overall performance fosters a sense of ownership and responsibility. With the right resources at your disposal, you can navigate any complexities that may arise, making informed decisions about repairs and upgrades.

Understanding John Deere X320 Components

Gaining insight into the various elements of your outdoor equipment can significantly enhance its performance and longevity. Each component plays a crucial role, contributing to the overall functionality and efficiency of the machine. By familiarizing yourself with these essential parts, you can ensure optimal care and maintenance.

Key Elements to Explore

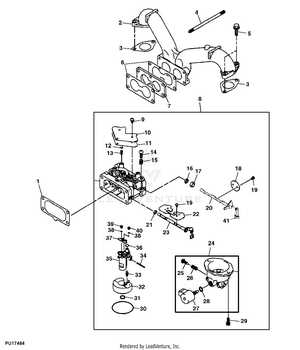

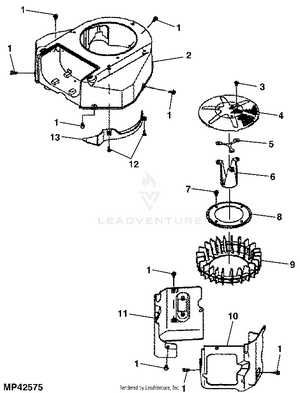

- Engine Assembly

- Transmission System

- Chassis and Frame

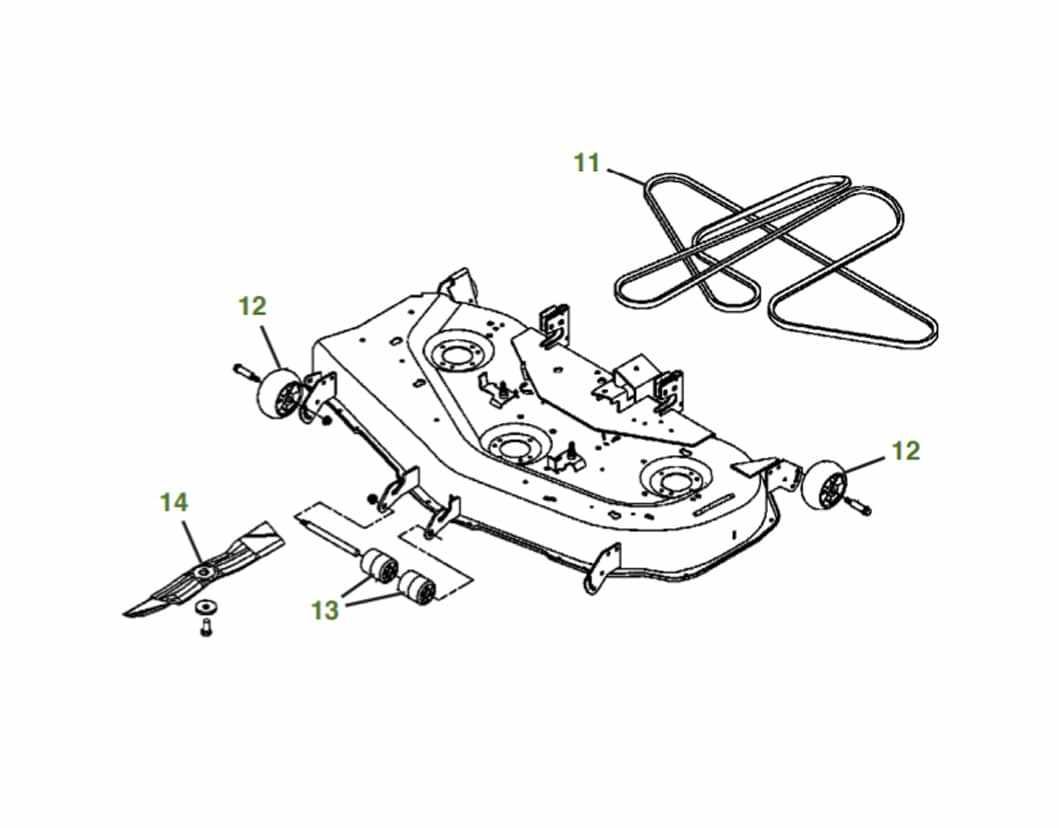

- Cutting Deck

- Wheels and Tires

Understanding these key components allows for better troubleshooting and more effective repairs when issues arise. A comprehensive knowledge of each part’s function will empower users to make informed decisions about maintenance and upgrades.

Benefits of Component Familiarity

- Improved Maintenance Practices

- Enhanced Problem-Solving Skills

- Extended Equipment Lifespan

- Increased Safety During Operation

Investing time to learn about the intricate details of your equipment not only supports its optimal functioning but also fosters a greater appreciation for the technology behind it.

Overview of Lawn Tractor Parts

Understanding the components of a garden vehicle is essential for effective maintenance and repair. Each element plays a crucial role in ensuring optimal performance and longevity. Familiarity with these parts can enhance the overall experience of managing outdoor spaces.

Key elements of these machines typically include:

- Engine: The heart of the machine, providing the necessary power for operation.

- Transmission: Facilitates the transfer of power from the engine to the wheels, affecting speed and control.

- Chassis: The framework that supports all other components, contributing to stability and durability.

- Cutting Deck: Responsible for achieving an even and precise trim, often adjustable for different grass heights.

- Wheels: Designed for traction and maneuverability, allowing for smooth navigation across various terrains.

Regular inspection and understanding of these components can lead to proactive maintenance, ultimately enhancing the machine’s functionality. Each part may require specific care or replacement, making it vital to know their characteristics and roles.

In summary, having a comprehensive grasp of the machinery’s elements empowers users to maintain and troubleshoot effectively, ensuring a pleasant and efficient gardening experience.

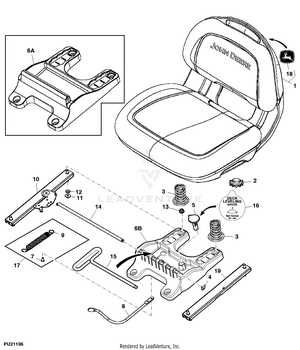

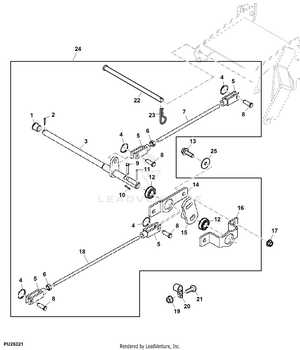

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repairs. Visual representations of these elements enable users to identify and locate each segment easily, ensuring efficient troubleshooting and replacement processes. Such illustrations serve as a roadmap, guiding individuals through complex assemblies and enhancing their overall comprehension of the equipment.

Enhanced Efficiency

Clear visual guides significantly streamline repair tasks. When individuals can quickly reference where each component is situated, they minimize downtime and reduce the chances of errors during assembly or disassembly. This efficiency ultimately leads to better performance and longevity of the machinery.

Facilitating Communication

Illustrative resources improve communication among technicians and users. With a common reference point, discussions regarding repairs or upgrades become more precise, fostering collaboration and reducing misunderstandings. This clarity is vital for ensuring that maintenance is performed correctly and in a timely manner.

Key Features of the X320 Model

This model stands out for its innovative design and functionality, offering a range of features that enhance performance and user experience. Its engineering focuses on durability and efficiency, making it a reliable choice for various tasks.

Powerful Engine: Equipped with a robust power source, this machine ensures smooth operation, allowing users to tackle challenging terrain with ease.

Comfortable Operation: The ergonomic seat and intuitive controls provide a pleasant experience, reducing fatigue during extended use.

Versatile Attachments: The ability to integrate various accessories maximizes its utility, catering to a wide array of landscaping needs.

Efficient Cutting System: The advanced cutting mechanism ensures a clean and precise finish, enhancing the aesthetic of any outdoor space.

Easy Maintenance: Thoughtful design elements facilitate straightforward upkeep, allowing users to spend less time on repairs and more on enjoyment.

How to Access Parts Diagrams Online

Finding detailed schematics for machinery components can significantly enhance maintenance and repair processes. Utilizing online resources provides a convenient way to view these illustrations, enabling users to easily identify and order necessary items.

Step-by-Step Guide

To locate these valuable resources, follow these steps:

| Step | Description |

|---|---|

| 1 | Visit official manufacturer websites that offer online support. |

| 2 | Use the search function to enter the model or type of equipment. |

| 3 | Navigate to the resources or support section to find visual aids. |

Additional Resources

Online forums and user communities often share links and insights about accessing these illustrations. Engaging with these platforms can provide further assistance and guidance.

Common Replacement Parts for X320

Regular maintenance is essential to keep your machine running efficiently. Over time, certain components may wear out or require replacement to ensure optimal performance. Understanding which elements commonly need attention can help you prepare for maintenance and minimize downtime.

- Blades: Essential for a clean cut, these components often require sharpening or replacement due to wear.

- Batteries: As power sources, batteries may lose their capacity over time, necessitating replacement.

- Belts: These are crucial for transferring power within the system; they can stretch or fray with usage.

- Filters: Air and fuel filters need regular checks and replacements to maintain optimal engine performance.

- Tires: Proper traction is vital, so keep an eye on tread wear and replace when necessary.

Having a good understanding of these common components can facilitate better maintenance planning and enhance the longevity of your machine.

Maintenance Tips for Your Tractor

Proper upkeep is essential for maximizing the performance and longevity of your outdoor machinery. Regular attention to maintenance can prevent costly repairs and ensure that your equipment runs smoothly throughout the season. Below are some essential tips to keep your machine in optimal condition.

Routine Checks

- Inspect oil levels regularly and change it according to the manufacturer’s recommendations.

- Check air filters and clean or replace them as needed to ensure proper airflow.

- Examine belts and hoses for wear and tear, replacing any damaged components promptly.

Seasonal Maintenance

- Before winter, prepare your machine by draining fuel and adding a stabilizer to prevent buildup.

- In the spring, check the battery and clean terminals to ensure a strong start.

- Sharpen blades to maintain an efficient cutting performance throughout the growing season.

Following these maintenance tips will help you keep your equipment running efficiently and effectively for years to come.

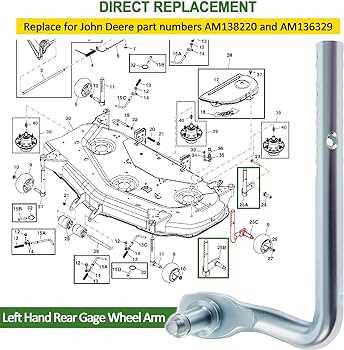

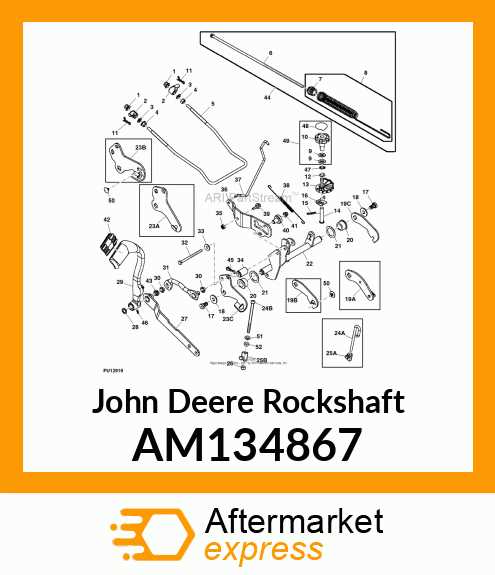

Identifying Parts by Model Number

Understanding components through their specific identifiers is crucial for effective maintenance and repairs. Each model carries unique characteristics that facilitate the identification of its various elements. By utilizing these designations, users can streamline their search for replacements or upgrades.

Familiarizing yourself with the model number not only enhances your knowledge but also ensures that you acquire the correct items for your equipment. Consulting manufacturer manuals and online resources can provide clarity on the parts associated with each model, reducing the likelihood of errors.

Additionally, recognizing the significance of these identifiers can lead to more informed decisions when purchasing, thereby prolonging the lifespan and performance of your machinery.

Using OEM vs. Aftermarket Parts

When it comes to maintenance and repairs, the choice between original equipment manufacturer (OEM) components and those from third-party suppliers can significantly impact performance and durability. Understanding the pros and cons of each option can help you make an informed decision that best suits your needs.

Benefits of OEM Components

- Quality Assurance: OEM items are produced to meet the manufacturer’s exact specifications, ensuring high-quality standards.

- Compatibility: Designed specifically for your equipment, these components guarantee a perfect fit and optimal functionality.

- Warranty Protection: Using OEM parts often maintains any existing warranties, providing peace of mind for repairs.

Advantages of Aftermarket Options

- Cost-Effectiveness: Generally, aftermarket components are more affordable, making them an attractive choice for budget-conscious consumers.

- Variety: The market offers a wide range of aftermarket products, often providing options that OEMs do not.

- Innovation: Some aftermarket manufacturers invest in research and development, offering enhanced performance features.

In summary, both choices have their merits and drawbacks. Assessing your priorities–whether they be cost, performance, or compatibility–will guide you in selecting the best option for your specific requirements.

Step-by-Step Repair Process

Understanding the repair procedure is essential for maintaining your equipment effectively. This section outlines a structured approach to tackle repairs, ensuring a smooth workflow and minimizing downtime.

- Preparation:

- Gather necessary tools and equipment.

- Review the user manual for specifications and guidelines.

- Clear the workspace to ensure safety and efficiency.

- Diagnosis:

- Identify the issue by observing the machine’s performance.

- Check for common problems such as leaks or unusual noises.

- Utilize diagnostic tools if necessary to pinpoint the fault.

- Disassembly:

- Carefully take apart the components involved in the repair.

- Organize screws and small parts to avoid misplacement.

- Take notes or photos to aid reassembly later.

- Repair:

- Replace or fix damaged components as needed.

- Ensure that all connections are secure and properly aligned.

- Use high-quality replacement parts for optimal performance.

- Reassembly:

- Follow your notes or photos to put everything back together.

- Double-check that all parts are reinstalled correctly.

- Tighten screws and fasteners to the specified torque.

- Testing:

- Start the machine to ensure it operates smoothly.

- Monitor for any unusual sounds or behaviors.

- Perform a thorough check of all systems to confirm successful repair.

By following these steps, you can effectively manage repairs and maintain the longevity of your equipment.

Frequently Asked Questions about X320

This section addresses common inquiries regarding the popular model, offering clarity on various aspects of its functionality and maintenance. Whether you are a new owner or seeking specific details, these questions provide valuable insights.

What are the maintenance requirements?

Regular upkeep is essential for optimal performance. This includes checking fluid levels, changing filters, and inspecting belts. Adhering to a maintenance schedule will prolong its lifespan.

How can I improve its performance?

To enhance efficiency, consider upgrading the blades or ensuring the tires are properly inflated. Additionally, using high-quality fuel can lead to better overall operation.

Finding Reliable Parts Suppliers

When searching for trustworthy vendors, it’s crucial to prioritize quality and service. Identifying sources that offer authentic components and support can significantly enhance your maintenance experience. Consider exploring both local and online options to discover a diverse range of offerings.

Check reviews and ratings to gauge customer satisfaction and reliability. Engaging with fellow enthusiasts can provide valuable insights and recommendations, helping you make informed choices. Always ensure that the supplier guarantees the authenticity of their items, as this is vital for optimal performance and longevity.

Additionally, evaluating return policies and customer service responsiveness can further assure you of a positive purchasing experience. By delving into these aspects, you can secure the ultimate supply chain for your needs.

Enhancing Performance with Upgrades

Upgrading components can significantly boost the efficiency and effectiveness of your machine. By selecting the right enhancements, you can ensure smoother operation, increased power, and a longer lifespan for your equipment. This approach not only optimizes performance but also enhances the overall user experience, making tasks easier and more enjoyable.

Key Areas for Improvement

Focus on areas such as the engine, transmission, and cutting systems. Upgrading the engine can lead to better fuel efficiency and increased horsepower, while enhancements to the transmission can provide smoother shifting and improved responsiveness. Additionally, refining the cutting system can result in cleaner cuts and reduced strain on the engine.

Choosing Quality Components

When selecting upgrades, prioritize quality over cost. Durable and reliable components will deliver consistent performance and minimize maintenance issues in the long run. Consider researching reputable brands and reading customer reviews to make informed decisions that align with your performance goals.