Comprehensive Guide to Poulan Pro Lawn Tractor Parts Diagram

Maintaining outdoor machines requires a deep understanding of their individual elements. Every mechanical unit, whether for home use or commercial applications, relies on a combination of well-constructed elements that ensure smooth operation. Knowing how each element functions and fits into the broader system helps in identifying potential issues and ensuring efficient repairs.

For those who frequently use such equipment, a detailed breakdown of the mechanical system becomes invaluable. Having an accurate illustration of the key elements and their connections can significantly enhance maintenance efforts. This not only aids in timely upkeep but also extends the lifespan of the machinery, ensuring it remains reliable for years to come.

With the proper visual reference, identifying any worn-out or malfunctioning parts becomes straightforward. Such knowledge is crucial when ordering replacements, making adjustments, or performing regular maintenance. A well-documented visual guide is an essential tool for anyone looking to keep their equipment in optimal condition.

Key Components of a Poulan Pro Lawn Tractor

The machinery used for outdoor maintenance relies on several essential elements to operate efficiently. These components work in harmony to ensure smooth performance, durability, and ease of use. Understanding how these crucial parts function together is key to keeping the equipment in optimal condition.

Engine System

The heart of the machine, this section powers all operations. It is typically designed for long-lasting performance and can vary in power output, depending on the model. Maintenance of this area ensures reliable starting and sustained operation, even under heavy use.

- Power output and efficiency

- Durability under demanding conditions

- Regular maintenance for longevity

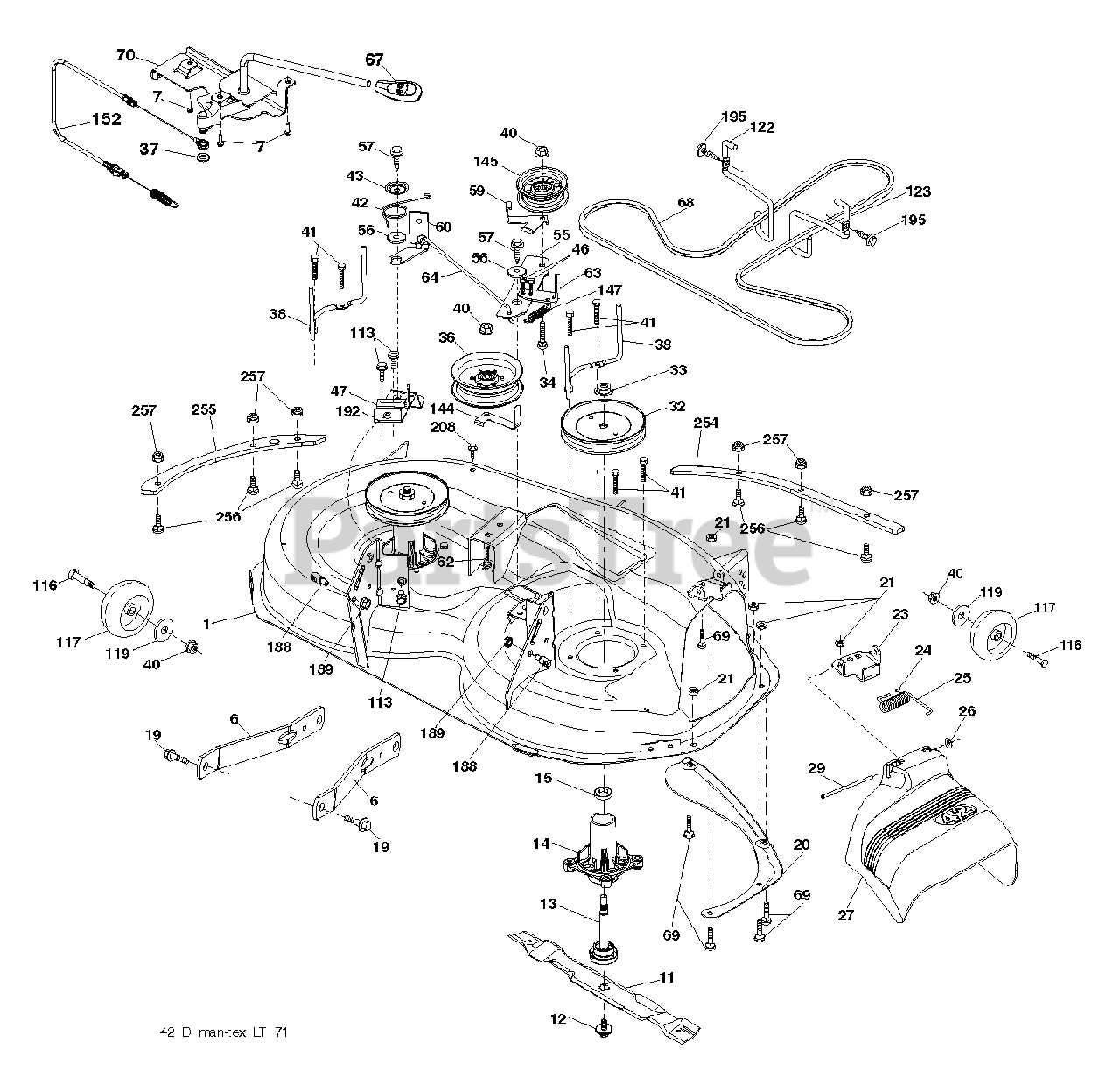

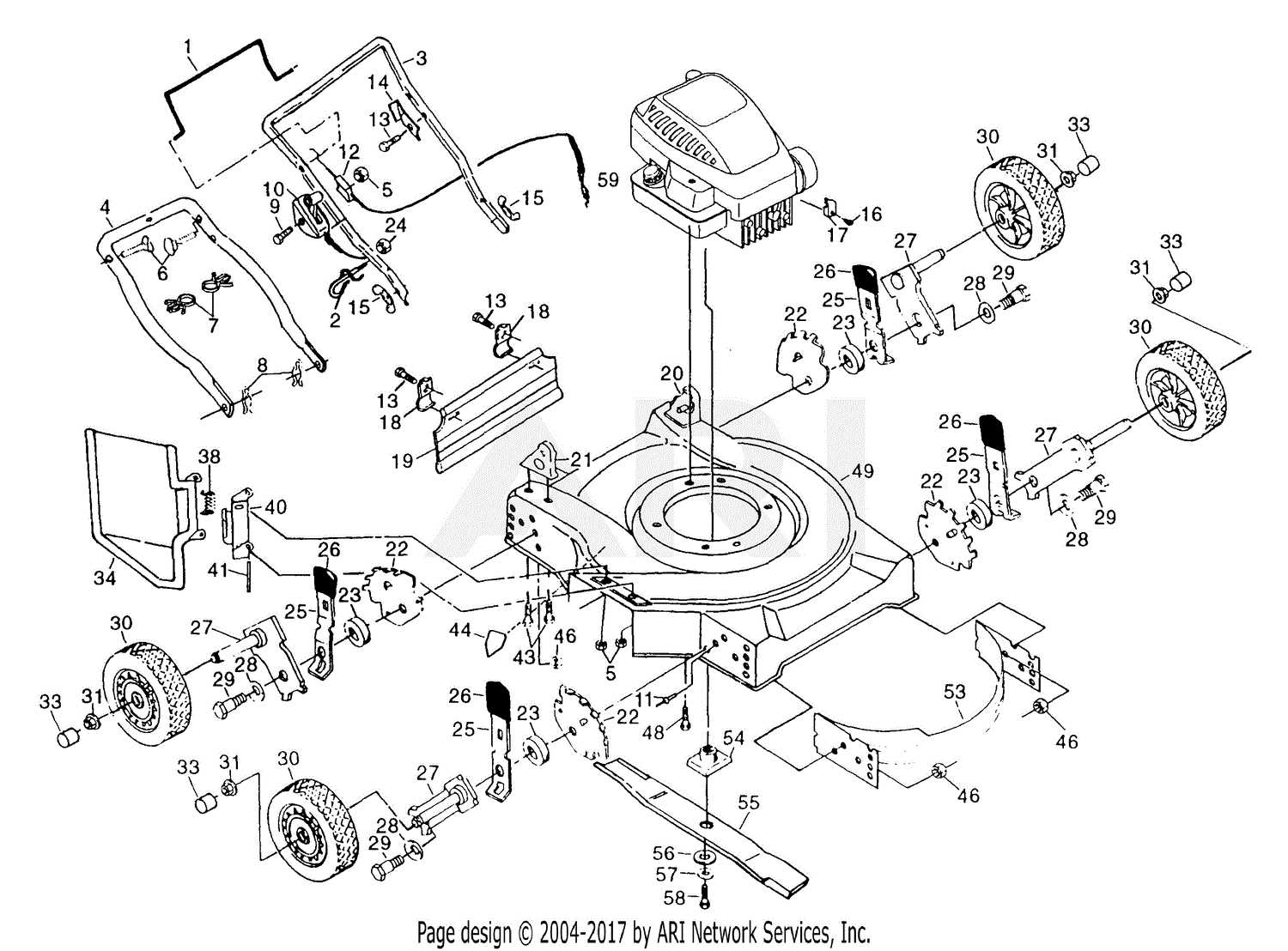

Cutting Mechanism

This system is responsible for delivering the desired results when working on outdoor spaces. It typically includes sharp blades, an adjustable deck, and controls that allow the user to customize the cutting height. Proper maintenance of the cutting mechanism is crucial for consistent performance.

- Adjustable deck for varying heights

- Blades designed for precision

- Easy-to-use controls for customization

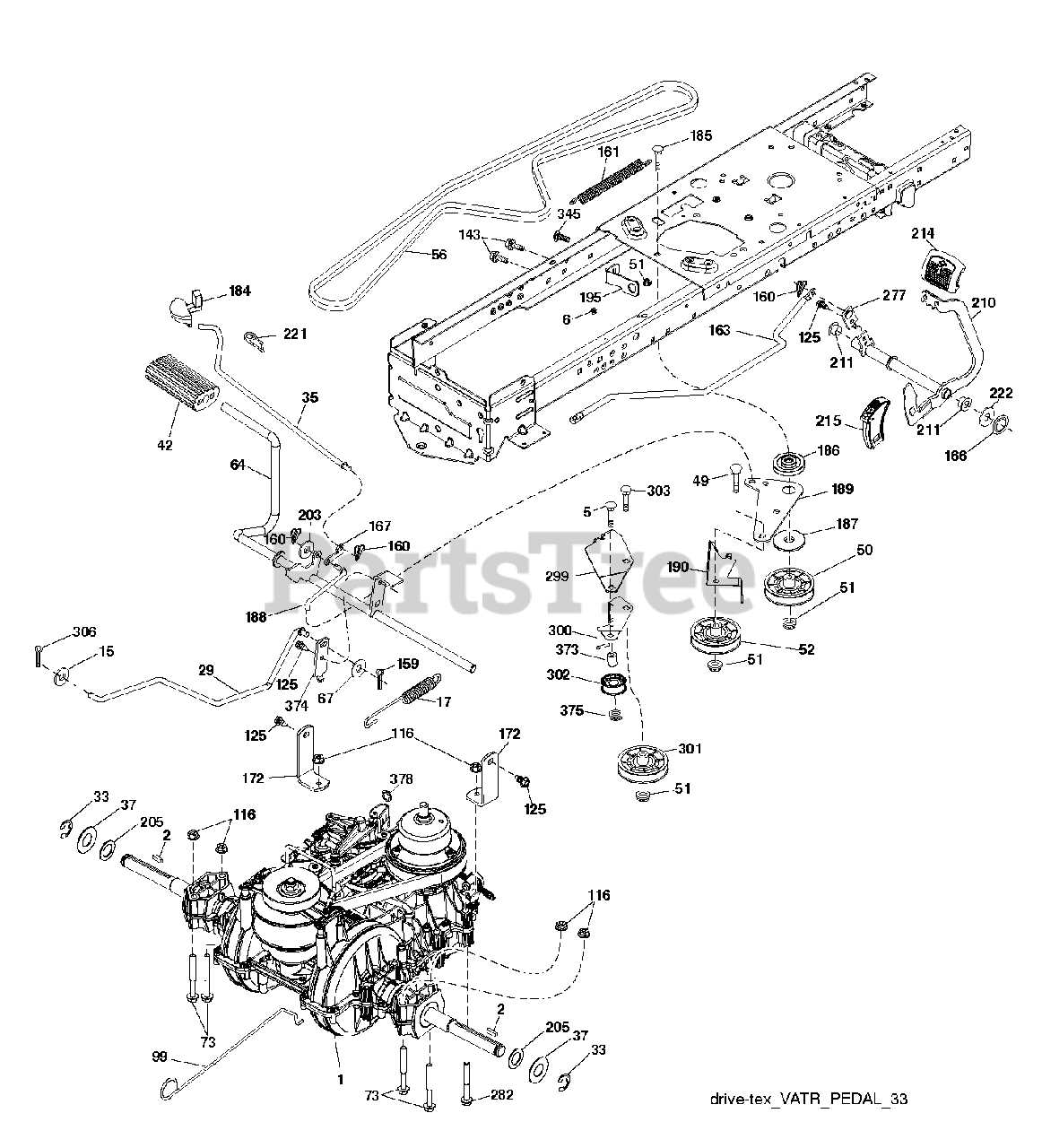

Understanding the Engine Layout

The mechanical structure under the hood is an intricate system designed to deliver power efficiently and reliably. By recognizing how the various components interconnect, one can better comprehend the workings of the entire machinery, from ignition to motion. A well-organized engine setup plays a critical role in ensuring smooth operation and long-term durability.

Main Sections of the Power Unit

In this section, we’ll break down the key areas of the power mechanism, including how fuel enters the system, combustion occurs, and power is transferred to the drive system. These sections are vital for maintaining proper function and identifying areas for maintenance or adjustment.

| Component | Function |

|---|---|

| Cylinder Block | Contains the combustion chambers where the fuel burns and generates power. |

| Carburetor | Regulates the air-fuel mixture to ensure proper combustion efficiency. |

| Crankshaft | Converts the vertical motion of the pistons into rotational motion for power delivery. |

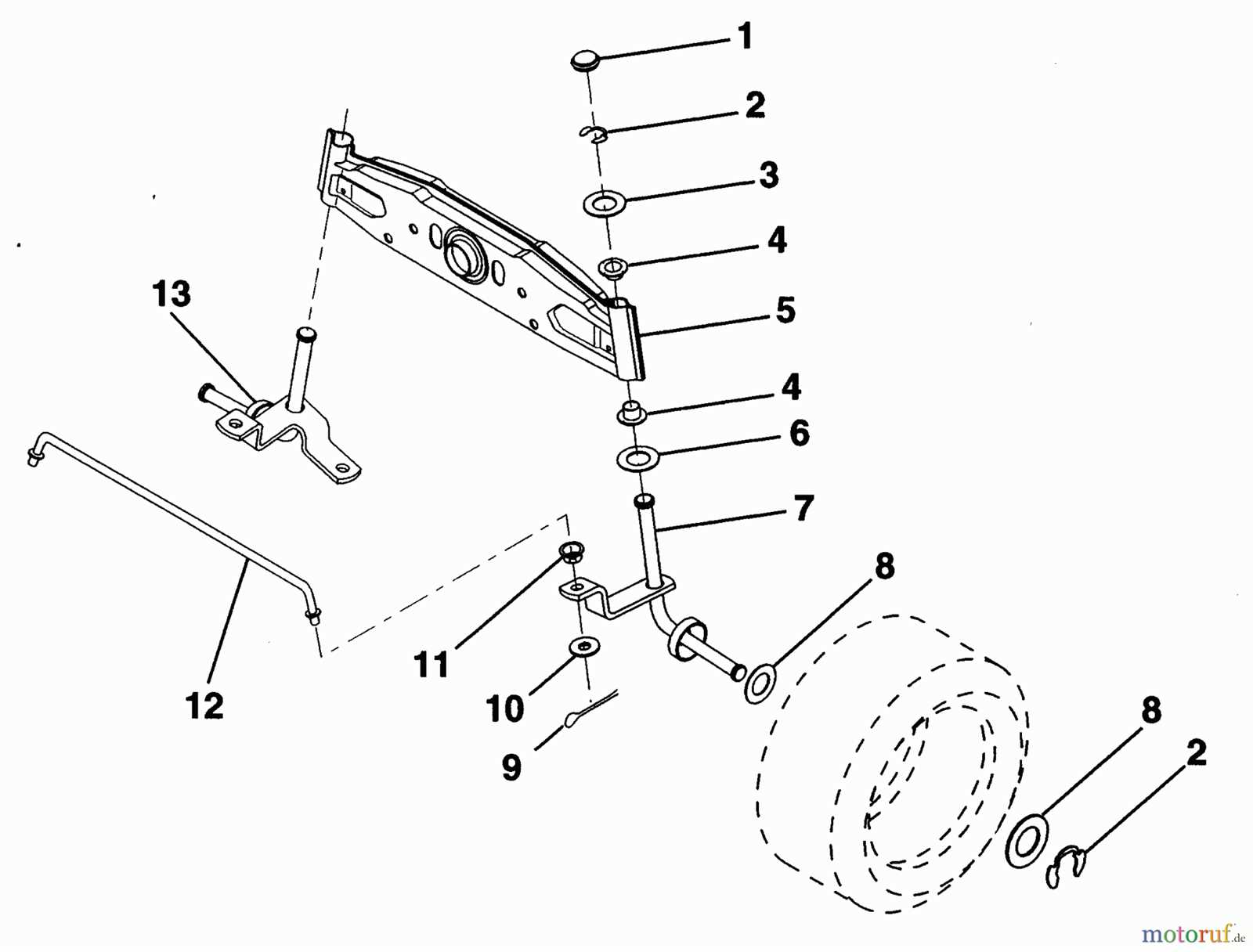

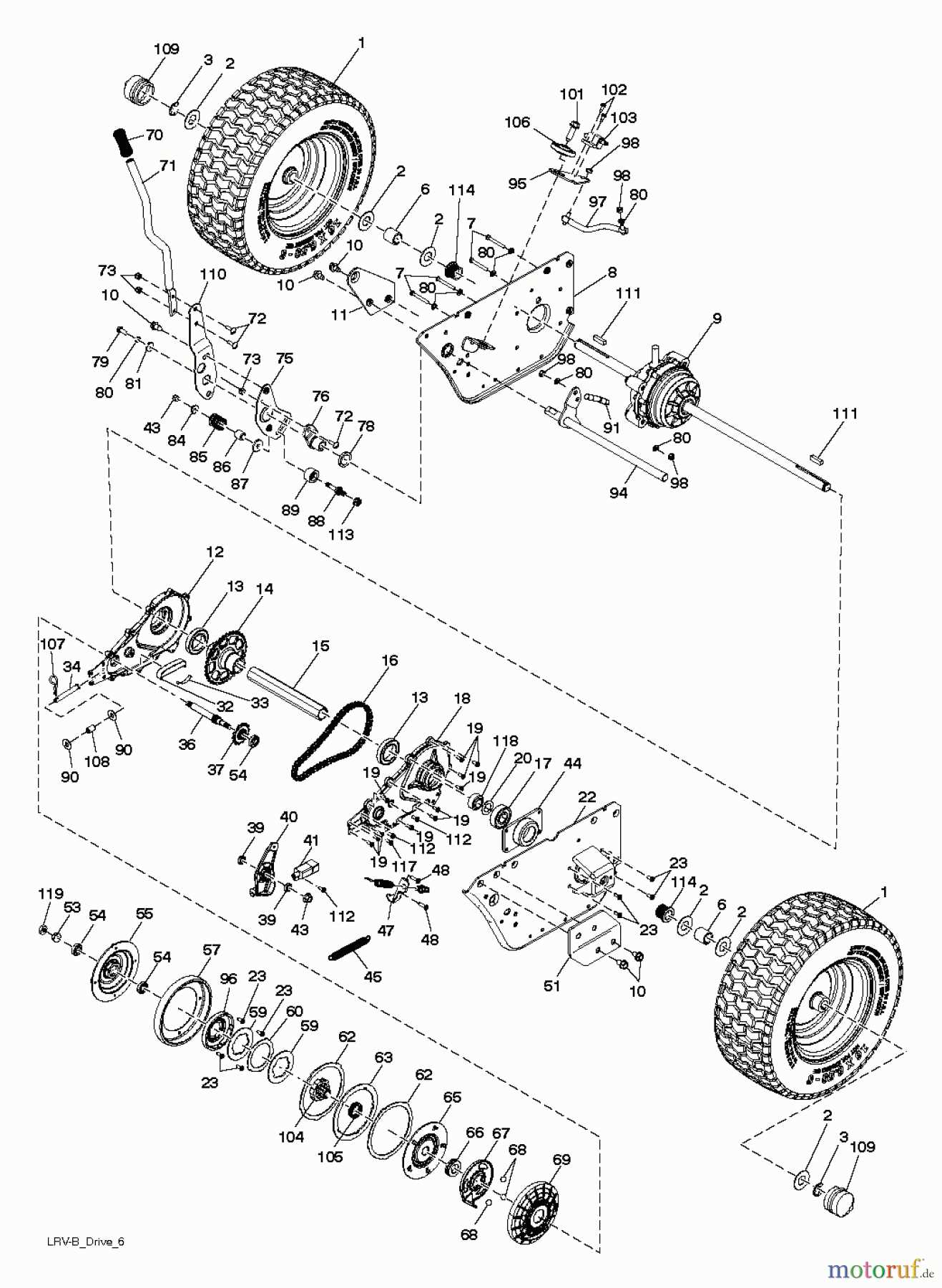

| Drive System Configuration and Parts

The drive mechanism is a critical element of the machine, ensuring smooth and efficient power transmission to the wheels. This section covers the essential components involved in transferring energy from the engine to the movement system, and how they are integrated to deliver optimal performance. Main ComponentsAt the heart of the drive mechanism are several key elements: the transmission, which adjusts power delivery; the belt system, which connects the engine to the drivetrain; and various pulleys that guide movement. Each part plays a vital role in ensuring proper operation and needs regular maintenance to avoid wear. Power Transmission ProcessPower generated by the engine is transferred through a belt and pulley system, engaging the transmission to control speed and direction. This process is enhanced by several supporting parts, including tensioners, which keep the belt taut, and axles that transfer the force to the wheels. Together, these parts create a reliable system that handles various terrains and conditions. Exploring the Cutting Deck AssemblyThe system responsible for trimming the grass plays a critical role in ensuring efficient performance. This section focuses on the structure beneath the machine that houses the rotating blades, allowing the operator to achieve precise grass height. Understanding the key components of this section helps maintain its functionality and ensures a smooth operation. Key Components of the AssemblyThe assembly consists of several essential parts working together. The cutting blades, positioned strategically, rotate to provide an even trim. These blades are supported by spindles, which act as their axis of rotation. The spindles are mounted on a plate that forms the main body of the system. Additionally, pulleys and belts connect the blades to the engine, ensuring synchronized motion. Maintenance Tips for LongevityRegular care is crucial to prevent wear and tear on the blades and other components. Keeping the blades sharp guarantees an even cut, while inspecting the belts for cracks or slack can help avoid breakdowns. Proper lubrication of moving parts, such as spindles, ensures a longer lifespan and smoother operation. Fuel System Overview and Maintenance TipsThe fuel system plays a crucial role in ensuring the efficient operation of any mechanical equipment. Proper care and routine checks can significantly extend the lifespan of the engine, ensuring smooth performance. This section will guide you through essential maintenance practices that keep the system running optimally, avoiding common issues that arise due to neglect or improper handling. Key Components of the System

Each of these parts requires specific attention to ensure fuel flows properly and the engine receives a clean and steady supply. Maintenance Tips

|