Understanding the Components of Harley 4 Speed Transmission

The intricate systems that facilitate motion in vintage motorcycles are a marvel of engineering. They blend artistry with functionality, creating a harmonious balance that enhances the riding experience. Delving into these mechanisms unveils the complexities involved in their design and operation.

Focusing on the components that contribute to efficient gear shifting can reveal insights into maintenance and performance optimization. Recognizing the roles of various elements within these systems can significantly improve both understanding and usage. By exploring each aspect, riders can appreciate the ultimate craftsmanship behind their machines.

In this section, we will examine a detailed breakdown of these essential elements, highlighting their interconnections and the significance of each part. Whether you’re a seasoned enthusiast or a newcomer, this exploration will provide valuable knowledge for anyone passionate about the mechanics of motorbikes.

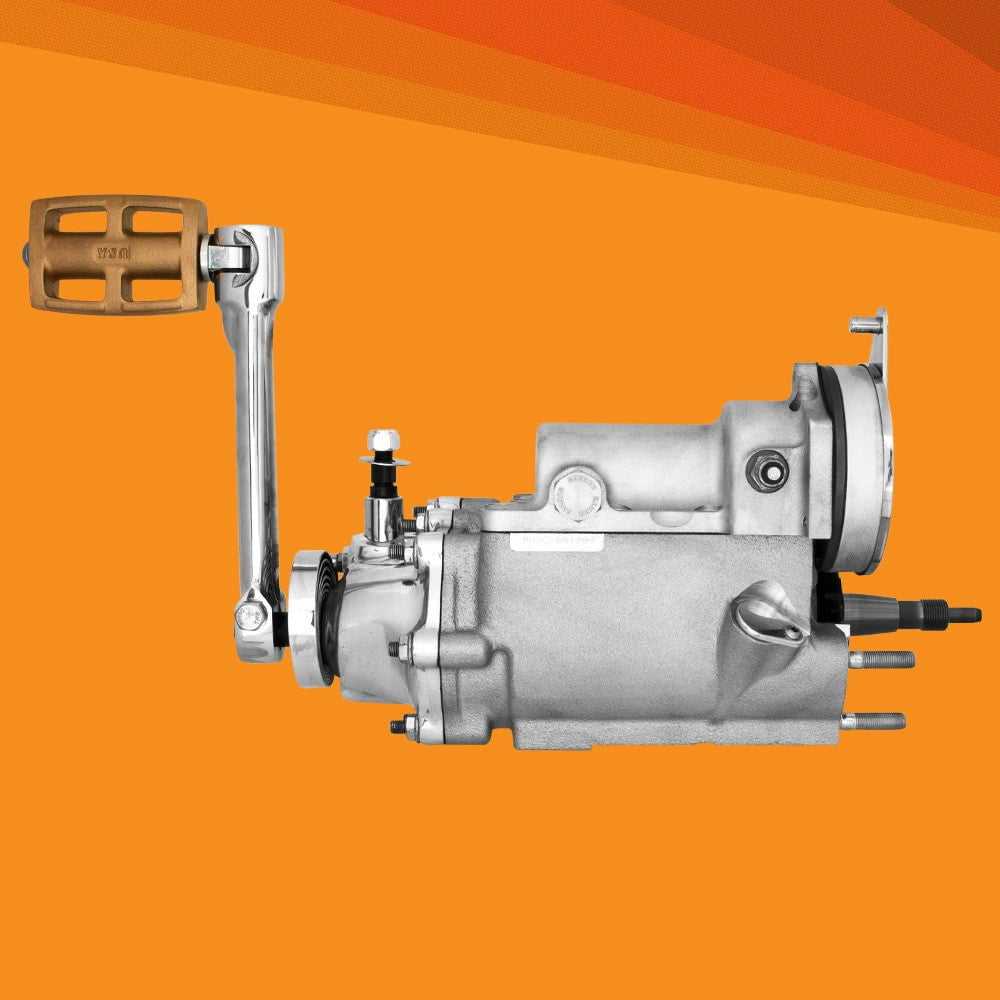

Understanding the 4 Speed Transmission

The mechanics behind a four-gear system play a crucial role in the performance and efficiency of motorized vehicles. This setup allows for a versatile range of gear ratios, enabling optimal power delivery and fuel efficiency under various conditions. Grasping the components and their functions is essential for any enthusiast looking to enhance their knowledge or perform maintenance.

In this context, a thorough comprehension of the internal mechanisms is vital. Each element works in harmony to facilitate smooth gear changes and reliable operation. Key components include the gear assembly, clutch, and shifting mechanism, all of which contribute to the overall functionality.

| Component | Function |

|---|---|

| Gear Assembly | Engages different ratios to control acceleration and power transfer. |

| Clutch | Disengages the engine from the gears during shifting, ensuring smooth transitions. |

| Shifting Mechanism | Allows the rider to select the desired gear for optimal performance. |

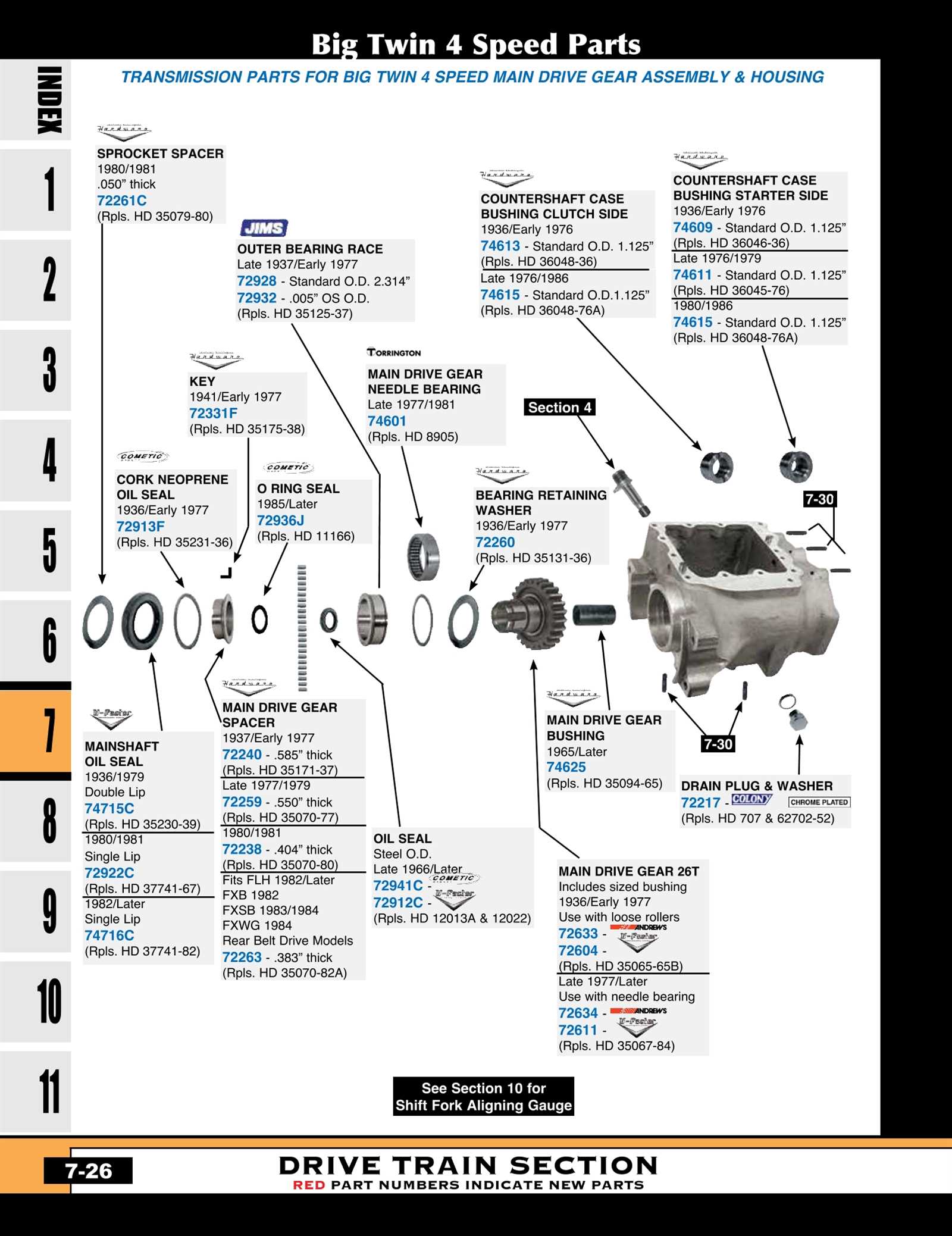

| Shafts | Transmit power between the engine and wheels, supporting the entire system. |

Understanding these components enhances one’s ability to troubleshoot and maintain the system effectively, ultimately leading to a more enjoyable riding experience.

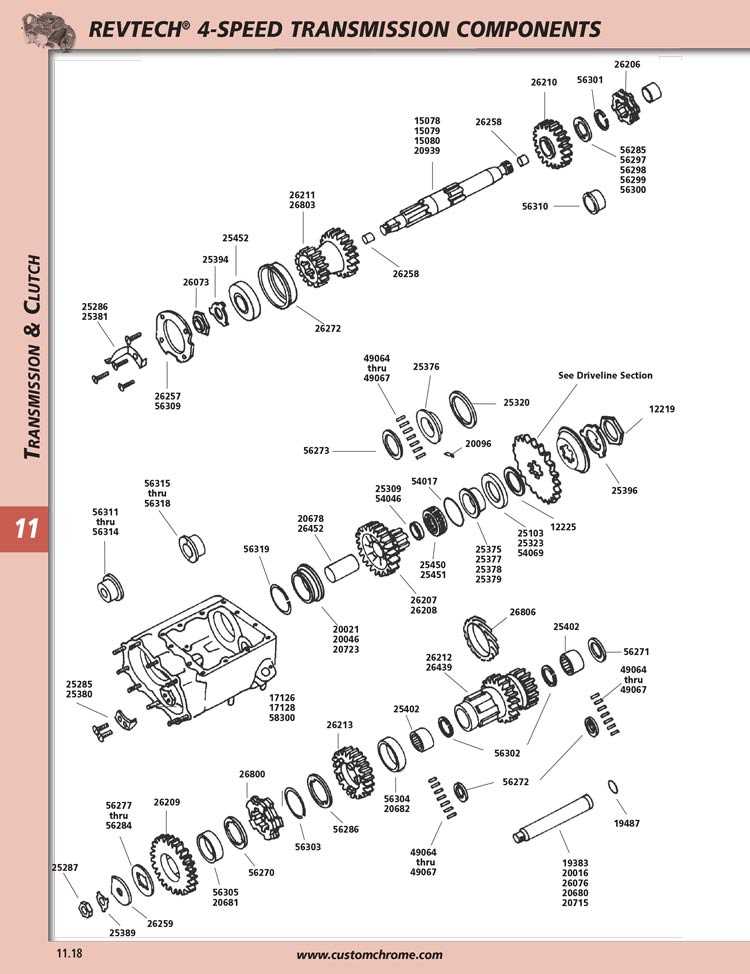

Components of Harley Transmission

The intricate system of a motorcycle’s gear-shifting mechanism plays a crucial role in its overall performance. Each element within this assembly is designed to work in harmony, ensuring smooth transitions and optimal power delivery. Understanding these essential components helps in appreciating their importance for a well-functioning ride.

| Component | Description |

|---|---|

| Clutch Assembly | Enables the rider to engage or disengage the engine power from the wheels. |

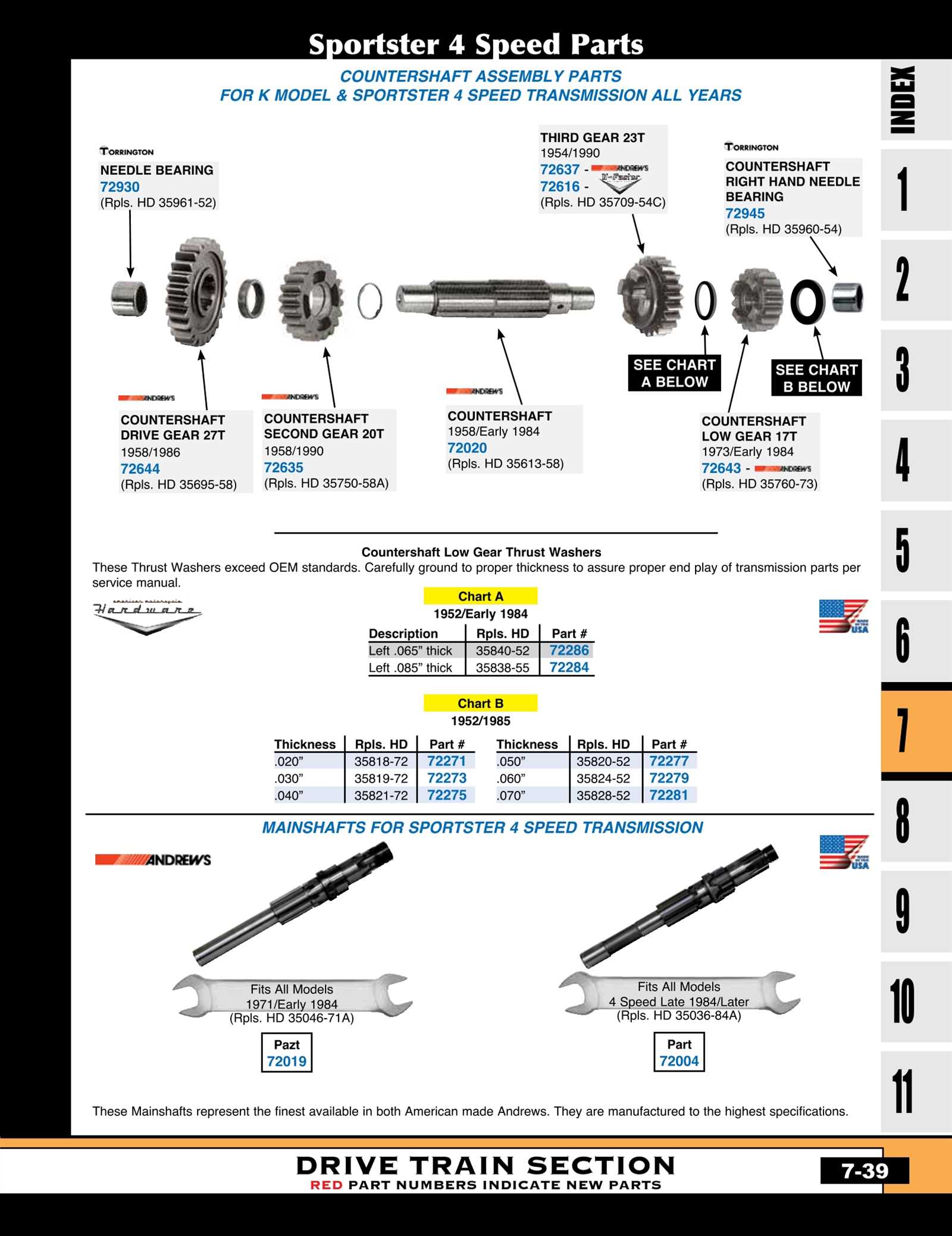

| Gears | Facilitate the multiplication of torque and control speed variations. |

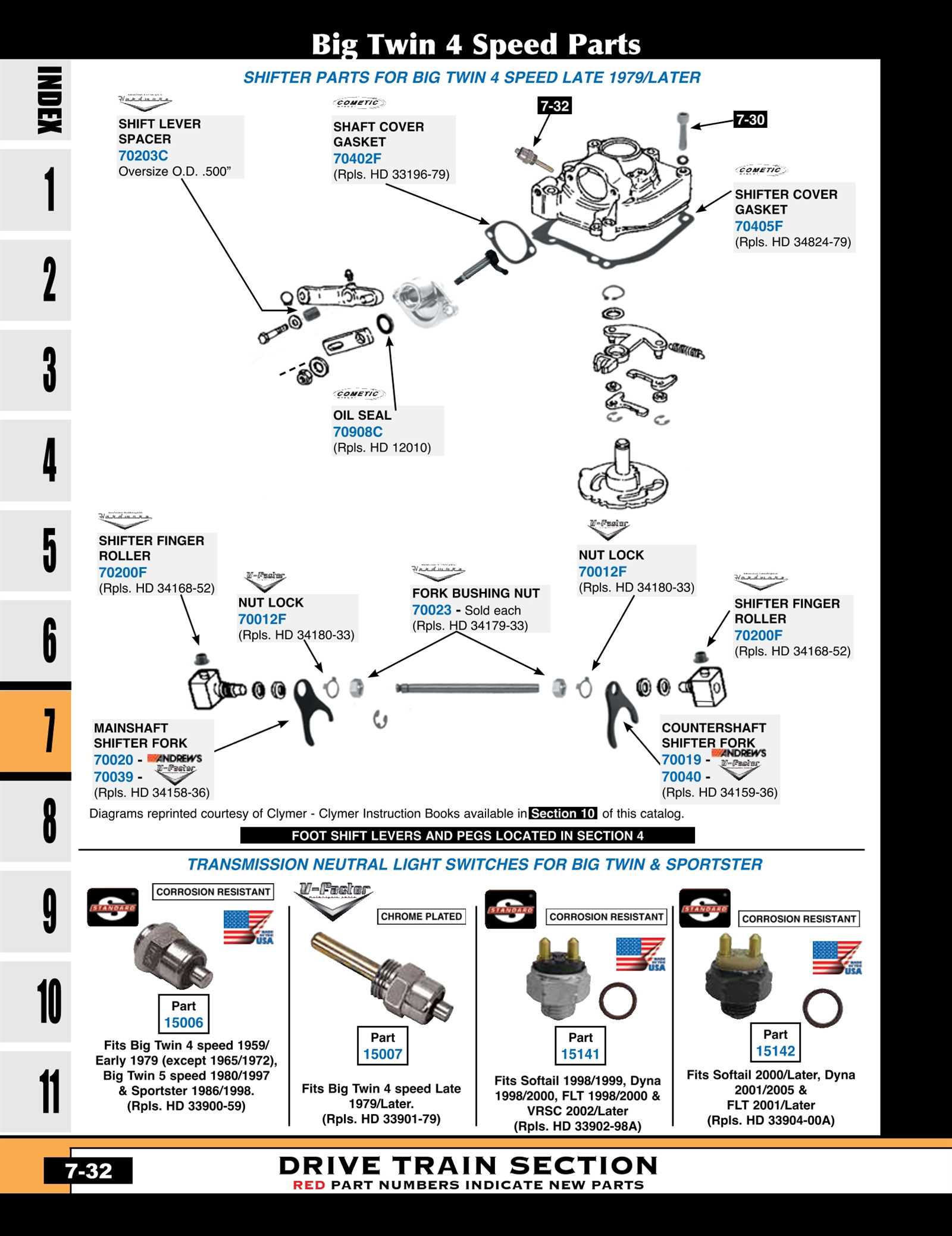

| Shift Forks | Guide the gears into the desired position during shifting. |

| Selector Mechanism | Allows the rider to choose different gear ratios easily. |

| Bearing | Supports rotating parts and reduces friction for smoother operation. |

| Oil Pump | Maintains lubrication throughout the system to prevent wear and overheating. |

Each of these components contributes to the effective functioning of the gear system, making it imperative for riders to ensure they are well-maintained for optimal performance.

Function of Each Transmission Part

Understanding the role of each component within a gear-shifting mechanism is crucial for optimal performance and longevity. Each element contributes to the overall functionality, ensuring smooth transitions and effective power transfer.

Gear Set: This assembly is responsible for altering the rotational speed and torque. It allows the rider to adjust power delivery based on riding conditions.

Clutch Assembly: This mechanism engages and disengages the engine from the drive system, facilitating smooth shifts and preventing stalling during transitions.

Shifter Fork: This component guides the movement of the gears, ensuring precise alignment for effective engagement during shifting.

Output Shaft: It transmits the rotational force from the gear set to the rear wheel, playing a key role in the bike’s acceleration and overall responsiveness.

Selector Mechanism: This system allows the rider to choose different gear ratios, enabling customized performance for various riding situations.

By delving into these individual roles, one can appreciate the complexity and sophistication involved in achieving seamless operation.

Common Issues with 4 Speed Units

Four-gear systems, while reliable, can encounter a range of challenges that affect their performance and longevity. Understanding these potential problems is crucial for maintenance and troubleshooting. From shifting difficulties to unusual noises, each issue can signify underlying mechanical wear or misalignment that needs attention.

Shifting Difficulties

One prevalent concern is the difficulty in engaging gears smoothly. This can stem from worn components, such as detent balls or springs, which play a vital role in gear engagement. Misadjustments in linkage can also contribute to this problem, leading to missed shifts or resistance during operation. Regular inspections and adjustments can help mitigate these issues.

Noise and Vibration

Unusual sounds during operation can indicate deeper problems within the gear assembly. Grinding noises may suggest worn or damaged gears, while clunking sounds can point to loose components. Excessive vibration may also arise from imbalance or improper mounting. Identifying the source of these noises is essential to prevent further damage and ensure a smooth ride.

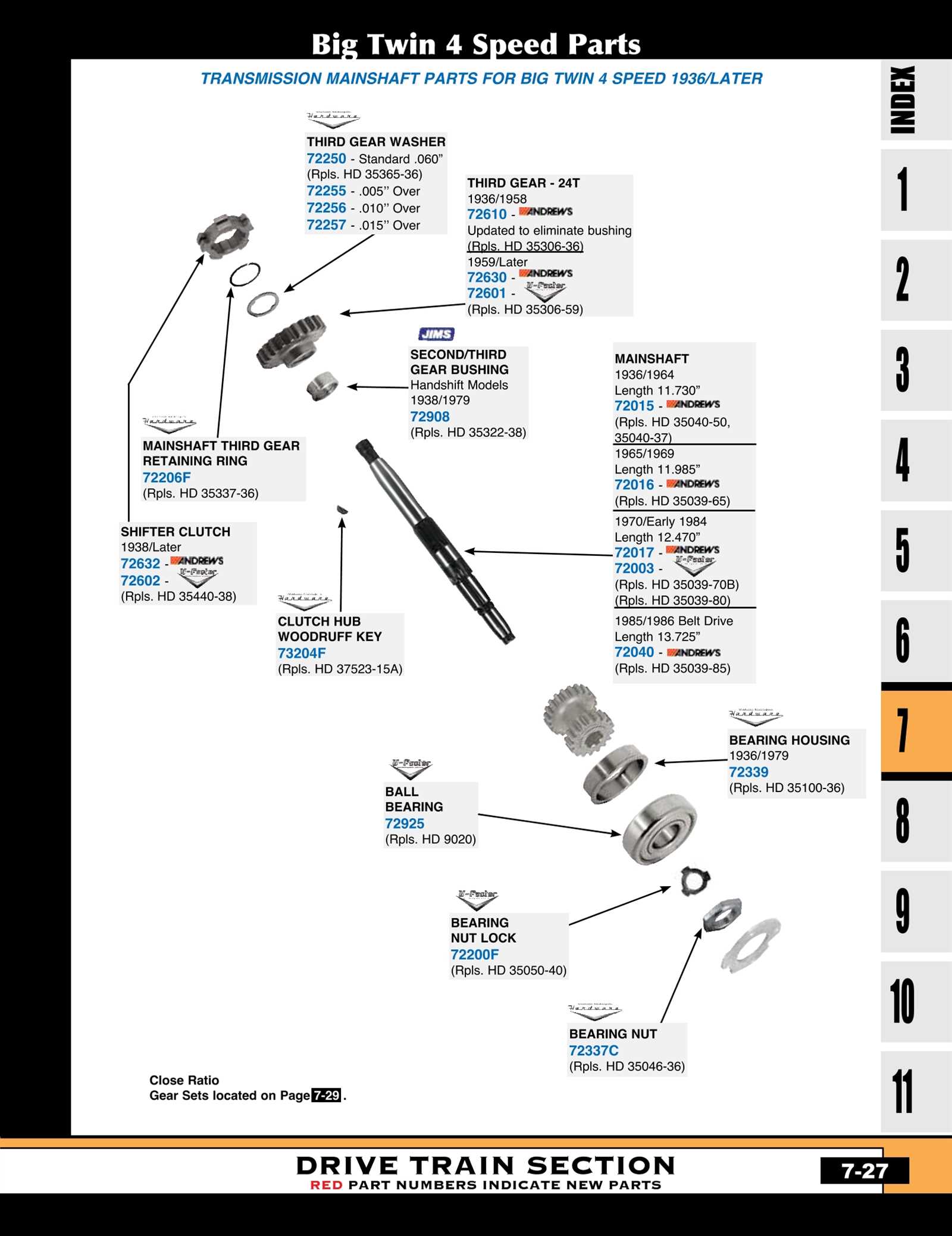

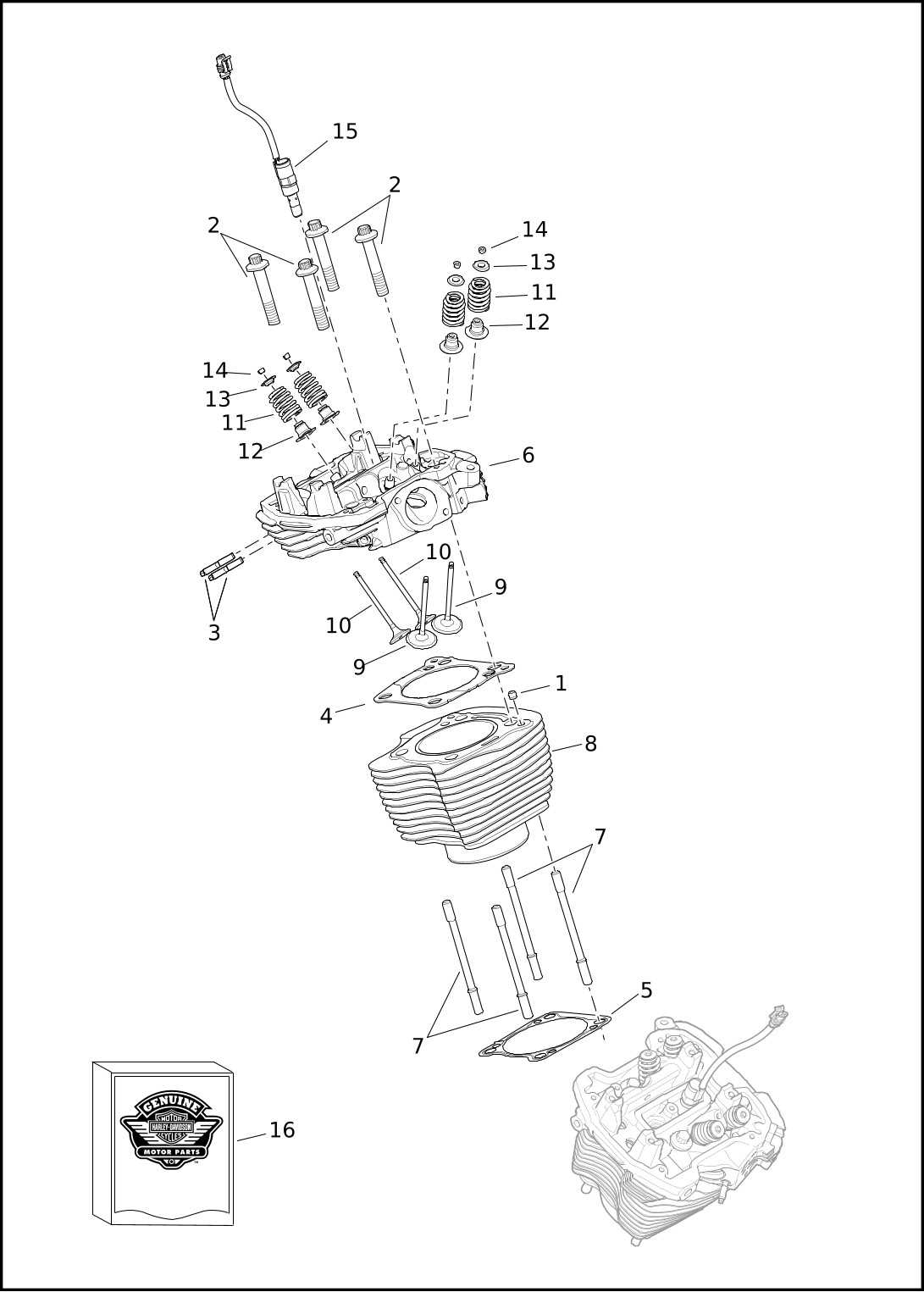

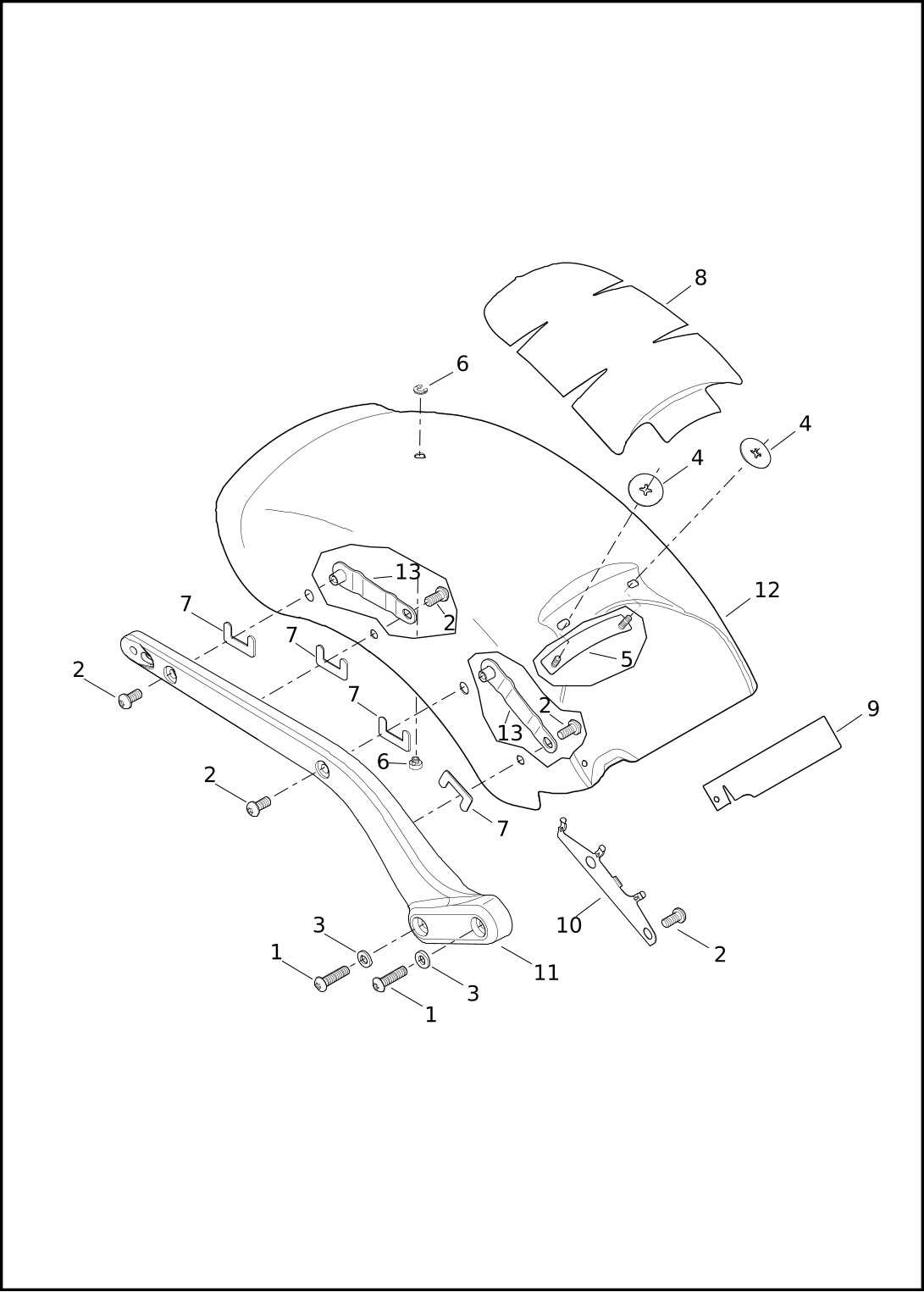

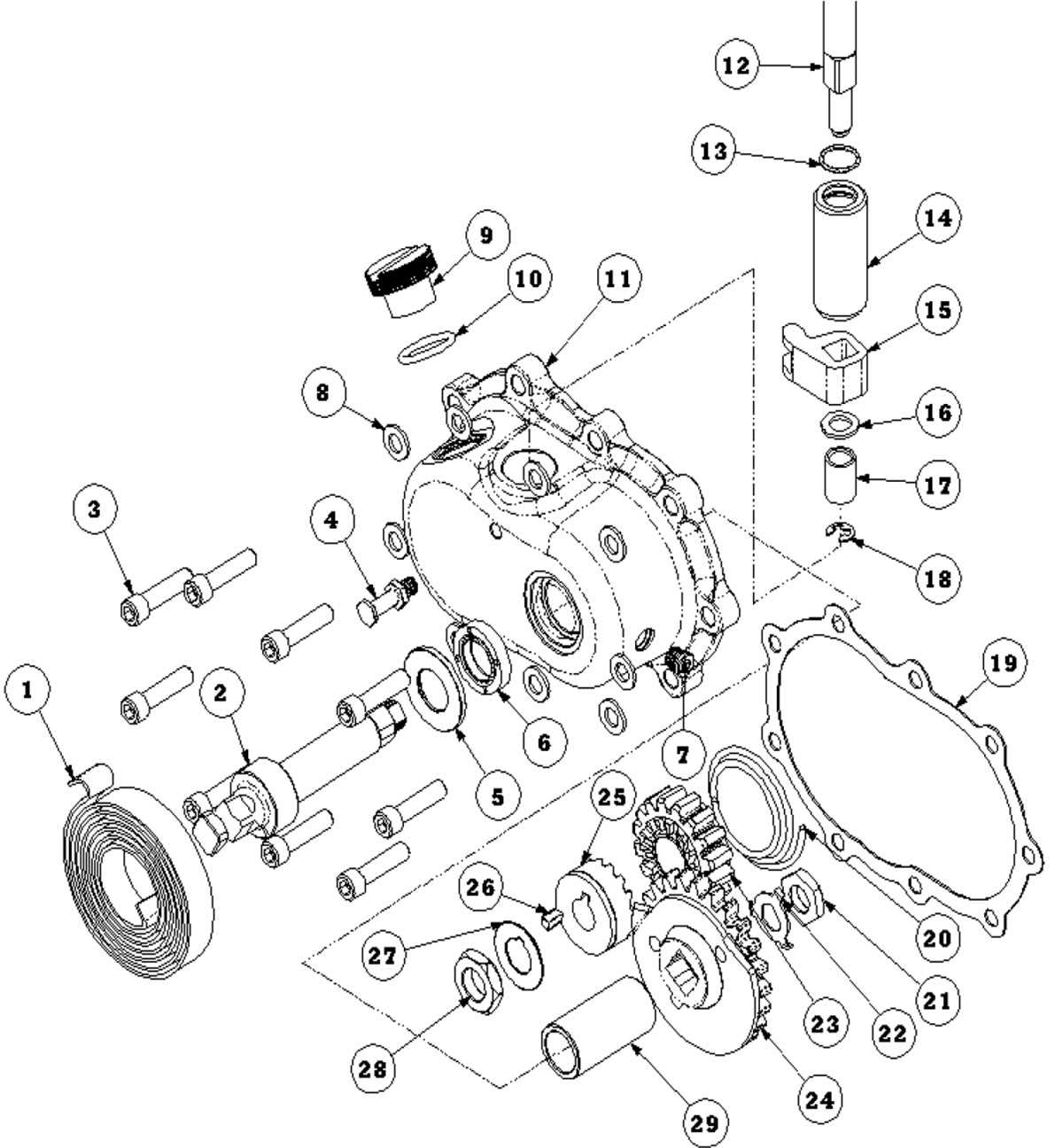

How to Identify Parts by Diagram

Understanding the various components of a mechanical system is crucial for effective maintenance and repair. Visual representations can significantly simplify the process of recognizing and locating each element, providing clarity in their functions and interactions. This section will guide you on how to effectively use visual aids for identifying components.

Steps for Effective Identification

- Familiarize Yourself with the Layout: Begin by studying the overall arrangement. Recognize the general categories of components to create a mental map.

- Use Labels and Annotations: Pay attention to any labels present. These can often indicate specific features or roles of each item.

- Compare with Real Components: If possible, reference the physical items while using the visual guide. This hands-on approach reinforces your understanding.

- Take Notes: Document your findings as you go along. This will help solidify your knowledge and provide a quick reference for future repairs.

Common Challenges

- Complex Structures: Intricate assemblies can be daunting. Break them down into smaller sections for easier navigation.

- Similar Components: Some items may appear alike. Focus on distinct characteristics to differentiate them accurately.

- Missing Information: If certain details are unclear, consult additional resources or seek expert advice to enhance your comprehension.

Maintenance Tips for Longevity

Ensuring the durability of your motorcycle’s mechanical components requires a consistent and thorough maintenance routine. Proper care can significantly enhance performance and extend the lifespan of vital systems.

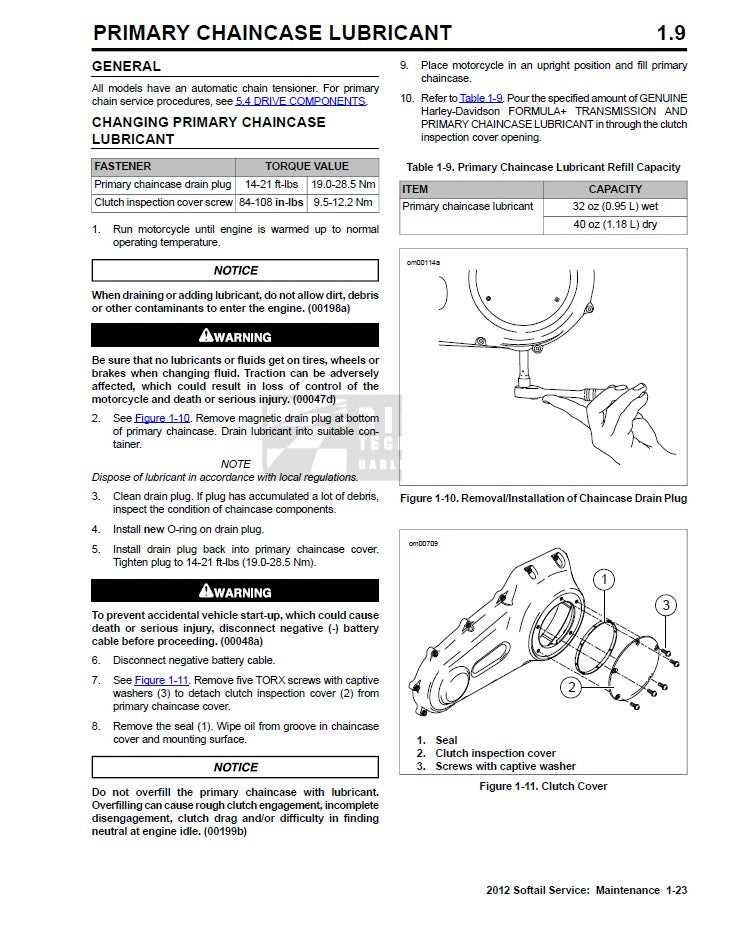

- Regularly check fluid levels and change them as needed to prevent wear.

- Inspect all seals and gaskets for leaks and replace them promptly.

- Clean and lubricate moving parts to minimize friction and corrosion.

In addition to routine checks, consider the following practices:

- Follow the manufacturer’s service schedule diligently.

- Store your motorcycle in a dry environment to avoid rust.

- Use quality replacement components to maintain optimal functionality.

Implementing these strategies will help you delve deeper into the care required for lasting performance.

Upgrading Your Harley Transmission

Enhancing the performance of your motorcycle’s gear system can significantly improve your riding experience. Whether you’re looking for better efficiency, smoother shifts, or increased durability, there are various options available to elevate your bike’s capabilities.

When considering modifications, it’s essential to assess the components involved in the gear mechanism. Upgrades can range from changing internal elements to implementing external modifications that boost overall functionality. Below is a table outlining common enhancements and their benefits:

| Upgrade Type | Description | Benefits |

|---|---|---|

| High-Performance Gears | Stronger and lighter materials designed for durability | Improved acceleration and longevity |

| Better Clutch Systems | Upgraded clutch components for smoother operation | Enhanced responsiveness and reduced slippage |

| Shifting Mechanisms | Precision-engineered parts for more accurate gear changes | Quicker shifts and improved rider control |

| Fluid Upgrades | High-quality lubricants to reduce friction | Lower operating temperatures and improved efficiency |

Ultimately, selecting the right enhancements will depend on your riding style and the specific goals you have for your machine. Each upgrade not only contributes to performance but also adds a personal touch to your ride.

Tools Needed for Repairs

Having the right equipment is essential for effective maintenance and repair work. Proper tools not only facilitate the process but also ensure safety and precision. Below is a list of essential instruments to consider.

- Socket Set: A variety of sockets will help with loosening and tightening bolts.

- Wrenches: Both adjustable and fixed wrenches are crucial for various fasteners.

- Screwdrivers: A selection of flathead and Phillips screwdrivers is necessary for screws of different types.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Cleaning Supplies: Rags, brushes, and solvents to keep parts free of debris and contaminants.

- Safety Gear: Gloves, goggles, and protective clothing to safeguard against hazards.

With these tools at hand, one can effectively delve into the repair process and achieve the ultimate results.

Installation Process Explained

The process of fitting mechanical components requires precision and a clear understanding of each step. Proper alignment and careful handling of individual elements are crucial for ensuring optimal performance and longevity.

Begin by gathering all necessary tools and components, ensuring everything is clean and free of debris. Follow the manufacturer’s guidelines closely to avoid mistakes that could lead to malfunction. Each piece should be checked for compatibility and wear, replacing any damaged parts before assembly.

Once prepared, carefully assemble the elements in the correct sequence, paying attention to torque specifications. This ensures a secure fit, minimizing the risk of future issues. After installation, conduct a thorough inspection to confirm everything is in place and functioning as intended.

Finally, perform a test run to validate the installation. Monitor for any unusual noises or behaviors, addressing any concerns immediately. This comprehensive approach guarantees that the assembly operates efficiently and reliably.

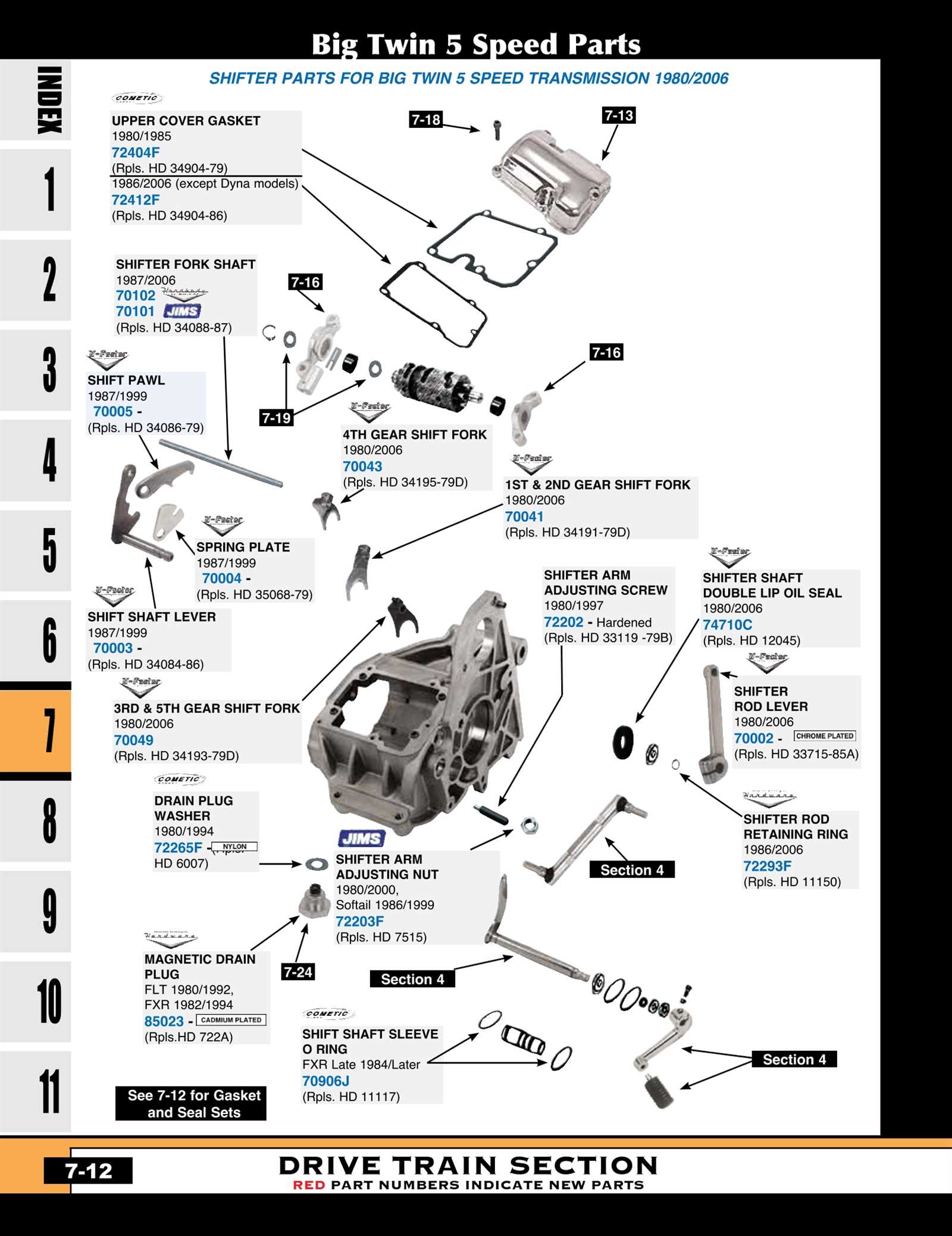

Differences Between Models

When examining the various configurations of motorbike gear systems, it’s essential to recognize how distinct models exhibit unique characteristics and functionalities. These differences often arise from advancements in technology, design choices, and intended usage, which can significantly affect performance and rider experience.

Engine compatibility plays a crucial role in differentiating models. Some designs may be optimized for specific engine types, which influences torque delivery and overall efficiency. As a result, understanding these compatibilities can guide enthusiasts in choosing the right setup for their riding style.

Another notable distinction is the gear ratios employed in different variants. Each model may feature a tailored set of ratios that cater to diverse riding conditions, from urban commuting to long-distance cruising. This aspect not only impacts acceleration but also fuel efficiency, making it a key consideration for riders.

Construction materials also vary across models, affecting both durability and weight. While some configurations utilize lightweight composites for enhanced performance, others may prioritize robust metals for increased longevity. This choice can influence maintenance needs and the overall lifespan of the system.

Lastly, user interface elements, such as shifting mechanisms, differ between models. The responsiveness and feel of the gear change can significantly impact rider satisfaction. Some systems are designed for quick shifts, while others emphasize a smoother transition, catering to various rider preferences.

Expert Recommendations for Modifications

When seeking to enhance the performance and reliability of your motorcycle’s gear system, several expert insights can guide your decisions. Implementing the right modifications can lead to a smoother riding experience and improved functionality.

- Upgrade Gears: Consider installing high-performance gears for better power transfer.

- Optimize Oil Type: Use high-quality lubricants specifically designed for mechanical components.

- Reinforce Clutch Components: Upgrading clutch plates can significantly enhance durability.

- Adjust Gear Ratios: Tailor gear ratios to suit your riding style and needs for improved acceleration.

These adjustments can ultimately lead to a more enjoyable and efficient ride. Always consult with a professional for personalized advice based on your machine’s specific requirements.

Resources for Further Learning

Exploring the intricacies of motorcycle mechanics can greatly enhance your understanding and skills. Various materials and platforms offer insights into component functionality and maintenance techniques, allowing enthusiasts to deepen their knowledge and practical expertise.

Books dedicated to motorcycle mechanics are invaluable resources. Titles focusing on engine assembly, gear systems, and overall maintenance provide comprehensive guidance. Online forums and communities also serve as excellent platforms for sharing experiences, troubleshooting issues, and discovering innovative solutions.

Video tutorials available on platforms like YouTube can visually demonstrate complex procedures, making learning more accessible. Additionally, manufacturer websites often include technical manuals and service bulletins that can clarify specifications and repair practices.

Lastly, consider joining local clubs or workshops. Engaging with fellow enthusiasts can facilitate hands-on learning and foster connections within the community, enriching your overall experience.