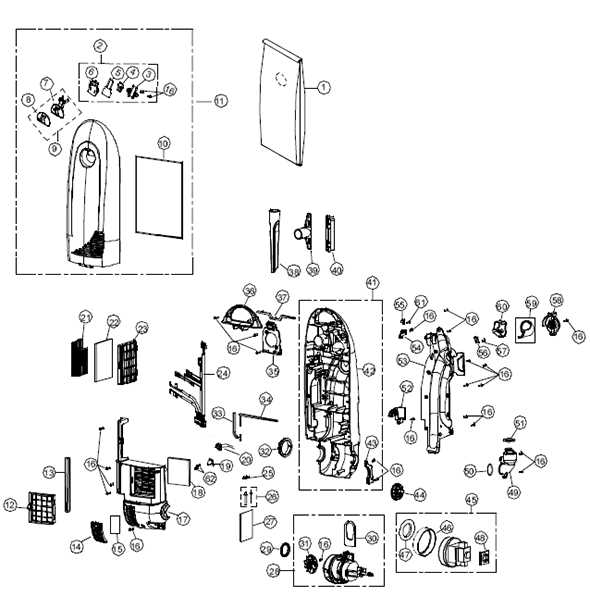

Riccar Vacuum Parts Diagram Overview

For anyone who relies on a cleaning machine to keep their home spotless, it’s important to understand how the internal components work together. By exploring the layout of essential mechanisms, you can better maintain and troubleshoot your equipment.

Each element inside the machine serves a critical function, from the core system that generates power to the various attachments and filters that improve performance. Knowing how these elements are connected helps ensure smooth operation and long-lasting use.

This guide will walk you through the different segments of your cleaning equipment, shedding light on the crucial elements and their roles in enhancing its overall efficiency. Proper understanding of these components can make a significant difference in optimizing your device’s effectiveness.

Key Components Overview

Understanding the essential elements of a cleaning device is crucial for maintaining its functionality and performance. Each piece plays a vital role in ensuring efficient operation and longevity, and knowing how these components work together can help in troubleshooting and upkeep.

Main Mechanisms

The core mechanisms are responsible for generating the necessary airflow and suction power, which are the foundation of the device’s performance. These include the motor, responsible for driving the airflow, and the filtration system that captures dust and debris, preventing blockages and ensuring clean air output.

Additional Features

Beyond the primary mechanisms, there are several auxiliary features that contribute to the overall functionality. These include the adjustable height settings, allowing for customization based on surface type, and the extension tools, which enhance usability for reaching tight spaces and elevated areas.

Understanding the Motor Component

The motor plays a pivotal role in any cleaning device, ensuring the necessary power to operate the system efficiently. Without a well-functioning motor, the entire cleaning process would be compromised. Understanding how the motor works is crucial for maintaining the performance and extending the lifespan of your device.

Below is a simplified table outlining the key elements associated with this essential component:

| Component | Function |

|---|---|

| Armature | Generates rotational force required for operation. |

| Carbon Brushes | Conduct electrical current to the motor’s moving parts. |

| Bearings | Ensure smooth rotation and reduce friction within the motor. |

| Cooling Fan | Prevents the motor from overheating during extended use. |

Regular maintenance and understanding of these core elements can significantly enhance the functionality and durability of the device’s motor.

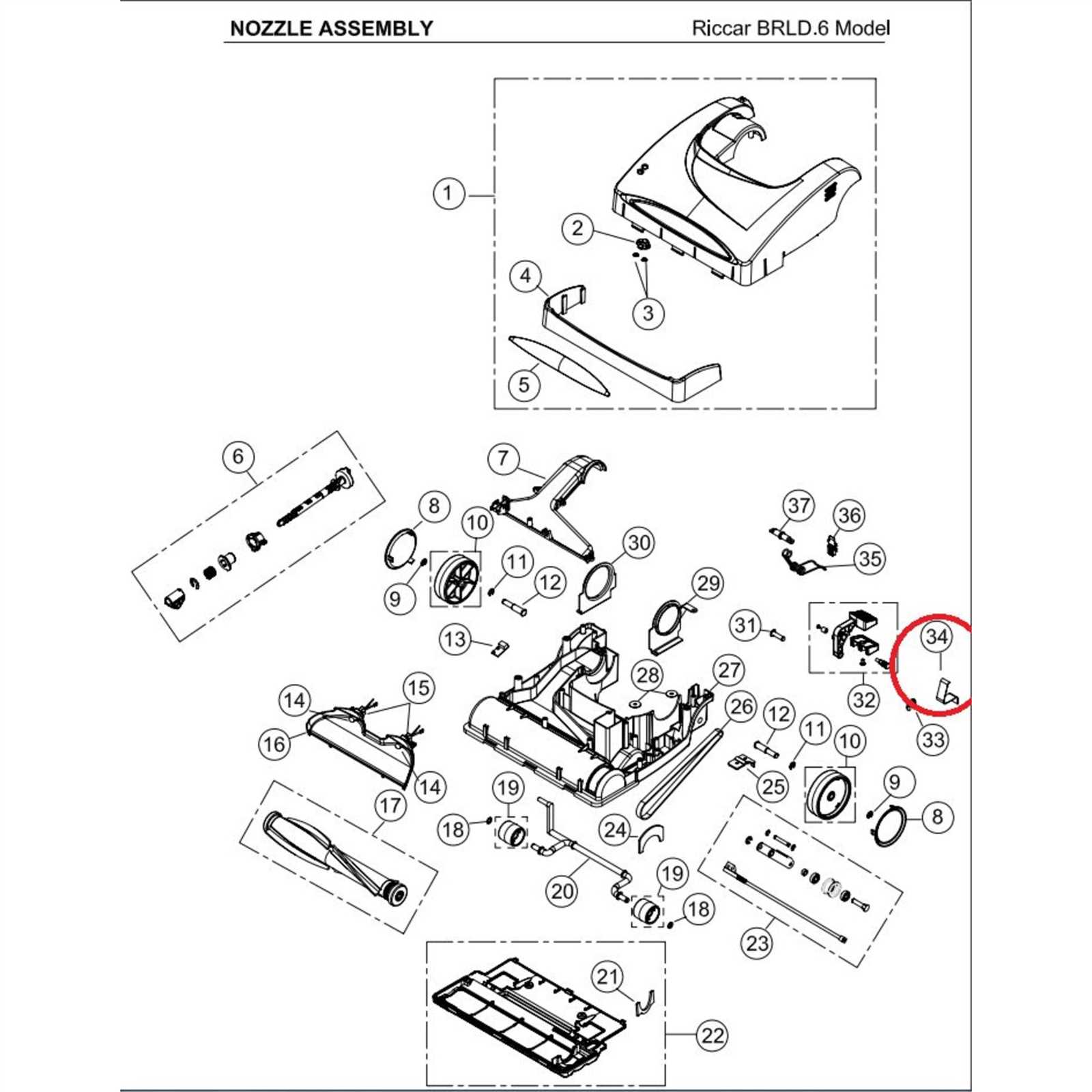

Brush Roll Mechanism in Cleaning Devices

The brush roll mechanism plays a critical role in ensuring efficient floor cleaning by agitating the surface, lifting dirt, and enabling the collection process. Its function revolves around providing constant motion, making it an essential component in any high-performance floor-cleaning machine.

How the Brush Roll Works

By rotating at a consistent speed, the brush roll interacts with carpets and hard surfaces, loosening dirt and debris. The rotating bristles come in contact with the surface, dislodging particles that are then easily collected. The design and speed of the roller affect its effectiveness in handling different types of debris.

Maintenance of the Brush Roll System

Proper maintenance is essential to keep the cleaning mechanism functioning optimally. Over time, hair, string, and other materials can become entangled around the roller, leading to reduced performance. Regular cleaning and occasional replacement of worn components ensure longevity and consistent operation.

| Component | Function | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Brush Roll | Agitates and lifts debris from surfaces | ||||||||||||||||||||||||||||||||

| Bearings | Allow smooth rotation of the brush roll | ||||||||||||||||||||||||||||||||

| Belt | Connects the motor

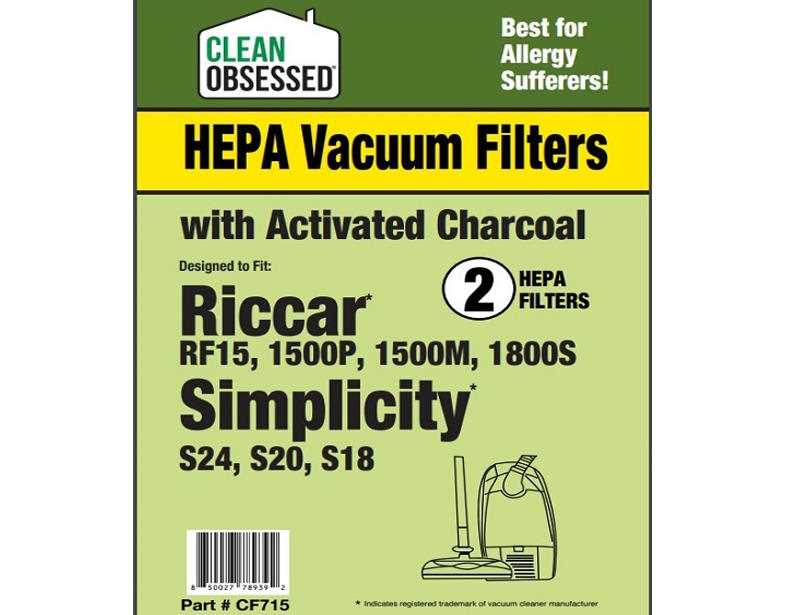

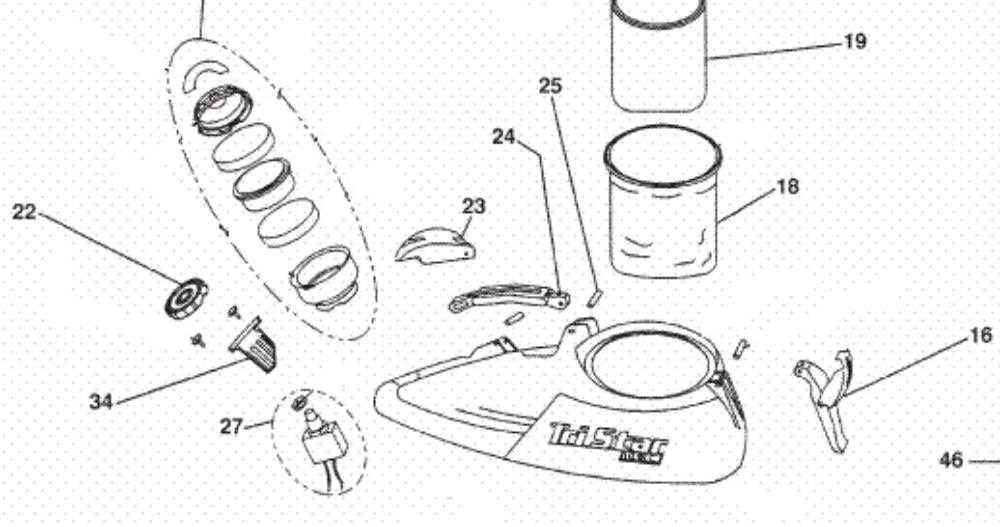

How Belts Affect PerformanceBelts play a crucial role in ensuring the smooth operation of any cleaning system. The efficiency of the system largely depends on how well the belt transmits power from the motor to the cleaning components. A properly functioning belt ensures consistent movement, enabling optimal dirt collection and a thorough clean. The Importance of Belt TensionThe tension of the belt is a key factor in maintaining peak performance. If the belt is too loose, it may slip, reducing the cleaning system’s ability to operate effectively. Conversely, a belt that is too tight can lead to excessive wear, causing early failure. Keeping the belt at the right tension ensures longevity and efficient operation. Impact of Belt Wear and TearOver time, belts can stretch or degrade due to regular use, which significantly affects performance. A worn-out belt may not provide the necessary grip, leading to decreased efficiency and potential strain on other components. Regular inspection and timely replacement are essential to avoid performance drops and maintain a high standard of cleaning. Filter Systems: Types and MaintenanceEffective filtration plays a crucial role in maintaining indoor air quality and ensuring optimal device performance. Different filtering methods serve specific purposes, helping to trap dust, allergens, and other particles, thus promoting a cleaner environment. Regular care of these systems ensures they continue to function efficiently over time. Types of Filters can vary depending on the design and purpose. Some common ones include HEPA filters, which capture tiny particles, and charcoal layers designed to neutralize odors. Each type offers unique benefits, from enhanced air purification to odor control. Maintenance Tips are vital to prolonging the efficiency of these filtering systems. Cleaning or replacing them at regular intervals is essential to prevent clogging, which can reduce the device’s effectiveness. Always consult the manufacturer’s guidelines for specific care instructions. Dustbin and Bag Compartments ExplainedThe efficient management of collected debris is crucial for maintaining optimal performance in cleaning devices. Understanding the functionality of dustbin and bag compartments enhances user experience and ensures proper maintenance. Understanding DustbinsDustbins serve as the primary collection area for dirt and debris. They are designed to be easily removable and washable, allowing users to maintain hygiene effortlessly. Here are some key features:

Exploring Bag CompartmentsBag compartments are essential for devices that utilize disposable or reusable bags to collect dust. These compartments provide an organized space for the bags, ensuring that they are secure and easy to replace. Key aspects include:

Understanding these components is essential for effective maintenance and operation, ensuring that the device functions at its best. Hose and Wand Assembly in Riccar ModelsThe hose and wand assembly is a crucial component in various cleaning devices, enabling efficient maneuverability and reach during operation. This section explores the significance of this assembly and its role in ensuring optimal functionality. Understanding its structure can aid in better maintenance and troubleshooting, enhancing overall user experience. Typically, this assembly comprises multiple elements that work together seamlessly. Below is a table detailing the main components, their functions, and how they contribute to the overall efficiency of the device:

Regular inspection and maintenance of these components ensure longevity and performance. Users should be familiar with the assembly to address any issues promptly, thereby maximizing efficiency in cleaning tasks. Importance of Power Cords in Riccar VacuumsPower cords play a crucial role in the overall functionality of cleaning appliances. They provide the necessary connection to electrical sources, enabling devices to operate efficiently. A reliable and well-designed cord ensures that the appliance receives consistent power, which is essential for optimal performance. The quality of the cord can significantly impact the longevity and safety of the equipment. Durability is a key factor; a robust cord can withstand wear and tear, reducing the risk of damage and potential hazards. Furthermore, the length of the cord can influence maneuverability, allowing users to reach various areas without constantly switching outlets. Additionally, it is vital to ensure that the power cord is compatible with the appliance’s specifications. This compatibility not only affects performance but also prevents overheating and electrical malfunctions. Regular inspection of the cord for fraying or damage is recommended to maintain safety standards and extend the life of the device. Wheels and Maneuverability FeaturesEfficient navigation and ease of use are crucial for any cleaning device, particularly when it comes to the design of its rolling mechanisms. The wheels and their configuration play a significant role in enhancing the overall user experience by allowing for smooth movement across various surfaces. Wheel Design and FunctionalityThe structure of the wheels is thoughtfully engineered to provide stability and control. Larger wheels facilitate effortless gliding over carpets, while smaller ones enable precision movements in tight spaces. This combination ensures that the unit can tackle a variety of environments with ease. Maneuverability EnhancementsIn addition to wheel size, the swivel capabilities contribute to agile handling. This feature allows the user to navigate around furniture and obstacles without lifting the device. Adjustable height settings further enhance versatility, ensuring optimal performance on different floor types. Overall, the design elements focused on mobility significantly enhance the cleaning process. Adjusting the Vacuum Height for EfficiencyEnsuring optimal performance of cleaning equipment involves fine-tuning various settings, one of which is the elevation adjustment. Correctly setting the height can significantly enhance cleaning efficiency, prolong the lifespan of the device, and improve user comfort. This section will explore the importance of height adjustment and provide guidance on how to achieve the best results. Importance of Proper Height SettingsUsing the right height for your cleaning tool allows for effective dirt removal without damaging surfaces. If the setting is too low, the equipment may struggle to move, causing strain on the motor and leading to potential malfunctions. Conversely, a height set too high can result in ineffective cleaning as it may miss debris. Understanding these dynamics is crucial for maintaining a clean environment efficiently. Steps to Adjust Height SettingsFollow these steps to properly adjust the height of your cleaning device:

By following these steps, users can ensure that their cleaning device operates at peak efficiency, leading to better results and a more enjoyable experience. Lighting Systems on Riccar Vacuum Cleaners

The illumination mechanisms in cleaning devices play a crucial role in enhancing visibility during operation. Effective lighting allows users to identify dust and debris, ensuring thorough cleaning in dimly lit areas. This section explores the various lighting systems found in these devices, focusing on their functionality and benefits. Types of Lighting Systems

Benefits of Enhanced Illumination

Handle and Grip Design for ComfortWhen it comes to using cleaning devices, the design of handles and grips plays a crucial role in enhancing user experience. A well-crafted handle ensures that the user can operate the machine efficiently while minimizing strain during extended use. Ergonomic considerations, such as the contour of the grip and the materials used, significantly influence comfort and usability. Effective handle design incorporates various elements that contribute to a pleasant user experience. These include:

Incorporating these design elements leads to a more enjoyable and efficient cleaning process. By focusing on comfort, manufacturers can enhance user satisfaction and make daily chores less cumbersome. Replacing Riccar Parts for LongevityEnsuring the durability and optimal performance of your cleaning device involves timely replacements of its essential components. By addressing wear and tear, you can extend the lifespan of your appliance, making it more efficient and reliable over time. Regular maintenance and the substitution of worn elements are key to preventing potential issues. Understanding which components require attention can help in maintaining peak functionality. Pay close attention to filters, brushes, and belts, as these parts often endure the most stress during operation. When it comes to replacements, selecting high-quality alternatives is crucial. Genuine components often provide better compatibility and performance. However, numerous third-party options are also available, offering cost-effective solutions without compromising quality. Additionally, consult your user manual or online resources for guidance on proper installation techniques. Properly replacing elements can significantly impact the efficiency of your appliance. Make it a routine to inspect these vital parts periodically to ensure that your cleaning device continues to perform at its best. |