Volvo D12 Engine Parts Diagram Overview

Understanding how the various elements of a powerful powertrain are interconnected is crucial for maintaining its optimal performance. This section provides an in-depth look at the layout and organization of key components in a complex mechanical system, ensuring a clearer understanding for anyone looking to delve into its structure.

Through a detailed exploration of each section, readers will be guided through the intricate arrangement of crucial elements. Identifying and familiarizing oneself with these components can greatly aid in both routine maintenance and troubleshooting tasks.

For those responsible for upkeep, knowing how different parts are connected will simplify diagnosing potential issues and performing repairs. This guide aims to equip you with the essential knowledge needed to approach these tasks with confidence.

Overview of Volvo D12 Engine Components

This section provides a comprehensive look at the key mechanical elements that form the heart of the system, responsible for ensuring efficient performance. Each part plays a critical role in supporting the system’s functionality, contributing to overall durability and smooth operation. By understanding how these components work together, one can appreciate the precision and engineering behind the system’s reliability.

From the fuel delivery mechanisms to the cooling elements, every aspect of the assembly is designed for optimal performance. This overview highlights the interconnectedness of the various systems, showcasing how they support both power generation and longevity in heavy-duty applications.

Key Features of the Volvo D12 Engine

The power unit discussed in this section is known for its remarkable durability, efficiency, and innovative design. It has been optimized for both performance and longevity, making it a popular choice in various heavy-duty applications. Below are some of the most important characteristics that set this model apart from others.

| Feature | Description | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Efficiency | This model is designed to minimize fuel consumption while maintaining high output, making it cost-effective for long-term use. | |||||||||||||||||||||||||||||||||||||

| Advanced Cooling System | The cooling mechanism is engineered to handle extreme conditions, ensuring stable operation in demanding environments. | |||||||||||||||||||||||||||||||||||||

| Emission Control | It meets modern emission standards, reducing environmental impact while maintaining excellent performance. | |||||||||||||||||||||||||||||||||||||

Maintenance Acce

Understanding the Fuel SystemThe fuel delivery system in this type of machinery is designed to ensure efficient combustion and power output. It plays a critical role in the overall performance by managing the flow and pressure of fuel from the tank to the combustion chambers. Understanding how this system operates can help in maintaining optimal functionality and troubleshooting potential issues.

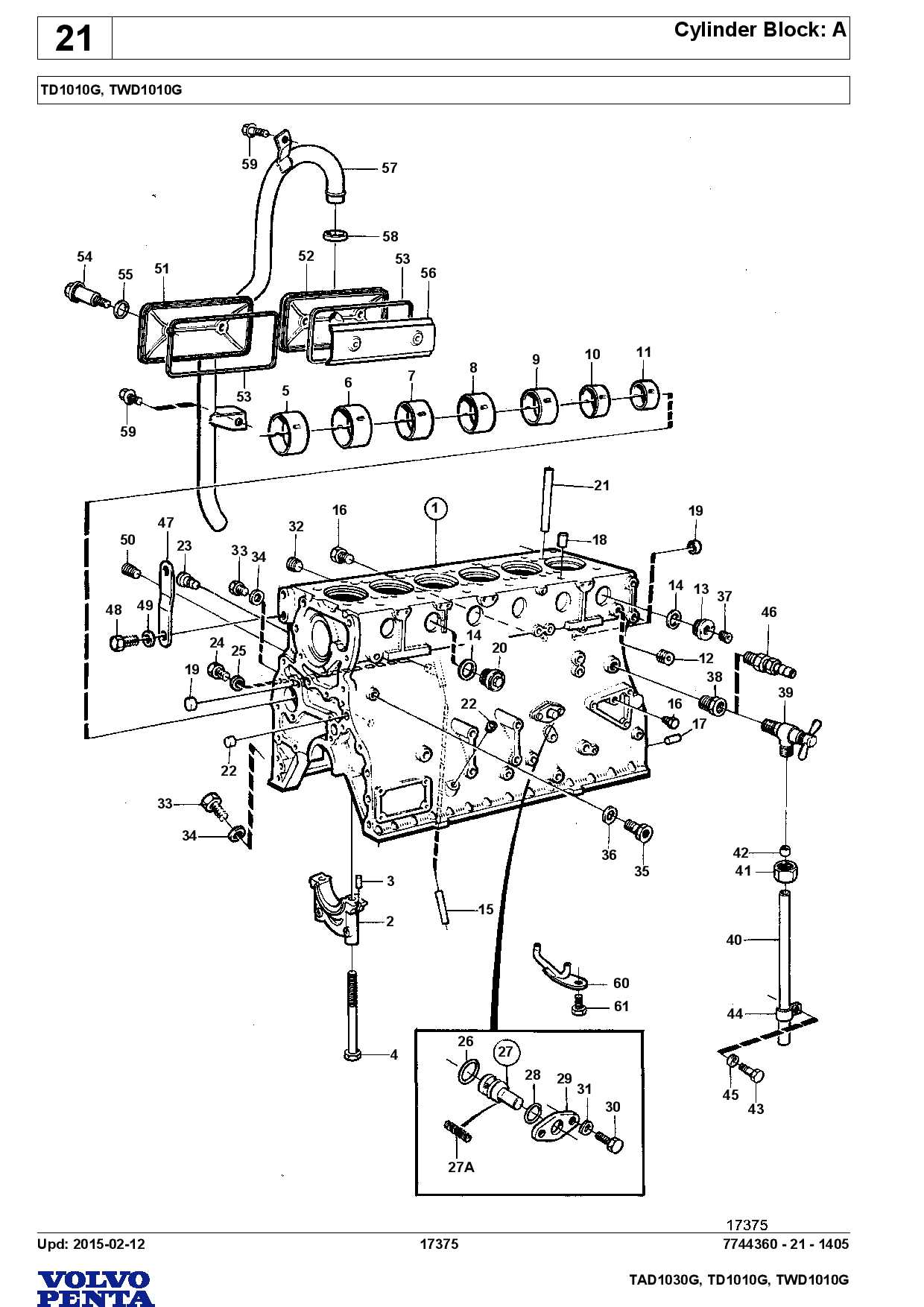

Each component in this system works in harmony to provide the necessary fuel for proper operation. A deeper understanding of these parts can help prevent malfunctions and extend the service life of the machinery. Detailed Look at the Cylinder BlockThe core structure that houses several essential components in a power unit is crucial for overall functionality and performance. This section will explore the critical aspects of the central housing and its role in ensuring smooth operation. By breaking down its components and connections, we can better understand how it contributes to the reliability of the system. Main Functions and Design

Key Features

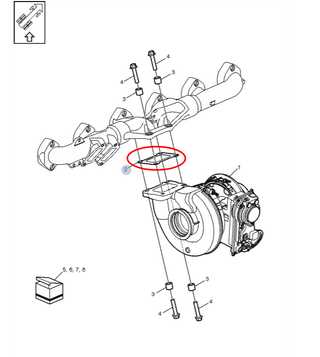

In summary, the central block plays an integral role in the system’s stability and efficiency, supporting various interconnected parts while maintaining ideal operational conditions Turbocharger Functionality in Volvo D12A turbocharger is a key component in enhancing the performance of a motor by increasing the amount of air entering the combustion process. This allows for greater efficiency and power output without significantly increasing the size or fuel consumption of the system. Understanding how this device works can provide insight into its role in improving overall vehicle performance. How the System WorksThe turbo works by using exhaust gases to spin a turbine, which drives a compressor. This compressor pushes more air into the intake, allowing for better combustion. The increase in airflow enhances the system’s power output while maintaining fuel efficiency. Main Components

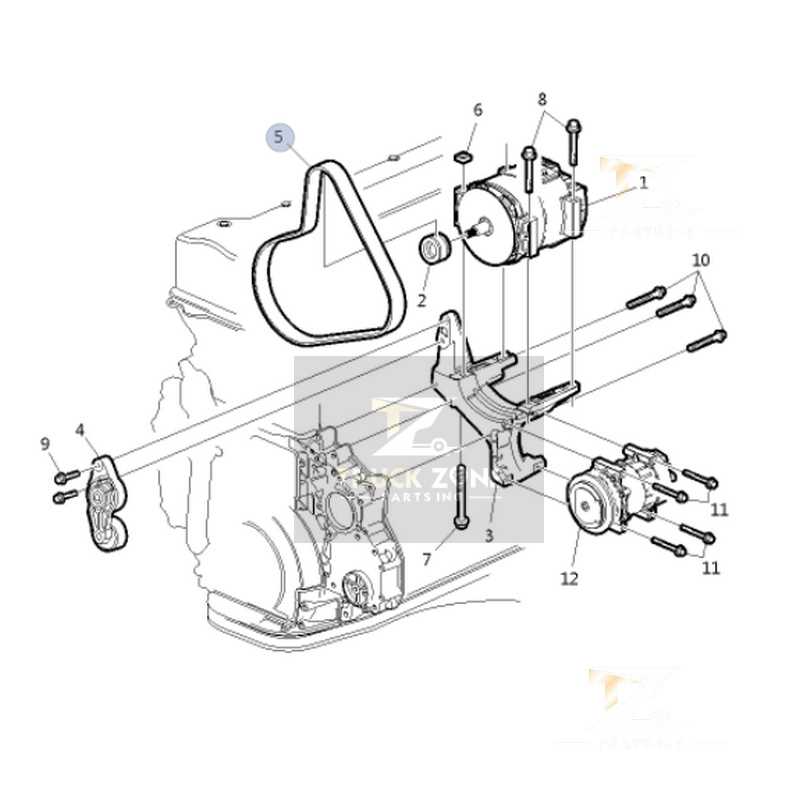

By efficiently managing the air intake, this component improves the overall responsiveness and power potential, making it a critical part of modern internal combustion systems. Cooling System Breakdown for Volvo D12

The cooling mechanism plays a crucial role in maintaining optimal temperatures within a mechanical system. Its primary function is to prevent overheating, ensuring that all components operate efficiently. Understanding the various elements of this system can enhance performance and longevity, allowing for effective management and timely maintenance. Key Components of the Cooling MechanismThis section outlines the main components that contribute to the effective functioning of the cooling apparatus:

Maintenance TipsRegular inspection and maintenance of the cooling system are vital for optimal performance. Ensure that coolant levels are adequate, check for leaks, and replace worn components promptly. Additionally, flushing the system periodically can prevent buildup and enhance efficiency. Importance of the Camshaft in Engine OperationThe camshaft plays a crucial role in the functionality of a motor. It controls the timing and movement of the valves, which are essential for the intake and exhaust processes. Understanding the significance of this component is vital for comprehending how an engine functions efficiently. Here are several reasons why the camshaft is important:

In summary, the camshaft is fundamental to the operation of a motor. Its precise function significantly impacts performance, efficiency, and overall reliability. How the Crankshaft Affects Engine PerformanceThe crankshaft is a crucial component that plays a significant role in the overall functionality of a powertrain. Its primary purpose is to convert linear motion into rotational motion, which is essential for driving various mechanisms within the system. The efficiency and design of this element can greatly influence the overall capability and responsiveness of the system, impacting power output and fuel consumption. One of the key factors in performance is the balance of the crankshaft. A well-balanced component minimizes vibrations, ensuring smoother operation and extending the lifespan of adjacent components. Additionally, the mass and design of the crankshaft affect how quickly it can accelerate and decelerate, which directly relates to responsiveness during operation.

In conclusion, the crankshaft’s design and characteristics are vital for optimal performance. By understanding its role, one can appreciate how this component influences overall power, efficiency, and the smoothness of operation in the system. Valve Operation in the Volvo D12 Engine

The functionality of valves plays a crucial role in the performance and efficiency of an internal combustion mechanism. Proper operation ensures optimal airflow and fuel delivery, significantly impacting the overall output and responsiveness of the system. Valves are responsible for regulating the intake and exhaust of gases within the combustion chamber. Their precise timing and movement are essential for maintaining the necessary pressure and temperature conditions for efficient fuel combustion. This process is intricately linked to the timing mechanism, which synchronizes valve movements with the piston’s position. In this sophisticated setup, the actuation system utilizes various components to open and close the valves at specific intervals. Typically, a combination of hydraulic pressure and mechanical linkages facilitate this movement, allowing for seamless operation. Regular maintenance of these components is vital to prevent malfunctions that could lead to decreased performance or damage. Understanding the operational dynamics of the valves can aid in troubleshooting issues related to airflow and combustion efficiency. Monitoring clearances and ensuring the integrity of the actuation mechanism can lead to enhanced reliability and longevity of the system. Analyzing the Volvo D12 Exhaust SystemThe exhaust system plays a crucial role in the performance and efficiency of a vehicle’s combustion process. It is responsible for directing harmful gases away from the internal workings, ensuring optimal functioning and adherence to environmental standards. Understanding the various components and their interactions within this system can provide insights into maintenance and potential enhancements. Key Components of the Exhaust SystemThis system typically includes elements such as the manifold, catalytic converter, and muffler. The manifold collects gases from multiple cylinders, channeling them into a single outlet. Following this, the catalytic converter transforms harmful emissions into less toxic substances before they exit the system. Lastly, the muffler reduces noise generated by the gases escaping, ensuring a quieter operation. Importance of Maintenance

Regular inspection and maintenance of the exhaust setup are essential for prolonging its lifespan and maintaining efficiency. Issues such as leaks or blockages can lead to decreased performance and increased emissions. By monitoring the condition of each component, owners can avoid costly repairs and ensure compliance with environmental regulations. Injection System Overview for Volvo D12The injection system is a crucial component in the overall performance of a vehicle’s combustion process. It ensures that the correct amount of fuel is delivered at the right time, facilitating optimal efficiency and power output. This system plays a significant role in minimizing emissions and improving fuel economy, making it vital for modern transportation. Key elements of this system include:

Understanding these components is essential for troubleshooting and maintaining the system. Regular checks and maintenance can prevent potential issues, ensuring long-term reliability and performance. Role of the Oil Pump in the Volvo D12The oil pump plays a crucial role in maintaining optimal performance and longevity of a vehicle’s internal components. By circulating lubricating fluid throughout the system, it ensures that moving parts operate smoothly and efficiently, reducing friction and wear. This vital mechanism helps to dissipate heat generated during operation, thereby contributing to the overall reliability of the vehicle. Functionality and Importance

The primary function of the oil pump is to draw lubricating fluid from the sump and distribute it under pressure to various components. This pressurized flow is essential for providing adequate lubrication to critical areas such as bearings, pistons, and camshafts. Without proper lubrication, these components are susceptible to damage, leading to decreased performance and potential failures. Maintenance ConsiderationsRegular inspection and maintenance of the oil pump are essential to ensure its proper functioning. Signs of wear or malfunction can include unusual noises or a drop in oil pressure. Prompt attention to these issues can prevent significant damage and prolong the life of the entire system. Implementing routine checks and fluid changes can enhance the efficiency and reliability of the lubrication system. Common Wear Parts in Volvo D12 EnginesWhen it comes to high-performance machinery, certain components are prone to deterioration over time. Understanding which elements experience the most wear can help in maintenance and ensuring the longevity of the system. Regular inspection and timely replacement of these critical components can significantly improve reliability and performance. Key Components Subject to WearAmong the various elements, several are particularly susceptible to damage due to their operational demands. These components often require more frequent checks and replacements to maintain optimal functionality. Maintenance and Replacement GuidelinesIt is essential to follow a strict maintenance schedule to address wear effectively. Timely interventions can prevent larger issues and extend the overall lifespan of the system. Below is a table highlighting some of the most commonly worn elements along with their recommended replacement intervals.

|