Comprehensive Guide to Volvo Penta DPS-A Parts Diagram

In the realm of marine engineering, the intricacies of propulsion systems are vital for optimal performance and reliability. A thorough grasp of the individual components that comprise these systems can significantly enhance both maintenance and operational efficiency.

Visual aids serve as invaluable tools in this process, allowing enthusiasts and professionals alike to pinpoint the essential elements that contribute to effective navigation. By examining the layout of these parts, one can identify wear patterns, potential issues, and opportunities for upgrades.

Ultimately, delving into the structure of marine propulsion mechanisms empowers users to make informed decisions, ensuring their vessels operate at peak capacity. This exploration not only enhances understanding but also fosters a deeper appreciation for the technology that drives maritime adventures.

Understanding Volvo Penta DPS-A System

The dynamic positioning system plays a crucial role in enhancing vessel maneuverability and stability. By integrating advanced technology, it allows for precise control in various marine environments, ensuring safety and efficiency during operation. Understanding the components and functionalities of this system is essential for optimal performance and maintenance.

Key Components

This system comprises several integral parts that work together seamlessly. Each component contributes to the overall effectiveness of maneuvering and positioning in challenging conditions. Here’s a brief overview:

| Component | Function |

|---|---|

| Control Unit | Manages system operations and integrates inputs from various sensors. |

| Thrusters | Provide the necessary thrust for movement and stabilization. |

| Sensors | Monitor environmental conditions and vessel position. |

| Hydraulic System | Facilitates power transmission for smooth operation. |

Operational Benefits

The implementation of this system offers numerous advantages, including enhanced maneuverability, reduced operator workload, and improved safety. By allowing vessels to maintain a fixed position even in adverse conditions, it significantly elevates operational efficiency and reliability.

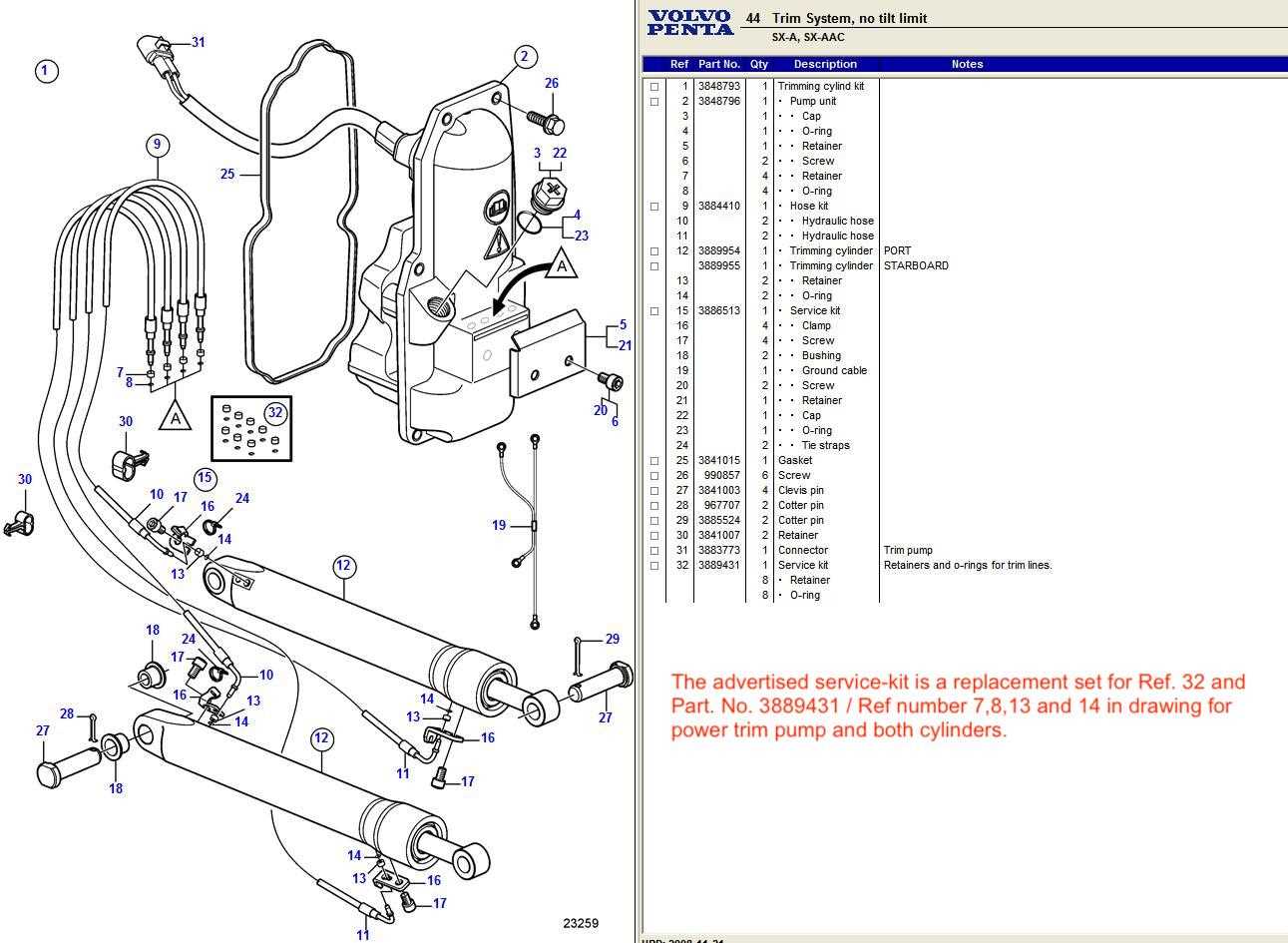

Key Components of the DPS-A

The efficient operation of any marine propulsion system relies on a variety of essential elements that work in harmony. Each component plays a crucial role in ensuring optimal performance, reliability, and safety on the water. Understanding these key parts can greatly enhance maintenance practices and overall vessel management.

One of the primary elements is the drive unit, which facilitates the transmission of power from the engine to the propellers. This component is vital for achieving the desired speed and maneuverability. Alongside it, the steering system enables precise navigation, allowing operators to respond swiftly to changing conditions.

Additionally, the hydraulic system is integral to the overall functionality, providing necessary pressure for various operations, including gear shifts and trim adjustments. Coupled with sensors and electronic control units, these components ensure seamless communication and operation, further enhancing the user experience.

Regular inspection and maintenance of these crucial parts can prevent malfunctions and extend the lifespan of the system, ultimately ensuring a safe and enjoyable boating experience.

Functionality of the DPS-A Mechanism

The dynamic positioning system plays a crucial role in ensuring stability and control in marine vessels. Its design enables precise maneuvering, allowing operators to maintain their desired course and position with minimal external influence. This mechanism combines various components to create a harmonious interaction, enhancing the overall performance of the watercraft.

Key to its effectiveness is the integration of advanced technologies that monitor environmental conditions and adjust the vessel’s orientation accordingly. By utilizing sensors and feedback systems, this setup can detect changes in wind, current, and wave activity, making real-time adjustments to optimize navigation.

Furthermore, the user interface provides operators with intuitive control over the system, allowing for seamless adjustments based on situational demands. This ensures that even in challenging conditions, the vessel remains steady and reliable, significantly improving safety and operational efficiency.

Overall, the mechanism’s design reflects a balance between innovation and functionality, paving the way for enhanced marine experiences and capabilities.

Importance of Maintenance for DPS-A

Regular upkeep is crucial for ensuring the longevity and performance of marine propulsion systems. Neglecting maintenance can lead to inefficiencies and potential failures, which could ultimately affect overall vessel operation.

- Performance Optimization: Routine checks and adjustments help maintain optimal functionality.

- Preventive Measures: Early detection of issues can prevent costly repairs down the line.

- Safety Assurance: Reliable equipment is essential for safe navigation and operation.

- Extended Lifespan: Consistent maintenance can significantly increase the lifespan of components.

Incorporating a structured maintenance schedule can ultimately enhance performance and reduce risks associated with marine operations.

Common Issues with DPS-A Parts

In the world of marine propulsion systems, certain components often encounter recurring challenges that can impact performance and reliability. Understanding these common issues is essential for effective maintenance and timely repairs.

Frequent Challenges

- Seal Failures: These can lead to leaks, resulting in reduced efficiency.

- Corrosion: Exposure to saltwater can degrade materials, necessitating replacements.

- Electrical Malfunctions: Wiring issues may cause inconsistent performance.

Maintenance Tips

- Regular Inspections: Check components for signs of wear and tear.

- Protective Coatings: Apply anti-corrosive treatments to enhance durability.

- Prompt Repairs: Address any issues immediately to prevent further damage.

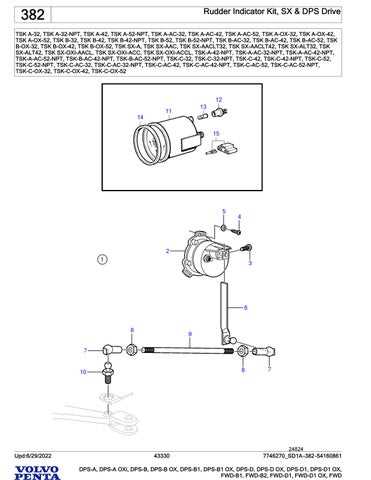

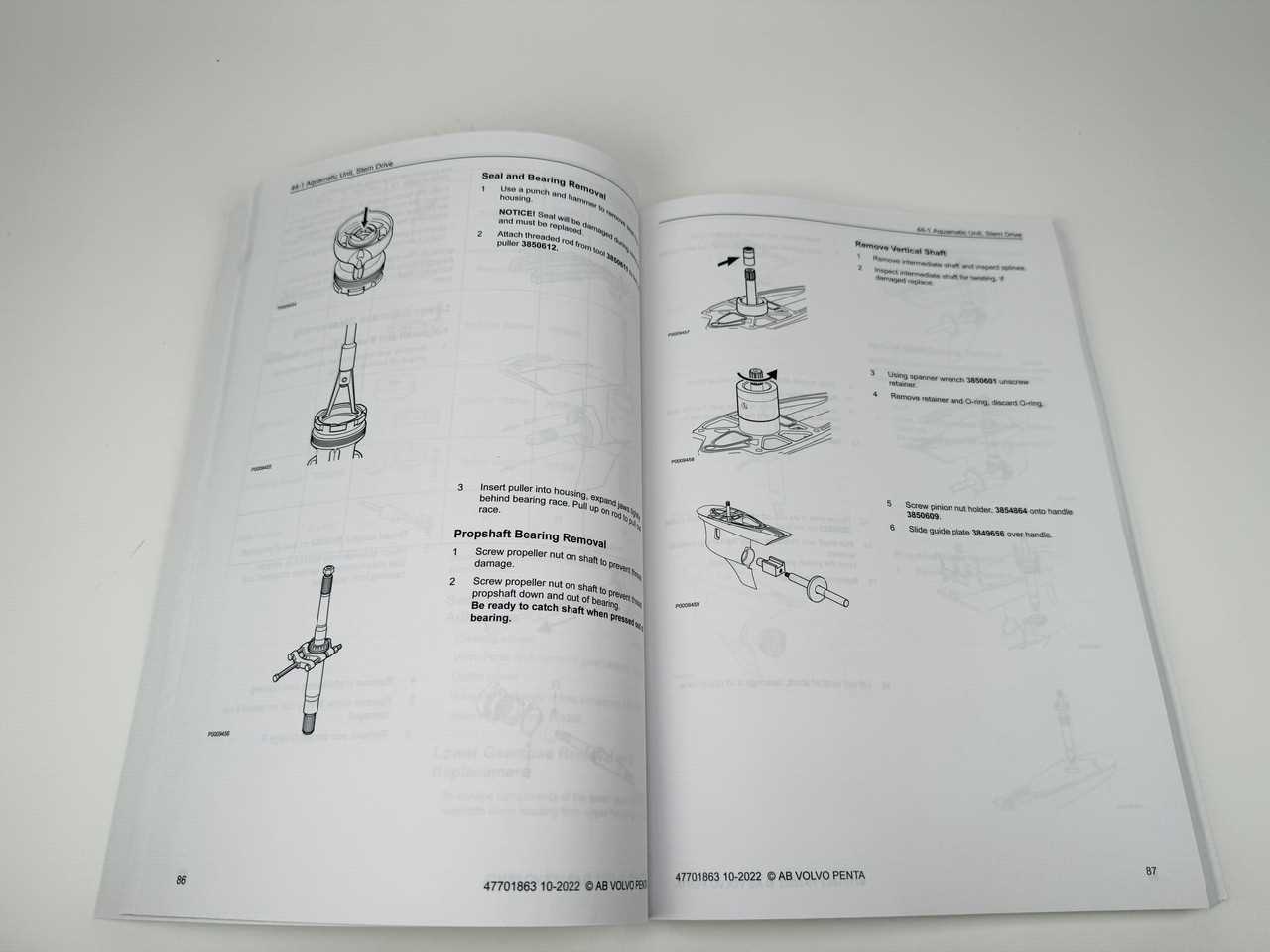

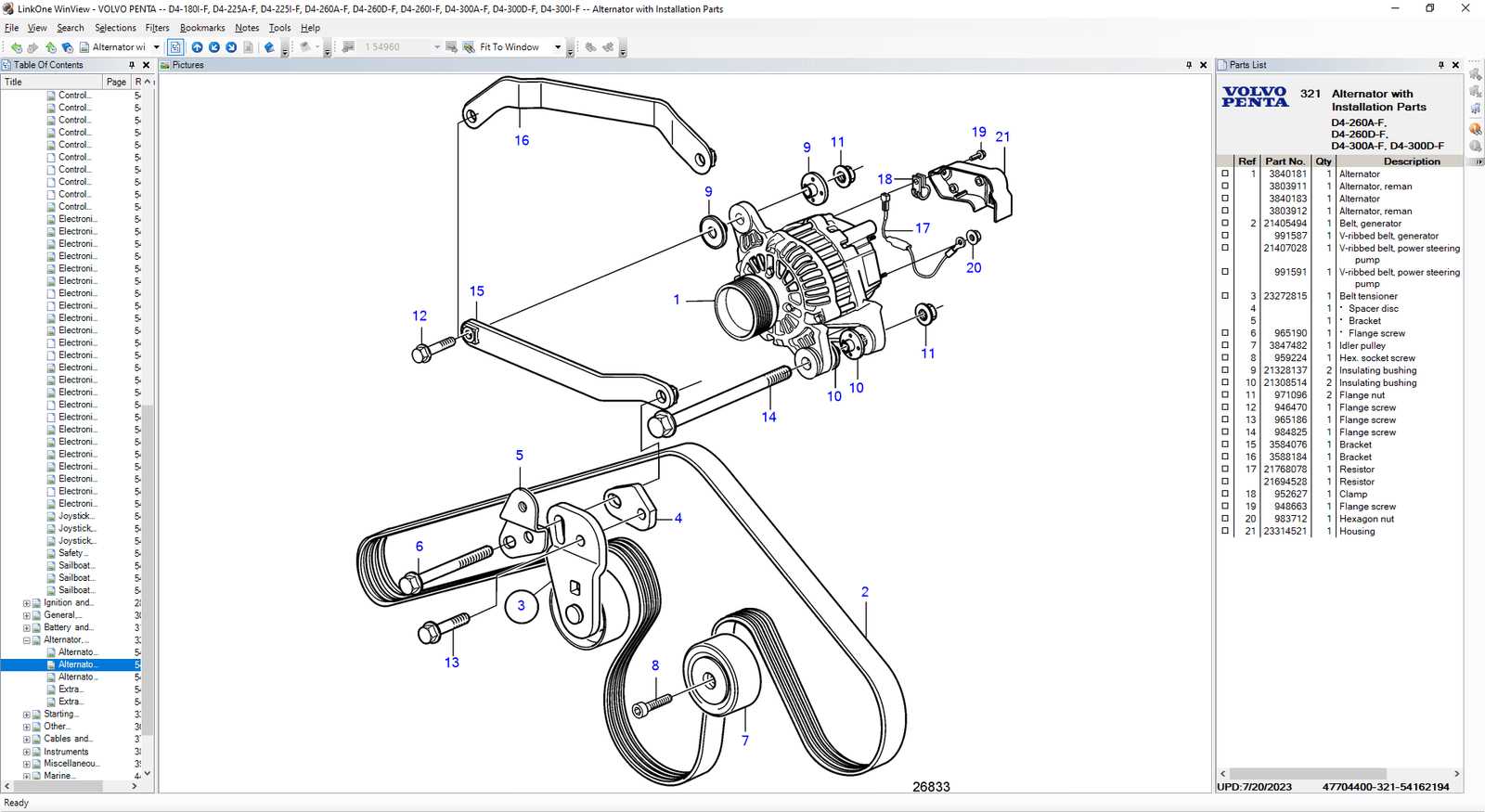

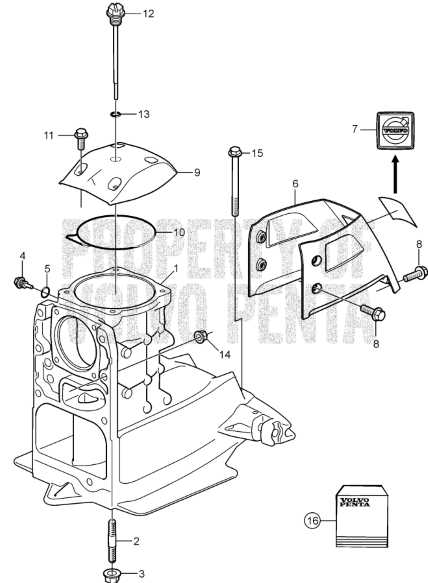

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you interpret the schematic accurately, ensuring that you can identify each element and its function within the assembly. A clear grasp of the layout will enhance your troubleshooting skills and facilitate part replacement.

Typically, the illustration is divided into several sections, each representing different components or assemblies. Familiarize yourself with the layout to streamline your workflow. Below is a brief overview of common symbols and their meanings:

| Symbol | Description |

|---|---|

| ⚙️ | Gear or rotational element |

| Fastener or bolt | |

| Tool required for assembly/disassembly | |

| Reference point for alignment | |

| ⚠️ | Safety notice or important information |

By referring to the key symbols and their corresponding parts, you can gain insight into how everything fits together. Take your time to study each segment and cross-reference it with your maintenance manual for better clarity. This knowledge will not only save time but also prevent errors during repairs.

Identifying Replacement Parts Efficiently

Finding suitable components for your marine engine can be a daunting task. However, with the right approach, you can streamline the process and ensure you acquire the correct items quickly and effectively. This section will guide you on how to navigate the search for essential parts, enhancing your repair or maintenance experience.

First, it’s crucial to gather as much information as possible about the specific item you need. Consulting the manual can provide valuable insights into compatibility and specifications. Additionally, knowing the model and serial number of your engine will facilitate a more precise search.

Utilizing online resources can greatly expedite your search. Websites dedicated to marine equipment often feature detailed catalogs and search functionalities. Make use of forums and community groups where fellow enthusiasts share their experiences and recommendations.

When browsing, look for reputable suppliers that offer comprehensive descriptions and high-quality images of the components. This will help you verify that the item meets your requirements before making a purchase.

Lastly, don’t hesitate to reach out to experts or customer service representatives from your chosen supplier. They can assist in confirming that the component you are considering is the right match for your needs, saving you time and potential frustration.

Comparative Analysis with Other Systems

This section delves into the evaluation of a specific marine propulsion system in relation to alternative mechanisms available in the market. By exploring the strengths and weaknesses of various technologies, we can better understand their operational efficiencies, maintenance requirements, and overall performance characteristics.

Performance Efficiency

When comparing different marine drive systems, performance efficiency often stands out as a critical factor. Some systems offer superior fuel economy and speed, benefiting from advanced engineering and design principles. In contrast, others may prioritize torque delivery and load handling capabilities, which can significantly impact vessel maneuverability and responsiveness.

Maintenance and Reliability

Another essential aspect to consider is the maintenance and reliability of the systems. While some options require frequent servicing and specialized knowledge, others are designed for longevity and ease of upkeep. A reliable system not only reduces downtime but also enhances the overall safety of maritime operations, making it a crucial point of consideration for vessel owners.

Ultimately, the choice of a marine propulsion system should reflect the specific needs and operational goals of the user, balancing performance, efficiency, and maintenance considerations.

Upgrades Available for DPS-A Components

Enhancing the functionality and performance of marine propulsion systems can significantly improve efficiency and reliability. Several modifications and enhancements are available that can help optimize various elements, ensuring a smoother and more powerful operation.

- Improved Propellers

- Advanced Trim Tabs

- High-Performance Gears

- Upgraded Cooling Systems

- Enhanced Electronic Controls

Each upgrade targets specific performance aspects, providing the ultimate benefit to users looking to maximize their vessel’s capabilities. Consider these options to elevate your system’s overall performance and durability.

Best Practices for Installation

Successful setup of marine equipment requires careful planning and attention to detail. By following proven methods, one can ensure longevity and optimal performance of the system. Understanding the components and their interactions is crucial for a seamless integration.

Preparation and Tools

Before starting the installation, gather all necessary tools and materials. Ensure you have the correct equipment, such as wrenches, screwdrivers, and any specialized items. Read the manual thoroughly to familiarize yourself with the specifications and guidelines.

Steps to Follow

Begin by securing the unit in a stable position. Double-check alignment to prevent undue stress on the parts during operation. Once everything is in place, follow the step-by-step instructions methodically, tightening connections as specified to avoid leaks or failures.

Resources for Ordering Parts Online

Finding reliable sources for procuring components online can significantly streamline maintenance and repairs. Numerous platforms cater to various needs, offering a wide range of options that ensure quality and compatibility.

Manufacturer Websites: Many producers maintain official sites that allow for direct purchases. These sites often provide detailed specifications and support resources, ensuring you get the correct item.

Online Marketplaces: Platforms like eBay and Amazon host numerous sellers, presenting opportunities for competitive pricing and diverse selections. Always check seller ratings and reviews to ensure a positive experience.

Specialty Retailers: Niche online stores focus on specific industries and may offer exclusive items or expert advice. Engaging with these retailers can lead to finding hard-to-locate components.

Forums and Community Groups: Engaging with online communities can provide valuable recommendations for trustworthy suppliers. Users often share experiences and tips that can lead you to great deals and reputable sellers.

Comparison Tools: Utilizing price comparison websites can save time and money by allowing you to evaluate various offers quickly. These tools help ensure you’re making an informed decision.

Expert Tips for Troubleshooting Problems

When dealing with marine propulsion systems, it’s essential to have a systematic approach to identify and resolve issues effectively. Proper troubleshooting can save time and reduce the likelihood of costly repairs. Here are some expert strategies to help you navigate common challenges.

Understanding Common Issues

- Start by familiarizing yourself with typical malfunctions, such as unusual noises, vibrations, or performance drops.

- Check for any warning lights or error codes displayed on the control panel, as these can provide valuable insights.

- Review maintenance logs to identify patterns or recurring issues that may need addressing.

Step-by-Step Diagnosis

- Begin with a visual inspection of the system to identify any obvious signs of wear, damage, or leaks.

- Test all electrical connections and wiring for signs of corrosion or looseness.

- Consult the manufacturer’s guidelines for specific diagnostic procedures relevant to the unit.

- Perform tests on components such as the battery, pump, and drive mechanism to ensure they are functioning correctly.

By following these steps and employing a thorough methodology, you can efficiently pinpoint and resolve issues, ensuring your marine propulsion system operates smoothly.